Gason Pasture Planter User manual

A member of

COPYRIGHT

Neither this manual or part thereof may be reproduced or published without the prior permission of AF Gason Pty Ltd

PASTURE PLANTER

ASSEMBLY, OPERATORS & PARTS MANUAL

GPN 215645 REVISION A 06/14

AIR SEEDER

PASTURE PLANTER

Page Intentionally Blank

CONTENTS

06/14

Warranty Form

Introduction...............................................................

1

Safety.......................................................................

2

Bolt Specifications....................................................

3

Ordering Parts..........................................................

4

Spare Parts Record..................................................

5

Distribution Kits Options ...........................................

7

Distribution Kits & Fitment Information......................

Broadcast Dist. Kit...........................................

8

Individual Placement System...........................

10

Combiner ‘Y’ Kit...............................................

11

Operating the Pasture Planter ..................................

12

Adjustments..............................................................

13

Fitment of Reducer Plate........................

13

Removal of Meterwheel Cover Plate.......

14

Changing Meterwheel.............................

14

Ground Drive Calibration..........................................

15

Calibration Handle Turns........................

18

Planting Details Reference .....................

19

VRT Hydraulic Drive Calibration ...............................

21

Planting Details Reference .....................

24

Spare Parts ..............................................................

26

06/14

Page Intentionally Blank

INTRODUCTION

Page 1

06/14

The Gason Pasture Planter has been

designed to operate in conjunction with the

range of Gason Air Seeders. The Pasture

Planter, sometimes referred to as a small seeds

box, is generally mounted direct to the Seeders

bin. It utilizes the seeders drive system to

operate the metering system and the blower to

convey the product.

The Gason Pasture Planter metering

system is a positive and accurate method of

placing small seeds into the air stream. The

system is capable of sowing a wide variety of

small seeds and other products with minimal

adjustment.

The Gason Pasture Planter bin capacity

has been designed to match the capacity of your

Gason Seeder.

380 litres for seeders with a main bin

capacity of 5,000L or less.

600 litres for seeders with a main bin

capacity of 6,000L or greater.

It will hold approximately 270kg / 420kg of canola

depending on the products density.

There are a number of distribution kits that

can be fitted to your implement and connected to

the Pasture Planter.

a) Broadcast Distribution Kit

b) Individual Placement System

c) Combiner ‘Y’ System

The distribution kits are more fully

explained in the Distribution System Option’s

sections of this manual.

Please read the appropriate sections of this

manual before assembling and operating your

machine. Field experience has shown that a

good understanding of the features and correct

method of operation greatly reduces problems in

the field.

References to the left and right hand sides

of the Air Seeder are from the rear of the

machine looking forward.

Fig. 1 Pasture Planter mounted on a Front Tow Air Seeder

While every effort has been made to ensure the accuracy of the information in this manual, A.F.Gason Pty. Ltd.

Reserves the right to delete, change or add information without notice.

SAFETY Page 2

10/09

The Air Seeder has been designed with

safety in mind. However, the equipment is

only as safe as the person operating it.

Do not operate the Air Seeder until you

have read and understood this manual. If you

feel you need help or advice on the operation of

the Seeder, contact your local authorized Gason

Dealer.

To ensure trouble free and safe operation

of your seeder, it is important to carry out a daily

safety check to reduce the possibility of a costly

breakdown.

Items to Check Daily During Operation

1.Check all wheel nuts are tight during the

first couple of days of seeding or after

transportation.

2.Check all tyre pressures and tyre

conditions in general. NOTE: a badly

worn rear drive tyre will affect the

metering accuracy.

3.Ensure the safety guard on the blower unit

is fitted.

4.Check all hydraulic breakaway

connections are locked into position.

5.Check all hydraulic hoses and fittings for

leaks.

6.Check all chains and sprockets for wear or

movement on the shaft.

7.Check metershafts turn freely before

operating each day or after transporting

when loaded.

8.Check draw bar pins for wear.

9.Ensure bin lids are closed and that there

are no air leakswhen blower is operating.

10. Check distribution hoses for damage or

kinks, especially after operating the wing

fold system on the implement.

General Safety Conditions

DO NOT ride on the machine when

operating.

DO NOT touch or attempt to adjust any

moving parts.

DO NOT adjust hydraulic fittings while under

pressure.

DO NOT remove any safety guards while the

seeder is operating.

DO carry out the daily safety checks and operate

the seeder in a safety conscious manner.

Hydraulics

Before working on the hydraulic system

always check that the blower is not operating,

and that there is no pressure in the hydraulic

system.

Never attempt to disconnect a breakaway

coupling if the blower is operating. Turn the

tractor off if working on the metering system of

a VRT equipped seeder.

Leaving the Air Seeder Unattended

Always close the bin lids and ensure that

no material is left in the bins after seeding.

Chock the Air Seeder wheels to prevent it

from rolling.

When Working on the Air Seeder

Place suitable stands under the trailer if

removing a wheel or carrying out major work.

Never enter the bin compartment unless

another person is present. Always take proper

safeguards if entering a bin or working on

components that have been exposed to treated

seed.

BOLT SPECIFICATIONS

Page 3

10/09

CAUTION: Loose bolts can cause elongation of holes and part failures resulting in dangerous operating

conditions and equipment breakdown. Check all bolts and nuts periodically during equipment

operation and keep them tightened to the specified torque. If hardware replacement becomes

necessary, replace with equivalent metric grade number.

NOTE: The following torque figures are those recommended for zinc plated, lightly oiled bolts.

Recommended assembly torques may be obtained by multiplying the torque figures in the

table below by:

0.78 –for degreased zinc plated bolts

1.10 –for black oxide finished bolts

0.81 –for M20x2.5P Tine Toolbar Hardware

It is necessary that all bolts be tightened to the correct recommended assembly torque.

lbf.ft Nm lbf.ft Nm lbf.ft Nm

7/16 UNF 43 59 60 82 - -

7/16 UNC 39 53 54 74 - -

1/2 UNF 67 91 94 128 - -

1/2 UNC 59 81 83 113 - -

5/8 UNF 135 184 186 253 - -

5/8 UNC 117 159 165 224 - -

3/4 UNF 235 319 325 441 - -

3/4 UNC 210 285 290 394 - -

7/8 UNF 370 502 520 706 - -

7/8 UNC 335 455 470 638 - -

1UNF 550 746 775 1052 - -

1UNC 505 685 710 963 - -

M10 1.5 29 40 41 56 - -

M12 1.75 51 70 73 100 - -

M16 - - - - - 170 231

M16 2.0 126 171 180 245 - -

M18 - - - - - 243 330

M20 - - - - - 265 360

M20 2.5 247 335 351 477 - -

M22 - - - - - 340 462

M24 - - - - - 370 502

M24 3.0 425 577 608 825 - -

Recommended Assembly Torque

8.8

10.9

Wheel Stud

Metric Grade Number

S.A.E Grade Number

5

8

Size

Thread

Pitch

Wheel Stud

Head Markings

(Manufacturers marks

mayvary)

Head Markings

(Manufacturers marks

mayvary)

ORDERING PARTS

Page 4

10/09

When Ordering Parts:

The following information must be supplied

to facilitate fast and accurate processing of a

replacement parts order:-

•Gason part number and description (as

given in this manual)

•Quantity

•Machine model and serial number

•Method of despatch.

