Gas-Tec FP50 Series User manual

Before Proceeding -

The FP50 Fuel Processor

requires an Oxygen Sensor

input, a Throttle Position

Sensor input and a Pulse

input. This processor should

not be installed if these three

inputs are not available.

Optional Resistive Emulation

is available as are separate

complex emulators. Please

seek further details from

your distributor before

installing if you are unsure

of its suitability.

The processor drives a high quality stepper valve (CV30) to

control the gas mixtures accurately via a 90 degree rotational

barrel. This valve operates continuously whilst driving on LPG or

CNG. The slotted barrel rotates slowly to achieve the exact air fuel

ratio required - unless it receives an increased load signal from the

throttle position sensor (in which case it opens very much faster).

The CV30/CE30 is made with brass sintered bearings and

contains no gears or worm drives to wear out. The design life

of the valve is in excess of 500,000km.

HIGH PERFORMANCE FUEL PROCESSOR MODEL FP50

3 Models: (3rd Edition)

FP50-DS-SS (Dual Start with Safety Switch)

FP50-DC (Changes over on Deceleration with Safety Switch)

FP50-AC (Changes over on Acceleration with Safety Switch)

FP50 Features:

•High Performance Microprocessor running at 20Mhz with 14 bit wide instructions;

•286 microsecond worst case loop times (this gives the mathematical power to calculate

the exact air/fuel ratio in real time);

•Two different air/fuel ratios — one for increased engine power during acceleration (and

when under constant heavy load) and a second to provide excellent economy while

cruising. This makes the FP50 an excellent choice for vehicles that tow heavy loads yet

require maximum economy;

•Adjustable Rev-Changeover point (FP50-DC & FP50-AC models);

•Adjustable Dual Fuelling when changing from petrol to LPG/CNG (all models);

•Inbuilt Safety Switch that accepts signals from vehicle coil, tachometer, or flywheel;

•Fuel Injector Emulation (Optional - Simple Resistive);

•Rich/Lean Lambda Tuning Lights;

•Oxygen Sensor Emulation.

Suitable for 1.3 to 6.2 litre vehicles

The mathematical calculations required to ensure fast air/fuel compliance are carried out by

a high performance microprocessor. Acceleration override and air/fuel calculations are given

priority. Usual minimum petrol injector pulses are in the vicinity of 2 milliseconds compared

to the FP50’s worst program loop times of 286 microseconds. The FP50 is therefore able to

calculate the required air fuel ratio 6.9 times faster than the minimum petrol injector pulse.

This places the FP50 in a new

performance class which is

only exceeded by electronic

fuel injection systems.

