- 3 -- 3 -

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................................................... 5

2. SAFETY INSTRUCTIONS ............................................................................................................................................. 6

2.1 SAFETY SYMBOLS ........................................................................................................................................................................ 6

2.2 GENERAL SAFETY INSTRUCTIONS ........................................................................................................................................... 7

2.3 LOADING AND UNLOADING INSTRUCTIONS......................................................................................................................... 8

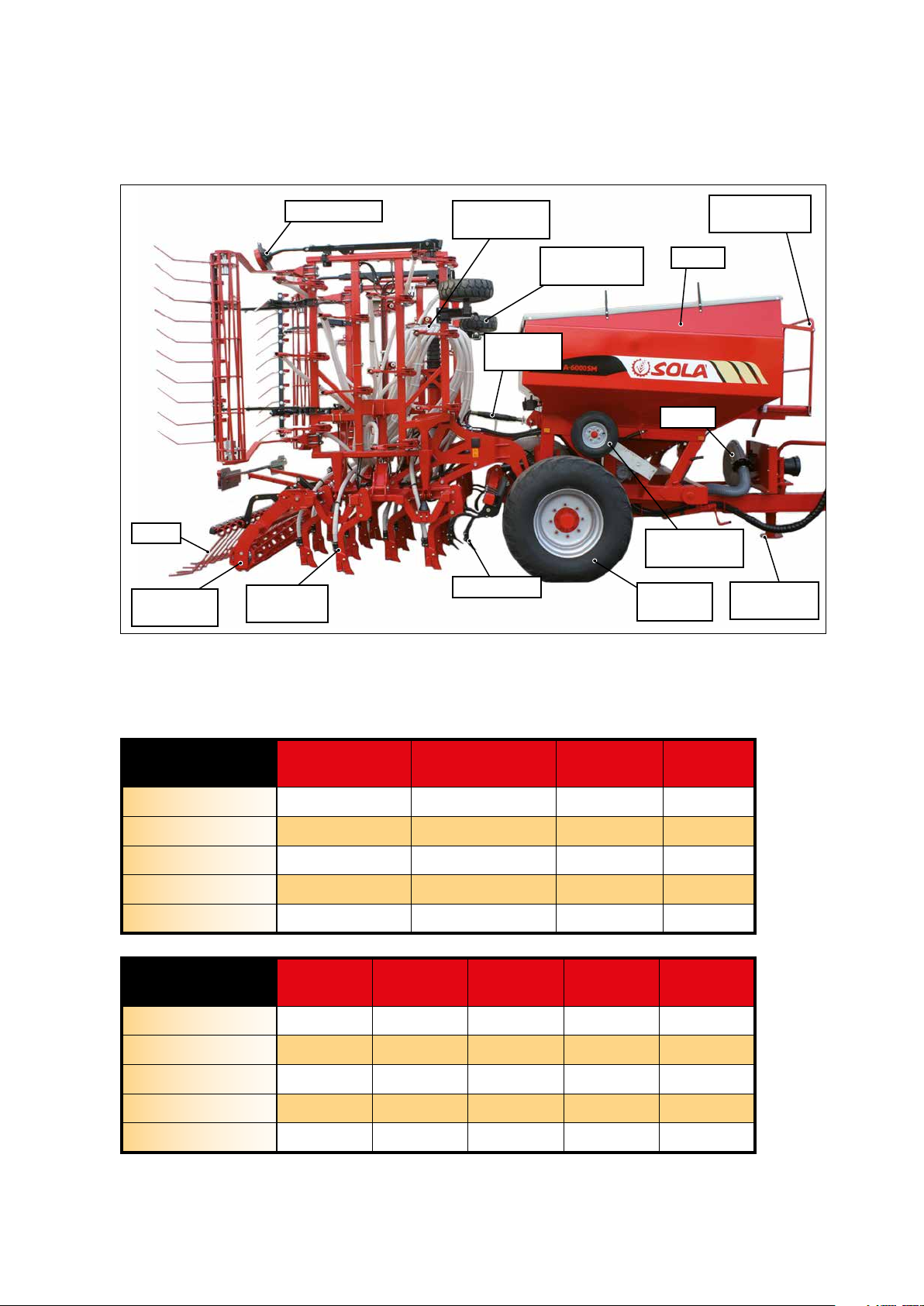

3. GENERAL DESCRIPTION............................................................................................................................................. 9