•Your Dealers name and address

For your convenience record the following

information below:

Name: ______________________________

Address: _____________________________

Telephone Number: ____________________

Machine Model No:_____________________

Date Machine Purchased:________________

Serial No.:____________________________

Fig.3

Subject to any applicable Federal, State or Territory laws or ordinances, which may apply from time to time, A. F.

Gason Pty Ltd reserves the right to make changes in design and specifications without notice or obligation and to

change or discontinue models at any time without incurring any liability to any Purchaser thereof.

Left and right hand: All references in this manual are determined by facing the direction of travel.

For warranty provisions please consult your Installation and Warranty Registration document.

SPARE PARTS RECORD

Page 5

10/09

PART No.

DESCRIPTION

QTY.

COST

DATE

Page Intentionally Blank

DISTRIBUTION KIT OPTIONS Page 7

06/14

Distribution Kits Options

As mentioned in the introduction, there are

a number of distribution kits that can be fitted to

your implement and connected to the Pasture

Planter.

a) Broadcast Distribution Kit

b) Individual Placement System

c) Combiner ‘Y’ System

1. Broadcast Distribution Kit

A Broadcast Distribution Kit can be fitted to most

Gason implements. Kits are supplied to suit

different implement widths. Each kit is supplied

with sufficient towers, heads, hoses and scatter

plates to allow for 450mm-600mm wide spacing

between toolbar mounted outlets. Mounted on

the rear row of the implement, light rates of seed

can be evenly scattered across the ground.

Fig. 4 Broadcast scatter plates mounted on bar.

2. Individual Placement System

The Individual placement system can allow for

low rates of small seeds to be placed throughout

the implement similar to the main distribution

system.

Gason’s do not manufacture a specific

sowing boot for the smaller final 12.7mm ID hose

but do have an adaptor that can be fitted to a

standard 32mm ID Gason sowing boots.

Alternatively, owners/dealers may wish to make

up their own sowing outlet device specific to their

requirements. This individual placement system

will service a maximum of 55 outlets.

Fig. 5 Secondary head used on the Broadcast

and Individual Placement Systems.

3. Combiner ‘Y’ System

The Combiner ‘Y’ System allows the operator to

combine product from the pasture planter into a

number or all of the main primary distribution

hoses. This can be particularly useful for planting

canola or other small seeds at low rates from the

pasture planter and combining them with

product, such as fertiliser, from the main seeder

bins.

Product can then be directed down a tine

or disc opener as required. Combiner systems

are normally ordered in kits to suit the number of

main primary hoses you wish to feed into.

Common kits are 2, 3, 4 and 6 outlet systems.

Individual kits are also available if required.

Fig. 6 A Combiner ‘Y’ tube fitted to a primary

hose. Note the 25mm hose from the pasture

planter’s distribution system attached.

