Garnet SeeLevel ProSeries II 810-PS2 User manual

Page 1

810-PS2 Manual

MODEL 810-PS2 MANUAL

IMPORTANT OPERATOR INFORMATION

DATE INSTALLED:_______________________________________________________________________________

UNIT NUMBER:_________________________________________________________________________________

COMPARTMENT: _______________________________________________________________________________

DISPLAY CALIBRATION UNITS (e.g. inches, gallons): ___________________________________________

MINIMUM TANK READOUT: ___________________________________________________________________

MAXIMUM TANK READOUT: ___________________________________________________________________

ALARM #1 POINT (IF APPLICABLE): ____________________________________________________________

ALARM #2 POINT (IF APPLICABLE): ____________________________________________________________

ALARM #3 POINT (IF APPLICABLE): ____________________________________________________________

ALARM #4 POINT (IF APPLICABLE): ____________________________________________________________

AUTOMATIC ALARM: WARNING LEVEL: ____________________________________________________

EMPTY LEVEL: ________________________________________________________

PROSERIES II

TM

S

EELEVEL

Tank Truck Level Gauge

USA

Garnet US Inc.

5360 Old Granbury Road

Granbury, TX 76049

CANADA

Garnet Instruments

286 Kaska Road

Sherwood Park, AB T8A 4G7

garnetinstruments.com

1-800-617-7384

Page 2 810-PS2 Manual

Table of Contents

CHAPTER 1 - OVERVIEW.............................................................................................3

CHAPTER 2 - NEW FEATURES OF THE 810-PS2.................................................4

CHAPTER 3 - GAUGE DESCRIPTION.......................................................................6

CHAPTER 4 - UNIQUE FEATURES ............................................................................8

CHAPTER 5 - SENDER BAR LIMITS OF RESISTIVITY........................................ 10

CHAPTER 6 - 810-PS2 INSTALLATION GUIDE................................................... 13

CHAPTER 7 - SETTING DISPLAY DENSITY.......................................................... 18

CHAPTER 8 - 810-PS2 PROGRAMMING INSTRUCTIONS ............................ 22

CHAPTER 9 - TROUBLESHOOTING GUIDE......................................................... 26

CHAPTER 10 - SERVICE & WARRANTY INFORMATION ............................... 29

MAIL IN WARRANTY ................................................................................................. 31

GARNET

SEELEVELPROSERIES TM

Tank Truck Level Gauge

MODEL 810-PS2

Software rev. 6.02

810-PS2 Manual_v6.5 - 05-Feb-2019

Page 3

810-PS2 Manual

Congratulations on purchasing the Garnet Instruments Model

810-PS2 ™ Gauge for Trucks. The 810-PS2

represents the latest in state of the art liquid level measurement

equipment for transport applications. The 810-PS2 is designed

for reliable, accurate level measurement of sour or sweet crude oil,

chemicals, acids, water, condensate, gasoline, or diesel fuel. The

liquid level is determined by sensing the position of a magnetic

can operate over a range of product temperatures from -40°C to

+90°C (-40°F to +194°F).

The 810-PS2 has been designed to withstand the vibration and

shock encountered in mobile applications. The components

eliminating the need for protective enclosures. The sender bar

in the tank can withstand steaming temperatures. The gauge

operates entirely on internal batteries, so 12 volt truck power is

not required (external alarms will require truck power).

The 810-PS2 can display in any units, such as inches of level or

cubic metres of volume. It has four alarm points which can be

alarm point to operate a high level warning horn or light.

The 817 Truck Gauge Programmer can be used to program the

810-PS2 to read the desired calibration units, and to set the

alarm points. They are designed to be easily operated by people

unfamiliar with electronics or computers.

CHAPTER 1 - OVERVIEW

Page 4 810-PS2 Manual

The 810-PS2 has a number of enhancements over the previous

810-PS series. It uses new technology in the display to provide

a number of new features:

1.

device which is much more secure and does not require

power to maintain the memory contents. This should result

in a much more reliable operation, with less chance of a lost

or corrupted calibration.

2. The display can be programmed with a magnet for 8 or 11

bit operation, to work with bars in either 1/3, 1/4, or 1/6 inch

mode. If a sender bar ends up in the wrong mode, then the

display will show bad light and the number of bits received.

The previous displays would either not accept bars in 11 bit

and 11 bit modes. The mode is stored in the display in the

same secure memory as the calibration.

3. The display has improved diagnostics:

a. If the wrong number of bits are received, then the display

shows “bL:xx” where xx is the number of bits actually

received.

b.

every few seconds.

c. By connecting together two end pins on the right hand

side of the programming plug (looking at the back of the

display), the display will show a basic inch calibration,

which aids in troubleshooting to determine if the sender

bar or display calibration is at fault.

d. If there is a fault during programming or if the memory is

not functioning correctly, the display shows “Err”.

e. If the memory does not have a valid value for the number

of received bits (either 8 or 11) then the display shows

“Prob”.

f.

strong light the display will show “Sun” indicating that

into the display opto then the display may show either

“Sun” or “bL:xx” depending on the exact nature of the light

getting in.

4. The optical receiver has been improved so it cannot be

overloaded with too much light from the sender bar.

CHAPTER 2 - NEW FEATURES OF THE 810-PS2

Page 5

810-PS2 Manual

5. The display is powered entirely by four “AA” penlight alkaline

cells instead of a combination of a lithium battery and AA

cells. This allows the end user to be able to fully service any

battery problems.

6.

or fails, the display can be quickly returned to service.

7. The display has a built in SpillStop transmitter, so an additional

SpillStop module is no longer required when connecting the

gauge to an 815 SpillStop controller.

8. The display has the ability to drive a remote transmitter for

applications which require the transfer of the data from the

gauge to another piece of equipment.

Software Revision 6.02

1. See Chapter 8 to determine the software revision.

2. Prior to revision 6.02, the alarm outputs would all go to an

open circuit condition if the gauge is in a failure mode such as

no light, bad light or sun.

3. Since revision 6.02, alarms 3 and 4 will go to a closed circuit

condition during a failure mode. This change has been made

so that if the gauge is being used with the 815-JBPC junction

a gauge failure.

4.

the event of a gauge failure.

Page 6 810-PS2 Manual

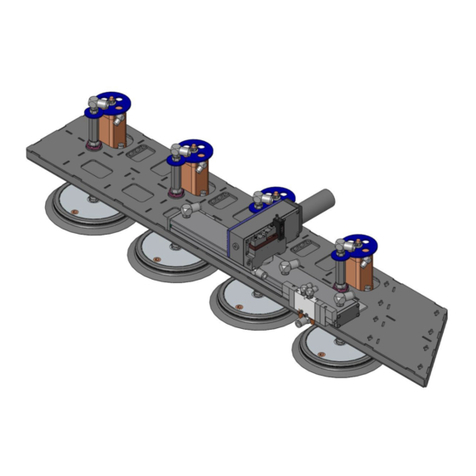

The 810-PS2 gauge consists of a sender bar, a donut shaped

display, which displays the level in appropriate units and operates

the alarms, SpillStop transmitter, and remote data transmitter.

activated switches are detected by the microprocessor at the top

of the bar. The microprocessor operates from a long life lithium

battery giving about 10 years of life. The level information is

used to maintain electrical isolation between the sender bar and

The display converts the level information to volume according

to the calibration programmed into it with the 817 Truck Gauge

Programmer. The calibration can be in inches, centimetres or

volumetric units such as cubic metres or barrels. The entire display

is enclosed in a cast aluminum box with a hinged cover, which is

durable enough to be mounted on the truck or trailer without any

additional protection. The hinged cover keeps the display face

clean and operates an internal switch for LED control and alarm

resetting. The tank level is shown on two displays - an LCD (Liquid

Crystal Display) which takes very little power to operate and gives

excellent daytime visibility, and an LED (Light Emitting Diode)

display which has higher power consumption but gives excellent

night time visibility. To reduce power drain the display only turns

on the LED when the cover is open and when there is not enough

light to see the LCD display. The entire display is powered by four

replaceable alkaline AA cells giving about 1½ to 2 years of life

under normal operation (assuming that the LEDs are on for about

2 hours per day).

The display contains four alarms which are programmed using the

any point in the tank. The alarm outputs are transistors which can

handle up to 1 amp of DC current at 24 volts. The transistors are

wired to complete a circuit to ground, so only one wire is needed

to connect to each alarm.

CHAPTER 3 - GAUGE DESCRIPTION

Page 7

810-PS2 Manual

WARNING: The use of alarm points is entirely at the owner’s

risk due to the nature of connecting external horns or lights,

the reliability of external horns or lights, and the requirement

for external switches to disarm them.

Alarm 4 also has an extra transistor output on the purple wire.

With this purple wire connected to a warning horn, alarm 4

functions as a self resetting high level warning alarm. Alarm 4 is

programmed as the warning point, and alarm 3 is programmed

near the tank empty point. When the product level rises in the

tank and hits the warning point, the horn will sound. Closing and

opening the lid of the display will silence the horn. When the tank

is unloaded below the empty point, the alarm is reset so that it

way the operator cannot forget to turn on the horn. The horn will

sound at the warning point even if the lid is opened and closed

prior to the product level hitting the warning point, and will sound

with the lid in either the open or closed position when the warning

point is reached.

