IMC F79/060 User guide

1 | P a g e

Operating and Servicing Instructions

A34/073 R6 ECN 4825 April 2021

WASTESTATION AUTO FEED F79/060 &

REMOTE DEWATERER F78/061

Please make a note of your product details for

future use:

Date Purchased:_________________________

Model Number:__________________________

Serial Number:__________________________

Dealer:_________________________________

________________________________

_______

2 | P a g e

CONTENTS

INTRODUCTION.................................................................................................... 3

MODEL INFORMATION......................................................................................... 3

ON DELIVERY ....................................................................................................... 3

GUARANTEE......................................................................................................... 3

INSTALLATION OPTIONS..................................................................................... 4

FOR THE INSTALLER ........................................................................................... 4

SELECTION OF SITE............................................................................................ 4

MODEL IDENTIFICATION ..................................................................................... 4

SAFETY INSTRUCTIONS...................................................................................... 6

WORKING DIMENSIONS ...................................................................................... 8

WASTESTATION AF.............................................................................................. 8

REMOTE DEWATERER ........................................................................................ 9

CONTROLS AND INDICATIONS......................................................................... 11

OPERATION ........................................................................................................ 13

USER MAINTENANCE ........................................................................................ 14

DAILY CLEANING................................................................................................ 14

CLEANING CYCLE.............................................................................................. 15

CLEARING A JAM................................................................................................ 16

WIRING DIAGRAM .............................................................................................. 17

ORDERING SPARE PARTS................................................................................ 19

FURTHER INFORMATION .................................................................................. 19

3 | P a g e

INTRODUCTION

This machine is intended for the processing of food waste matter by maceration under an

automatic water flow, dewatering of the macerated food waste and discharge of the dewatered

food waste into a receptacle. The ‘grey’ water will be discharged into the drainage system.

MODEL INFORMATION

F79/060 WasteStation AF, 400 volt, 3-phase, 50/60 Hz

F78/061 Remote Dewaterer AF, 400 volt, 3-phase, 50/60 Hz

Please read these instructions carefully for trouble-free installation and operation.

Please observe these instructions carefully.

The guarantee applies in this form to installations within the United Kingdom. Contact your

WasteStation supplier first.

ON DELIVERY

Please check the contents against the following list and notify both the Carrier and Supplier

within 24 hours if anything is missing or damaged.

Fully assembled WasteStation with following items loose: -

Release key = 1 off

Waste bin (240Ltr) = 2 off

Instruction Manual = 1 off

Operating Plaque = 2 off (wall mounted self-adhesive)

Appliance hoses = 3 (2 x WS AF, 1 x DWR)

GUARANTEE

This machine is guaranteed by Lincat for 2 Year from the date of its purchase from Lincat, or

from one of its stockists, dealers or distributors. The guarantee is limited to the replacement of

faulty parts or products and excludes any consequential loss or expense incurred by

purchasers. Defects, which arise from faulty installation, inadequate maintenance, incorrect

use, and connection to the wrong electricity supply or fair wear and tear, are not covered by the

guarantee.

The guarantee applies in this form to installations within the United Kingdom only.

4 | P a g e

Please observe the following instructions carefully.

INSTALLATION OPTIONS

FOR THE INSTALLER

These Instructions contain important information designed to help the user obtain themaximum

benefit from the investment in an IMC WasteStation.

Please read them carefully before starting work, and consult with the supplier in the event of

any queries.

Be sure to leave this Instruction Manual with the user after the installation of the machine is

complete.

The machine is operated from the built-in control box.

SELECTION OF SITE

Select the site of the WasteStation with care so that it is convenient both for the major source

of food waste and for access by machine operators. The machine should be installed as close

to the existing drains as reasonably practicable.

MODEL IDENTIFICATION

The IMC WasteStation AF & Remote Dewaterer grey water macerator appliances are

for the use in commercial establishments only and are for permanent connection.

IMC WASTESTATION

The WasteStation AF comprises of the control cabinet, macerator and pump

assemblies with a hopper capacity of 200 litres.

5 | P a g e

The Remote Dewaterer comprises of a cabinet with a dewaterer unit and removable

240 litre capacity wheeled waste bin.

IMC REMOTE DEWATERER

6 | P a g e

SAFETY INSTRUCTIONS

All safety instructions detailed within this document are to be adhered to for safe

operation, of personnel and the equipment.