DISTRIBUTION KITS & FITMENT INFORMATION Page 8

06/14

Broadcast Distribution Kit Fitment

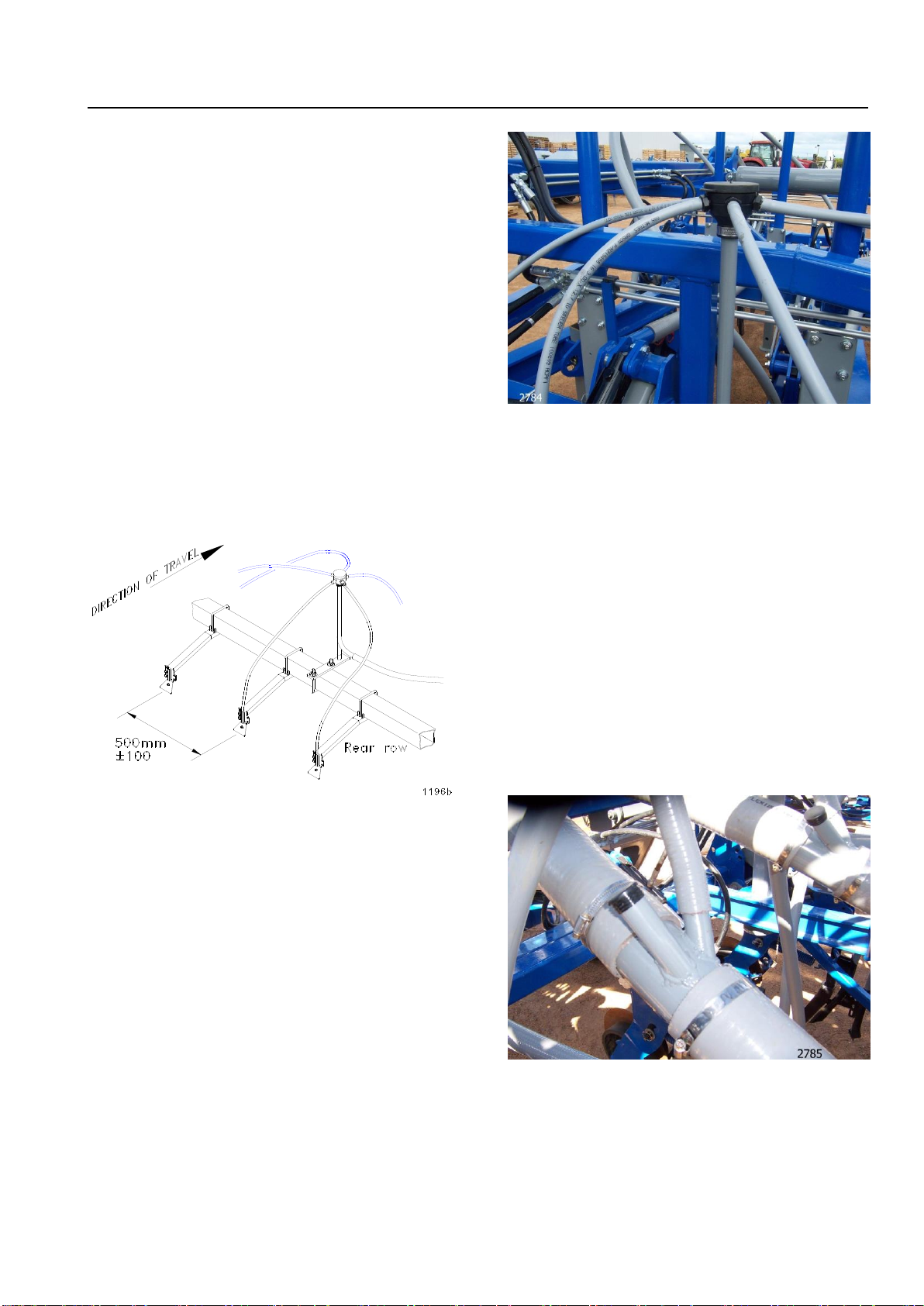

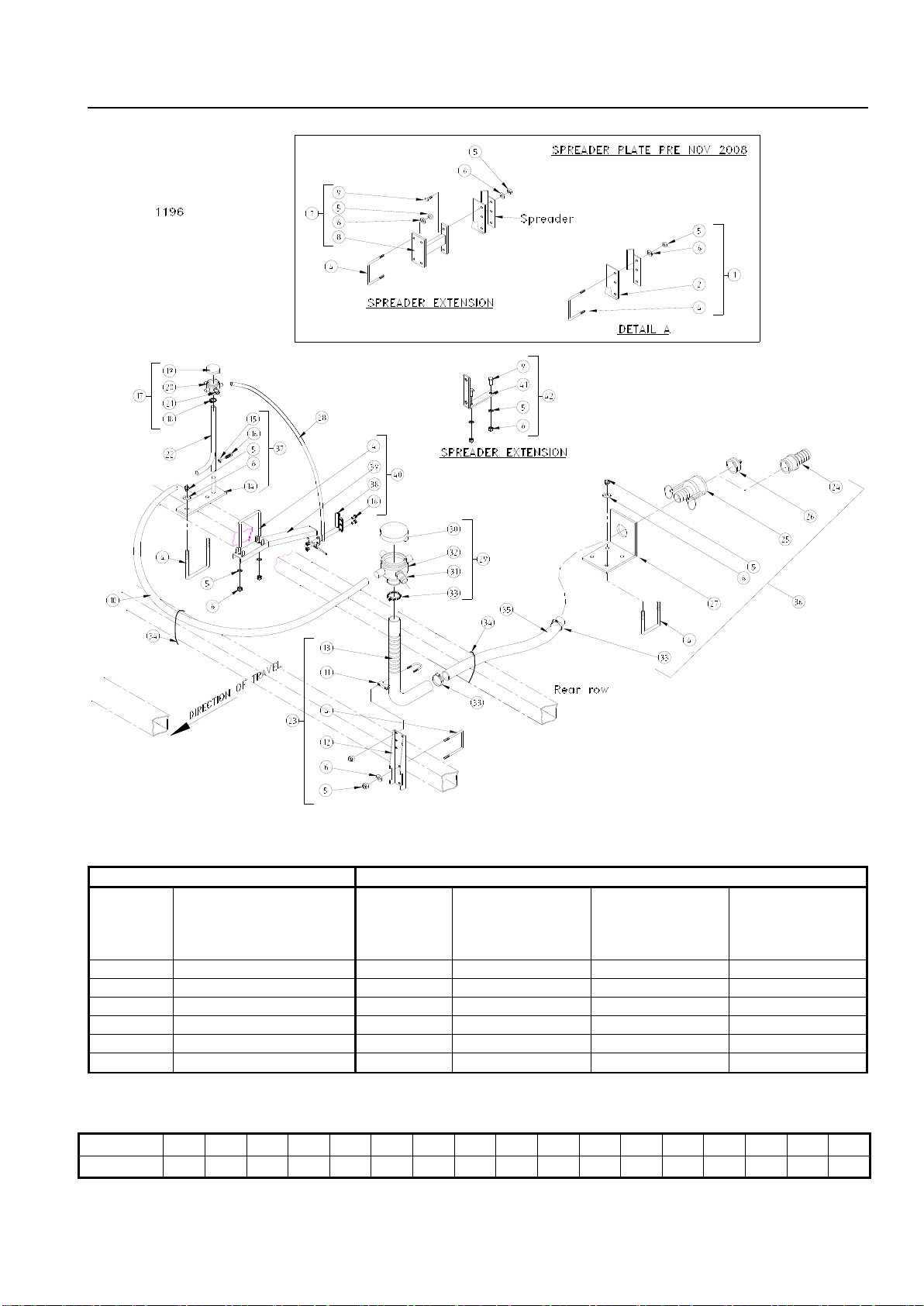

Instructions (refer fig. 7 and 8.)

1. Attach the primary manifold support and

bracket (Items 12 & 13) using the M10 U -

Bolt to the last or secondlast row near to the

centre of the implement frame. Place the

primary manifold (Item 29) on top of the

manifold support. Connect a length of grey

50mm hose (Item 35) between the camlock

fitting (Item 25) and the manifold support.

Use bracket (Item 27) to secure camlock

fitting and attach the hose tothe frame using

the plastic ties (Item 34).

2. Attach thefive port secondary manifolds and

support brackets (Item 17, 22 & 37) to the

last row of the implement at approximately

2.5 metre spacings.

3. Attach the spreader assemblies (Item 1)

using the U-Bolts supplied to the last row of

the implement at approximately 500mm

spacings. Do not tighten as the 13mm

hose will be held between these assemblies

and the frame.

4. It may be necessary to use a spreader

extension (Item 7) to position the spreader

assemblies further rearward to clear

machine obstructions. Typical problem

areas are where cylinder mount brackets

protrude out the back of a machine or if a

tine tower is obstructing clear flow of the

seed.

5. Connect the outlets of the primary manifold

(Item 29) to the secondary manifold support

pipes (Item 22) using the 25mm grey hose

(Item 10). When cutting the hose to length,

ensure the shortest hose is not less than

half the length of the longest hose

(Example: 4 outlet primary head –the 2

long hoses are 8m therefore any

remaining hoses are not to be less than

4m). Allow slack, where necessary for wing

folding and secure these hoses to the frame

using plastic ties. Avoid dipping of hoses to

prevent material build-up and blockages.

6. Connect the outlets of the five port

secondary manifold assemblies to the

spreader assemblies using the 13mm hose

(Item 28). When cutting the hose to length,

ensure the shortest hose is not less than

half the length of the longest hose. These

hoses should RUN DIRECTLY TO the

assemblies (not down and along the frame)

and are clamped between the spreader

assemblies and the frame.