(C) GASTEC Corporation December 2009

www.gastec.ws

Page 3

Install the FP50 away from excessive heat (ie exhaust manifold) and moisture

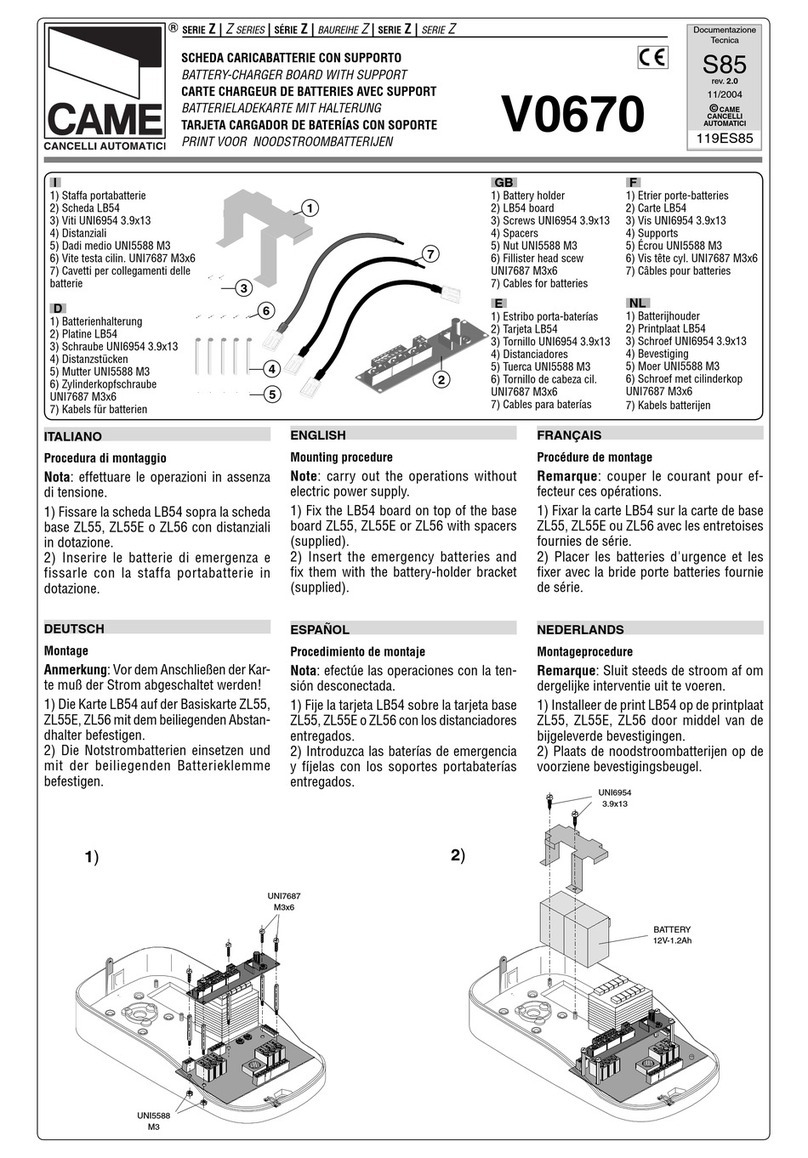

WIRING CONNECTIONS

The FP50 is supplied with two looms. Each loom snaps into the connector on the side of the

processor box. The first loom has the CV30/CE30 stepper valve connected to it (do not plug in

the stepper valve until the tuning procedure is complete) and the second loom is connected to

the various vehicle sensors.

Important Note: Fully unscrew and remove the adjusting cap from the CV30/CE30 stepper

valve. Using your fingers, gently open the slotted barrel assembly until the valve is fully

open (it rotates 90 degrees between the stops). Screw on the adjusting cap a full 2 turns

and lightly lock into place with the locking ring. The valve should be fully open before

installing it.

The CV30/CE30 stepper valve should now be installed in the vapour line between the convertor

and the gas mixer. A separate manual high speed adjuster (power valve) is not required to be

installed in the vapour line.

For performance reasons, the vapour line should be kept as short as possible. The FP50 and

associated CV30/CE30 valve are high performance components and are designed for 19mm

vapour hose. Do not install the CV30/CE30 near large amounts of radiated heat. Do not install the

stepper valve near the exhaust manifold. Do not connect the stepper motor loom until advised

to do so in the section “ADJUSTMENTS & TUNING THE GASTEC FP50 FUEL PROCESSOR”

The second (vehicle) loom containing five wires is connected as follows;

Red wire

Locate a suitable +12 volt source to drive all the gas conversion electrics from the vehicle’s ignition

switch. The power supplying the gas/petrol switch should come from a "clean" power source never

from the positive side of the vehicle’s high tension coil and never from the vehicle’s fuel

pump. Fuel pump brushes and commutators wear over time (which can lead to unstable voltages

being fed to the fuel processor). The chosen +12 volt source must be able to safely supply 10

amps and must have a 10 amp fuse inserted to protect the vehicle’s electrical system from any

overloads. The fused wire should be connected to the central terminal on the petrol/gas

changeover switch. The FP50’s red +12 volt wire should then be connected the gas terminal of the

gas/petrol changeover switch (so that it only receives power when the driver wishes to run the

vehicle on gas - see wiring diagram).

Black wire

This should be connected to the negative side of the vehicle’s battery. Sometimes it can be

connected to the vehicle’s OEM computer earth or to the engine earth, but should any

unstable or unusual fuel processor operations be observed, please relocate to the vehicle’s

negative battery terminal. The vehicle chassis must not be used as the FP50 must be

referenced to the oxygen sensor correctly. Do not earth this wire close to electrical noise

generators such as high tension wires or alternators.

Green wire

This should be connected to the throttle position sensor (TPS). This sensor is normally found

near the throttle butterfly on the engine. On vehicles that operate “Drive by Wire” (where a

stepper motor is used to move the throttle butterfly), the TPS sensor adjacent to the

driver’s accelerator pedal should be used and not the sensor alongside the throttle

butterfly stepper motor (otherwise engine management lights, engine surging or failure to

Page 4

lock into overdrive may occur). Most TPS sensors, read approximately 0.20 to 1.6 volts at idle.

When the throttle is slowly depressed fully, the voltage normally slowly increases to around 2.5 to

5.0 volts. Note: TPS sensors provide a varying voltage as the throttle is depressed. A

minority of vehicles contain only a throttle position switch which suddenly switches the voltage.

The FP50 should not be installed on vehicles that contain only a throttle position switch.

Brown wire

The standard FP50 is programmed to suit O2 sensors that operate at 0.0 volts lean and 0.9 volts

rich. A label will be affixed to the side of the FP50 if it has been programmed to operate with a

different O2 sensor. The vehicle’s (pre-catalytic convertor) O2 signal output wire should be

isolated from all other wires leading from the O2 sensor, and then cut. The Brown wire should then

be soldered to the cut signal wire that leads directly to the O2 sensor. This wire provides the FP50

with the rich/lean signals from the oxygen sensor. If the O2 signal wire is shielded make sure the

shield is not broken. Also make sure the shield wire is not shorted (connected) to the O2 signal

wire. Do not run this wire in close proximity to noisy high tension or alternator wires.

