Pieces thrown from worn or damage-tines can cause serious injury. Always inspect the tines

before using the tiller.

Gasoline is extremely flammable, and gasoline vapor can explode. Use extreme care when

handling gasoline.

NOTES

Refuel in a well-ventilated area with the engine stopped. Allow the engines to cool

before refueling. Fuel vapor or spilled fuel may be ignited.

The engine and exhaust system become very hot during operation and remain hot for a

while after stopping. Contact with hot engine components can cause burn injuries and

can ignite some materials.

Avoid touching a hot engine or exhaust system.

Allow the engine to cool before performing maintenance or storing the tiller indoors.

Carbon Monoxide Poisoning Hazard

Exhaust contains poisonous carbon monoxide, a colorless and odorless gas. Breathing

exhaust can cause loss of consciousness and may lead to death.

If you run the engine in an area that is confined or even partially enclosed, the air you

breathe could contain a dangerous amount of exhaust gas. To keep exhaust gas from building

–up, provide adequate ventilation.

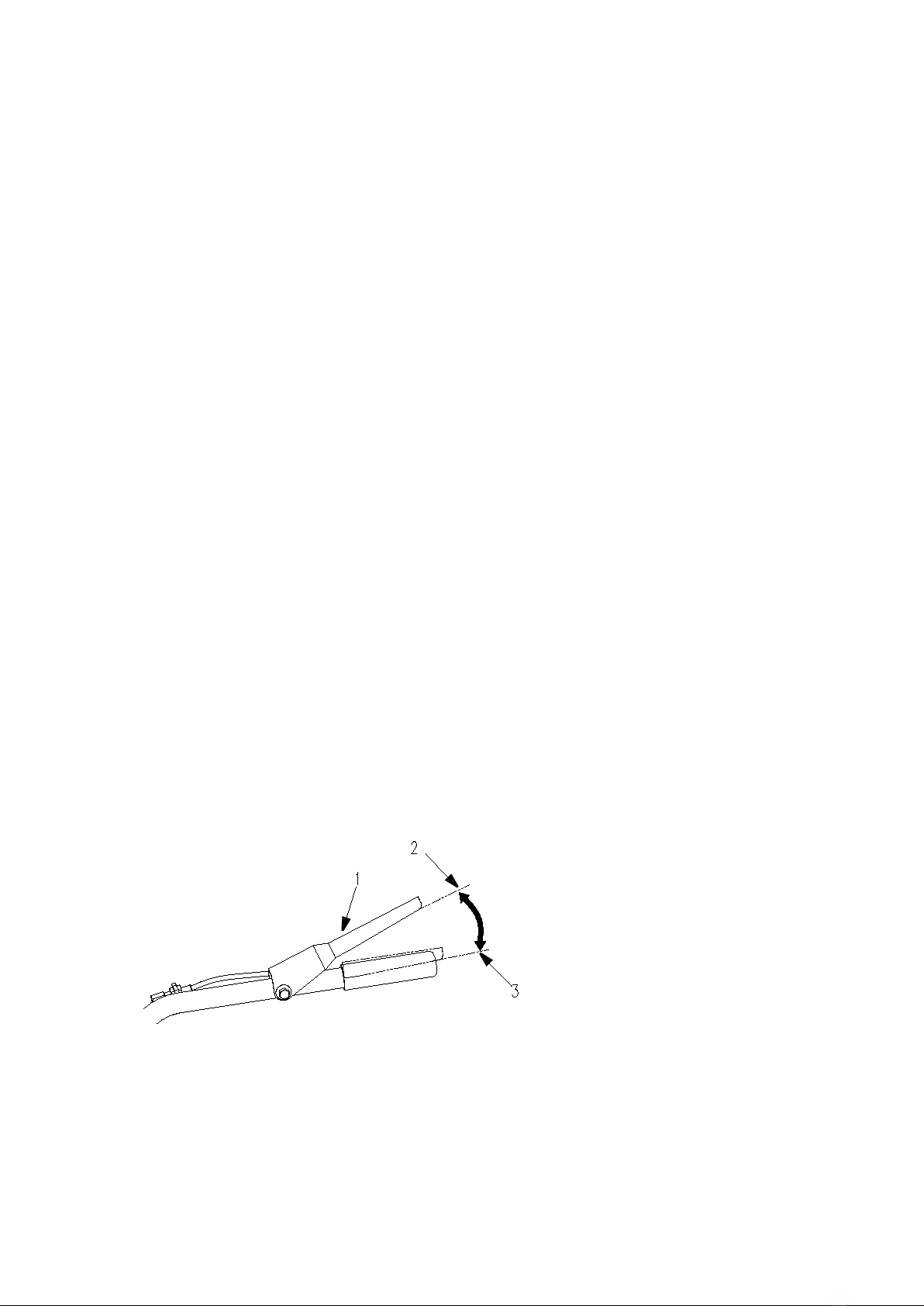

Operation on Slope

When tilling on slopes, keep the fuel tank less than 2/3 full to minimize fuel spillage.