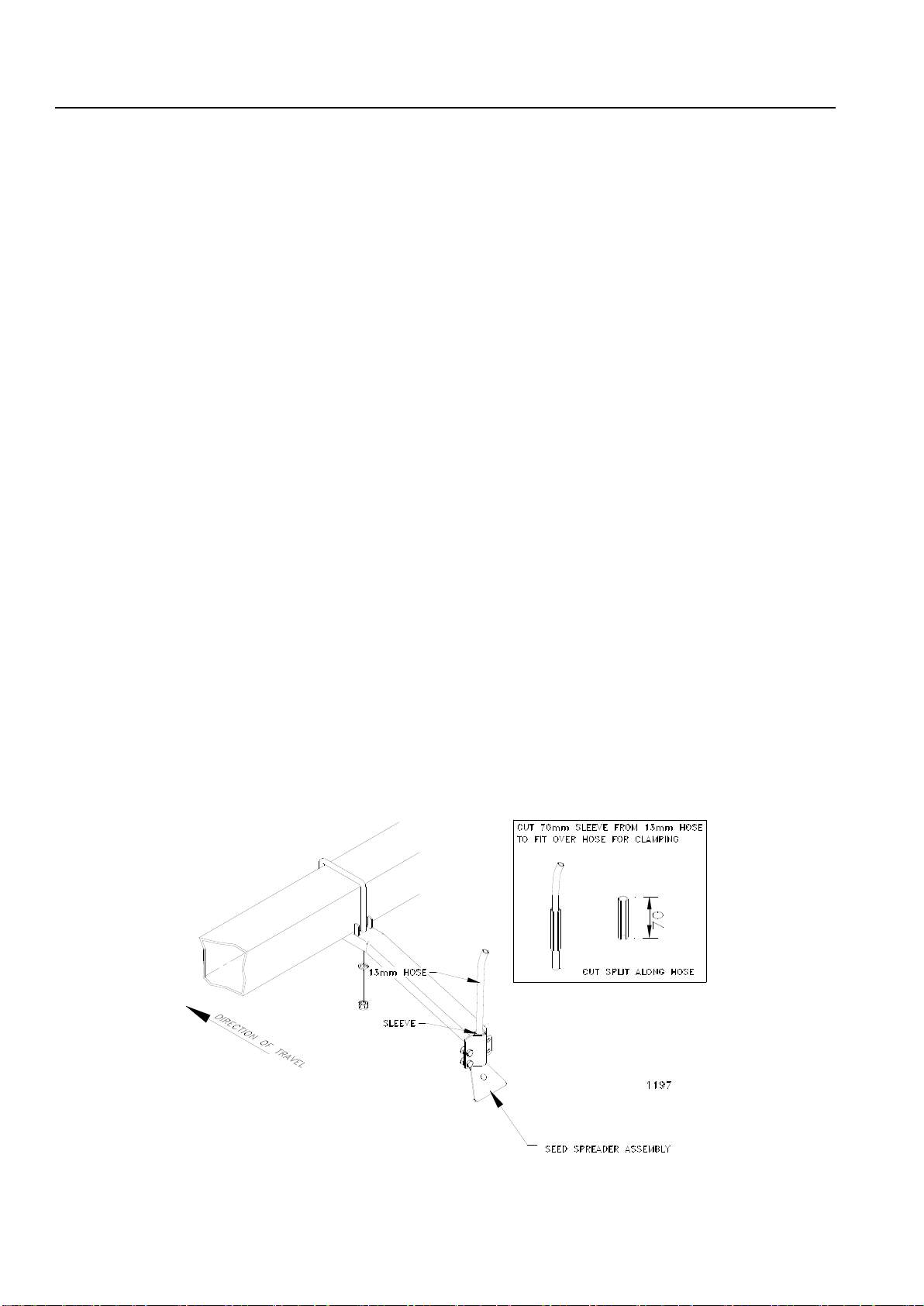

To ensure the hose is firmly clamped a

sleeve will need to be cut and placed over

the hose at the clamped position (see Fig.

7). Allow 25mm between the hose outlets

and the spreader plates and when secure

check the alignment of the spreader plates

(see Fig. 7).

Fig. 7

DISTRIBUTION KITS & FITMENT INFORMATION Page 9

06/14

Fig. 8 Pasture Planter Broadcast Distribution System

Note: Refer to spare parts section for all part numbers

DISTRIBUTION SYSTEM

COMPONENTS SUPPLIED

KIT

GPN:

IMPLEMENT WIDTH

PRIMARY

MANIFOLD

(ITEM 29)

SECONDARY

MANIFOLD

(ITEM 17)

SEED

SPREADER

ASSEMBLY

(ITEM 40)

SPREADER

EXTENSION

(ITEM 42)

215634

4 to 5.5 metres

2 outlet

2 qty

10 qty

2 qty

215636

6 to 8.5 metres

3 outlet

3 qty

15 qty

4 qty

215638

9 to11.5 metres

4 outlet

4 qty

20 qty

4 qty

215640

12 to 14.5 metres

5 outlet

5 qty

25 qty

4 qty

215642

15 to 17.5 metres

6 outlet

6 qty

30 qty

6 qty

215644

18 to 20.5 metres

7 outlet

7 qty

35 qty

8 qty

Metric to Imperial Conversion Scales : 1m = 3.28ft

m

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

ft

13

16

20

23

26

30

33

36

39

43

46

49

52

56

59

62

66

DISTRIBUTION KITS & FITMENT INFORMATION Page 10

06/14

Individual Placement System Fitment

Instructions (refer fig. 9.)

1. Attach the primary manifold support and

bracket (Item 9) using the M10 U-Bolts and

fasteners to a central location on the

implement. This central location will reduce

the length of the 25mm secondary hose

that needs to be routed across the

machine.

2. Fit the small Secondary towers & heads

(item 2) centrally amongst the tines to be

serviced.

3. Use the 12.7mm ID hose to distribute the

small seeds to the appropriate sowing boot

supplied by the owner or to a dedicated

Gason sowing boot with the aid of an

adaptor (item 7).