The display has a SpillStop transmitter for direct connection to a

Garnet 815-UHP SpillStop or 815-UHP SpillStop Ultra controller.

The transmitter operates in accordance with the programmed

alarm points 1, 2, and 3. This provides the user with automated

horn warnings and automated control of PTO loading to prevent

Installation of the gauge consists of cutting a hole in the top of

the tank and welding in a 1 inch coupler, and welding an anchor

assembly to the bottom of the tank. The sender bar is cut to

length, the end is sealed, and it is inserted from the top of the tank

is mounted at a convenient point on the truck frame or panel,

and 1/4” air brake hose is connected from the sender head to

at each end, and the gauge is programmed. Fastening on the

covers for the head and display completes the installation. The

Page 8 810-PS2 Manual

The 810-PS2 gauge has been designed for maximum ease of

installation and servicing, and for the best operational features.

The anchor at the bottom of the tank provides a shock mount for

no tank entry is required for sender bar replacement. If the new

sender bar is cut to the same length as the old, no re-calibration

is required.

good esthetic appearance, and high durability due to the “give”

in the plastic. The light weight of the polyethylene allows the

density products.

potting material to enhance reliability. The use of a digital rather

than analog sensing technique lowers power consumption to

permit battery operation, and ensures high accuracy with no drift

simply cut to length with a hacksaw, and the cut end sealed with a

cap to prevent moisture or product contamination. This way only

the maximum height is less than 5 inches above the top of the

tank so that it will not protrude above the spillway.

display can be disconnected at both ends. There is approximately

10 times as much light as is required for operation available for

ensures that even with faulty wiring into the display, no explosion

The display enclosure was designed to eliminate the need for an

external enclosure, thus saving cost and space. The hinged cover

has a magnetic latch which will not jam, and the hinge is very

simple with plastic and stainless steel components, for long life

and easy replacement. If alarms are not connected, the only entry

opportunity for water to enter the box. The internal circuitry is also

protected against moisture with a protective coating. Along with

being battery operated and not requiring truck power to operate,

CHAPTER 4 - UNIQUE FEATURES

Page 9

810-PS2 Manual

mounting location. The dual displays ensure that the gauge

display is always visible, regardless of ambient lighting conditions.

The use of an on-site programmer eliminates downtime waiting

for factory calibration parts, and allows easy reprogramming

should the need arise. The entire display, including decimal

point, is completely programmable to whatever units are

desired. In addition to numbers, the letters F, U, L, and E can be

programmed to provide displays such as FULL, E, etc. The alarms

wiring, and uses transistors rather than relays to increase current

capability, eliminate sparking, and eliminate gauge battery power

drain.

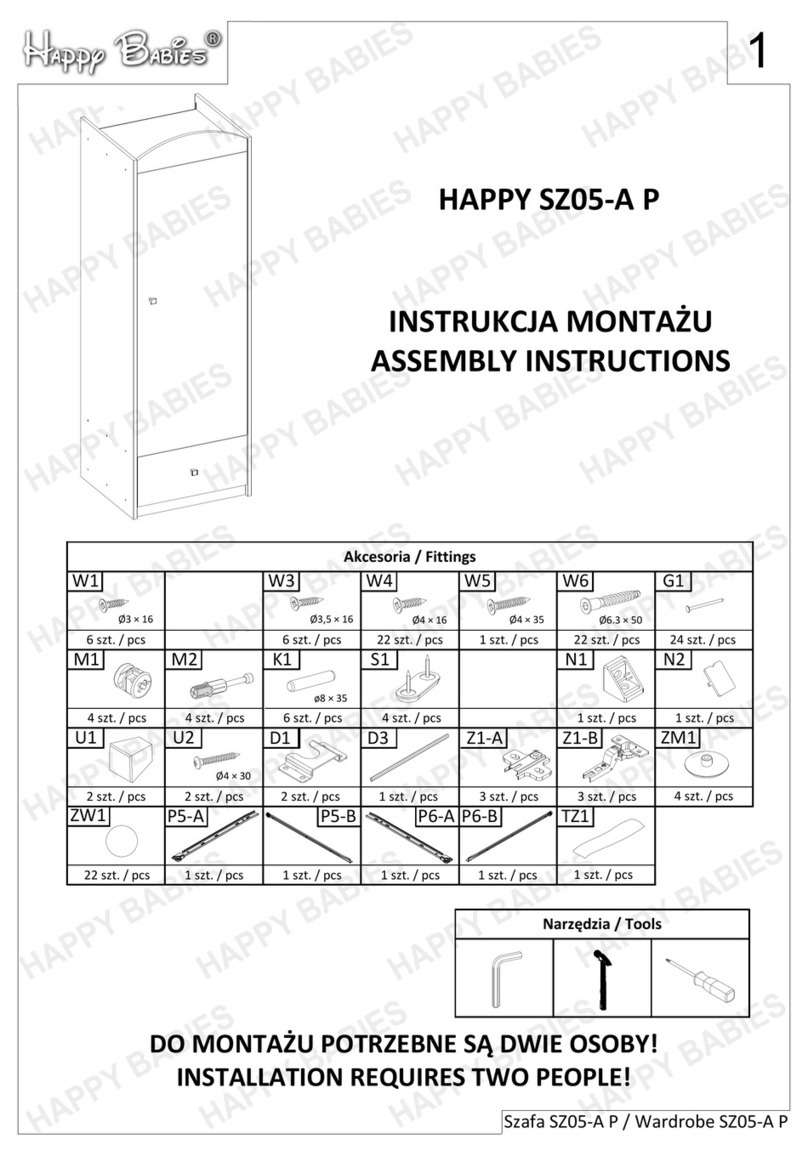

ANCHOR SUPPORT

TAPER ALLOWS

DEBRIS TO SLIDE

OFF FLOAT

COMPRESSION FITTING 1” COUPLER

TANK CUTAWAY

STAINLESS STEEL

SENSOR BAR

HEAD (INSTALLED HEIGHT LESS THAN 5 INCHES ABOVE THE TOP OF THE TANK)

ALL WEATHER

DISPLAY ENCLOSURE

(LID NOT SHOWN)

WIRES FOR OPTIONAL

ELECTRICAL HOOKUPS FOR

SPILLSTOP CONNECTION AND ALARM

OUTPUT CAN BE BROUGHT INTO

DISPLAY USING APPROPRIATE WATER

TIGHT FITTINGS AND CONDUIT

1/4” AIR LINE CONTAINING FIBER

OPTIC INTERCONNECT CABLE

NIGHT LED DISPLAY ONLY COMES ON

WHEN LID OPEN AND IT IS DARK

LED DISPLAY

(NIGHT VIEWING)

LCD DISPLAY

(DAY VIEWING)

OPTICAL SENSOR FOR

NIGHT LIGHT ACTIVATION

GENERAL MECHANICAL ASSEMBLY

Page 10 810-PS2 Manual

The temperature of the product being transported should be

and sender bar can occur if this value is exceeded.

The tube used in the manufacturing of the sender bar is seamless

316 stainless steel. It should be noted that certain corrosive

products, as well as high concentrations of acid products, may

attack the stainless steel and cause perforations to develop. It is the

operator’s responsibility to determine the products compatibility

with the sender bar.

WARNING: Perforation of the sender bar or heat damage is

not warrantable.

The Loctite products used to secure the end cap can be attacked

by certain chemicals as well. For reference, a chemical resistance

chart from Loctite showing product compatibility with various

chemicals can be found on the following pages.

The 680 retaining compound we specify is similar to Loctite #592,

567, 565, 569, 545, 580, 571, 242, 577, 572, 542, 565, 545, 243. If

you require more information, please call the Loctite Corporation,

in Canada, 1-800-263-5043, in USA, 1-800-562-8483.