3.1 OVERVIEW OF THE MACHINE .................................................................................................................................................... 9

3.2 TECHNICAL SPECIFICATIONS .................................................................................................................................................... 9

3.3 IDENTIFICATION OF THE MACHINE ....................................................................................................................................... 10

3.4 USAGE ACCORDING TO DESIGN ............................................................................................................................................. 10

4. FUNDAMENTAL CONCEPTS FOR PLANTING .............................................................................................................11

4.1 TERRAIN....................................................................................................................................................................................... 11

4.2 SEED ............................................................................................................................................................................................. 11

4.3 DEPTH.......................................................................................................................................................................................... 11

5. COMMISSIONING ......................................................................................................................................................12

5.1 COUPLING THE SEED DRILLER TO THE TRACTOR................................................................................................................ 12

5.2 COUPLING AND ADAPTING THE PTO SHAFT ....................................................................................................................... 14

5.3 HYDRAULIC SYSTEM................................................................................................................................................................. 15

5.4 TRANSPORTATION POSITION.................................................................................................................................................. 16

5.5 LOADING AND UNLOADING THE HOPPER ........................................................................................................................... 17

5.6 SUPPORT FEET............................................................................................................................................................................ 18

5.6.1 FRONT SUPPORT FOOT............................................................................................................................................ 19

5.6.2 REAR SUPPORT FOOT .............................................................................................................................................. 19

5.7 PARKING BRAKE......................................................................................................................................................................... 20

5.8 END OF MACHINE WORK ......................................................................................................................................................... 20

6. ADJUSTMENTS ......................................................................................................................................................... 21

6.1 MACHINE LEVELLING ................................................................................................................................................................ 21

6.1.1 TOW-BAR AND TRACTOR LEVELLING .................................................................................................................... 21

6.1.2 SOWING EQUIPMENT LEVELLING .......................................................................................................................... 22

6.2 DEPTH CONTROLS..................................................................................................................................................................... 22

6.2.1 DEPTH TINES.............................................................................................................................................................. 22

6.2.2 DEPTH CONTROL WHEELS...................................................................................................................................... 23

6.2.3 COULTERS................................................................................................................................................................... 23

6.2.3.1 SM MODEL................................................................................................................................................. 24

6.2.3.2 NS-PLUS MODEL ...................................................................................................................................... 25

6.3 DOSAGE....................................................................................................................................................................................... 25

6.3.1 VOLUMETRIC DISPENSER ........................................................................................................................................ 26

6.3.1.1 NORMAL SEEDS (N position) .................................................................................................................. 26

6.3.1.2 SMALL SEEDS (F position)....................................................................................................................... 27

6.3.2 ROLLER DISPENSER .................................................................................................................................................. 28

6.3.3 DISPENSERS FOR FERTILIZER AND/OR MICROGRANULATE KITS.................................................................... 29

6.3.3.1 INTERNAL KIT HOPPER - FERTILIZER AND/OR MICROGRANULATE DISPENSER .......................... 30

6.4 SEED DOSAGE ADJUSTMENT .................................................................................................................................................. 31

6.5 SEED FLOW PRE-TESTING ........................................................................................................................................................ 32

6.5.1 MODELS WITH MECHANICAL TRANSMISSION ...................................................................................... 32

6.5.2 MODELS WITH ISOBUS ELECTRICAL TRANSMISSION .......................................................................... 34

6.6 SEED DOSE FIELD TESTING...................................................................................................................................................... 37

6.7 HARROW...................................................................................................................................................................................... 38

6.8 TRACK ERASERS (OPTIONAL).................................................................................................................................................. 38

6.9 COMPACTING ROLLER .............................................................................................................................................................. 39

6.10 HYDRAULIC TRACK MARKERS............................................................................................................................................... 40

6.10.1 TRACK MARKER LENGTH ADJUSTMENT............................................................................................................. 40

6.10.2 TRACK MARKER DISC INCLINATION ADJUSTMENT.......................................................................................... 41

6.11 INCLINATION OF FOLDING PARTS........................................................................................................................................ 41