Gason SR Series User manual

A member of

COPYRIGHT

Neither this manual or part thereof may be reproduced or published without the prior permission of A.F. Gason Pty. Ltd.

1800 & 2000 SR SERIES AIR SEEDER

OPERATOR’S MANUAL

Covering the 1860, 1880/90 & 2120/50 Models

GPN 216593 REVISION - 10/09

Page Intentionally Blank

CONTENTS

Warranty Form

Introduction ........................................................

1

General Information ...........................................

3

Safety.................................................................

6

Specifications.....................................................

8

Conversions.......................................................

16

Bolt Specifications..............................................

17

Ordering Parts....................................................

18

Spare Parts Record............................................

19

Assembly Instructions........................................

20

Implement Hitch Systems...........................

21

Distribution System ....................................

25

Pre-Delivery Checklist................................

24

Transporting.......................................................

29

Operating the Air Seeder ...................................

30

Monitor Operation.......................................

31

Ground Drive Model

Monitor Introduction & Operation ...............

32

Calibration..................................................

34

Method A (using chart)......................

34

Method B (preferred) .........................

37

Method C (Wheel Circumference).....

38

Calibrating a 3 Bin Seeder.................

40

Variator Setting Guide .......................

41

Calibration Handle Turns...................

56

Area Rate Chart ...............................

57

Converting lb/acre to kg/ha................

58

Planting Details Reference................

59

Meter Drive System...........................

61

Variator Gearbox...............................

61

High sprocket Ratio...........................

63

VRT Hydraulic Drive Model

Introduction Operation................................

64

Monitor Operation.......................................

65

Manual Override.........................................

71

Calibration..................................................

74

Sprocket Ratio Selection Guide.........

78

Planting Details Reference................

89

Maintenance...............................................

91

Trouble Shooting........................................

93

Liquid Equipped Air Seeder

Introduction Operation................................

96

General Safety ...........................................

96

Operating Machine.....................................

97

Calibration..................................................

98

Trouble Shooting........................................

100

CONTENTS

Metering System

SR Meterbox Assembly Features ..............

103

Low/High Rates....................................

104

Reducing the Outlets............................

104

Large Seeds.........................................

105

Deep Banding.......................................

106

Triple Shooting .....................................

106

Removing Metershaft Assembly ................

108

Removing Meterwheels .............................

108

Blanking Metershft Housing.......................

110

Fitting Meterwheel Reduction Cover Plates

110

High / Low Sprocket Ratio..........................

111

Blocking Air Flow .......................................

111

Metering Oats ............................................

112

Fitting Broad Beans Metershaft Assy.........

112

Bearing Replacement in Nose Assy...........

113

Hydraulic System...............................................

114

Tractor Requirements ................................

114

Hydraulic Connections...............................

115

Disconnecting the Hyd. Hoses...................

116

Filter Maintenance .....................................

117

Blower Capacity.................................................

118

Blower Speed.............................................

120

Maximum Application Charts .....................

122

General Maintenance.........................................

126

Trouble Shooting ...............................................

129

Optional Attachments.........................................

129

Auger Operation ................................................

134

Storage and Cleaning........................................

136

INTRODUCTION Page 1

05/06

A.F. Gason Pty Ltd is an Australian owned

family business operating from within rural

Victoria. The Gason company has been

servicing the needs of rural Australians for

more than 60 years. We operate through a

local dealer support network that spans the

country. A.F. Gason’s would like to thank

you for purchasing your Australian made Air

Seeder, and trust that you will have many

years of trouble free service.

The Air Seeders have been designed

to be functional, practical and reliable. They

incorporate the latest technology in air

seeder design but retain their basic

functionality to ensure ease of

maintenance.

The Gason 1800 and 2000 range of

Air Seeders can perform a variety of

seeding operations and are available in

either a front tow (FT) or rear tow (RT)

model. There are a number of bin

capacities available with either 2 or 3 bin

configurations. A large range of sowing

outlet configurations are available, making

the Air Seeder adaptable to a variety of

implements to perform different tillage

practices.

The Gason metering system is a

positive and accurate method of placing seed

and fertilizer into the air stream. The system

is capable of sowing conventionally, often

referred to as single shooting (seed and

fertilizer together), deep banding (separating

the seed and fertilizer) or triple shooting

(handling 3 separate products through to the

implement). The system can also sow

summer and winter crops with minimal

adjustment.

This manual endeavors to provide the

owner with a complete understanding of the

Air Seeder’s operation and the processes

required to obtain the highest level of

performance possible. It is suggested that

the owner/operator read this manual and any

other literature that has been supplied with

your machine to ensure a safe and trouble

free operation.

References to the left and right hand sides of

the Air Seeder are from the rear of the

machine looking forward.

Fig. 1 1880RT Series Air Seeder.

While every effort has been made to ensure the accuracy of

the information in this manual, A. F. Gason Pty Ltd reserves

the right to delete, change or add information without notice.

Introduction

Page 2

02/07

Fig. 2 2150FT Series Air Seeder with Auger and rear walkway (optional).

Fig. 3 2150RT Series Air Seeder.