CHAPTER 5 - SENDER BAR LIMITS OF RESISTIVITY

Page 11

810-PS2 Manual

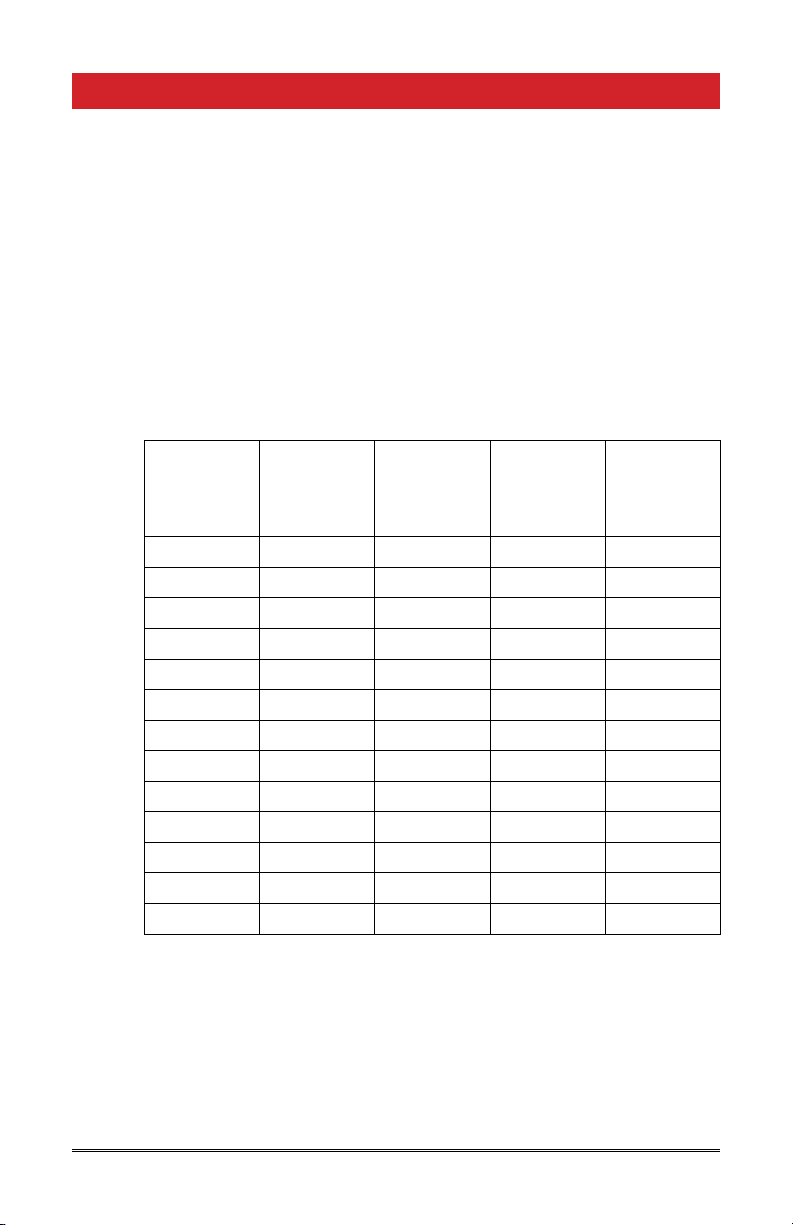

LIQUIDS, SOLUTIONS & SUSPENSIONS

Loctite product numbers in red are worldwide or application-specic products

(This is a list of chemical stability only. It does not constitute approval for use in the processing of food, drugs, cosmetics, pharmaceuticals, and

ingestible chemicals.) Loctite

®sealants are not recommended for use in pure oxygen or chlorine environments or in conjunction with strong

oxidizing agents, an explosive reaction can result.

Abrasive Coolant.......................

Acetaldehyde ...........................

Acetate Solvents ......................

Acetimide .................................

Acetic Acid................................

Acetic Acid................................

Acetic Acid - glacial ..................

Acetic Anhydride ......................

Acetone ....................................

Acetyl Chloride .........................

Acetylene (Liquid Phase) ..........

Acid Clay...................................

Acrylic Acid ..............................

Acrylonitrile .............................

Activated Alumina ....................

Activated Carbon .....................

Activated Silica ........................

Alcohol-Allyl ............................

Alcohol-Amyl ...........................

Alcohol-Benzyl .........................

Alcohol-Butyl ...........................

Alcohol-Ethyl ...........................

Alcohol-Furfuryl .......................

Alcohol-Hexyl ..........................

Alcohol-lsopropyl ....................

Alcohol-Methyl ........................

Alcohol-Propyl .........................

Alum-Ammonium ....................

Alum-Chrome ..........................

Alum-Potassium ......................

Alum-Sodium ..........................

Alumina ...................................

Aluminum Acetate ...................

Aluminum Bicarbonate .............

Aluminum Biuoride.................

Aluminum Chloride...................

Aluminum Sulfate ....................

Ammonia Anhydrous................

Ammonia Solutions ..................

Ammonium Bisulte .................

Ammonium Borate....................

Ammonium Bromide ................

Ammonium Carbonate..............

Ammonium Chloride.................

Ammonium Chromate ..............

Ammonium Fluoride .................

Ammonium Fluorosilicate ........

Ammonium Formate.................

Ammonium Hydroxide..............

Ammonium Hyposulte............

Ammonium Iodide....................

Ammonium Molybdate .............

Ammonium Nitrate ...................

Ammonium Oxalate ..................

Ammonium Persulfate..............

Ammonium Phosphate .............

Ammonium Picrate...................

Ammonium Sulfate...................

Ammonium Sulfate Scrubber ...

Ammonium Sulde...................

Ammonium Thiocyanate...........

Amyl Acetate ............................

Amyl Amine .............................

Amyl Chloride ..........................

Aniline ......................................

Aniline Dyes .............................

Anodizing Bath .........................

Antichlor Solution ....................

Antimony Acid Salts ................

Antimony Oxide .......................

Antioxidant Gasoline ................

Aqua Regia ...............................

Argon........................................

Armeen §..................................

Arochlor § ................................

Aromatic Gasoline ....................

Aromatic Solvents ...................

Arsenic Acid .............................

Asbestos Slurry .......................

Ash Slurry ................................

Asphalt Emulsions ...................

Asphalt Molten..........................

LEGEND:

All Loctite

®Anaerobic Sealants are

Compatible Including #242

®,243,

542,545,565, 567, 569, 571, 572,

577, 580, 592

†

Use Loctite

®#270, 271™, 277,554

Not Recommended

<10% (same as )

>10% (same as

†

)

*

<5% (same as )

>5% (same as †)

Use Loctite

®#242®,243, 290, 565

FLUID COMPATIBILITY CHART

for metal threaded ttings sealed with Loctite

®

Sealants

Bagasse Fibers..........................

Barium Acetate ........................

Barium Carbonate.....................

Barium Chloride........................

Barium Hydroxide.....................

Barium Sulfate..........................

Battery Acid ..............................

Battery Diuser Juice ...............

Bauxite (See Alumina) .............

Bentonite .................................

Benzaldehyde ...........................

Benzene ...................................

Benzene Hexachloride ..............

Benzene in Hydrochloric Acid ..

Benzoic Acid ............................

Benzotriazole ...........................

Beryllium Sulfate .....................

Bicarbonate Liquor ..................

Bilge Lines ...............................

Bleach Liquor ...........................

Bleached Pulps ........................

Borax § Liquors .......................

Boric Acid ................................

Brake Fluids .............................

Brine Chlorinated .....................

Brine Cold ................................

Bromine Solution...................... †

Butadiene..................................

Butyl Acetate ............................

Butyl Alcohol ...........................

Butyl Amine .............................

Butyl Cellosolve § ....................

Butyl Chloride ..........................

Butyl Ether - Dry ......................

Butyl Lactate ............................

Butyral Resin ...........................

Butyraldehyde ..........................

Butyric Acid ..............................

Cadmium Chloride....................

Cadmium Plating Bath .............

Cadmium Sulfate ......................

Calcium Acetate .......................

Calcium Bisulfate .....................

Calcium Carbonate ...................

Calcium Chlorate .....................

Calcium Chloride ......................

Calcium Chloride Brine .............

Calcium Citrate ........................

Calcium Ferrocyanide ...............

Calcium Formate ......................

Calcium Hydroxide....................

Calcium Lactate .......................

Calcium Nitrate ........................

Calcium Phosphate...................

Calcium Silicate .......................

Calcium Sulfamate....................

Calcium Sulfate ........................

Calcium Sulte .........................

Camphor ..................................

Carbitol ....................................

Carbolic Acid (phenol) ..............

Carbon Bisulde .......................

Carbon Black ...........................

Carbon Tetrachloride ...............

Carbonic Acid ...........................

Carbowax §...............................

Carboxymethyl Cellulose .........

Carnauba Wax .........................

Casein ......................................

Casein Water Paint ..................

Celite.........................................

Cellosolve § .............................

Cellulose Pulp ..........................

Cellulose Xanthate ....................

Cement Dry/Air Blown ..............

Cement Grout ..........................

Cement Slurry ..........................

Ceramic Enamel .......................

Ceric Oxide ..............................

Chalk ........................................

Chemical Pulp ..........................

Chestnut Tanning .....................

China Clay.................................

Chloral Alcoholate ....................

Chloramine ..............................

Chlorinated Hydrocarbons .......

Chlorinated Paperstock ............

Chlorinated Solvents.................

Chlorinated Sulphuric Acids .....

Chlorinated Wax ......................

Chlorine Dioxide .......................

Chlorine Liquid ........................

Chlorine Dry ............................

Chloroacetic Acid......................

Chlorobenzene Dry ...................

Chloroform Dry.........................

Chloroformate Methyl...............

Chlorosulfonic Acid ..................

Chrome Acid Cleaning ..............

Chrome Liquor..........................

Chrome Plating Bath.................

Chromic Acid 10%....................

Chromic Acid 50% (cold) .........

Chromic Acid 50% (hot) ..........

Chromium Acetate ...................

Chromium Chloride ..................