Grey wire

This wire should be soldered to the cut oxygen sensor signal wire that leads directly back to the

vehicle's ECM. This wire supplies an oxygen emulation signal to the vehicle's ECM to prevent the

injector "block learn" from logging different values when operating on gas. Should the "block learn"

parameters move significantly, rough idling, stuttering during acceleration and surging may occur

when next operating the vehicle on petrol. Do not run this wire in close proximity to noisy high

tension or alternator wires. Standard factory emulation is a 0.7 Hz square wave of 0.0 volts to

0.9 volts.

Gas Valve Terminal

This terminal should be connected to the gas (LPG-CNG) valves. All FP50 models contain an

in-built gas safety switch rated at 10 amps. The gas valves should be shut down within 3 seconds

of the engine stalling and/or within 0.2 seconds of the ignition being turned off.

Coil/Tacho/Flywheel/Camshaft/Crank Angle Sensor Terminal

This terminal is designed to accept input pulses from a variety of sensors. The pulse information is

used to activate the changeover from petrol to LPG-CNG (FP50-DC & FP50-AC) along with the

gas safety switch function. The terminal should be connected to one of the following sensors-

1. The negative (-ve) side of the engine coil (this provides a 12 volt pulse); or

2. The vehicle’s tachometer pulse input (many vehicle manufacturers supply a spare

connection to this for diagnostic purposes – normally a 5 volt pulse); or

3. The vehicle’s engine management system is usually provided with a pulse from the engine’s

flywheel (crank angle sensor) and/or camshaft sensor. Normally the FP50 may be

connected to either side of one of these sensors. Very occasionally one side of the sensor is

grounded or provided with a fixed voltage. In these cases the other side of the sensor must

be used.

Do not connect the FP50 pulse terminal to a High Tension Lead (either directly or by

induction). High voltages in close proximity to the sensitive electronic components may

interfere or damage the operation of the FP50.

Vehicle +12V Injector Feed Terminal

Locate the +12 volt source feeding the fuel injectors. This wire should be cut at a point close to the

fuel injectors to ensure power is not interrupted to other parts of the vehicle. Connect this terminal

to the wire that leads back to the vehicle’s loom (ie this will be the wire that supplies the +12 volts).

Page 5

+12V to Injectors Terminal

Connect this terminal to the wire that leads directly to the Fuel Injectors. The internal relay is rated

at 10 amps and this should not be exceeded. The FP50 uses a normally closed relay to operate

the vehicle’s injectors. If power to the FP50 is interrupted, the vehicle should default to petrol

operation.

OPERATION & ADJUSTMENTS

Green light – ACCEL TPS SET

The green ACCEL TPS SET light performs two functions;

A. TPS SET Function FP50-DC & FP50-AC - When the vehicle’s Throttle Position Sensor

(TPS) voltage is below the TPS/RPM SET potentiometer setting, the TPS SET light will

flash quickly (refer to the Adjustments & Tuning section). The vehicle is prevented from

changing over from petrol to gas when this light flashes quickly. When the accelerator is

held (steady) above the TPS SET position, the green light should remain off.

B. TPS SET Function FP50-DS-SS - When the vehicle’s incoming Throttle Position Sensor

(TPS) voltage is below the TPS/RPM SET potentiometer setting, the green TPS SET light

will flash quickly. This indicates that the CV30/CE30 stepper valve is being help open (ie the

processor is in Open Loop mode).

C. ACCEL Function - The green TPS SET light should come on when the accelerator is

depressed quickly. This indicates an increasing load condition to the processor. The

processor will now open the CV30/CE30 valve at a much faster rate to ensure adequate fuel

is delivered to the engine during acceleration. The green light will stay on for varying times

depending on how far and how fast the accelerator is depressed. It should however, go off

within 5 seconds after depressing the accelerator.

Lean & Rich Orange Lights

The left orange Lean light indicates when the engine is running Lean (ie not enough gas). The

right orange Rich light indicates when the engine is running Rich (ie too much gas). As long as

the gas mechanical delivery components (the convertor, vapor hose and mixer) can deliver

sufficient gas to the engine, these lights should flicker constantly (when the engine is above idle)

between rich and lean. This indicates that the Lambda (or stoichiometric) region is being

maintained. The exception to this is if the green acceleration light is on (in which case the rich light

should also remain on) and on the FP50-DS-SS model when Open Loop at idle is chosen.

Gas Light

The green Gas light comes on when the vehicle is operating on Gas (LPG-CNG).

Petrol Light

The red Petrol light comes on when the vehicle is operating on Petrol.

ADJUSTMENTS & TUNING THE GASTEC FP50 FUEL PROCESSOR

Note that clear (see-through) CV30/CE30 stepper valve cups are available so that

you can visually check the operation of the FP50 stepper valve.

1. Ensure that the CV30/CE30 stepper valve is fully open and its associated loom is not currently

connected to the FP50. The stepper valve must not be connected until the initial setup

procedures below have been completed.

2. Turn on the ignition but do not start the engine. Ensure that the gas/petrol switch is in the

gas position.