Fig. 9 Pasture Planter Individual Placement System

DISTRIBUTION KITS & FITMENT INFORMATION Page 11

08/14

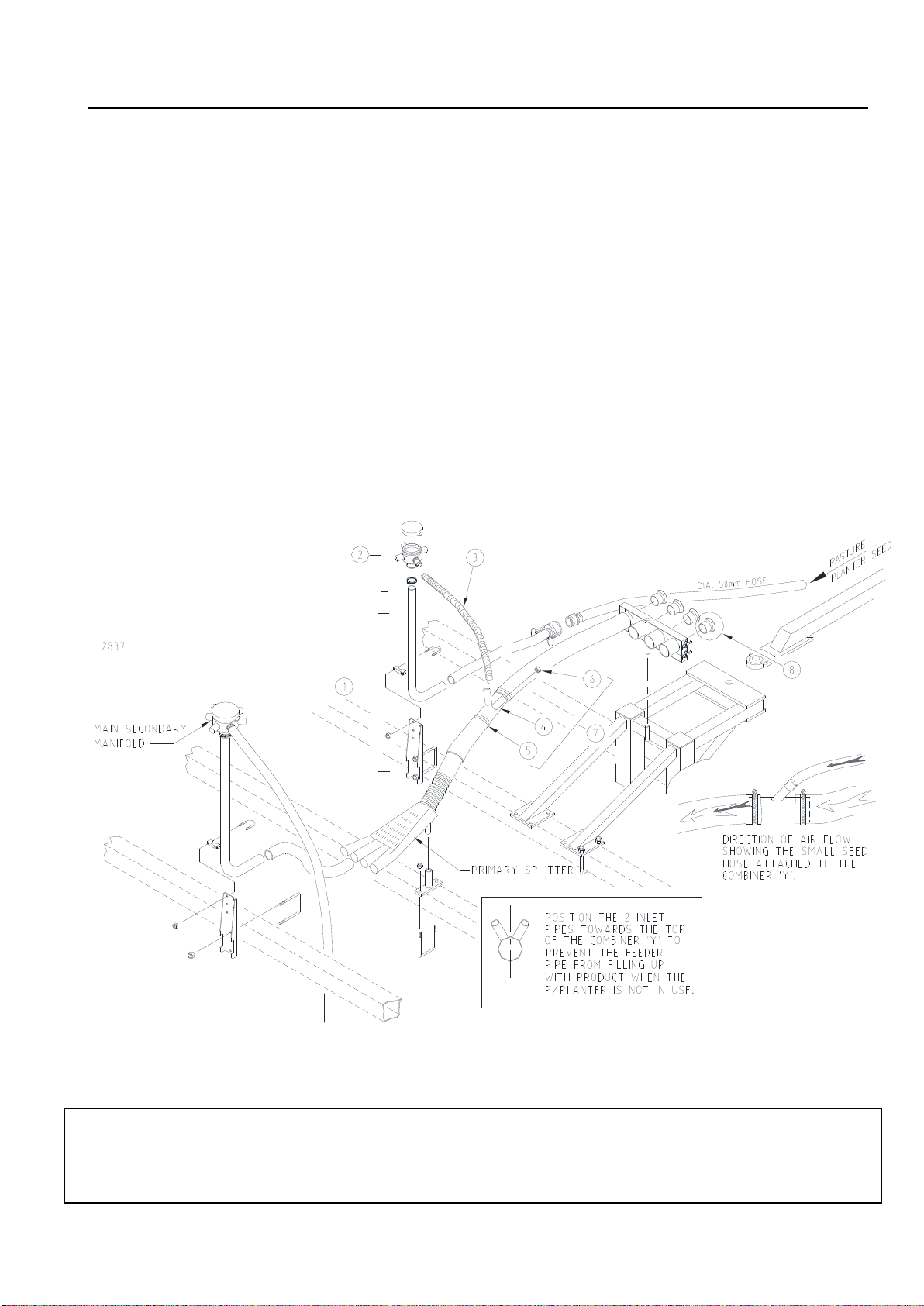

Combiner ‘Y’ Kit Fitment Instructions

(refer fig.10.)

Combiner ‘Y’s can be fitted to multiple

primary hoses to allow the incorporation of

product from the Pasture Planter to the main

distribution system. The position and direction of

fitment of the Combiner ‘Y’s is important and if

not done correctly will cause distribution issues.

If operators are wishing to combine

material from the pasture planter down all of the

tines on a single shoot system, they would select

a quantity of combiners the same as the number

of primary hoses fitted. If the objective was to

plant on the rear row only on a machine that had

a deep banding system, then only half the

number of combiners will be required.

1. Attach the full height primary manifold

support kit (item 1) near the entry side of the

cluster of primary seeder splitters. By doing

this, it will be easier to maintain short and

continuously falling 25mm secondary hoses

from the primary manifold to the inlet on the

Combiner ‘Y’s.

2. Ensure any open 25mm inlet pipes on the

Combiner ‘Y’s are capped with the supplied

black plastic cap (item 6). Two are supplied

with each kit.

3. Both inlet pipes must be set in the correct

direction and so that they are facing upwards

as per the sketches in Fig.10 below.

Fig. 10 Combiner ‘Y’ System showing one possible configuration.

Note regarding the use of the equalisation funnels (item 8) supplied with the combiner ‘Y’ Kit.

Equalisation funnels have been supplied for use in distribution system with a high back pressure in the

main Secondary system. They are rarely used but can be helpful in restricted systems with either a small

number of tertiary outlets or restricted sowing boots. If used, they must be fitted to all primary lines.

OPERATING THE PASTURE PLANTER Page 12

10/09

General Information

The pasture planter has been designed to

integrate with the complete range of Gason Air

Seeders. General operation of the pasture

planter is similar to the main system.

It will be necessary to calibrate the pasture

planter metering system to obtain the desired

application rate for the particular material being

sown. Refer to either the Ground Drive or VRT

Hydraulic Drive sections in this manual for the

appropriate calibration information.

For a more detailed description of Air

Seeders operation refer to the Air Seeder

Operator’s Manual.

Setting Pasture Planter Air flow

The Pasture Planters air supply is taken

from a secondary outlet on the plenum chamber

and is controlled by a shut off valve. For general

use the valve will be fully open when operating

the pasture planter. Fan speed setting is based

upon application rate in the seeders main

system.

Fan speed may need to be varied

depending on type and size of distribution

system and application rate through main

system and pasture planter. The shut off valve

can be used to restrict airflow to the Pasture

Planter if required.

Contact your Gason dealer for specific

information about Pasture Planters air flow.

Filling the Bins

Before filling, check that the clean out

hatch on the meterbox has been fixed into

position, and that there are no adjustments

needed to the Pasture Planter meterbox.

The grate that is fitted to the top of the bin

should always be left in place when filling. This

will help in preventing large clumps of material

and foreign objects from entering the bin and

possibly damaging or blocking the meter system.

To Empty the Bin

Place a suitable container underneath the

pasture planter and open meterbox clean out

hatch. To ensure all of the bin’s contents has

been removed it is recommended that you open

the bottom door of the Pasture Planter and rotate

the metershaft one full revolution.

Use a broom from the top of the bin if any

material remains in the bin.