Chromium Sulfate ....................

Classier ..................................

Clay ..........................................

Coal Slurry ...............................

Coal Tar ...................................

Cobalt Chloride ........................

Copper Ammonium Formate.....

Copper Chloride .......................

Copper Cyanide .......................

Copper Liquor ..........................

Copper Naphthenate .................

Copper Plating, Acid Process ...

Copper Plating, Alk. Process ....

Copper Sulfate .........................

Core Oil ....................................

Corundum ................................

Creosote ..................................

Creosote-Cresylic Acid..............

Cyanide Solution ......................

Cyanuric Chloride ....................

Cyclohexane ............................

Cylinder Oils .............................

De-Ionized Water ......................

De-Ionized Water Low

Conductivity............................

Detergents ...............................

Developer, photographic...........

Dextrin .....................................

Diacetone Alcohol ....................

Diammonium Phosphate ..........

Diamylamine ............................

Diatomaceaus Earth Slurry ......

Diazo Acetate ...........................

Dibutyl Phthalate .....................

Dichlorophenol ........................

Dichloro Ethyl Ether..................

Dicyandamide ..........................

Dielectric Fluid .........................

Diester Lubricants ...................

Diethyl Ether Dry .....................

Diethyl Sulfate .........................

Diethylamine ............................

Diethylene Glycol .....................

Diglycolic Acid .........................

Dimethyl Formamide ................

Dimethyl Sulfoxide....................

Dioxane Dry ............................

Dioxidene .................................

Dipentene - Pinene ...................

Diphenyl ..................................

Distilled Water (Industrial)........

Dowtherm § .............................

Drying Oil ................................

Dust-Flue (Dry) ........................

Dye Liquors ..............................

Emery - Slurry .........................

Emulsied Oils .........................

Enamel Frit Slip.........................

Esters General .........................

Ethyl Acetate ............................

Ethyl Alcohol ............................

Ethyl Amine .............................

Ethyl Bromide ..........................

Ethyl Cellosolve § ....................

Ethyl Cellosolve Slurry §...........

Ethyl Formate ...........................

Ethyl Silicate ............................

Ethylene Diamine .....................

Ethylene Dibromide ..................

Ethylene Dichloride...................

Ethylene Glycol ........................

Ethylenediamine Tetramine .......

Fatty Acids ...............................

Fatty Acids Amine ....................

Fatty Alcohol.............................

Ferric-Floc ................................

Ferric Chloride .........................

Ferric Nitrate ............................

Ferric Sulfate ............................

Ferrocence-Oil Sol ...................

Ferrous Chloride ......................

Ferrous Oxalate.........................

Ferrous Sulfate10%..................

Ferrous Sulfate (Sat).................

Fertilizer Sol .............................

Flotation Concentrates..............

Fluoride Salts ...........................

Fluorine, Gaseous or Liquid......

Fluorolube ................................

Fluosilic Acid ...........................

Flux Soldering ..........................

Fly Ash Dry ..............................

Foam Latex Mix .......................

Foamite ....................................

Formaldehyde (cold).................

Formaldehyde (hot) .................. †

Formic Acid (Dil cold)...............

Formic Acid (Dil hot) ................ †

Formic Acid (cold) ....................

Formic Acid (hot)...................... †

Freon § ..................................... †

Fuel Oil......................................

Fuming Nitric Red.....................

Fuming Sulfuric .......................

Fuming Oleum .........................

Furfural.....................................

Gallic Acid ................................ *

Gallium Sulfate .........................

Gasoline-Acid Wash .................

Gasoline-Alk. Wash ..................

Gasoline Aviation .....................

Gasoline Copper Chloride .........

Gasoline Ethyl ..........................

Gasoline Motor ........................

Gasoline Sour ..........................

Gasoline White .........................

Gluconic Acid ...........................

Glue-Animal Gelatin .................

Glue-Plywood ..........................

Glutamic Acid ..........................

Glycerine Lye-Brine...................

Glycerol ...................................

Glycine .....................................

Glycine Hydrochloride ..............

Glycol Amine ...........................

Glycolic Acid ............................

Glyoxal......................................

Gold Chloride ...........................

Gold Cyanide ...........................

Granodine ................................

Grape Pomace Graphite............

Grease Lubricating....................

Green Soap ..............................

Grinding Lubricant ...................

Grit Steel ..................................

Gritty Water .............................

Groundwood Stock ..................

GRS Latex ................................

Gum Paste ...............................

Gum Turpentine .......................

Gypsum ....................................

Halane Sol ...............................

Halogen Tin Plating...................

Halowax § ................................

Harvel-Trans 0il .......................

Heptane ...................................

Hexachlorobenzene...................

Hexadiene ................................

Hexamethylene Tetramine.........

Hexane .....................................

Hydrazine .................................

Hydrazine Hydrate ...................

Hydrobromic Acid.....................

Hydrochloric Acid ....................

Hydrocyanic Acid......................

Hydroouric Acid......................

Hydrogen Peroxide (dil)............

Hydrogen Peroxide (con) .........†

Hydroponic Sol ........................

Hydroquinone ..........................

Hydroxyacetic Acid ...................

Hypo ........................................

Hypochlorous Acid ...................

Ink ............................................

Ink in Solvent-Printing..............

Iodine in Alcohol ......................

Iodine-Potassium Iodide ..........

Iodine Solutions........................

Ion Exchange Service ..............

Ion Exclusion Glycol .................

Irish Moss Slurry......................

Iron Ore Taconite .....................

Iron Oxide ................................

Isobutyl Alcohol .......................

Isobutyraldehyde .....................

Isooctane .................................

Isopropyl Alcohol .....................

Isocyanate Resin .....................

Isopropyl Acetate .....................

Isopropyl Ether .........................

Itaconic Acid ............................

Jet Fuels ..................................

Jeweler's Rouge ......................

Jig Table Slurry.........................

Kaolin-China Clay §...................

Kelp Slurry ...............................

Kerosene ..................................

Kerosene Chlorinated................

Ketone .....................................

Lacquer Thinner .......................

Lactic Acid ...............................

Lapping Compound ..................

Latex-Natural ...........................

Latex-Synthetic ........................

Latex Synthetic Raw .................

Laundry Wash Water ................

Laundry Bleach ........................

Laundry Blue ...........................

Laundry Soda ..........................

Lead Arsenate ..........................

Lead Oxide................................

Lead Sulfate .............................

Lignin Extract............................

Lime Slaked .............................

Lime Sulfur Mix .......................

Liquid Ion Exchange .................

Lithium Chloride ......................

LOX (Liquid 02) .......................

Ludox .......................................

Lye............................................

Machine Coating Color .............

Magnesite Slurry .....................

Magnesite.................................

Magnesium Bisulte .................

Magneslum Carbonate..............

Magnesium Chloride.................

Magnesium Hydroxide..............

Magnesium Sulfate...................

Maleic Acid ..............................

Maleic Anhydride .....................

Manganese Chloride .................

Manganese Sulfate ...................

Melamine Resin .......................

Menthol ...................................

Mercaptans ..............................

Mercuric Chloride ....................

Mercuric Nitrate .......................

Mercury ...................................

Mercury Dry ............................

Methane ...................................

Methyl Alcohol .........................

Methyl Acetate .........................

Methyl Bromide .......................

Methyl Carbitol .........................

Methyl Cellosolve §...................

Methyl Chloride .......................

Methyl Ethyl Ketone..................

Methyl Isobutyl Ketone.............

Methyl Lactate .........................

Methyl Orange .........................

Methylamine ............................

Methylene Chloride...................

Mineral Spirits .........................

Mixed Acid, Nitric/Sulfuric........

Monochloracetic Acid ...............

Morpholine ..............................

Mud ..........................................

Nalco Sol. .................................

Naphtha ...................................

Naphthalene .............................

Naval Stores Solvent.................

Nematocide ..............................

Neoprene Emulsion ..................

Neoprene Latex ........................

Nickel Acetate ..........................

Nickel Ammonium Sulfate ........

Nickel Chloride..........................

Nickel Cyanide .........................

Nickel Fluoborate .....................

Nickel Ore Fines .......................

Nickel Plating Bright .................

Nickel Sulfate ...........................

Nicotinic Acid............................

Nitrate Sol.................................

Nitration Acid(s) .......................

Nitric Acid ................................

Nitric Acid10%..........................

Nitric Acid 20%......................... †

Nitric Acid Anhydrous...............

Nitric Acid Fuming ....................

Nitro Aryl Sulfonic Acid ............

Nitrobenezene-Dry ...................

Nitrocellulose ...........................

Nitrofurane ..............................

Nitroguanidine .........................

Nitroparans-Dry ....................

Nitrosyl Chloride ......................

Norite Carbon ...........................

Nuchar......................................

Oakite § Compound ..................

Oil, Creosote ............................

Oil, Emulsied ..........................

Oil, Fuel ....................................

Oil, Lubricating ........................

Oil, Soluble ..............................

Oleic Acid, hot .........................

Oleic Acid, cold ........................

Ore Fines-Flotation....................

Ore Pulp ...................................

