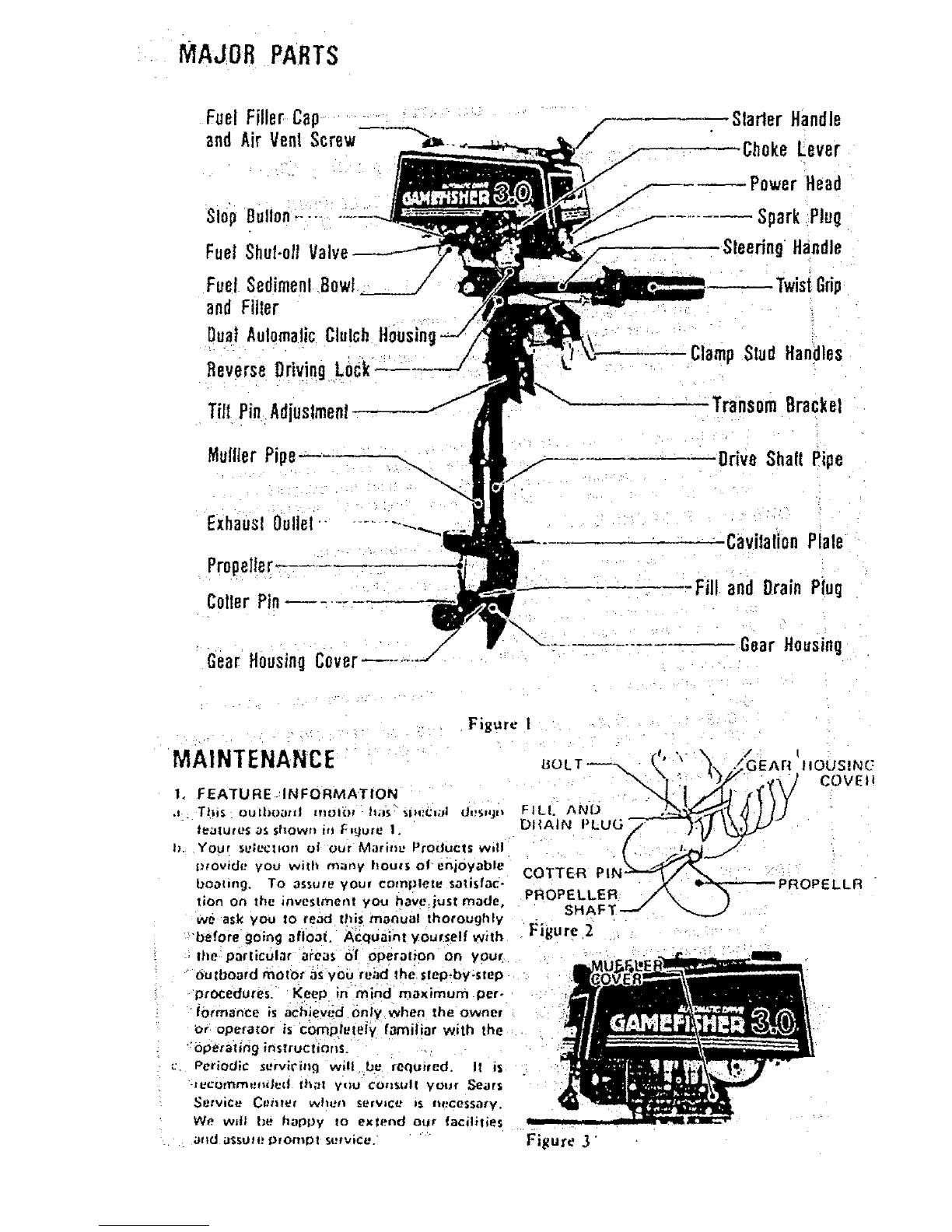

MAINTENANCE

2. LUBRICATION--GEAR HOUSING

a. The Gear Housing has been pre.lubricated at

the factory; however, the grease level should

be checked as follows using SAE 90 out-

board mo_ur grease° ISee Figure 2).

(I) Prior to initial operation.

{2) After firstfour (4) hoursof use.

(31 Recheck after every fifty (50) hours

runmng time.

(4) Replace with new lubricant at the end

at your outboard motor season. This

i_ important, as it removes any water

from the gear housing and prevents

possible corrosion to internal parts.

b. To Check. Drain or Fill gear housing, follow

these steps:

(I) Position outboard motor upright.

(2) Remove drain plug and washer, then

insert nozzle of gear lubricant tube

into hole.

(3) Squeeze tube until lubricant is forced

out around tube.

(4} Replace p!ug and Washer. Be_ure plug

is tightehed _curely.