Page 6

3. The "TPS/RPM SET" potentiometer is adjusted differently according to the model being

installed. Carefully place a small screwdriver through the hole (in the rear of the box) to engage

the potentiometer on the circuit board. The initial setup positions are;

FP50-DS-SS

Open Loop at Idle - Adjust the TPS/RPM SET potentiometer slowly until the green ACCEL

TPS SET light on the front of the FP50 blinks rapidly. This will allow richer mixtures at idle (by

holding the stepper valve open). Open loop is the preferred option on vehicles that are

known to backfire on hard acceleration from idle and/or vehicles that “stutter” when

accelerating hard from idle. Emissions testing has found that running Open Loop operation at

idle generally makes insignificant changes to tailpipe emissions. The TPS voltage at idle

(standard model) must be between 0.2 volts and 1.6 volts. If it is outside of this range you may

not be able to adjust for open loop at idle.

Closed Loop at Idle - Adjust the TPS/RPM SET potentiometer against its minimum stop so

that the green ACCEL TPS SET light on the front of the FP50 remains off. This gives the

maximum economy and minimum exhaust emissions by allowing the stepper valve to operate

around the Lambda point all of the time. Be aware that the majority of the gas required at idle is

supplied by the needle idle jet. The CV30/CE30 stepper valve only has a significant effect on

the atmospheric diaphragm gas valve. For this reason, stoichiometric control will/may only be

achieved just above engine idle. Please note that Open Loop operation is the preferred

option as fewer problems are encountered under hard acceleration from idle.

FP50-DC

Adjust the TPS/RPM SET potentiometer slowly until the green ACCEL TPS SET light on the

front of the FP50 blinks rapidly. Continue to turn the potentiometer in the direction of the arrow

another 5 degrees (ie a little bit further). This sets the TPS setting at which the vehicle will

change over to gas on Deceleration. If it is set too low, the vehicle may stall on Deceleration.

If it is set too high, the engine will need to be revved excessively before (during the

Deceleration phase) the engine will change over from petrol to gas.

FP50-AC

Adjust the TPS/RPM SET potentiometer slowly until the green ACCEL TPS SET light on the

front of the FP50 blinks rapidly. Continue to turn the potentiometer in the direction of the arrow

another 5 degrees (ie a little bit further). This sets the TPS setting at which the vehicle will

change over to gas on Acceleration. If it is set too low, the vehicle may stall during

Acceleration or it may back-fire during Acceleration. If it is set too high, the engine will need to

be revved excessively before (during the Acceleration phase) the engine will change over from

petrol to gas.

4. The "PETROL OVERLAP" potentiometer is adjusted differently according to the model being

installed. Carefully place a small screwdriver through the hole (in the rear of the box) to engage

the potentiometer on the circuit board. The initial setup positions are;

FP50-DS-SS

Adjust the PETROL OVERLAP potentiometer to midway between the minimum and maximum

stops. This potentiometer adjusts the time both fuels are allowed to enter the engine during the

cranking (starting) phase.

FP50-DC

Adjust the PETROL OVERLAP potentiometer to one third of its travel from the minimum

Page 7

position. This potentiometer adjusts the time both fuels are allowed to enter the engine during

the Deceleration changeover.

FP50-AC

Adjust the PETROL OVERLAP potentiometer to one third of its travel from the minimum

position. This potentiometer adjusts the time both fuels are allowed to enter the engine during

the Acceleration changeover.

5. Now start the engine (still with the CV30/CE30 stepper valve disconnected). If this is a new

installation it may take several starting attempts to suck all of the air out of the gas lines. The

vehicle should changeover to run on gas on either Deceleration (FP50-DC), Acceleration (FP50-

AC) or during cranking (FP50-DS-SS). If the vehicle does not idle smoothly, adjust the idle jet on

the convertor.

NOTE: For the vehicle to change over to operate on LPG-CNG (gas) the following conditions

must be met;

A. The gas/petrol switch must be in the gas position and it must be supplying +12 volts to the

FP50;

B. A suitable pulse is supplied to the pulse input terminal during cranking/engine running;

C. The FP50-DS-SS will open the gas valves within 0.5 seconds of commencing cranking.

Depending on which sensor is chosen as the pulse input, the FP50-DS-SS may open the

gas vales to prime the gas system for 0.5 seconds before cranking commences.

D. The FP50-DC will change over on to gas on Deceleration, provided the TPS SET light is

not flashing, the vehicle is not under heavy load and the engine is not at idle;

E. The FP50-AC will change over to gas during Acceleration, provided the TPS SET light is

not flashing, the vehicle is not under heavy load and the engine is not at idle;

6. The CV30/CE30 stepper valve should still be disconnected. AFTER DETERMINING THAT

THE ENGINE IS IN GOOD CONDITION, rev the motor to approximately 2500 rpm with no load

being applied (ie in neutral). Wait for the O2 sensor to warm up (typically takes 10-20 seconds).