Be very careful when changing the direction of the tiller on a slope.

Do not use the tiller on a slope of more than 10°.

WARNING

The maximum safe grade angle shown is for reference purpose only and should be

determined according to the type of the tool, before starting the engine, check that the tiller is

not damaged and in good condition. For your safety of others, exercise extreme care when using

the tiller up or down hill.

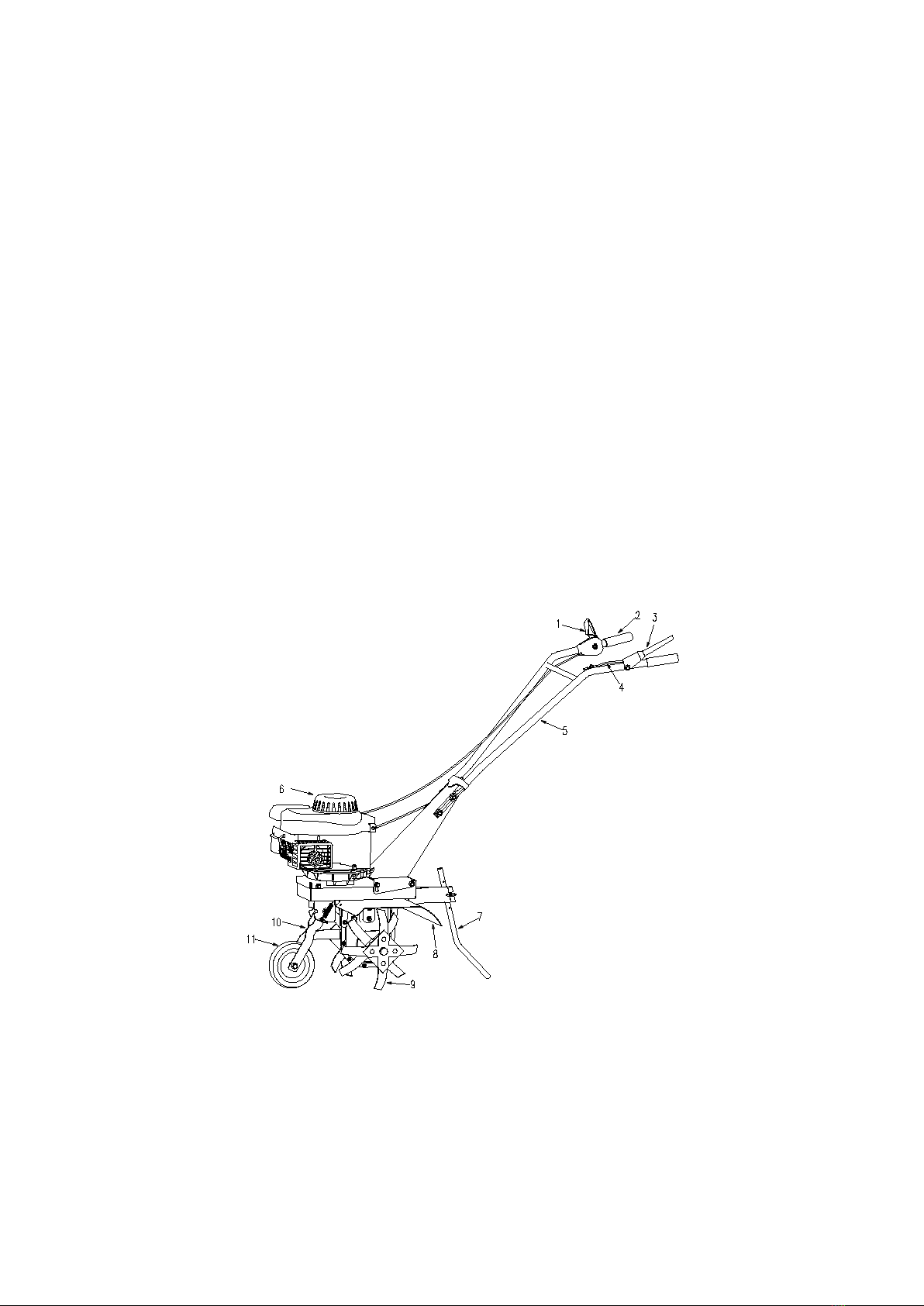

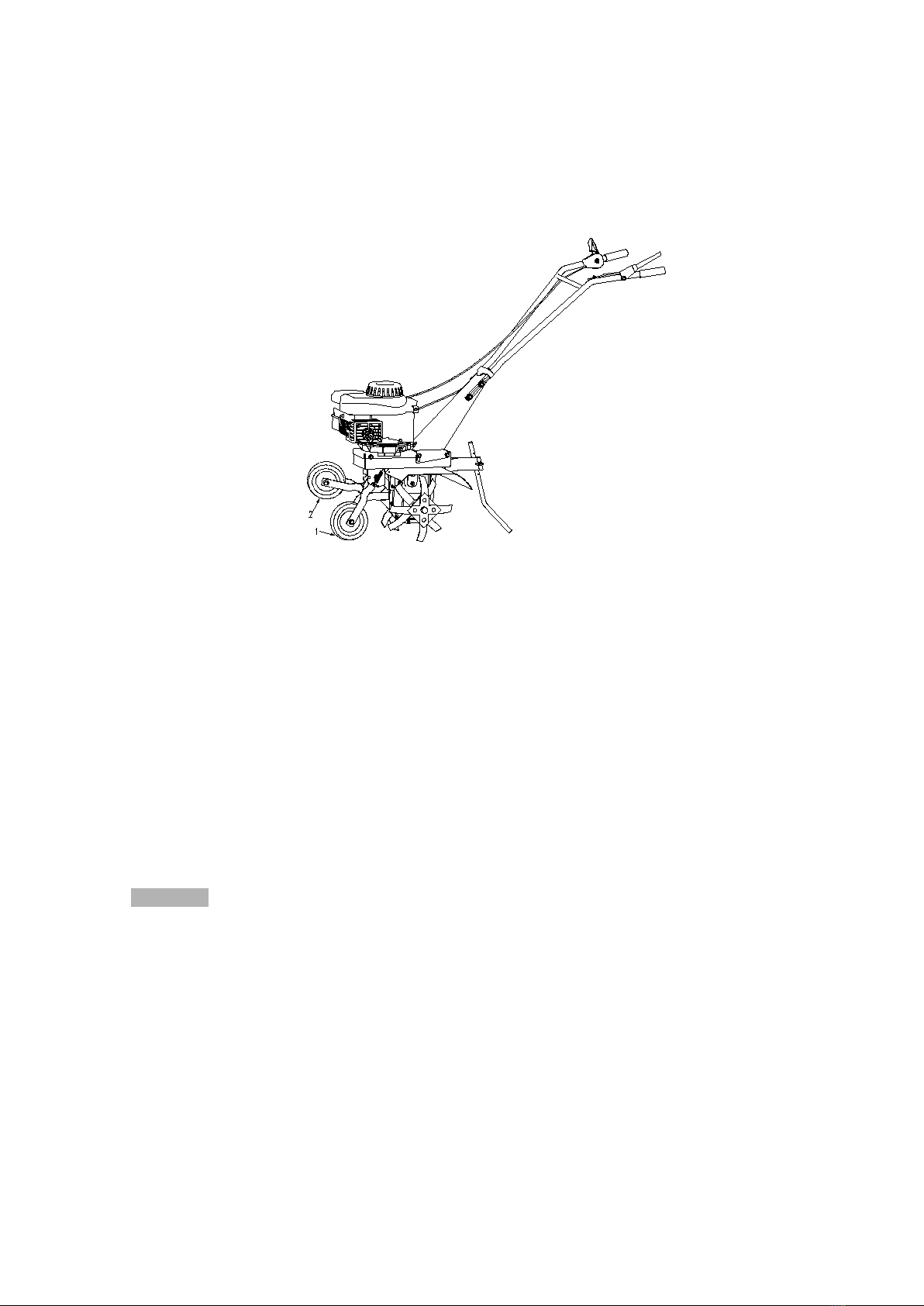

2 SAFETY LABEL LOCATION

These labels position, shown in the below right corner from your operation side.

These labels warn you of potential hazards can cause serious injury. Read the labels and safety

notes and precautions described in this manual carefully.

If a label comes ff or become hard to read, contact your WORLD dealer for a replacement.