Organic Dyes ............................

Oxalic Acid cold ........................

Ozone, wet................................

Paint-Linseed Base ...................

Paint-Water Base .....................

Paint-Remover-Sol. Type .........

Paint-Vehicles...........................

Palmitic Acid ............................

Paper Board Mill Waste ............

Paper Coating Slurry ................

Paper Pulp ...............................

Paper Pulp with Amun..............

Paper Pulp with Dye ................

Paper Pulp, bleached................

Paper Pulp, bleached-washed ..

Paper Pulp Chlorinated.............

Paper Groundwood...................

Paper Rag ................................

Paper Stocks, ne ....................

Paradichlorobenezene...............

Paran Molten ........................

Paran Oil ...............................

Paraformaldehyde ....................

Pectin Solution Acid .................

Pentachlorethane .....................

PentaerythritoI Sol. ..................

Perchlorethylene (Dry)..............

Perchloric Acid .........................

Perchloromethyl Mercaptan .....

Permanganic Acid.....................

Persulfuric Acid .......................

Petroleum Ether .......................

Petroleum Jelly ........................

Phenol Formaldehyde Resins ..

Phenol Sulfonic Acid.................

Phenolic Glue ...........................

Phloroglucinol .........................

Phosphate Ester .......................

Phosphatic Sand ......................

Phosphoric Acid 85% hot ........

Phosphoric Acid 85% cold ......†

Phosphoric Acid 50% hot.........†

Phosphoric Acid 50% cold ......†

Phosphoric Acid 10% cold ......

Phosphoric Acid 10% hot ........†

Phosphorous Molten ................

Phosphotungstic Acid...............

Photographic Sol. ....................

Phthalic Acid.............................

Phytate ....................................

Phytate Salts ............................

Pickling Acid, Sulfuric...............

Picric Acid Solutions.................

Pine Oil Finish ..........................

Page 12 810-PS2 Manual

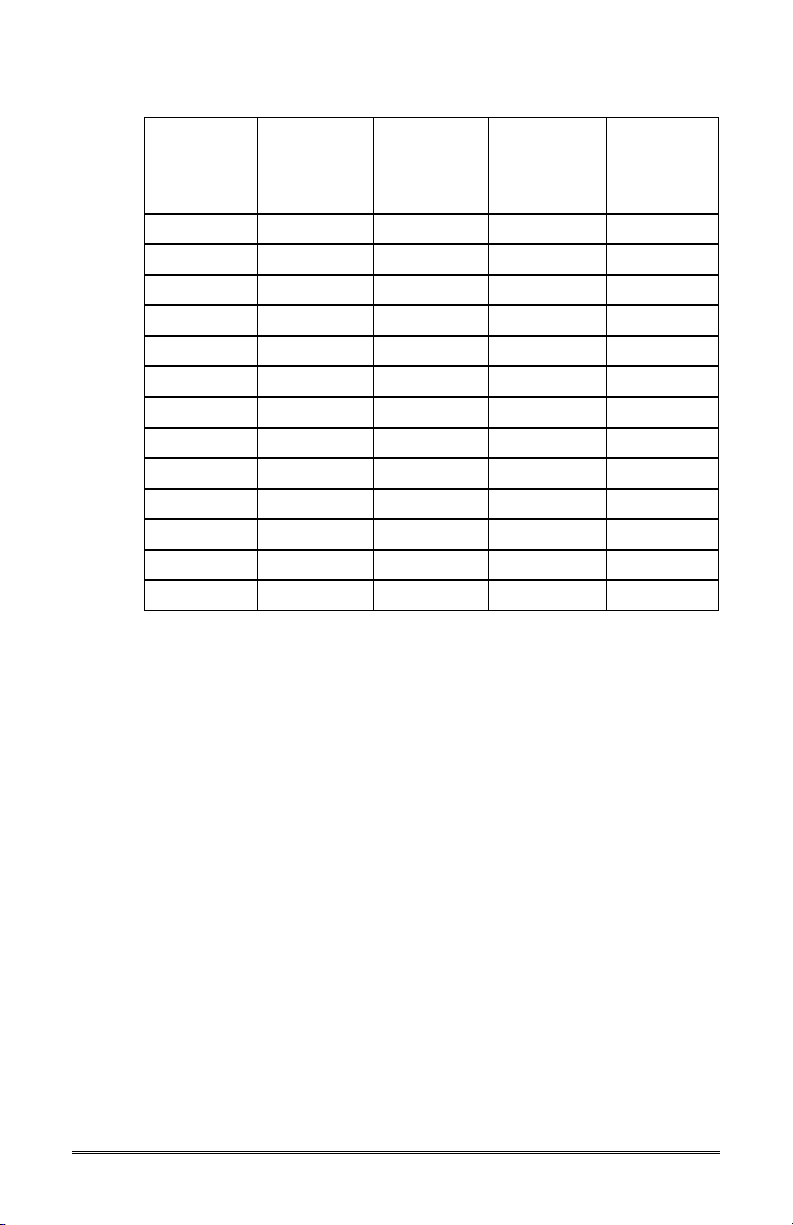

LIQUIDS, SOLUTIONS & SUSPENSIONS

Loctite product numbers in red are worldwide or application-specic products

(This is a list of chemical stability only. It does not constitute approval for use in the processing of food, drugs, cosmetics, pharmaceuticals, and

ingestible chemicals.) Loctite

®sealants are not recommended for use in pure oxygen or chlorine environments or in conjunction with strong

oxidizing agents, an explosive reaction can result.

Abrasive Coolant.......................

Acetaldehyde ...........................

Acetate Solvents ......................

Acetimide .................................

Acetic Acid................................

Acetic Acid................................

Acetic Acid - glacial ..................

Acetic Anhydride ......................

Acetone ....................................

Acetyl Chloride .........................

Acetylene (Liquid Phase) ..........

Acid Clay...................................

Acrylic Acid ..............................

Acrylonitrile .............................

Activated Alumina ....................

Activated Carbon .....................

Activated Silica ........................

Alcohol-Allyl ............................

Alcohol-Amyl ...........................

Alcohol-Benzyl .........................

Alcohol-Butyl ...........................

Alcohol-Ethyl ...........................

Alcohol-Furfuryl .......................

Alcohol-Hexyl ..........................

Alcohol-lsopropyl ....................

Alcohol-Methyl ........................

Alcohol-Propyl .........................

Alum-Ammonium ....................

Alum-Chrome ..........................

Alum-Potassium ......................

Alum-Sodium ..........................

Alumina ...................................

Aluminum Acetate ...................

Aluminum Bicarbonate .............

Aluminum Biuoride.................

Aluminum Chloride...................

Aluminum Sulfate ....................

Ammonia Anhydrous................

Ammonia Solutions ..................

Ammonium Bisulte .................

Ammonium Borate....................

Ammonium Bromide ................

Ammonium Carbonate..............

Ammonium Chloride.................

Ammonium Chromate ..............

Ammonium Fluoride .................

Ammonium Fluorosilicate ........

Ammonium Formate.................

Ammonium Hydroxide..............

Ammonium Hyposulte............

Ammonium Iodide....................

Ammonium Molybdate .............

Ammonium Nitrate ...................

Ammonium Oxalate ..................

Ammonium Persulfate..............

Ammonium Phosphate .............

Ammonium Picrate...................

Ammonium Sulfate...................

Ammonium Sulfate Scrubber ...

Ammonium Sulde...................

Ammonium Thiocyanate...........

Amyl Acetate ............................

Amyl Amine .............................

Amyl Chloride ..........................

Aniline ......................................

Aniline Dyes .............................

Anodizing Bath .........................

Antichlor Solution ....................

Antimony Acid Salts ................

Antimony Oxide .......................

Antioxidant Gasoline ................

Aqua Regia ...............................

Argon........................................

Armeen §..................................

Arochlor § ................................

Aromatic Gasoline ....................

Aromatic Solvents ...................

Arsenic Acid .............................

Asbestos Slurry .......................

Ash Slurry ................................

Asphalt Emulsions ...................

Asphalt Molten..........................

LEGEND:

All Loctite

®

Anaerobic Sealants are

Compatible Including #242

®

,243,

542,545,565, 567, 569, 571, 572,

577, 580, 592

†

Use Loctite

®

#270, 271™, 277,554

Not Recommended

<10% (same as )

>10% (same as†)

*

<5% (same as )

>5% (same as †)

Use Loctite

®

#242

®

,243, 290, 565

FLUID COMPATIBILITY CHART

for metal threaded ttings sealed with Loctite

®

Sealants

Bagasse Fibers..........................

Barium Acetate ........................

Barium Carbonate.....................

Barium Chloride........................

Barium Hydroxide.....................

Barium Sulfate..........................

Battery Acid ..............................

Battery Diuser Juice ...............

Bauxite (See Alumina) .............

Bentonite .................................

Benzaldehyde ...........................

Benzene ...................................

Benzene Hexachloride ..............

Benzene in Hydrochloric Acid ..

Benzoic Acid ............................

Benzotriazole ...........................

Beryllium Sulfate .....................