Now adjust the power valve (the large screw adjustment on the CV30/CE30 stepper valve) until

the mixture is CONSTANTLY JUST RICH. Now allow the engine to fall back to idle before

unscrewing the power valve a further 1/4 of a turn. Rev the vehicle several times from idle

and observe the processor lights. The lean light should not come on at all or should only

come on for 1/4 of a second or less (while accelerating). If the lean light comes on for more

than 1/4 of a second then unscrew the power valve another 1/4 of a turn and test again.

Continue this process until the lean light is lit for 1/4 of a second or less. Now tighten the locking

ring firmly on the power valve making sure the adjustment cup is not moved. This then sets the

maximum richness point. The CV30/CE30 will then lean the mixtures from this point.

7. The CV30/CE30 valve should still be disconnected. Allow the engine to idle for 10 minutes

and then re-adjust the idle mixture on the convertor (vapourisor) to obtain a JUST RICH reading

(the rich light on the processor should be on). Ensure the engine idles smoothly with the air-

conditioning on, head-lights on high beam, the front wheels turned to the full lock position

(if power steering is fitted) and with the automatic transmission (if fitted) in DRIVE

(obviously with your foot securely on the brake). This places the maximum load onto the

engine at idle. The vehicle should continue to idle smoothly. If it does not idle smoothly, re-

adjust the idle mixture until it does.

Page 8

ENGINE CHANGEOVER TO GAS

If the engine does not change smoothly to gas, adjust the potentiometers on the FP50 as follows;

8. Fine Adjustments to the PETROL OVERLAP Potentiometer

The FP50 contains an internal relay (with normally closed 10 amp contacts). This relay will turn the

petrol injectors off when operating on gas. A short (adjustable) overlap is provided to ensure a

smooth transition from petrol to gas. This helps to prevent back-firing due to lean mixtures. The

FP50 may also contain an optional in-built current controlled injector emulator. This will satisfy the

many engine management systems (but not all). If you experience dashboard engine

management error lights, please contact your local distributor for more information.

FP50-DS-SS (Changes to LPG/CNG during Cranking)

If the engine is difficult to start, observe the green Gas light and the red Petrol light. If the

Petrol light goes out before the engine has properly started, turn the PETROL OVERLAP

potentiometer a little more towards the arrow (for more petrol start). If the engine appears to

start and then stalls while the Petrol light remains on, turn the PETROL OVERLAP

potentiometer slightly away from the arrow (for less petrol start). This procedure may need to be

done several times to ensure easy starting is achieved. Remember that slightly more petrol start

is required after the vehicle has been left overnight. Don't forget to plug the hole with the plastic

stopper to prevent water entry.

FP50-DC (Changes on Deceleration) & FP50-AC (Changes on Acceleration)

If the actual changeover from Petrol to Gas is not smooth, the PETROL OVERLAP

potentiometer will need to be adjusted. Observe both the Petrol and the Gas lights during the

changeover to gas. If the engine loses power as soon as the Petrol light goes out, turn the

PETROL OVERLAP potentiometer slightly towards the arrow (for increased petrol overlap). If

the engine loses power when the Petrol light is still on, turn the PETROL OVERLAP

potentiometer slightly away from the arrow (for reduced petrol overlap). This procedure may

need to be done several times to ensure you arrive at a comfortable PETROL OVERLAP time.

Don't forget to plug the hole with the plastic stopper to prevent water entry.

9. Fine Adjustments to the TPS/RPM SET Potentiometer

FP50-DS-SS

With the engine running, check that the green ACCEL TPS SET light flashes quickly at idle and

stops flashing when you slightly depress (and hold) the accelerator (assuming you wish to run

the preferred Open Loop option at idle). Don't forget to plug the hole with the plastic stopper to

prevent water entry.

FP50-DC & FP50-AC

If the changeover to gas occurs when the engine revs are too low, adjust the TPS/RPM SET

potentiometer slightly towards the arrow (this sets a higher TPS changeover voltage). If the

changeover to gas occurs when the engine revs are too high (or you cannot changeover the

vehicle to gas at all), adjust the TPS/RPM SET potentiometer slightly away from the arrow

(this sets a lower TPS changeover voltage). This procedure may need to be done several times

to ensure you arrive at a comfortable TPS/RPM changeover point. Don't forget to plug the hole

with the plastic stopper to prevent water entry.

10. Turn off the engine. Connect the CV30/CE Stepper Valve for the very first time.

Page 9

11. Restart the engine again and changeover to run on gas. To check that the CV30/CE30 valve is

operating correctly, hold the revs steady at about 2500rpm. The two orange rich and lean

lights should toggle back and forth (the O2 sensor may take 20 to 30 seconds to warm up).

This indicates that the stepper valve is controlling the gas mixtures around the Lambda

(stoichiometric) point.

12. Check that the engine idles smoothly. If not, check the status of the orange Lean and Rich

lights. If the idle becomes "lumpy" (while either the rich or the lean lights are lit), either choose

the preferred option of Open Loop operation or make a small readjustment to the idle mixture

screw on the convertor.