(5)

(6)

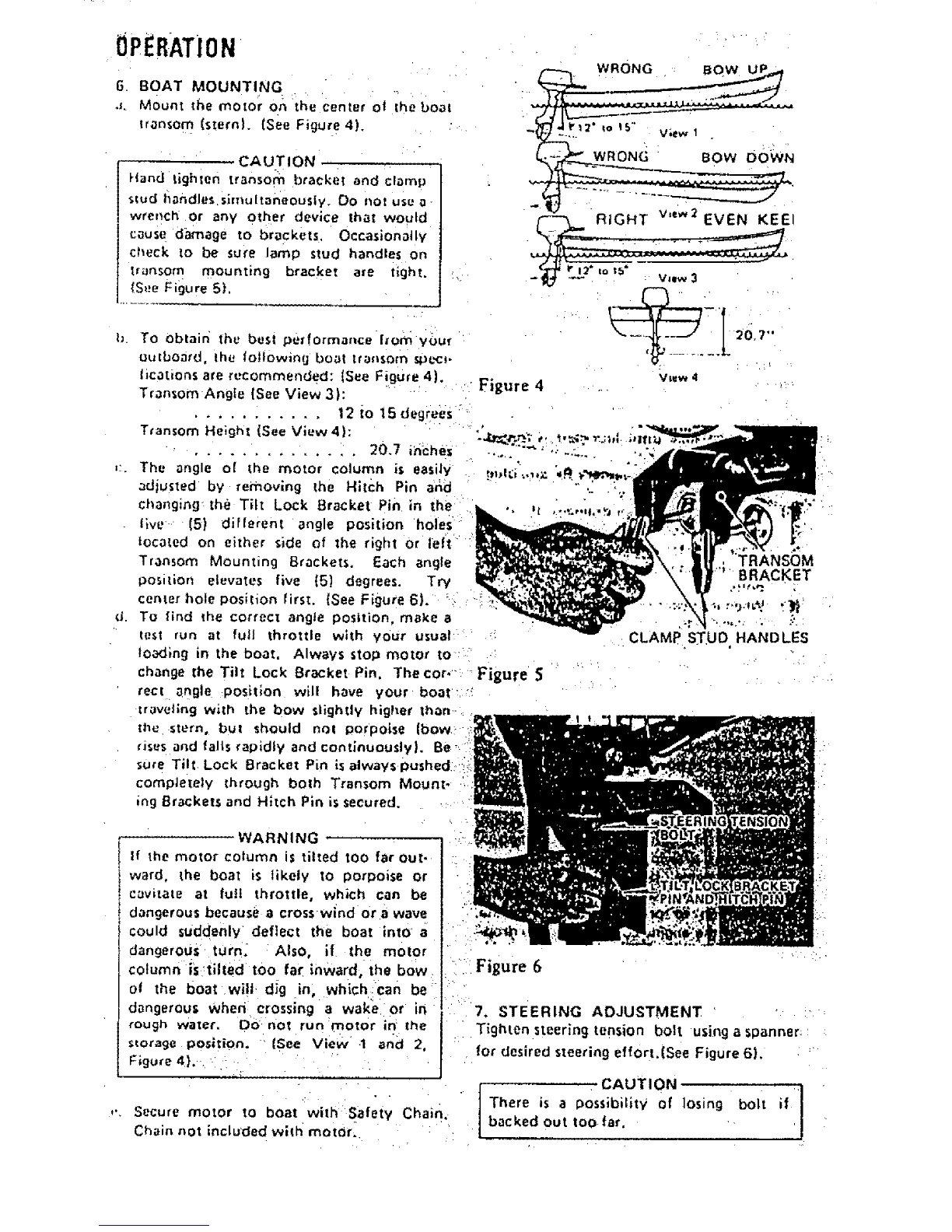

{3} The outboard motor should be

mounted on astand vertically with

power head up for storage.

(4] Pull starter handle slowly until resist.

ance is felt due to compression pres.

sure. then stoP. Reteas;e starter tension

SlOWly tO prevent engine from revers.

ing rotation due to compression

pressure. This positlon'will close both

the intake and exhaust ports for

storage.

(5) Drain and fill gear'housing as oullined

under Lubrication of Gear Housing.

fRet. 21

[6) Wipe exterior completely with fresh

water Cloth and then apply light coat-

ing of oil,

b. When slatting a new season, always use fresh

gasoline. Last year's gasoline may have

varnish deposits that will plug the carbu-

retor lels. thus recluiring a complete over.

haul.