GENERAL INFORMATION

Page 3

02/07

Introduction

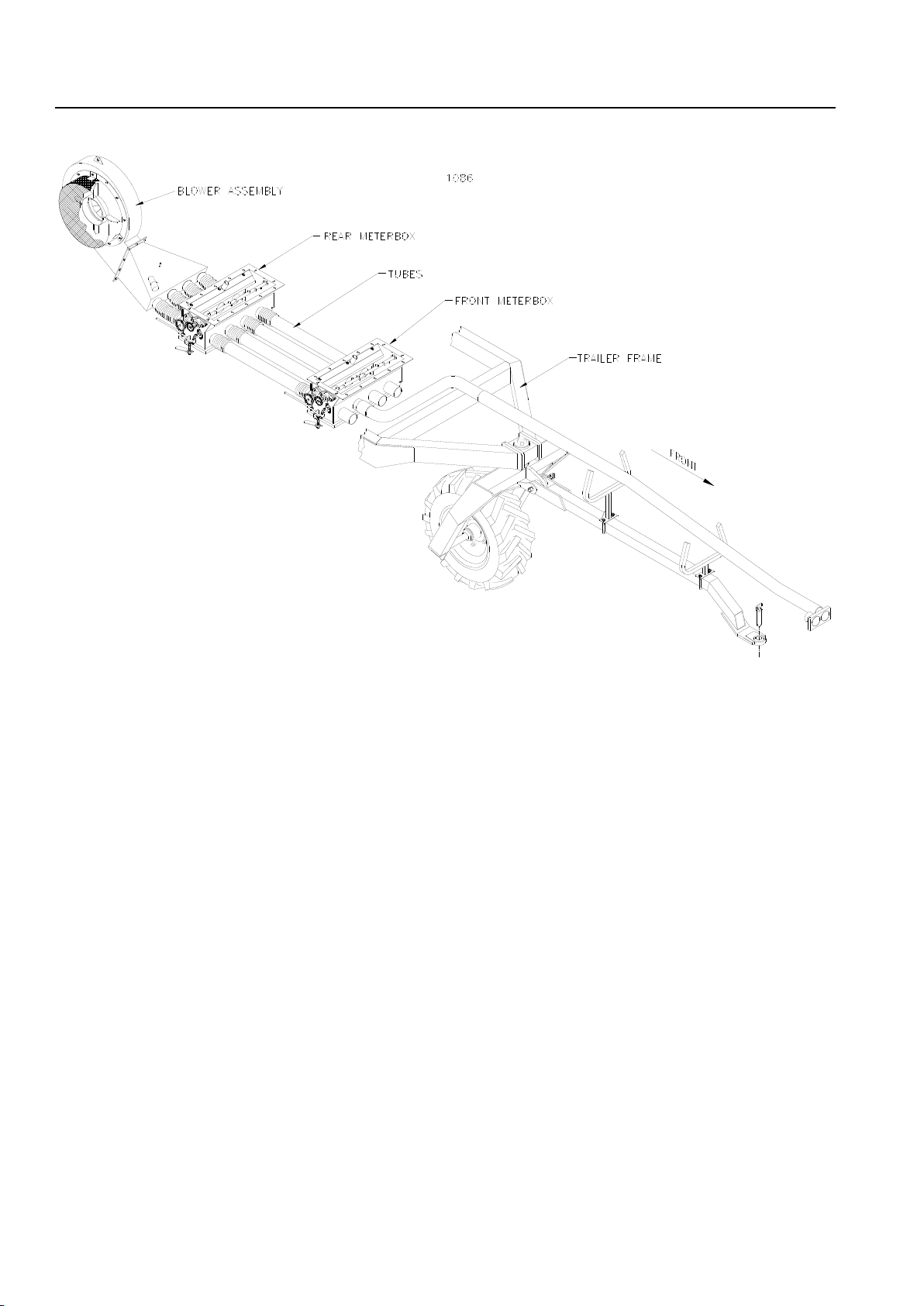

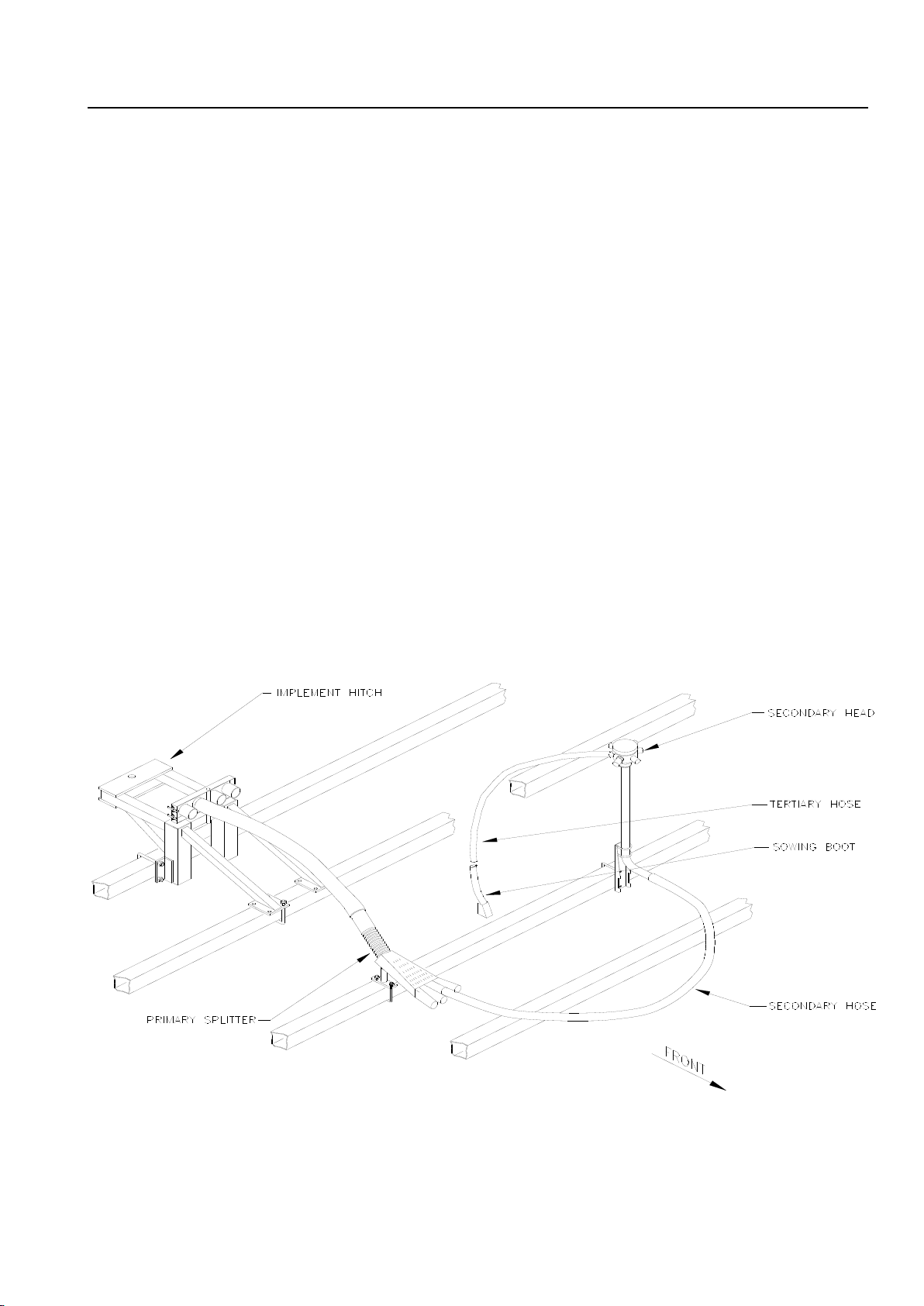

The Air Seeder uses the flow of air to

convey seed and fertilizer to each tine. This

type of material transfer is known as

pneumatic conveyance (refer Fig. G1).

The material being sown must be

metered accurately into the air stream to

deliver a constant application rate.

How the Air Seeder Operates

Seed and fertilizer are transferred from

pressurized bins to multiple conveying

tubes via separate meterboxes. A

meterwheel arrangement inside the

meterbox is rotated by either a ground

wheel (ground drive seeder) or hydraulic

motor (VRT equipped Seeder).

As the ground wheel rotates, so too does

the metering system. The metering system

can be disengaged or engaged at the tractor

cab.

A blower is located upstream of the

meterbox on the Air Seeder. It is used to

produce the airflow required to convey the

material.

The seed and fertilizer is conveyed

towards the implement. It is then evenly

divided into smaller amounts as it passes

through the primary splitters.

The material then travels along the

secondary hoses to the secondary manifold

heads. It is distributed to the tertiary hoses

and transferred to the sowing boots mounted

on the tines.

Fig. G1 Two bin model shown.

1088

General Information

Page 4

02/07

Air Seeder Construction

The RT model air seeders trail behind

the implement while the FT models are

towed in front of the implement. The basic

operation of both designs is the same other

than the location of the seeder.

The RT models are supplied with all

