5100 OmniSteel™ Volleyball System

4

Floor Sleeve Installation

1. Mark (2) spots on the floor exactly 36 feet apart (refer to most recent set of architectural

prints for exact locations within the gym). These represent the CENTERS of each sleeve

installation. If sleeves are to be more or less than 36 feet apart, contact a PSS or Gared

representative for information regarding this alteration.

2. Cut (2) round holes 5” in diameter through the playing surface and centered on the spots

marked in step one. (See pages 8 & 9)

3. After cutting out the circle in the surface flooring, cut a similar hole in the concrete slab

below. The diameter of this hole should also be 5”, however the size is not critical. The

hole must be large enough to accommodate the sleeve with room for grout.

4. When drilling the hole in concrete, the slab must be fully penetrated. Under the slab,

hollow out (by hand) an area about 16-20 inches deep from the playing surface. The hole

should be about 6 to 8 inches deeper than the bottom of the sleeve once it is inserted.

(See page 8)

5. It is recommended that a “non-shrink” grout be used to anchor the sleeve. Pour the grout

mixture into the hole until it is just below the BOTTOM of the concrete hole. Cover the

sleeve during installation to prevent debris from falling into it or grout from entering

bottom of sleeve.

6. Insert the 3 1/2” O.D. sleeve and work it down into the grout until the inside bottom of

the sleeve is 11” below the TOP surface of the floor. Incorrect sleeve depth will result in

a net height error. Make sure the sleeve is vertical, perpendicular to the playing surface.

(See page 5)

7. Wait a minimum of (7) days to allow the grout to cure before setting up the posts.

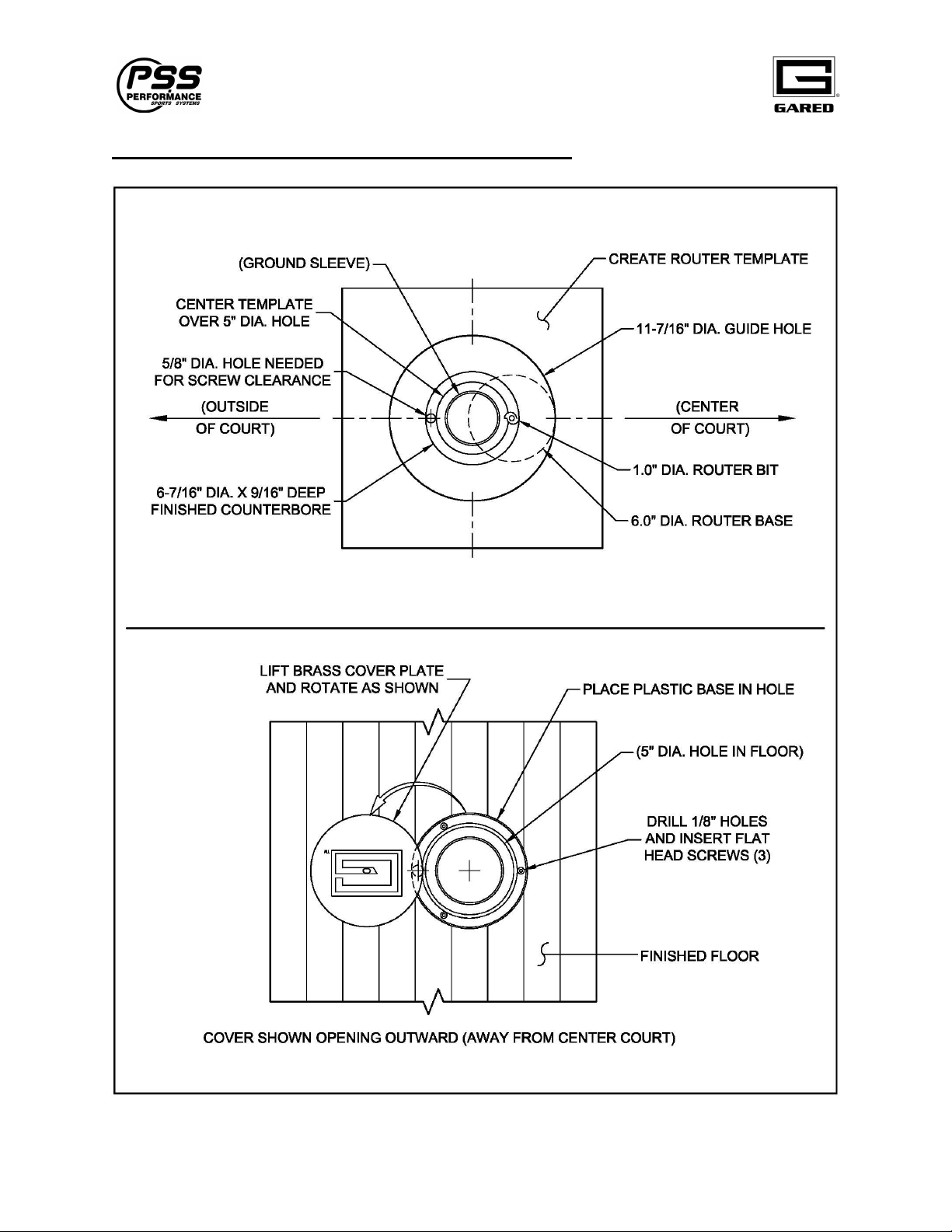

8. Using a router and template, make a counterbore 6-7/16” diameter by 9/16” deep

centered over the original 5.0” hole in the floor, to receive the brass floor cover

with plastic base. A template can be made from a piece of Masonite or thick

plastic. Make a hole in the template material so that when the router is used with

it, the counter bore achieves a good fit. Many router bit and template

combinations are possible. A skilled woodworker will be needed for this

operation! A finished counterbore of 6-7/16” diameter is what is important!

Practice on a piece of scrap wood first. If the hole is too big, corrections may not

be possible. (see page 6)

9. Install the floor covers. Place floor covers; drill holes and install screws as shown.

(see page 6)