C. TO plan for the coming season, we recom-

mend you contact your Sears Service

To achieve complete drainage of fubd. : Center before the new season for any semice

cant. remove cotter pin0Propelier andi:: ' _-_.repair work required.

sheep pin from proPeller:shafto, ai=6. :. :; _

gear housing covet b'f unscrewing 2

bolts.

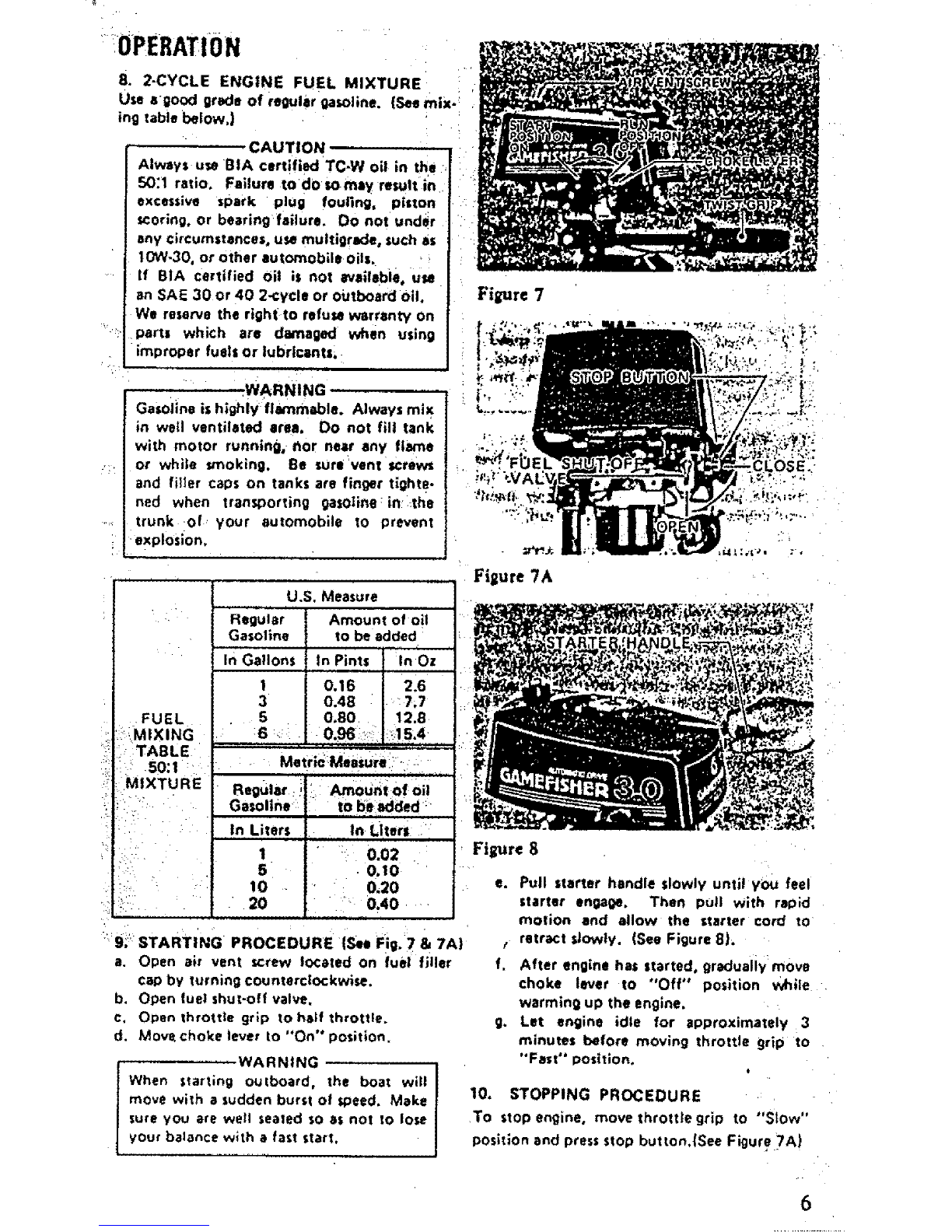

When ub.canthascompletetyarain .OPERATION

replace parts and refill geai" housing 5. NEW AUTOMATIC CLUTCH

using filling procedure above. a. New automatic clutch. Based on a dual

c. For best results, lubricate propeller shaft centrifugal clutch design, it allows the out.