The following symbols are used on the product and throughout the product

documentation:

MEANING / DESCRIPTION

SYMBOL

SIGNIFICATION /

DESCRIPTION

WARNING/CAUTION

An appropriate safety

instruction should be

followed or caution to a

potential hazard exists.

AVERTISSEMENT

Une consigne de sécurité

appropriée doivent être

suivies ou garde d'un danger

potentiel existe.

PROTECTIVE EARTH (GROUND)

To identify any terminal which

is intended for connection to

an external conductor for

protection against electric

shock in case of a fault, or

the terminal of a protective

earth (ground) electrode.

TERRE DE PROTECTION

Pour marquer bornes

destinées à être raccordées à

un conducteur de protection

extérieur contre les chocs

éclectiques en cas de défaut

d’isolement, ou pour marquer

la borne de la terre de

protection

DANGEROUS VOLTAGE

To indicate hazards arising

from dangerous voltages.

TENSION DANGEREUSE

Pour indiquer les dangers

résultant des tensions

dangereuses.

HEAVY

This product is heavy and

reference should be made to

the safety instructions for

provisions of lifting and

moving.

LOURD

Ce produit est lourd et se

référer aux instructions de

sécurité pour les dispositions

de soulever et déplacer.

7 | P a g e

SAFETY INSTRUCTIONS (Continued)

•THIS PRODUCT IS TO BE INSTALLED BY A QUALIFIED IMC

APPOINTED INSTALLATION ENGINEER OBSERVING ALL LOCAL

AND REGIONAL CODES.

•ALL ELECTRICAL AND WATER SERVICES ARE TO BE ISOLATED

BEFORE CARRYING OUT ANY REMEDIAL WORK OR

MAINTENANCE TO THE IMC WASTE APPLIANCE.

•THE MACERATOR APPLIANCE CONTAINS NO USER

SERVICEABLE PARTS.

•ENSURE ALL WATER SUPPLY AND WASTE CONNECTIONS ARE

TIGHT BEFORE OPERATION.

•NEVER RUN THE UNIT WITHOUT WATER SUPPLY; SERIOUS

PUMP DAMAGE MAY OCCUR.

•DO NOT POUR HOT OILS/LIQUIDS INTO THE MACERATOR –THIS

COULD LEAD TO DAMAGE TO MACERATOR MOTOR SEALS.

•NEVER PUT HANDS OR OBJECTS OTHER THAN FOOD WASTE

INTO THE HOPPER CHUTE.

•DO NOT PUT STRING, CLOTH, PLASTIC, WIRE, GLASS, CORK OR

METAL OBJECTS INTO THE MACHINE.

•THE MACERATOR APPLIANCE IS RATED FOR 30% NON-

CONTINUOUS DUTY, (18 MINUTES PER HOUR). –issue, 200 kg

waste takes approx. 1 hour to process therefore 60 minutes of use

per 3 hours 20 minutes.

•IN THE EVENT OF A FAULT OR AN EMERGENCY, ISOLATE BOTH

THE ELECTRICAL AND WATER SUPPLIES. THE IMC WASTE

APPLIANCE IS PROVIDED WITH AN ELECTRICAL ISOLATOR.

•THE IMC WASTE APPLIANCE IS FITTED WITH AN EMERGENCY

STOP. THIS SHOULD NOT BE USED TO ISOLATE THE MACHINE.

•THE EMERGENCY STOP BUTTON MUST NOT BE USED AS A

GENERAL ‘STOP’ BUTTON; SERIOUS BLOCKAGES MAY OCCUR.

•ENSURE METALLIC OBJECTS SUCH AS CUTLERY ETC. ARE NOT

EMPTIED INTO THE HOPPER. IF THEY ARE, THEY MUST BE

REMOVED BEFORE STARTING THE MACHINE.

8 | P a g e

•EGG AND CRAB SHELLS MUST NOT BE MACERATED IN BULK, ONLY

TO BE MIXED WITH OTHER FOOD WASTE

THIS CAN CAUSE SERIOUS MACHINE DAMAGE.