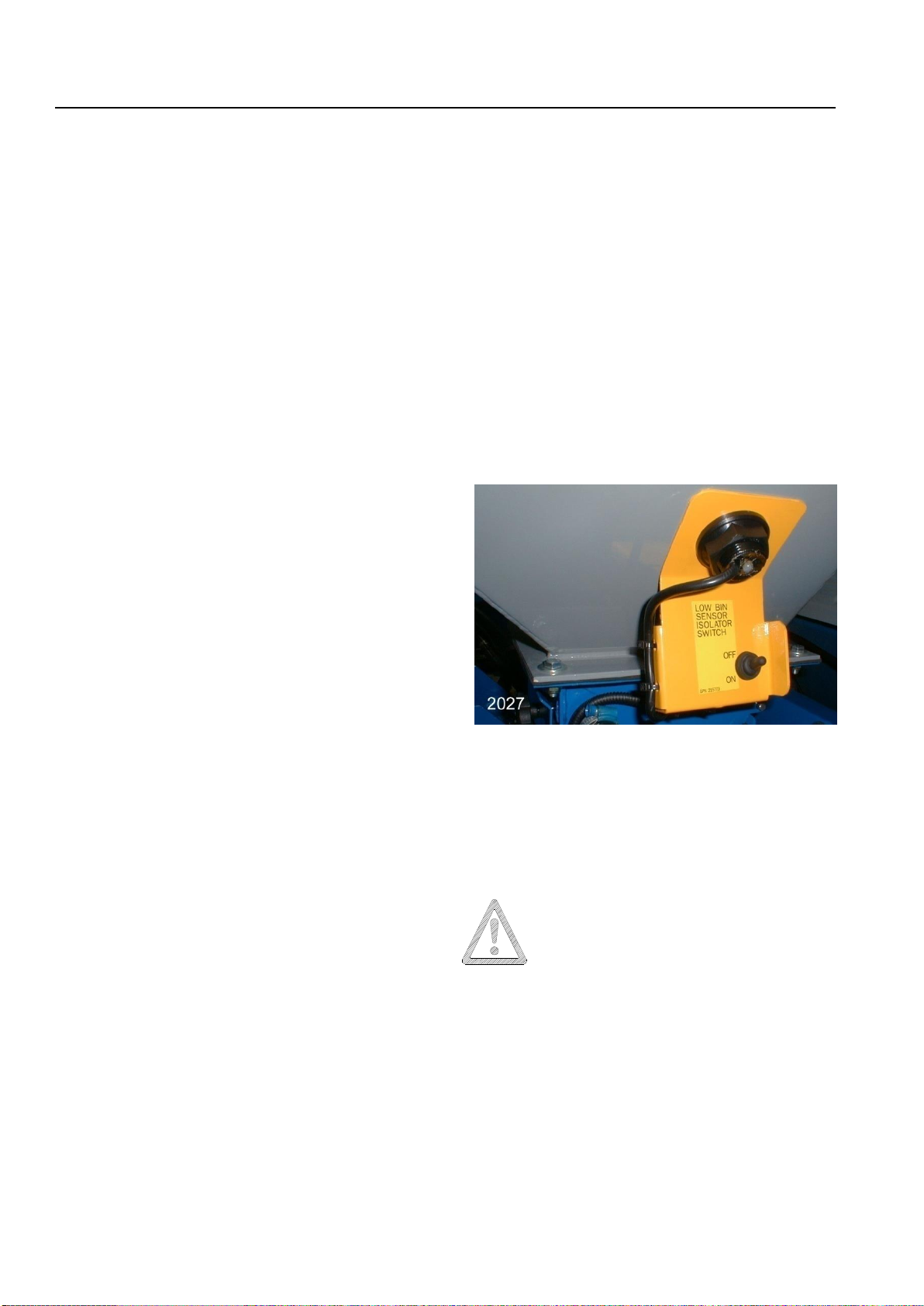

Low Bin Sensor - Ground Drive Only

The “Low Bin Sensor Isolation Switch”

enables the sensors in the main bins to operate

independently of the pasture planter. When

operating the Pasture Planter the bin sensor

needs to be turned ON.

Fig.11 Low Bin Sensor Isolation Switch

Disengaging Pasture Planter –Ground Drive

Only

When the pasture planter is not in use, set the

variator to zero. This effectively disengages the

metershaft.

The Pasture Planter Metershaft will

still gradually creep when variator is

set to zero.

PASTURE PLANTER METERBOX - ADJUSTMENTS Page 13

10/09

Fitment of Reducer Plate

To achieve very low rates with small seeds

a reducer plate is fitted to the Pasture Planter

meterbox. This reduces the meterwheels output

to approximately 1/3. The following steps are for

fitment ofthe reducer plate, removalis a reversal

of this procedure.

Step 1. Remove window assembly.

Fig.12 Removal of window assembly

Step 2. Fit reducing plate onto bolt inside the

meterbox.

Fig.13 Fit reducing plate.

Step 3. Fit wing nut and tighten and then refit

window assembly.

Fig.14 Wing nut securing reducer plate.

Caution: Only use with very small seeds such as

Canola, Medics (clover seed) or Sorghum.

Always re-calibrate Pasture Planter after

fitting or removing the reducer plate.