with lithium grease every 30 to 60days. board prop to turn at very slow speeds or

even come to acomplete stop while the

.engine continues operating efficiently. 1t

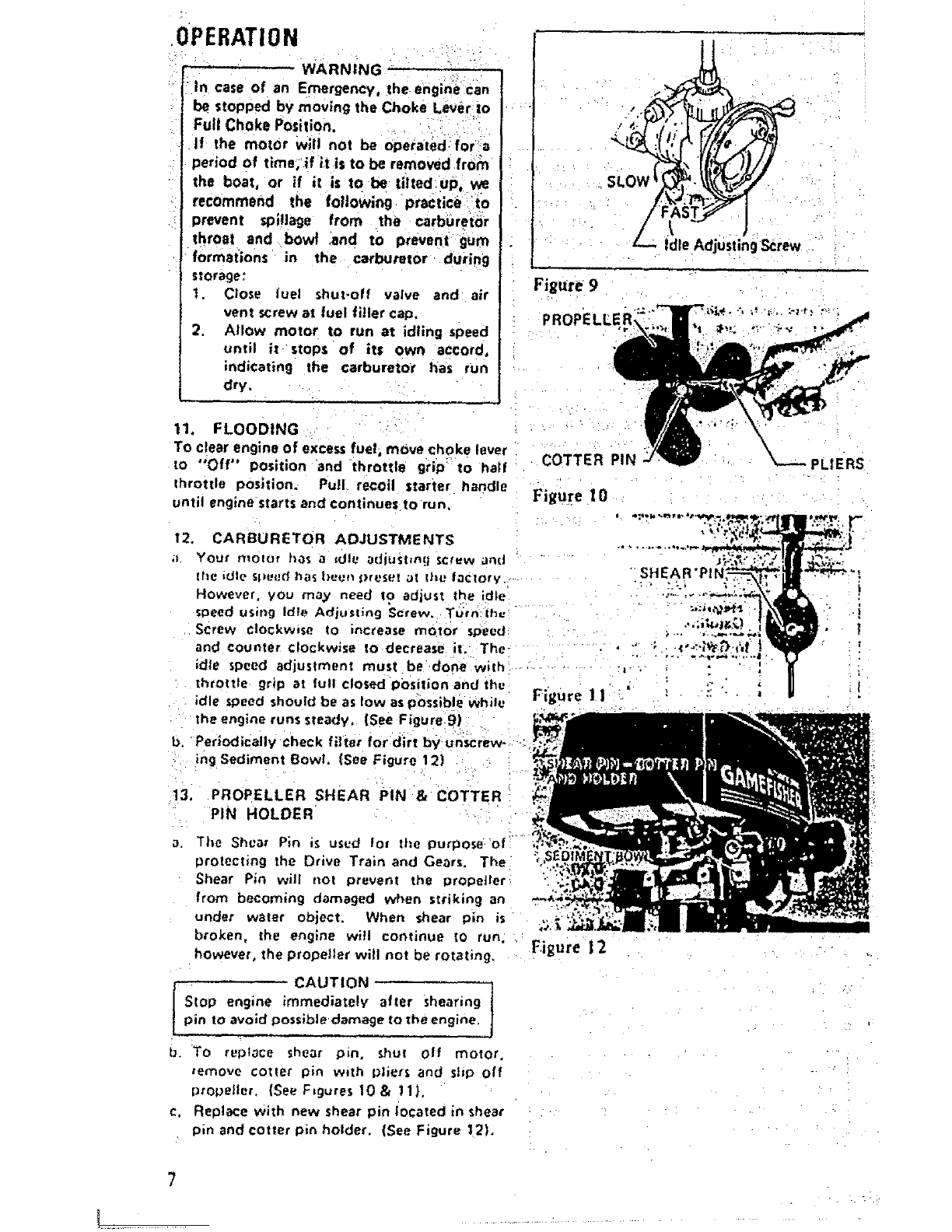

3. MUFFLER INSPECTION i:i?': eliminates the need to shift gears by hand

a. Periodically remove muffler cover 13y:.un. ':and prevents the engine from overheating

screwing screws and in._koect f0r Ca_:bo:n and stalling at slow speed._.

build.up inside the muffler inlet andoutlet. When aniline starts, motor ts neutral. As

the ; exhaust port and the combustion throttle increases, sub clutch engages. AI

chamber of the cylinder. Excessive carb0_- ::'. approx. 6 MPH. main clutch engages to

will prevei_t `drawing the maximum powei: provide direct drive for cruising.

out Of the engine. (See Figure 3}, r__%1: "''

b. Care should be exercised While €leaning, _

away carbon to prevent _t-atcbe$ t0:the" ......

sudace of the engine components and drop.

ping carbon inside of crankcase.

4. PROLONGED STORAGE

.a. To store your outboard motor for pro.

longed storage, prepare outboard as fol-

Iows:

(1] See paragraph on stopping procedures.

{Ref. lOJ

(2) When removing outboard motet from

boat. allow all water to drain from

unit.