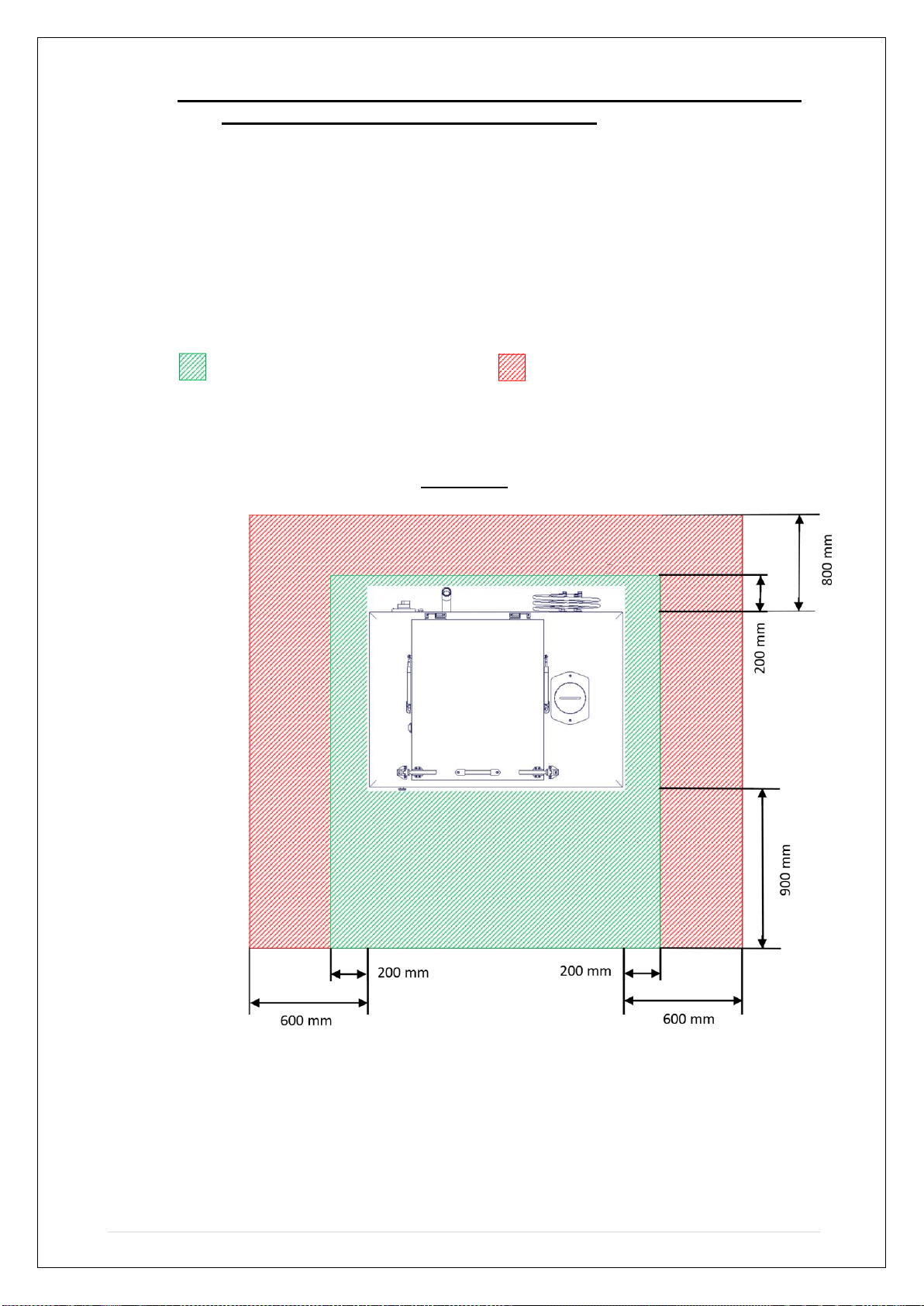

WORKING DIMENSIONS

The following clearances are required for safe operation of the WasteStation

AF appliance and Remote Dewaterer; and also for servicing:

Clearance required for normal Recommended Clearance

required operation for Service Engineer functions

WasteStation AF Plan View

9 | P a g e

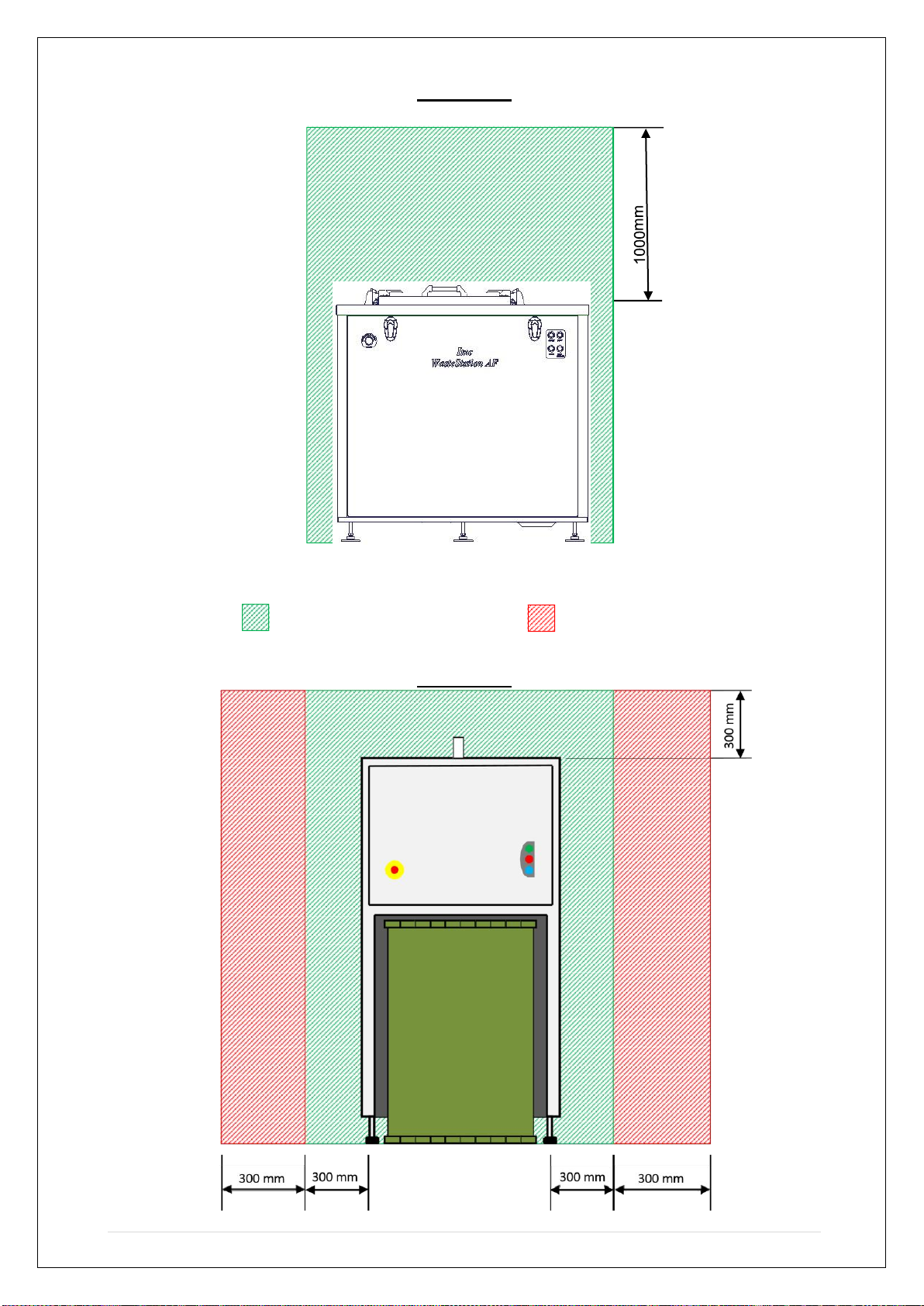

Front View

Remote Dewaterer

Clearance required for normal Clearance required

Recommended operation for Service Engineer

functions Front View

10 | P a g e

Plan View

CAUTION:

Controls and Indications should not be obstructed

mm

600

mm

300

mm

300

600

mm

11 | P a g e

CONTROLS AND INDICATIONS

The WasteStation AF is easy to use; this section details the controls and

indications of the WasteStation AF & Remote Dewaterer.

The WasteStation AF & Remote Dewaterer appliances are provided with an

electrical isolator. The isolator is located at the rear of the WasteStation AF, the

Remote Dewaterer does not have a separate isolator as it is provided with all its

power signals by the WasteStation AF and so by isolating the WasteStation AF; it

also isolates the Remote Dewaterer.