Bicarbonate Liquor ..................

Bilge Lines ...............................

Bleach Liquor ...........................

Bleached Pulps ........................

Borax § Liquors .......................

Boric Acid ................................

Brake Fluids .............................

Brine Chlorinated .....................

Brine Cold ................................

Bromine Solution...................... †

Butadiene..................................

Butyl Acetate ............................

Butyl Alcohol ...........................

Butyl Amine .............................

Butyl Cellosolve § ....................

Butyl Chloride ..........................

Butyl Ether - Dry ......................

Butyl Lactate ............................

Butyral Resin ...........................

Butyraldehyde ..........................

Butyric Acid ..............................

Cadmium Chloride....................

Cadmium Plating Bath .............

Cadmium Sulfate ......................

Calcium Acetate .......................

Calcium Bisulfate .....................

Calcium Carbonate ...................

Calcium Chlorate .....................

Calcium Chloride ......................

Calcium Chloride Brine .............

Calcium Citrate ........................

Calcium Ferrocyanide ...............

Calcium Formate ......................

Calcium Hydroxide....................

Calcium Lactate .......................

Calcium Nitrate ........................

Calcium Phosphate...................

Calcium Silicate .......................

Calcium Sulfamate....................

Calcium Sulfate ........................

Calcium Sulte .........................

Camphor ..................................

Carbitol ....................................

Carbolic Acid (phenol) ..............

Carbon Bisulde .......................

Carbon Black ...........................

Carbon Tetrachloride ...............

Carbonic Acid ...........................

Carbowax §...............................

Carboxymethyl Cellulose .........

Carnauba Wax .........................

Casein ......................................

Casein Water Paint ..................

Celite.........................................

Cellosolve § .............................

Cellulose Pulp ..........................

Cellulose Xanthate ....................

Cement Dry/Air Blown ..............

Cement Grout ..........................

Cement Slurry ..........................

Ceramic Enamel .......................

Ceric Oxide ..............................

Chalk ........................................

Chemical Pulp ..........................

Chestnut Tanning .....................

China Clay.................................

Chloral Alcoholate ....................

Chloramine ..............................

Chlorinated Hydrocarbons .......

Chlorinated Paperstock ............

Chlorinated Solvents.................

Chlorinated Sulphuric Acids .....

Chlorinated Wax ......................

Chlorine Dioxide .......................

Chlorine Liquid ........................

Chlorine Dry ............................

Chloroacetic Acid......................

Chlorobenzene Dry ...................

Chloroform Dry.........................

Chloroformate Methyl...............

Chlorosulfonic Acid ..................

Chrome Acid Cleaning ..............

Chrome Liquor..........................

Chrome Plating Bath.................

Chromic Acid 10%....................

Chromic Acid 50% (cold) .........

Chromic Acid 50% (hot) ..........

Chromium Acetate ...................

Chromium Chloride ..................

Chromium Sulfate ....................

Classier ..................................

Clay ..........................................

Coal Slurry ...............................

Coal Tar ...................................

Cobalt Chloride ........................

Copper Ammonium Formate.....

Copper Chloride .......................

Copper Cyanide .......................

Copper Liquor ..........................

Copper Naphthenate .................

Copper Plating, Acid Process ...

Copper Plating, Alk. Process ....

Copper Sulfate .........................

Core Oil ....................................

Corundum ................................

Creosote ..................................

Creosote-Cresylic Acid..............

Cyanide Solution ......................

Cyanuric Chloride ....................

Cyclohexane ............................

Cylinder Oils .............................

De-Ionized Water ......................

De-Ionized Water Low

Conductivity............................

Detergents ...............................

Developer, photographic...........

Dextrin .....................................

Diacetone Alcohol ....................

Diammonium Phosphate ..........

Diamylamine ............................

Diatomaceaus Earth Slurry ......

Diazo Acetate ...........................

Dibutyl Phthalate .....................

Dichlorophenol ........................

Dichloro Ethyl Ether..................

Dicyandamide ..........................

Dielectric Fluid .........................

Diester Lubricants ...................

Diethyl Ether Dry .....................

Diethyl Sulfate .........................

Diethylamine ............................

Diethylene Glycol .....................

Diglycolic Acid .........................

Dimethyl Formamide ................

Dimethyl Sulfoxide....................

Dioxane Dry ............................

Dioxidene .................................

Dipentene - Pinene ...................

Diphenyl ..................................

Distilled Water (Industrial)........

Dowtherm § .............................

Drying Oil ................................

Dust-Flue (Dry) ........................

Dye Liquors ..............................

Emery - Slurry .........................

Emulsied Oils .........................

Enamel Frit Slip.........................

Esters General .........................

Ethyl Acetate ............................

Ethyl Alcohol ............................

Ethyl Amine .............................

Ethyl Bromide ..........................

Ethyl Cellosolve § ....................

Ethyl Cellosolve Slurry §...........

Ethyl Formate ...........................

Ethyl Silicate ............................

Ethylene Diamine .....................

Ethylene Dibromide ..................

Ethylene Dichloride...................

Ethylene Glycol ........................

Ethylenediamine Tetramine .......

Fatty Acids ...............................

Fatty Acids Amine ....................

Fatty Alcohol.............................

Ferric-Floc ................................

Ferric Chloride .........................

Ferric Nitrate ............................

Ferric Sulfate ............................

Ferrocence-Oil Sol ...................

Ferrous Chloride ......................

Ferrous Oxalate.........................

Ferrous Sulfate10%..................

Ferrous Sulfate (Sat).................

Fertilizer Sol .............................

Flotation Concentrates..............

Fluoride Salts ...........................

Fluorine, Gaseous or Liquid......

Fluorolube ................................

Fluosilic Acid ...........................

Flux Soldering ..........................

Fly Ash Dry ..............................

Foam Latex Mix .......................

Foamite ....................................

Formaldehyde (cold).................

Formaldehyde (hot) .................. †

Formic Acid (Dil cold)...............

Formic Acid (Dil hot) ................ †

Formic Acid (cold) ....................

Formic Acid (hot)...................... †

Freon § ..................................... †

Fuel Oil......................................

Fuming Nitric Red.....................

Fuming Sulfuric .......................

Fuming Oleum .........................

Furfural.....................................

Gallic Acid ................................ *

Gallium Sulfate .........................

Gasoline-Acid Wash .................

Gasoline-Alk. Wash ..................

Gasoline Aviation .....................

Gasoline Copper Chloride .........

Gasoline Ethyl ..........................

Gasoline Motor ........................

Gasoline Sour ..........................

Gasoline White .........................

Gluconic Acid ...........................

Glue-Animal Gelatin .................

Glue-Plywood ..........................

Glutamic Acid ..........................

Glycerine Lye-Brine...................

Glycerol ...................................

Glycine .....................................

Glycine Hydrochloride ..............

Glycol Amine ...........................

Glycolic Acid ............................

Glyoxal......................................

Gold Chloride ...........................

Gold Cyanide ...........................

Granodine ................................

Grape Pomace Graphite............

Grease Lubricating....................

Green Soap ..............................

Grinding Lubricant ...................

Grit Steel ..................................

Gritty Water .............................

Groundwood Stock ..................

GRS Latex ................................

Gum Paste ...............................

Gum Turpentine .......................

Gypsum ....................................

Halane Sol ...............................

Halogen Tin Plating...................

Halowax § ................................

Harvel-Trans 0il .......................

Heptane ...................................

Hexachlorobenzene...................

Hexadiene ................................

Hexamethylene Tetramine.........

Hexane .....................................

Hydrazine .................................

Hydrazine Hydrate ...................

Hydrobromic Acid.....................

Hydrochloric Acid ....................

Hydrocyanic Acid......................

Hydroouric Acid......................

Hydrogen Peroxide (dil)............

Hydrogen Peroxide (con) .........†

Hydroponic Sol ........................

Hydroquinone ..........................

Hydroxyacetic Acid ...................

Hypo ........................................

Hypochlorous Acid ...................

Ink ............................................

Ink in Solvent-Printing..............

Iodine in Alcohol ......................

Iodine-Potassium Iodide ..........

Iodine Solutions........................

Ion Exchange Service ..............

Ion Exclusion Glycol .................

Irish Moss Slurry......................

Iron Ore Taconite .....................

Iron Oxide ................................

Isobutyl Alcohol .......................

Isobutyraldehyde .....................

Isooctane .................................

Isopropyl Alcohol .....................

Isocyanate Resin .....................

Isopropyl Acetate .....................

Isopropyl Ether .........................

Itaconic Acid ............................

Jet Fuels ..................................

Jeweler's Rouge ......................

Jig Table Slurry.........................

Kaolin-China Clay §...................

Kelp Slurry ...............................

Kerosene ..................................

Kerosene Chlorinated................

Ketone .....................................

Lacquer Thinner .......................

Lactic Acid ...............................

Lapping Compound ..................

Latex-Natural ...........................

Latex-Synthetic ........................

Latex Synthetic Raw .................

Laundry Wash Water ................

Laundry Bleach ........................