13. It is critical to test that safety switch function in the FP50 operates correctly. With the

engine idling on gas, remove the +12 volt supply wire from an under-bonnet gas valve. This

will starve the engine of gas and it should stall within several seconds. Observe the lights

on the FP50. Within 3 seconds (of the engine stalling), the green Gas light should go off

and the red Petrol light should come on. This indicates that the FP50 is correctly shutting

down power to the gas valves when the engine stops. This completes the tuning procedure.

SUBSEQUENT RETUNING

All tuning procedures must be carried out with the CV30/CE30 stepper valve fully open. To

force the CV30/CE30 stepper valve fully open, start the engine and wait for the O2 sensor to

warm up. Now adjust the idle mixture on the convertor to lean (the rich light must not

flicker). Wait for 15 seconds (the CV30 valve should now be fully open), then stop the

engine by turning off the ignition. Now disconnect the CV30/CE30 loom and commence the

tuning procedures from step 5.

Note that a clear cup for the CV30/CE30 stepper valve is available. This will allow you to

visually observe the operation of the stepper valve while the engine is running.

FP50 OPERATIONAL PROBLEMS AND HOW YOU MIGHT OVERCOME THEM

FP50 LEAN LIGHT IS ON ALL THE TIME

Ensure that the CV30/CE30 stepper valve is plugged into the FP50 and the stepper loom is

undamaged.

Check that the FP50 is earthed to the negative side of the vehicle’s battery (the preferred

option) and not to the vehicle’s chassis. Ensure that the FP50’s oxygen sensor signal wire is

not connected to the vehicle’s oxygen sensor heater or earth wire. Oxygen sensors have a finite

life, sometimes only 80,000km to 150,000km. When their life is expired they generally give out a

constant lean signal.

Unscrew the power valve almost all the way. Check if the lean light remains on constantly. If so,

check if the CV30/CE30 valve is fully open. To do this, allow the vehicle to run on gas at

approximately 1500 rpm for 15 seconds. After 15 seconds have elapsed (but still holding the revs

at approximately 1500 rpm) immediately stop the engine by turning off the ignition. Now

unscrew the CV30 power valve completely. Check that the rotational barrel in the valve is fully

open (so the gas can pass through the slot in the middle). Note that a clear cup for the

CV30/CE30 stepper valve is available. This will allow you to visually observe the operation of the

stepper valve while the engine is running.

Page 10

IF THE ROTATIONAL BARREL IS IN THE FULLY OPEN POSITION the problem lies with the

mechanical gas system, not the FP50. Areas to examine would be: A/ the correct mixer is fitted to

the vehicle, B/ no air leaks exist in the vehicle’s intake system, especially around the mixer, C/ the

inner wall of the vapour hose has not collapsed nor is the hose kinked, D/ the convertor is

delivering gas without fault, E/ the tank contains a useable amount of gas, F/ the excess flow valve

(in the tank) has not triggered, G/ the filters in the gas solenoids are not blocked.

IF THE BARREL IS NOT IN THE FULLY OPEN POSITION the problem is likely to be a wiring

fault, or the processor, or valve itself. Check the following: A/ the fuel processor is earthed to the

negative side of the vehicle’s battery and not the vehicle’s chassis, B/ the loom connector to the

CV30/CE30 is fully plugged in. If the above have been checked carefully, replace the CV30/CE30

stepper valve and retest. If the problem remains, replace the FP50 (the original CV30/CE30

stepper valve may well be fully operational).

FP50 RICH LIGHT IS ON ALL THE TIME

Ensure that the CV30/CE30 stepper valve is plugged into the FP50 and the stepper loom is

undamaged.

Check that the FP50 is earthed to the negative side of the vehicle’s battery and not the

vehicle’s chassis. Ensure that the FP50’s oxygen sensor wire is not connected to the oxygen

sensor heater wire. This will give a constant rich reading while the oxygen sensor is being

electrically heated. On some vehicles the heater wire will contain +12 volts for several minutes. If

the heater is turned off when the sensor is hot, the FP50 will then read a constant lean signal from

this time on.

If the green ACCEL TPS SET light is constantly on, the CV30/CE30 valve will be held open. If the

green ACCEL light is constantly on, check that you have the correct TPS output wire. You may

have connected the green TPS input wire to the TPS earth wire or to a throttle position switch

(which does not give a slowly changing voltage on acceleration). For the standard FP50, the

minimum TPS voltage (at idle) is 0.20 volts and the maximum TPS voltage (with the accelerator

fully depressed) is 5.0 volts. TPS sensors wear with age and if the voltage increase is not even the

sensor may need replacing.

NOTE:

1/ For the FP50-DS-SS, the green ACCEL light will flash at approx twice per second when the

throttle is held below the TPS/RPM SET potentiometer setting. The flashing green ACCEL light

indicates that Open Loop has been selected. This will cause the valve to remain open. Open

Loop operation should only occur at idle.