Each unit is also provided with an emergency stop button, located on the front

panel of each unit.

The control panel on the WasteStation AF comprises of four illuminated buttons to

operate the machine and their function is described below; the buttons are

replicated on the Remote Dewaterer as indicator lights only:

BUTTON/

LAMP

ACTION

INDICATOR LIGHT (STATUS)

Solid

Flashing

Green

Cycle START

Cycle running

Cycle stopping

Red

Cycle STOP

Bin not in position

Bin full (nearing full

with siren, see

below)

Blue

Cleaning cycle

START

N/A

Cleaning cycle in

progress

Yellow

Auger feed

reverse

START

Feed reversing (to

prevent food jams)

N/A

12 | P a g e

The Green button will START a waste cycle.

The Red button will STOP a waste cycle. The red

indicator provides a collection bin status.

The Blue button starts and provides an indication of the

cleaning cycle.

The Yellow button starts and provides an indication of the

reverse rotation of the auger feed screw to prevent

blockages.

To START a waste cycle, press the Green button.

The indicator will remain illuminated to show that the cycle

is active.

The indicator will flash indicating the cycle is shutting

down.

When the Yellow button is illuminated, this indicates the

direction of the auger feed is reversing.

To STOP the cycle, press the RED button.

A steady red indicator means that the waste collection bin

is not fitted.

A flashing red indicator AND a siren means that the waste

collection bin is nearing fill level.

WARNING!–STOP FEEDING THE MACERATOR

INSTANTLY!

This is essential to prevent blockages. The siren will

cease after 2 seconds and the machine will stop after a

timed period.

When the Yellow button is illuminated, this indicates the

auger feed direction is reversed to prevent blockages.

13 | P a g e

To start a cleaning cycle, press the Blue button

The indicator will flash during the cycle and will stop

flashing when the cleaning cycle has finished.

When the Yellow button is illuminated, this indicates the

direction of the auger feed is reversing to help prevent

blockages.

OPERATION

•For safe operation refer to the Safety Instructions detailed

within this manual.

The macerator appliance is not for continuous duty and should be used for

18 minutes per hour. –issue, 200 kg waste takes approx. 1 hour to process

therefore 60 minutes of use per 3 hours 20 minutes.

DO NOT leave the macerator unattended while in operation.

In the event of an emergency only, use the emergency stop button

provided, isolate both the electrical and water supplies.

If the emergency stop is activated with food waste flowing through the

system, (if possible) the problem should be addressed IMMEDIATELY and

the system should be restarted to prevent waste from settling in the

pipework. If waste settlement occurs, flushing may be needed to help clear

the pipework before restarting, this is to help prevent a blockage.

Operation of the WasteStation AF / Dewaterer appliance is relatively straight

forward.

A. Ensure that the electrical isolator is set to ON and that the water supply

is available.

B. Ensure the collection bin is in position in the Remote Dewaterer for the

collection of the processed waste.

C. Feed accepted waste into the hopper –if unsure, refer to the manual

for accepted and non-accepted types of waste. Fully secure the lid.

D. At the control panel, press the GREEN button to START. This

activates the start-up sequence. Allow the system to fully start before

proceeding to the next step.

E. When the machine has finished processing the food waste, press the

RED button located on the control panel to STOP the cycle.

14 | P a g e

NOTE: The stop cycle time will be in accordance to the installation type and will be

set on commissioning. The green indicator will flash during this period.

The stop cycle has to be allowed to run its course to flush the full system of food

waste.

USER MAINTENANCE

The WasteStation AF / Remote Dewaterer appliance is of low maintenance.

CAUTION: Before carrying out any maintenance task(s), isolate the

electrical power.

The appliance requires daily cleaning only as described below.

DAILY CLEANING

DO NOT use a pressure washer.

Pouring a bucket of warm (NOT HOT), soapy water into the hopper at the end of

each day will help clean the equipment and disperse any residual solids in the

piping. Using the warm, soapy bucket of water, gradually pour the contents along

the internal sides of the hopper and along the auger screw.

If needed, use a ‘dishwashing type brush’ and brush off any deposits of food

necessary.

Wipe over the exterior of the machine, including the back areas that are not

normally visible. Proprietary cleaners may safely be used but avoid particularly

aggressive cleaners and neat bleach solutions.