Pasture Planter Meterbox - Adjustments Page 14

10/09

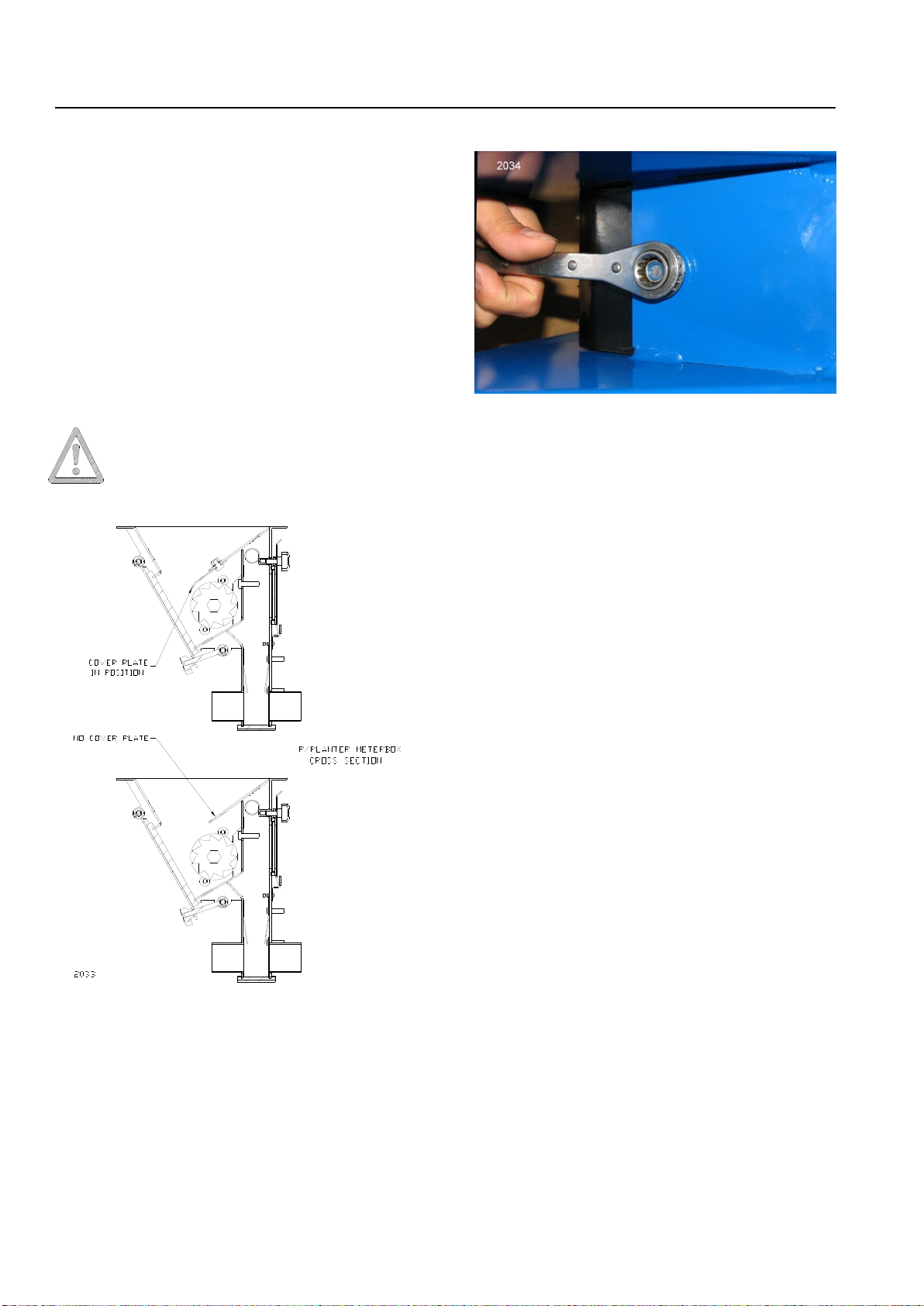

Removal of Meterwheel Cover Plate

It may be necessary to remove the

meterwheel cover plate from inside of the

meterbox for lightweight and large seed if high

rates are required.

To remove the cover plate you will need to

have the bin empty. Gaining access through the

clean out hatch, remove the M8 nyloc nut

retaining the cover plate with a 13mm ratchet

ring spanner (Refer Fig.16). Fitting cover plate is

the reversal of this procedure.

Always re-calibrate Pasture Planter after

removal or fitting of cover plate.

Fig. 15 Cover plate fitted and removed.

Fig.16 Access to remove cover plate through

clean out hatch.

Changing Meterwheel

It is possible to replace the standard

meterwheel with a more aggressive and deeper

meterwheel if metering large and light seeds at

high rates.

Refer parts section for more detail.

GROUND DRIVE - CALIBRATION Page 15

10/09

Introduction

The calibration procedure involves the

rotation of the metering system by hand to

simulate the coverage of a certain area. A

material sample needs to be collected and

weighed to calculate the application rate. This is

done by taking a sample equal to 1/20th of a

hectare.

It will be necessary to disengage the drive

system for the main air seeder when calibrating

the pasture planter.

For more detail on calibration refer: Air Seeder

Operator’s Manual, Ground Drive –Calibration.

When calibrating, ensure that there is

enough material in the Pasture Planter Bin. In

most cases 1/2 a bag will be sufficient.

It must be remembered that this style of

seeder is dependent upon a correct wheel

diameter for its operating accuracy. If this

diameter is altered, (e.g. incorrect tyre fitted,

wrong tyre pressure or extreme ground

conditions), inaccurate metering may occur. If

extremely accurate metering is desired refer to

Air Seeder Operator’s Manual, Ground Drive –

Calibration - Method C for checking the wheel

circumference.

Meterbox Adjustments

It may be necessary to make adjustments

to the pasture planter meterbox when metering

low or high rates of seed. The meterbox has

been supplied with a reducer plate (yellow) that

is fitted to the front face of the meterwheel

opening. This plate is suitable for light to average

application rates of small seeds. This plate

should be removed when metering high rates of

seed or large/light seeds (eg. rye grass).

As a guide, the variator setting should be

between 1 and 7 after calibration. If the setting is

too low you may need to fit the reducing plate if

not already in place. If the setting is too high,

above 7, remove the reducing plate if fitted and

recalibrate.

When using product that has poor flow

characteristics or larger seeds it may be

necessary to remove the meterwheel cover

plate. Refer to the adjustments section of this

manual for further information.

Calibration Procedure

Step 1. Open the bottom door of the Pasture

Planter.