components to attach to the rear of the

implement. Some modifications may be

required when fitting to non-Gason

implements but in most cases fitment is a

straight forward operation. The rear tow

models are also available with a rear hitch

system that attaches to the rear of the

seeder, which will allow a set of harrows or

light prickle chain to be towed.

The FT models are fitted with a roller

style rear hitch with which to pull the

implement. This hitch, when left unpinned,

dramatically reduces the load on the seeder

during turning which will help extend the life

of the machine. The trailer has also been

designed to withstand the high loads exerted

on the frame while pulling the implement.

In both cases, the seeders have been

designed to allow quick and easy

detachment from the implement and tractor.

The 1800 and 2000 air seeder range

has a folding ladder that is fitted to the left

hand side of the machine. The walkway is

set low and runs along the left side or

between the front and rear bins. This offers

a safe environment in which to fill the large

capacity machine.

The bins have been made from 2.5 and

3mm thick mild steel with folded corners,

which are fully welded, on both internal and

external joints.

The bins have been produced in two

halves and are painted using a high bake

enamel to reduce corrosion both inside and

out before joining. The bin halves are then

joined using structural quality rivets and

sealed with high-grade sealant. The sealant

Fig.G2 RT Model Air Seeder

shown fitted with

4 outlet meterboxes.

General Information

Page 5

02/07

can be replaced at any time, if required,

without splitting the bins.