A cleaning cycle should now be carried out.

15 | P a g e

CLEANING CYCLE

Following the standard daily cleaning routine, the automated cleaning cycle should

also be run.

NOTE: (The Remote Dewaterer needs to be on).

Ensure the power and water supplies are ON.

Press the BLUE button at the control panel to start the cleaning process. Allow the

appliance to complete the cleaning cycle.

16 | P a g e

FAULT FINDING

WARNING:

In the unlikely event of a fault occurring, immediately

isolate the power and water supplies.

If the appliance develops a fault, stop the machine immediately and isolate both the

electrical and water supplies.

In an emergency situation only, the emergency stop button should be used. This

is located on both front panels of the WasteStation AF and Remote Dewaterer.

Pressing the emergency button stops both machines instantly, refer to important

notes in section 6.

NOTE: The emergency stop button should only be used to stop the machine in

an emergency. The red button found on the control box at the front of the

WasteStation AF should be used for routine stopping of the machine operation.

CLEARING A JAM

As a result of a jam occurring, the machine will stall and stop. If this occurs,

proceed as follows:

1. Switch off the machine at the mains or at the isolator switch on the rear panel.

2. Unscrew the macerator lid.

3. Engage the prongs of the release key into the vanes of the rotor and exert

pressure in either direction (i.e. clockwise & anti-clockwise) to free the

blockage.

4. Check that the rotor is free to rotate 360°in both directions and if so, withdraw

the release key, screw down the macerator lid. (If there is still some resistance

when rotating, then repeat steps 3-4 until the jam is cleared).

5. Restore power to the machine and check normal operation by pressing the

green button.

17 | P a g e

WIRING DIAGRAM

18 | P a g e

Machine does not start

Cause

Action

Electrical supply is not turned on.

Switch on supply.

The mains isolator has tripped.

Call site electrician to reset the isolator. If

problem persists contact service personnel.

Waste bin is full (flashing red light)

Empty and then replace the bin

Waste bin is out of position (solid red light)

Replace the bin in its correct position inside the

bin enclosure on the machine.

Baffle is not correctly fitted.

Check baffle is in position and secured. If

problem persists contact service personnel.

One of the motor overload relays has tripped.

Rectify the problem then reset the overload

relay.

Emergency stop button has been pressed.

Deal with the emergency then reset the button

by turning it clockwise as shown on the button.

Unexpected system stop

Cause

Action

Electrical supply turned off.

Switch on supply.

The mains isolator has tripped.

Call site electrician to reset the isolator. If

problem persists contact service personnel.

Waste bin is full (flashing red light)

Empty and then replace the bin

Waste bin is out of position (solid red light)

Replace the bin in its correct position inside the

bin enclosure on the machine.

Baffle is not correctly fitted.

Check baffle is in position and secured. If

problem persists contact service personnel.

Motor overload has tripped.

Allow motor to cool for 10 minutes and restart.

If problem persists contact service personnel.

Emergency stop button has been pressed.

Deal with the emergency then reset the button

by turning it clockwise as shown on the button.

Waste jammed in disposer grinding unit.

Remove blockage from grinding unit.

See instructions on page 3.

Waste not processed

Cause

Action

A blockage has occurred in the waste pipe.

Clear blockage from waste pipe.

Slurry in Bin

Cause

Action

Feeding too quickly.

Allow to clear and feed more slowly.

19 | P a g e

ORDERING SPARE PARTS

In the event that spare parts or accessories need to be ordered, please always quote the

SERIES AND SERIAL NUMBER of the machine. This is to be found on the rating plate

located near the supply cable.

For installations outside the UK please contact your supplier.

For information on IMC spares and service support (if applicable), please call Lincat on +44

(0) 1522 875520. Alternatively, contact us via email:

Lincat Spares Desk E-mail: spar[email protected]o.uk

Lincat Limited

Whisby Road,

Lincoln, LN6 3QZ,

United Kingdom

Tel: +44 (0)1522 875500

E-mail: [email protected]

Website: www.Lincat.co.uk

FURTHER INFORMATION

HTTPS://LINCAT.CO.UK/BRANDS/IMC

https://www.youtube.com/watch?v=1hSfEPKi-fg

This manual suits for next models

1

Table of contents

Other IMC Industrial Equipment manuals