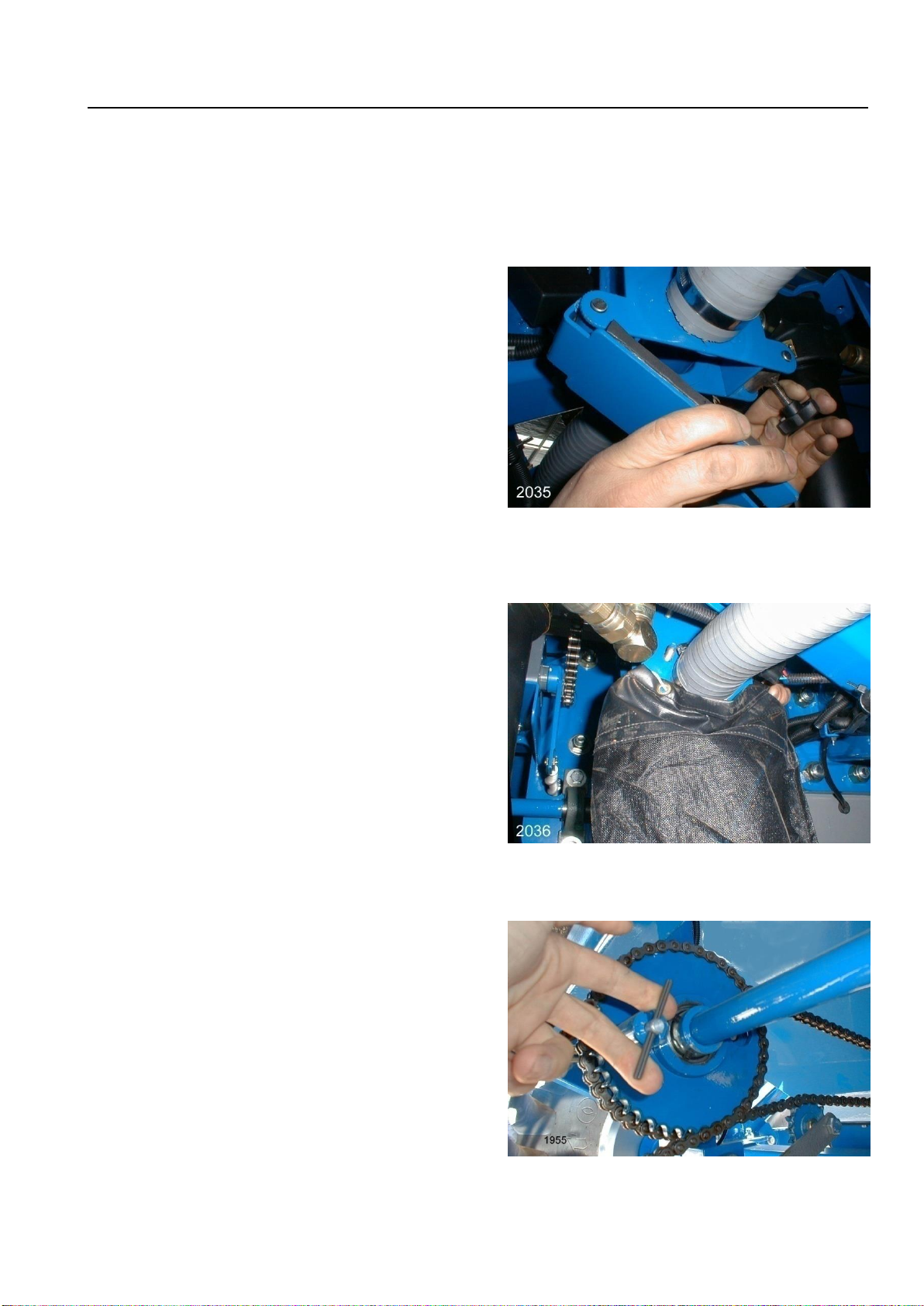

Fig.17 Bottom door on pasture planter.

Step 2. Fit calibration collection bag to the

p/planter meterbox using the draw

string.

Fig.18 Fitting the calibration collection bag.

Step 3. Disengage drive pin from the seeders

main bins.

Fig.19 Disengaging Sprocket.

Ground Drive - Calibration Page 16

10/09

Step 4.Rotate calibration handle for the correct

number of turns to simulate 1/20th of a

hectare (see table page 14). Rotate

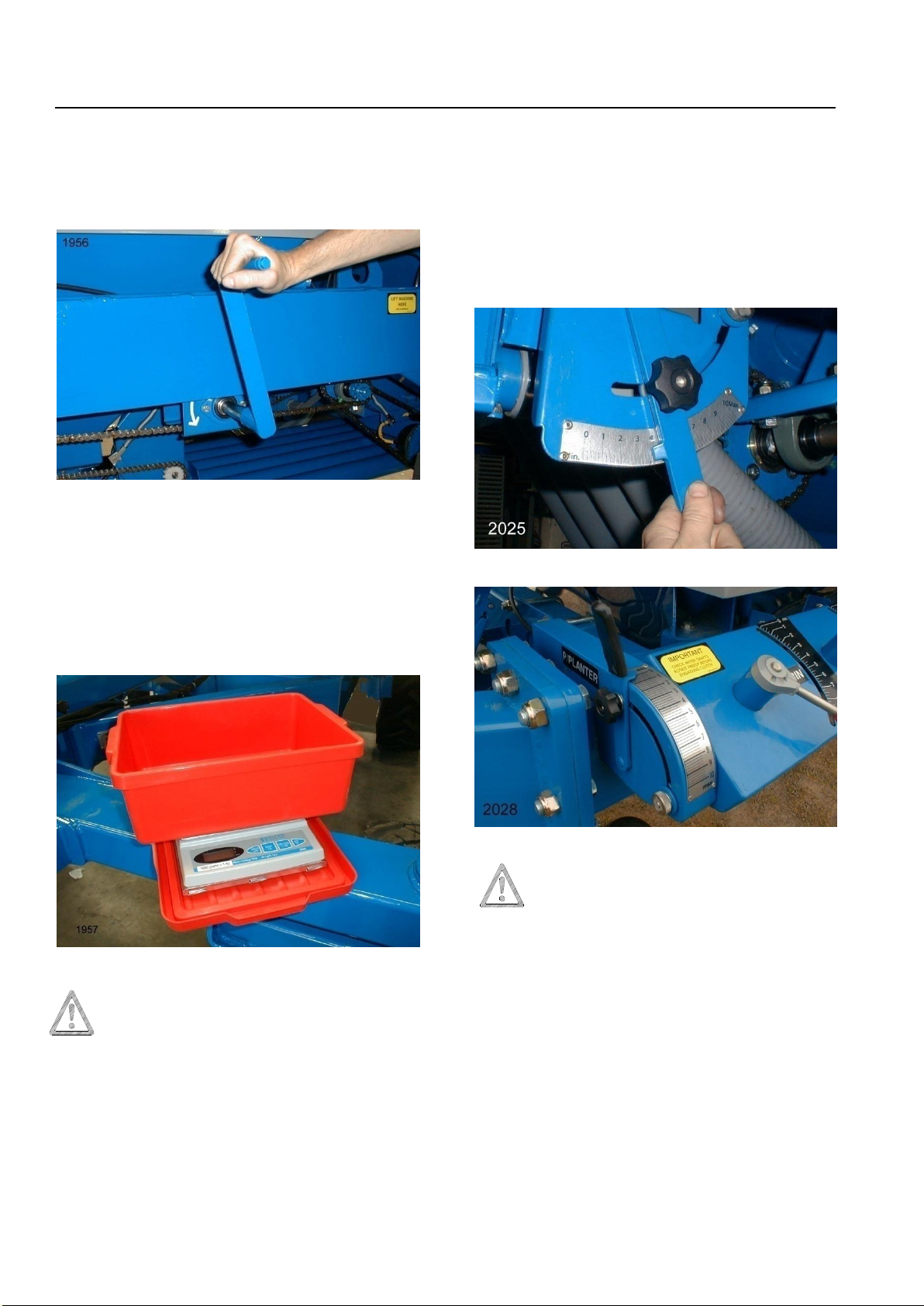

handle anti-clockwise.

Fig.20 Calibration handle rotates anti-clockwise,

as shown by the arrow.

Step 5.Weigh sample taken on scales supplied.

When using scales use the scale box as

the container. Place box on top of scales

before switching on. Check that the

scales are set at zero before weighing

sample.

Fig.21 Scales.

NOTE: It is the responsibility of the

operator to check the accuracy of the

scales on a regular basis.

Step 6.If the result is too low you will need to

increase the setting on the variator. If too

much material was collected the reverse

applies. After making the adjustment you

will need to retest the system following

steps 4 and 5.

NOTE: It is recommended that when adjusting

the variator setting the operator goes past the

desired setting (higher rate) a short distance and

then rotates the handle back to the required

setting. This method of adjustment will ensure

that there is no slack in the cable if a cable is

fitted.

Fig. 22 1830/50 P/Planter Variator Adjustment

Fig.23 1880/2120 P/Planter Variator Adjustment

IMPORTANT When the

calibration procedure is completed

close the bottom door of the pasture

planter and engage the drive pins on

the main bins to allow the drive

system to operate normally.

Table of contents

Other Gason Seeder manuals