The trailers are built from 350/450-

grade rectangular hollow section with either

side plates or truss system for stiffening. It

has been designed and tested to reduce

the possibility of rearing if unevenly loaded.

The metering system incorporates

nylon and stainless steel componentry in

areas affected by fertiliser induced

corrosion.

The output of the ground driven

metering system is controlled by a stepless

variable speed gearbox, which can easily

be adjusted. Each meter system has its

own separate adjustment. VRT equipped

seeders use individual hydraulic motors to

control metering rates.

The blower’s hydraulic system uses

quality components and will require minimal

maintenance. The system has been

designed to operate in a harsh environment.

It is fitted with a check valve to prevent

damage if incorrectly connected.

The blower is mounted on the trailer

frame and houses a high capacity impeller.

It has been specifically designed to operate

in the rough conditions that occur during

normal operation. The impeller is directly

mounted to the motor, which means that

there are no external bearings or an external

coupling.

Calibrating the ground driven metering

system has been simplified by providing a

chart with instructions to the side of the bin.

There is no need to calculate figures if

calibrating within average application rates.

A collection tray and an accurate scale

set is included with the Air Seeder.

For further information on individual

aspects of the seeder refer to the appropriate

section in this manual.

Fig. G3 Distribution System.

1087

SAFETY

Page 6

02/07

The Air Seeder has been designed

with safety in mind. However, the

equipment is only as safe as the person

operating it.

Do not operate the Air Seeder until

you have read and understood this manual.

If you feel you need help or advice on the

operation of the Seeder, contact your local

authorized Gason Dealer.

To ensure trouble free and safe

operation of your seeder, it is important to

carry out a daily safety check to reduce the

possibility of a costly breakdown.

Items to Check Daily During Operation

1. Check all wheel nuts are tight during the

first couple of days of seeding or after

transportation (refer page 17).

2. Check all tyre pressures and tyre

conditions in general. NOTE: a badly

worn rear drive tyre will affect the

metering accuracy.

3. Ensure the safety guard on the blower

unit is fitted.

4. Check all hydraulic breakaway

connections are locked into position.

5. Check all hydraulic hoses and fittings for

leaks.

6. Check all chains and sprockets for wear

or movement on the shaft.

7. Check metershafts turn freely before

operating each day or after transporting

when loaded (refer page 62).

8. Check draw bar pins for wear.

9. Ensure bin lids are closed and that there

are no air leaks when blower is

operating.

10.Check distribution hoses for damage or

kinks, especially after operating the wing

fold system on the implement.

General Safety Conditions

DO NOT ride on the machine when

operating.

DO NOT touch or attempt to adjust any

moving parts.

DO NOT adjust hydraulic fittings while

under pressure.

DO NOT remove any safety guards while

the seeder is operating.

DO NOT operate the machine unless all

safety guards are securely fitted.

DO carry out the daily safety checks and

operate the seeder in a safety conscious

manner.

Hydraulics

Before working on the hydraulic system

always check that the blower is not

operating, and that there is no pressure in

the hydraulic system.

Never attempt to disconnect a

breakaway coupling if the blower is

operating. Turn the tractor off if working on

the metering system of a VRT equipped

seeder.

Leaving the Air Seeder Unattended

Always close the bin lids and ensure

that no material is left in the bins after

seeding. Chock the Air Seeder wheels to

prevent it from rolling.

When Working on the Air Seeder

Place suitable stands under the trailer if

removing a wheel or carrying out major work.

Never enter the bin compartment

unless another person is present. Always

take proper safeguards if entering a bin or

working on components that have been

exposed to treated seed.

Wear ear protection if working near the

blower while operating.

Safety

Page 7

02/07

Transporting

Never transport the seeder with the

clutch switch engaged (ground drive

models).

Avoid transporting the seeder long

distances when loaded. Do not exceed

20km/h when towing the seeder when

loaded. Maximum speed for towing an

empty seeder is 40km/h. Use safety chains

where provided.

For further information and helpful tips

on transporting refer to the Transporting

section of this manual (refer page 29).

Lifting the Air Seeder

The Air Seeder has been supplied

with 2 lifting eyes located on the trailer

frame between the bins.

The 1860-2150 model seeders will

require a third front sling for lifting.

Ensure you have safe lifting

equipment with the correct capacity before

attempting to hoist the machine.

Fig. G4 2150RT fully assembled being lifted.

When lifting the seeder it is preferable

to use soft slings and shackles at the trailer.

If chains must be used ensure that the bins

are protected against paint damage.

Seeder Weight Unloaded

1860 model 2900kg approx.

1880 model 3300kg approx.

1890 model 3500kg approx.

2120 model 4900kg approx.

2150 model 5500kg approx.

Auger Operation and Safety

Refer to the Auger section of this manual.

Pasture Planter Operation and Safety

Refer to the Pasture planter Operators

Manual.

Fig. G5 Pasture planter fitted to a 1880FT.