Laundry Blue ...........................

Laundry Soda ..........................

Lead Arsenate ..........................

Lead Oxide................................

Lead Sulfate .............................

Lignin Extract............................

Lime Slaked .............................

Lime Sulfur Mix .......................

Liquid Ion Exchange .................

Lithium Chloride ......................

LOX (Liquid 02) .......................

Ludox .......................................

Lye............................................

Machine Coating Color .............

Magnesite Slurry .....................

Magnesite.................................

Magnesium Bisulte .................

Magneslum Carbonate..............

Magnesium Chloride.................

Magnesium Hydroxide..............

Magnesium Sulfate...................

Maleic Acid ..............................

Maleic Anhydride .....................

Manganese Chloride .................

Manganese Sulfate ...................

Melamine Resin .......................

Menthol ...................................

Mercaptans ..............................

Mercuric Chloride ....................

Mercuric Nitrate .......................

Mercury ...................................

Mercury Dry ............................

Methane ...................................

Methyl Alcohol .........................

Methyl Acetate .........................

Methyl Bromide .......................

Methyl Carbitol .........................

Methyl Cellosolve §...................

Methyl Chloride .......................

Methyl Ethyl Ketone..................

Methyl Isobutyl Ketone.............

Methyl Lactate .........................

Methyl Orange .........................

Methylamine ............................

Methylene Chloride...................

Mineral Spirits .........................

Mixed Acid, Nitric/Sulfuric........

Monochloracetic Acid ...............

Morpholine ..............................

Mud ..........................................

Nalco Sol. .................................

Naphtha ...................................

Naphthalene .............................

Naval Stores Solvent.................

Nematocide ..............................

Neoprene Emulsion ..................

Neoprene Latex ........................

Nickel Acetate ..........................

Nickel Ammonium Sulfate ........

Nickel Chloride..........................

Nickel Cyanide .........................

Nickel Fluoborate .....................

Nickel Ore Fines .......................

Nickel Plating Bright .................

Nickel Sulfate ...........................

Nicotinic Acid............................

Nitrate Sol.................................

Nitration Acid(s) .......................

Nitric Acid ................................

Nitric Acid10%..........................

Nitric Acid 20%......................... †

Nitric Acid Anhydrous...............

Nitric Acid Fuming ....................

Nitro Aryl Sulfonic Acid ............

Nitrobenezene-Dry ...................

Nitrocellulose ...........................

Nitrofurane ..............................

Nitroguanidine .........................

Nitroparans-Dry ....................

Nitrosyl Chloride ......................

Norite Carbon ...........................

Nuchar......................................

Oakite § Compound ..................

Oil, Creosote ............................

Oil, Emulsied ..........................

Oil, Fuel ....................................

Oil, Lubricating ........................

Oil, Soluble ..............................

Oleic Acid, hot .........................

Oleic Acid, cold ........................

Ore Fines-Flotation....................

Ore Pulp ...................................

Organic Dyes ............................

Oxalic Acid cold ........................

Ozone, wet................................

Paint-Linseed Base ...................

Paint-Water Base .....................

Paint-Remover-Sol. Type .........

Paint-Vehicles...........................

Palmitic Acid ............................

Paper Board Mill Waste ............

Paper Coating Slurry ................

Paper Pulp ...............................

Paper Pulp with Amun..............

Paper Pulp with Dye ................

Paper Pulp, bleached................

Paper Pulp, bleached-washed ..

Paper Pulp Chlorinated.............

Paper Groundwood...................

Paper Rag ................................

Paper Stocks, ne ....................

Paradichlorobenezene...............

Paran Molten ........................

Paran Oil ...............................

Paraformaldehyde ....................

Pectin Solution Acid .................

Pentachlorethane .....................

PentaerythritoI Sol. ..................

Perchlorethylene (Dry)..............

Perchloric Acid .........................

Perchloromethyl Mercaptan .....

Permanganic Acid.....................

Persulfuric Acid .......................

Petroleum Ether .......................

Petroleum Jelly ........................

Phenol Formaldehyde Resins ..

Phenol Sulfonic Acid.................

Phenolic Glue ...........................

Phloroglucinol .........................

Phosphate Ester .......................

Phosphatic Sand ......................

Phosphoric Acid 85% hot ........

Phosphoric Acid 85% cold ......†

Phosphoric Acid 50% hot.........†

Phosphoric Acid 50% cold ......†

Phosphoric Acid 10% cold ......

Phosphoric Acid 10% hot ........†

Phosphorous Molten ................

Phosphotungstic Acid...............

Photographic Sol. ....................

Phthalic Acid.............................

Phytate ....................................

Phytate Salts ............................

Pickling Acid, Sulfuric...............

Picric Acid Solutions.................

Pine Oil Finish ..........................

Page 13

810-PS2 Manual

1. Pick a spot in the tank for the sender bar to be mounted. It

should be as close to the middle of the tank as possible. Allow

room for the head at the top of the sender bar. Make sure

the hatch, to make any future service work easier. For this

reason do not

be reached from the hatch.

2. Drill or cut a hole in the top of the tank to mount a 1 inch NPT

coupler (not provided). Weld the top coupler in place. Slide

down, and insert the bar through the coupler and align it

vertically in the tank. Determine how much length needs to

expansion and contraction. For tanks greater than 75 inches

in height, increase the gap to 1.5 inches. Cut the bar with a

hack saw and trim exposed circuit board with a sharp knife.

Do not use a disk type cuto saw since the heat generated

will short circuit the internal circuit board.

3. Ensure that the compression tting is on the bar and clean

the end of the bar and the inside of the end cap with Loctite

7070 Cleaner. Spray Loctite T7471 Primer onto both the end

of the bar and the inside of the end cap. Allow the primer to

dry for a few minutes. Apply a bead of Loctite 680 Retaining

Compound around the bottom of the tube and around the top

of the end cap. Place the cap onto the end of the tube with

a twisting motion so that the retaining compound is smeared

completely on the portion of the bar where the end cap is. To

bar until excess air has escaped. Keep the end cap in position

by gently clamping the bar in a vise with the end against a

as this will slow the curing process. The curing time should

be about an hour at room temperature. The Loctite must

be set before the tank is put into service. Bar failure due

to a leaking end cap is NOT covered by warranty. Note

that a kit with all the required Loctite products is available

from Garnet. For further details on the Loctite products

see Technical Service Bulletin #17 on our web site, www.

garnetinstruments.com.

CHAPTER 6 - 810-PS2 INSTALLATION GUIDE

Page 14 810-PS2 Manual

4. Make up an anchor by cutting a 4” X 16” piece of 1/4” thick

material. Bend each end down at 90 degrees (see the diagram

3” sides. Drill a hole to insert a 2”ID schedule 40 pipe in the

center of the plate, weld tube to plate. Insert the bar into the

tank and slide the anchor assembly over the sensor bar with

the “U” facing down. Align the sensor bar vertically and weld

the anchor in place to the bottom of the tank. Pull the sensor

Lower the bar back into the anchor.

5.

few inches to set the bottom reading.

6. Pick a spot for the display. It should be easy to reach and out

of direct road spray. Put a bead of non-hardening sealant

around the perimeter of the display enclosure and mount the

hardware. Make sure that the enclosure is mounted so that

either way).

7. Route 1/4” Nylon air brake hose from the sender head to

the display and fasten with brass inserts and compression

provide a drain for any water than may get into the system. If

Page 15

810-PS2 Manual

(see diagram below). If alarm wiring is to be connected, drill

and tap extra holes as needed into the enclosure. Make sure

optic cable through the hose, leaving about 12 inches extra at

each end.

MODEL 810

LIQUID LEVEL GAUGE

MADE IN CANADA

UNITS

S

EE

L

EVE

L

GARNET

INSTRUMENTS LTD.

24" length

Display shown with lid and bracket removed.

8.

into the connectors at each end and tighten the connector

lock nuts. The display should change from reading “no L” (no

If the display shows bL: 8 or bL:11 then the display and bar are

not programmed for the same mode.

9.

grease on the rubber O-ring and snap on the head cap.

10. Program the gauge as directed in the programming section.

To determine the bottom reading of the gauge, measure from

the bottom of the tank to 2/3 way up of the straight vertical

NOT set the gauge to read “0” at the bottom since this will not

the product. In addition, if the gauge ever goes below “0” due

to tank expansion, it will read some nonsensical value since

this region has not been programmed.