2/ For models FP50-DC & FP50AC the green ACCEL light will flash at approx twice per second

when the throttle is held below the petrol to gas changeover point (the vehicle is therefore

prevented from changing over to gas). This does however not cause the CV30/CE30 stepper

valve to remain open.

Finally, check the CV30/CE30 stepper valve. At revs ensure you can lean the mixture by screwing

in the power valve. If you need to turn the CV30/CE30 power valve inwards by more than 2 turns,

return to step 6. and retune the vehicle.

If the orange Rich light remains on, check that the CV30/CE30 is actually fully closed. Run the

vehicle on gas at 1500 rpm for 15 seconds. Immediately stop the engine by turning off the

ignition. Unscrew the manual power valve on the CV30 stepper valve. If the rotational barrel is

Page 11

fully closed then the problem does not lay with the FP50 Fuel Processor or the CV30/CE30

stepper valve. If the rotational barrel is fully open (and you were able to adjust the mixture lean by

screwing in the CV30/CE30 power valve by no more than two turns), replace the CV30/CE30.

Start the engine and hold the engine at 1500rpm. If the rotational barrel remains fully open replace

the FP50 (the original CV30/CE30 stepper valve may well be fully operational).

Warranty - First 3 Years (36 months)

Gastec is proud of the high quality components used to manufacture the FP50. This processor is

therefore sold with a three year warranty that is transferable between owners, provided it has not

been abused in any way [ie it must not be melted from excessive heat, must not have been

damaged by fluids such as water, must not be burnt out due to electrical overload (always install

the 10 amp fuse) and it must not be crushed etc]. Within this warranty period the FP50 should be

returned to your local Gastec distributor for repair and/or replacement at no cost to the owner.

Each FP50 is date coded so no invoice is required by the factory.

Warranty - Years 4 to Year 10

The processor should be returned directly to the factory (or to the importer in your country of

purchase) with a payment of US$40 (AUD$40) to cover its direct return. Each FP50 is date coded

so no invoice is required by the factory. The same warranty conditions apply as listed for the first

36 months.

NOTE – Fuel Economy & Air Fuel Ratios

LPG contains only 26 Megajoules per litre compared with 32 Megajoules for Unleaded Petrol (ie

19% less energy). To ensure maximum power while accelerating the FP50 will allow the engine to

run richer on LPG/CNG. This is governed by the TPS sensor.

The FP50 operates around two factory set air/fuel ratios. The rich and lean lights indicate when

the engine is running richer or leaner than the air/fuel ratio chosen by the FP50 at that time. To

determine exactly which air/fuel ratio is currently chosen, you must measure the output of the O2

sensor itself. The standard FP50 programming forces a richer air/fuel ration when the TPS voltage

rises above 3.5 volts. For the standard programming, light load conditions operate around an O2

voltage of 0.37 volts. This increases the vehicle’s economy significantly during light load highway

running. For the standard programming, heavy load conditions operate around an O2 voltage of

0.51 volts. This gives a significant increase is power under heavy load conditions which is ideal for

highway overtaking and when pulling caravans etc.

The FP50 programming was updated in December 2009. It will only further open the CV30/CE30

stepper valve for one acceleration in every 2 seconds. Emissions testing has shown that this

provides the most accurate (richer) air/fuel ratios. The CV30 stepper valve steps at 7.5 degrees,

the CE30 stepper valve steps at 3.6 degrees.

Gastec certify that the FP50 is CE Compliant. Installers should contact their closest distributor for

wiring and placement instructions for specific vehicles to comply with local standards and

emission regulations. Updated instructions and information on the FP50 and other Gastec

products may be found at www.gastec.ws

The Gastec Group appreciates feedback from its customers. If any of our instructions need

improvement, please let us know. If you would like to see changes to a product or have other

suggestions for us, please visit our website and send us a message. We thank our customers for

supporting our products.

© Gastec Group (December 2009)