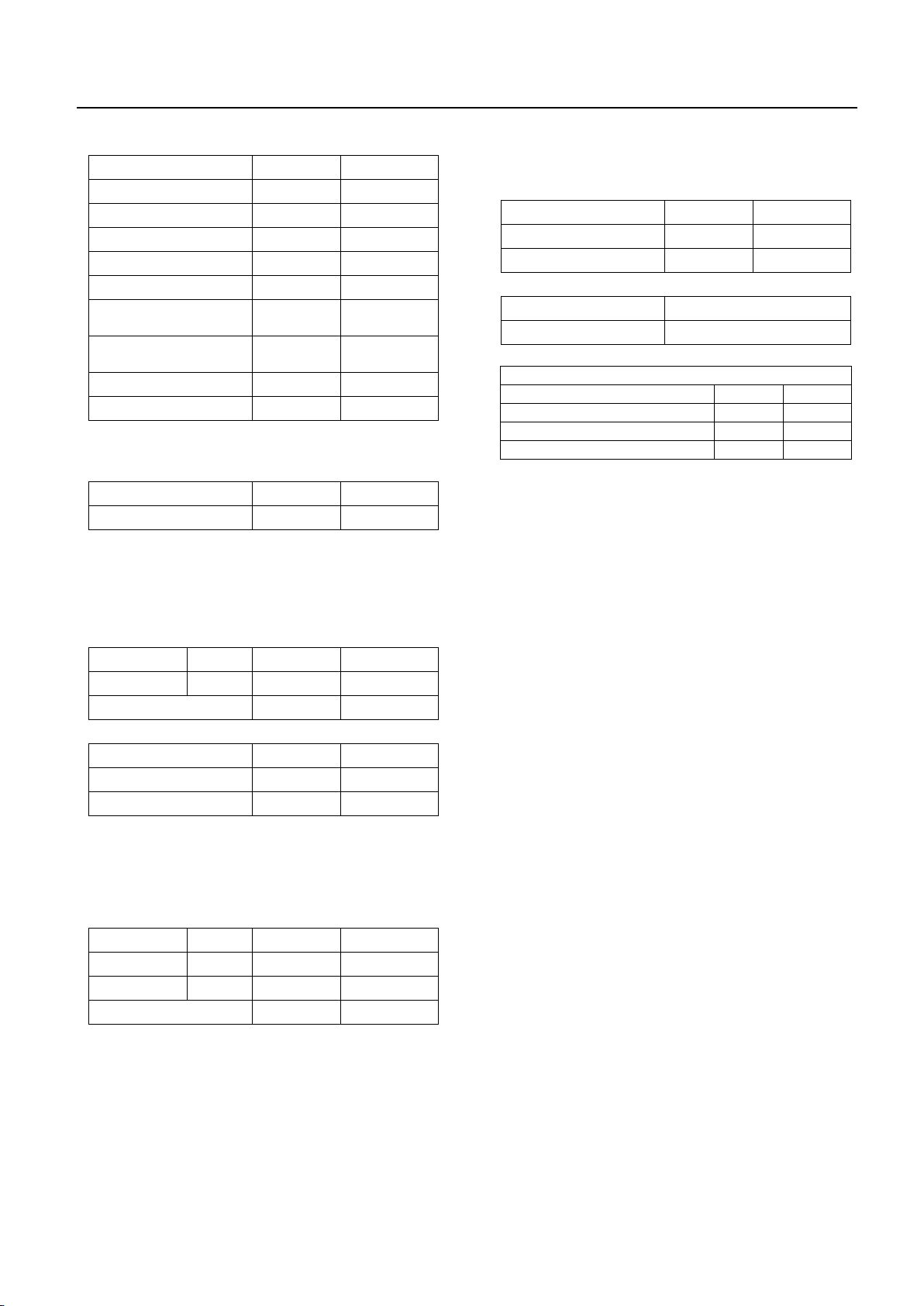

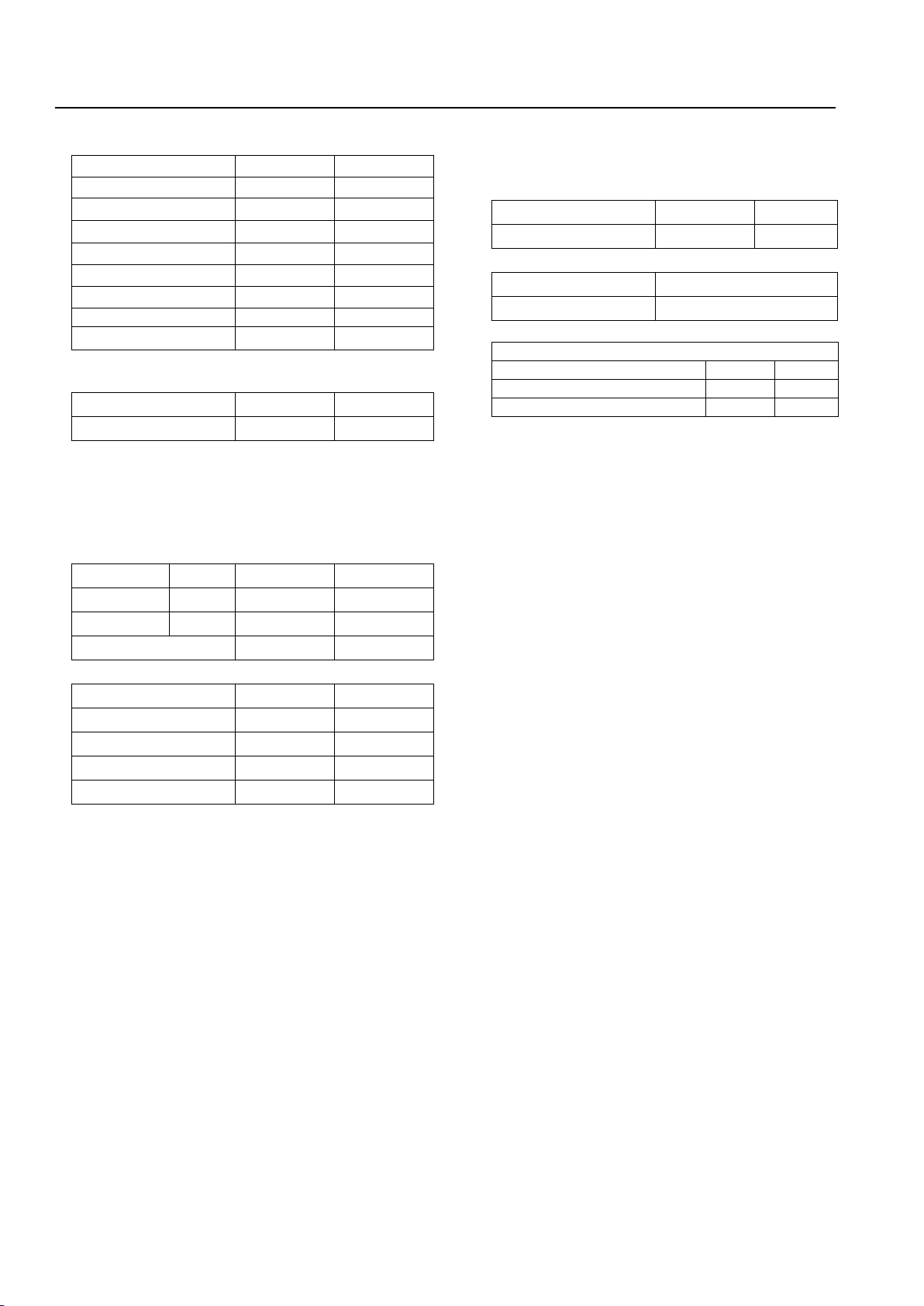

SPECIFICATIONS –1860 SR SERIES

10/09

Page 8

Dimensions

1860FT

1860RT

Overall width

2500

2760mm

Overall height*

2870

2870mm

Top of bin height

2750

2750mm

Overall length^

6160

9485mm

Seeder length

6160

5740mm

Rear wheel centres

2000

2000mm

Front wheel centres

(CTC models)

-

2000mm

Step height

500

500mm

Ground Clearance

440

460mm

*Worklight stand folded down. ^Includes hitch but no options

CTC model on 2 metre & 3 metre centres.

CTS model on 3 metre centres

Weights*

Unloaded

2500

2500kg

Loaded

8830

8830kg

(material in both bins at 1000kg/1000 litres)

*Weights are for 2 bin models only and excludes Auger and

options.

Bin Capacity 2 Bin

By volume:

Front bin

44.5%

2760

2760 L

Rear bin

55.5%

3440

3440 L

Total capacity

6200

6200 L

By weight:

Front bin (wheat)

2340

2340kg

Rear bin (super)

3990

3990kg

Total weight

6330

6330kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Bin Capacity 3 Bin (Equal Middle/Rear Bin)

By volume:

Front bin

42.5%

2760

2760 L

Middle bin

28%

1815

1815 L

Rear bin

29.5%

1915

1915 L

Total capacity

6490

6490 L

Bin Capacity 3 Bin (Larger Rear Bin)

By volume:

Front bin

42.5%

2760

2760 L

Middle bin

26.1%

1695

1695 L

Rear bin

31.4%

2035

2035 L

Total capacity

6490

6490 L

Wheels

Size:

1860FT

1860RT

Front tyre (Single)

----

400/55-22.5

Front tyre (CTC)

----

340/80 R18

Front tyre (CTS)

----

15.5/80-24

Rear tyres Std.

18.4-30

18.4-30

Type:

Front tyres

Radial/Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

340/80 R18 Radial

140

20

400/55-22.5 (14pr) Flotation

140

20

15.5/80-24 (12pr) Gripster

140

20

18.4-30 (12pr) Gripster

220

32

Refer to page 13 for Hydraulic, Variator

and Drive System Specifications.