Page 16 810-PS2 Manual

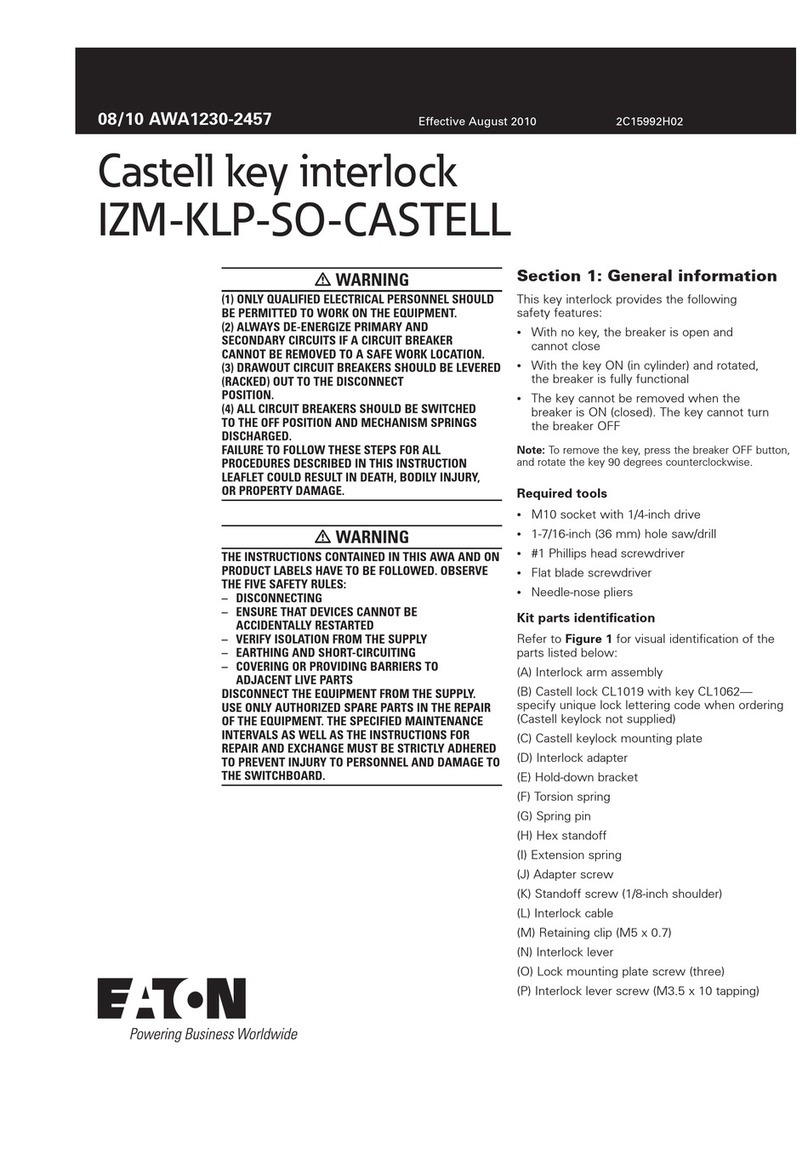

11. If the alarms are used, route the wires into the display

enclosure. Connect the alarm wires to the gauge wires as

follows: Alarm 1 is the yellow wire, Alarm 2 is the orange wire,

Alarm 3 is the black wire, Alarm 4 is the red wire, Ground is the

green wire, and the automatic alarm is the purple wire. The

SpillStop output is the grey wire. Your display may also be

equipped with an optional green/yellow remote output wire.

To program the alarms see the programming section. See

the enclosed wiring diagram for connection of the automatic

alarm (the purple wire) and the optional remote output display

(the green/yellow wire).

12. Fasten on the display front panel and the hinged cover using

the stainless #8 screws provided. The lid can be mounted to

open up or down as desired. Be sure to coat the #8 screws

13.

number, calibration units, minimum and maximum readout

values, and any alarm points programmed in the IMPORTANT

OPERATOR INFORMATION area on the front page of the

owner’s manual. The truck operator must be given the

owners manual upon delivery with all front page data

lled in.

Page 17

810-PS2 Manual

CONSTANT 12 VOLT

POWER SOURCE

AUTOMATIC ALARM WIRING DIAGRAM

+

-

SYSTEM STATUS

LAMP (USE

CLEARANCE

TYPE LAMP)

WARNING HORN

810PS2 SeeLeveL GAUGE

GREEN WIRE

PURPLE WIRE

The system status lamp is used to verify

that power is present to operate the

warning horn in the event of an overfill

#85#86

#30#87

- COIL -

- CONTACTS -

ALARM

RELAY

A relay is needed when the warning device draws greater than 1 amp.

GREEN/YELLOW WIRE

(OPTIONAL) To Remote Display

Wiring Guide

Wire Color Operation

Yellow Alarm 1

Orange Alarm 2

Black Alarm 3

Red Alarm 4

Purple Alarm 4 (resettable)

Grey SpillStop signal line

Green/Yellow Remote line

Green Ground

White Density compensation switch wire

Page 18 810-PS2 Manual

W

the product will vary somewhat with the density of the product,

and hence the gauge reading will change slightly. For lower

product density.

Plastic Truck Float Buoyancy

Product

Specic

Gravity

Amount

Float

Sinks

(Inches)

Level

Error

(Inches)

Correction

1/3”

Mode

(inches)

1/6”

Mode

0.60 1.88 0.63 2/3 4/6

0.65 1.73 0.48 1/3 3/6

0.70 1.61 0.36 1/3 2/6

0.75 1.50 0.25 1/3 2/6

0.80 1.41 0.16 0 1/6

0.85 1.32 0.07 0 0

0.90 1.25 0.00 0 0

0.95 1.18 -0.07 0 0

1.00 1.13 -0.13 0 0

1.05 1.07 -0.18 0 -1/6

1.10 1.02 -0.23 0 -1/6

1.15 0.98 -0.27 -1/3 -2/6

1.20 0.94 -0.31 -1/3 -2/6

Nominal calibration is 2/3 way up straight side of oat.

Bold indicates density of water

CHAPTER 7 - SETTING DISPLAY DENSITY

Page 19

810-PS2 Manual

Stainless Steel Truck Float Buoyancy

Product

Specic

Gravity

Amount

Float

Sinks

(Inches)

Level

Error

(Inches)

Correction

1/3”

Mode

(inches)

1/6”

Mode

0.60 2.92 0.97 3/3 6/6

0.65 2.69 0.75 2/3 4/6

0.70 2.50 0.56 2/3 3/6

0.75 2.33 0.39 1/3 2/6

0.80 2.19 0.24 0 1/6

0.85 2.06 0.11 0 0

0.90 1.94 0.00 0 0

0.95 1.84 -0.10 0 0

1.00 1.75 -0.19 0 -1/6

1.05 1.67 -0.28 -1/3 -2/6

1.10 1.59 -0.35 -1/3 -2/6

1.15 1.52 -0.42 -1/3 -2/6

1.20 1.46 -0.49 -1/3 -3/6

Bold indicates density of water

To compensate for density variations, the display can be set for the

product density. When this is done, it will change the reading by

the amount shown in the “Correction” column so that the gauge

will read correctly. Note that the amount of variation with density

is not large. The density correction will only be needed if the

range of product densities is very wide.

If the gauge is put into raw inch mode by jumping pins 1 and 2

programming or copying.

Page 20 810-PS2 Manual

To set the density:

1. The display must be showing a valid reading in order to set

the density. If “no L” or some other error message is showing,

repair or connect the gauge before proceeding.

2. Press and hold the button on the side of the enclosure. After

about 7 seconds the display will show the current density

setting, for example, “C .90” indicates a current density setting

of 0.90 which is the default. Release the button at this point.

3. If no further action is taken, the display will revert to normal

operation after about 5 seconds with no change in the density

setting. This is useful if you just want to check the current

density setting.

4. To change the density setting, press and release the button

repeatedly until the correct density is shown. This must be

started before the 5 second time expires, otherwise start

again at step 2. The “C” for “current density” on the display

will change to “P” for “Program density” and the density will

increase from the current setting in 0.05 increments for each

button press. For example, if the current density is 0.90, then

the display will show “P .95”, “P1.00”, “P1.05”, “P1.10”, “P1.15”,

“P1.20”, then it will start over at “P .60”, “P .65”, and so on.

5. When the correct density is shown, stop pressing the button.

After 5 seconds the display will show “Stor” for 2 seconds,

indicating that the new density value has been stored.

6. The display will then return to normal operation.

To program which oat is being used:

1.

buoyancies, the display must be programmed with the type

only needs to be done once during installation.

2. The display must be showing a valid reading in order to

is showing, repair or connect the gauge before proceeding.

3. Press and hold the button on the side of the enclosure. After

about 7 seconds the display will show the current density

setting, for example, “C .90” indicates a current density setting

of 0.90 which is the default. Continue to hold down the

button.

4. Put a magnet next to the display face by the “G” in Garnet.

Table of contents

Popular Industrial Equipment manuals by other brands

EUTHANEX

EUTHANEX SMARTBOX M1-TSFF-FM manual

Dorner

Dorner Aquaguard 7350 Series Installation, Maintenance, and Parts Manual

Panblast

Panblast ZVP-PC-0075-01 Product Operating Manual

READY

READY EPSON VT6L Startup guide

SMC Networks

SMC Networks IBG Series Operation manual

Quincy Compressor

Quincy Compressor QAF 6-1500 Instruction book

HYTROL

HYTROL 199-LRSSP Installation and maintenance manual

Knew Value

Knew Value Sentinel B operating manual

ABB

ABB HT571880 Operation manual

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FluidAqua Mobil FAM 5 Operating and maintenance instructions

IMC