This manual suits for next models

3

Table of contents

Popular Computer Hardware manuals by other brands

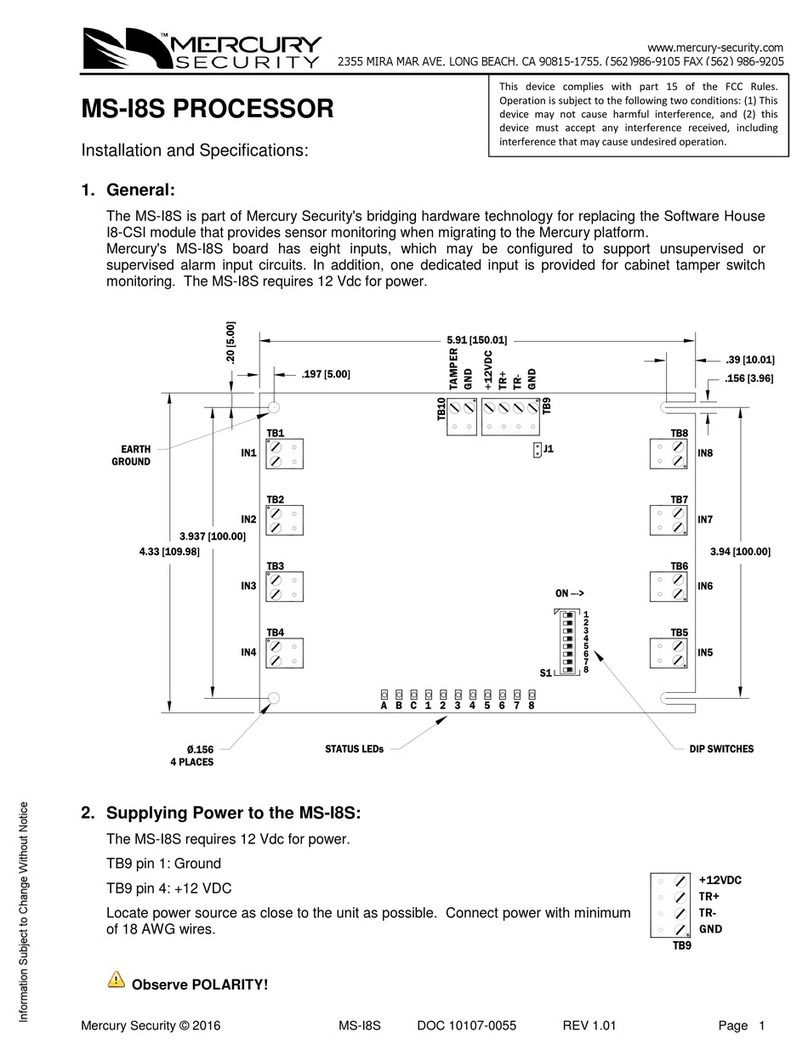

Mercury Security

Mercury Security MS-I8S Installations and specifications

Intel

Intel P8700 - Core 2 Duo Processor datasheet

Infineon

Infineon DEMO-MIPI-4K-CAM01 quick start guide

StarTech.com

StarTech.com SATSASBAY3BK instruction manual

Renesas

Renesas M3A-HS64 user manual

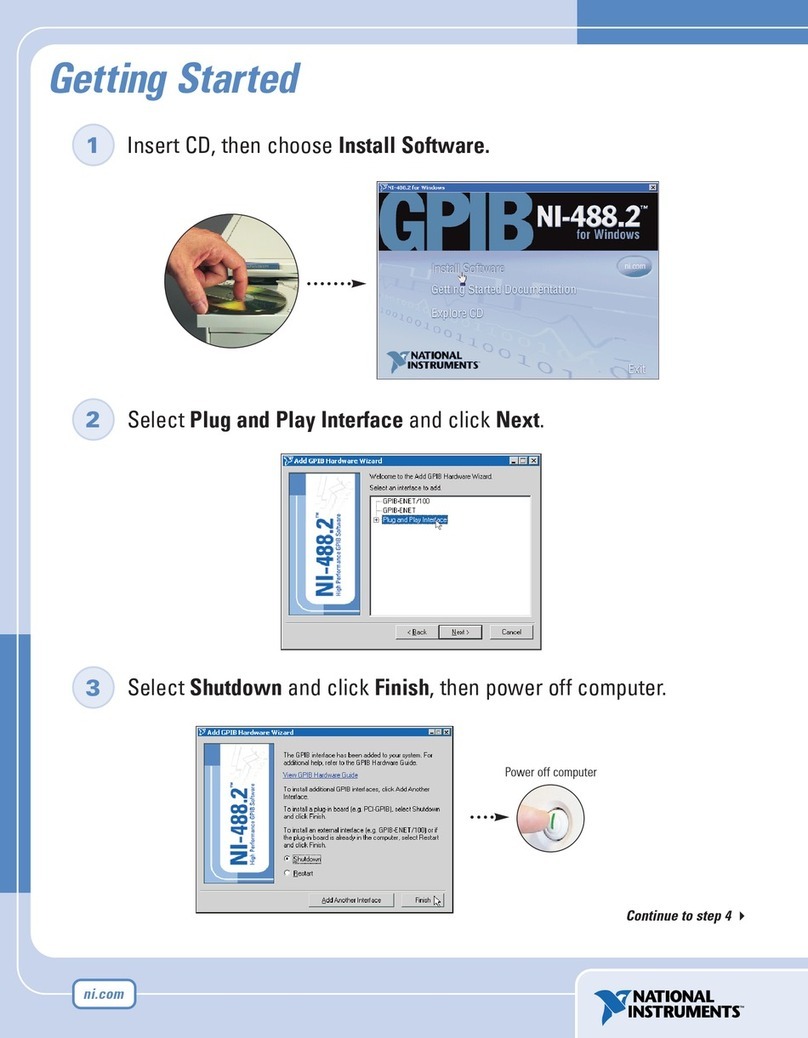

National Instruments

National Instruments PMC-GPIB Getting started