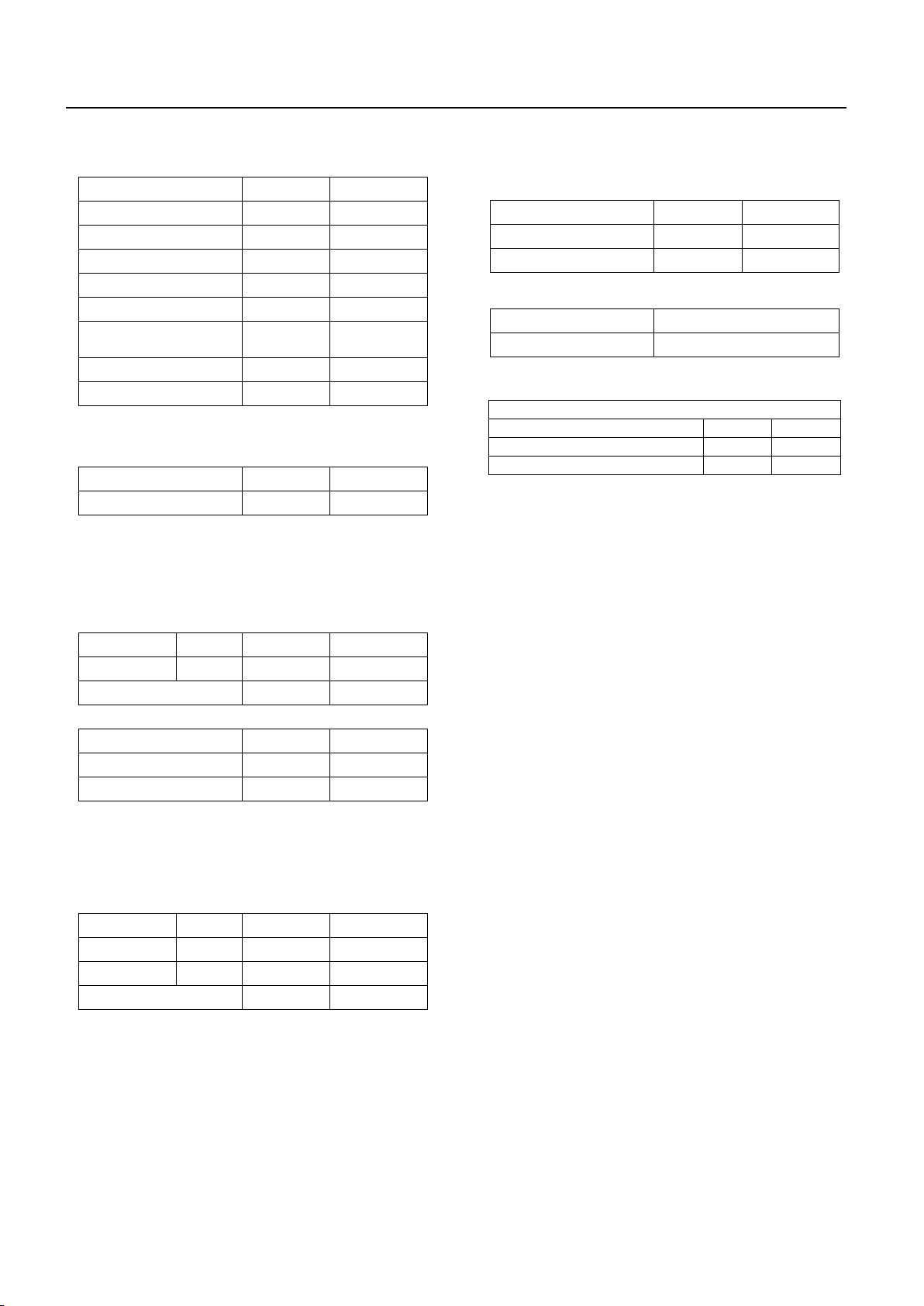

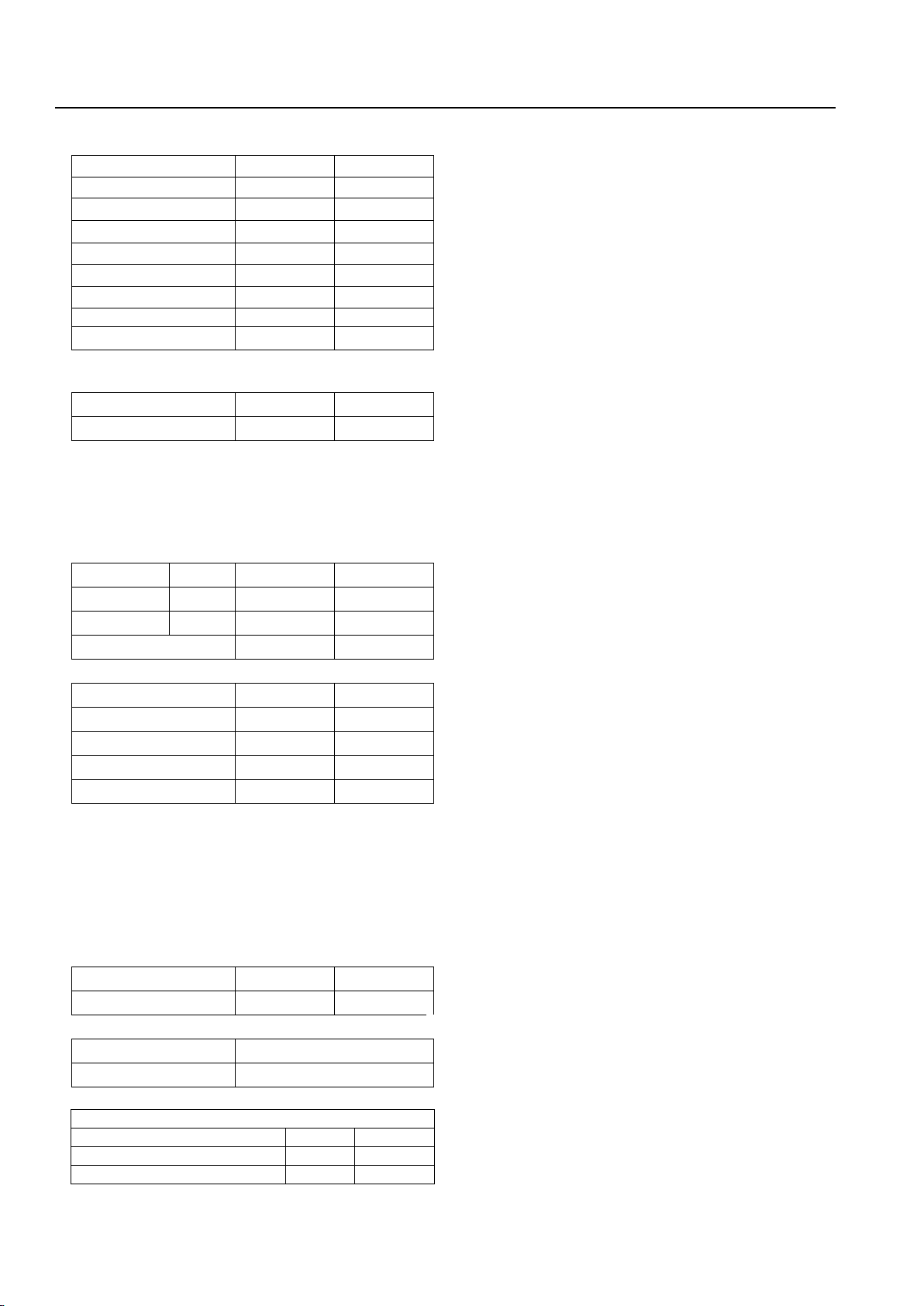

SPECIFICATIONS –1880 SR SERIES

Page 9

10/09

Dimensions

1880FT

1880RT

Overall width

3620

3620mm

Overall height*

2980

2980mm

Top of bin height

2830

2830mm

Overall length^

6375

10,250mm

Seeder length

6375

5870mm

Rear wheel centres

3010

3010mm

Front wheel centres

(dual)

-

650mm

Front wheel centres

(CTS & CTC)

-

3000mm

Step height

530

530mm

Ground Clearance

440

595mm

*Worklight stand folded down. ^Includes hitch but no options

Weights*

Unloaded

2990

2990kg

Loaded

11,400

11,400kg

(material in both bins at 1000kg/1000 litres)

*Weights are for 2 bin models only and excludes Auger and

options.

Bin Capacity 2 Bin

By volume:

Front bin

44%

3600

3600 L

Rear bin

56%

4600

4600 L

Total capacity

8200

8200 L

By weight:

Front bin (wheat)

3060

3060kg

Rear bin (super)

5330

5330kg

Total weight

8390

8390kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Bin Capacity 3 Bin (Non-packed)

By volume:

Front bin

44%

3600

3600 L

Middle bin

24%

1950

1950 L

Rear bin

32%

2650

2650 L

Total capacity

8200

8200 L

Wheels

Size:

1880FT

1880RT

Front tyre (dual)

----

340/80 R18

Front tyre (CTS/CTC)

----

15.5/80-24

Rear tyres

23.1-30

23.1-30

Type:

Front tyres

Radial/Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

340/80 R18 Radial

140

20

15.5/80-24(12pr) Gripster

140

20

23.1-30 (8pr) Gripster

170

25

Refer to page 13 for Hydraulic, Variator and

Drive System Specifications.

SPECIFICATIONS –1890 SR SERIES

Page 10

10/09

Dimensions

1890FT

1890RT

Overall width

3620

3620mm

Overall height*

3160

3160mm

Top of bin height

3000

3000mm

Overall length^

6375

10,250mm

Seeder length

6375

5870mm

Rear wheel centres

3010

3010mm

Front wheel centres

(CTS & CTC)

-

3000mm

Step height

530

530mm

Ground Clearance

440

595mm

*Worklight stand folded down. ^Includes hitch but no options

Weights*

Unloaded

3090

3090kg

Loaded

12,500

12,500kg

(material in both bins at 1000kg/1000 litres)

*Weights are for 2 bin models only and excludes Auger and

options.

Bin Capacity 2 Bin

By volume:

Front bin

44%

4050

4050 L

Rear bin

56%

5150

5150 L

Total capacity

9200

9200 L

By weight:

Front bin (wheat)

3440

3440kg

Rear bin (super)

5970

5970kg

Total weight

9410

9410kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Bin Capacity 3 Bin (Non-packed)

By volume:

Front bin

44%

4050

4050 L

Middle bin

25.5%

2360

2360 L

Rear bin

30.5%

2850

2850 L

Total capacity

9260

9260 L

Wheels

Size:

1890FT

1890RT

Front tyre (dual)

----

Not available

Front tyre (CTS/CTC)

----

15.5/80-24

Rear tyres

23.1-30

23.1-30

Type:

Front tyres

Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

15.5/80-24(12pr) Gripster

140

20

23.1-30 (8pr) Gripster

170

25

Refer to page 13 for Hydraulic, Variator and

Drive System Specifications.

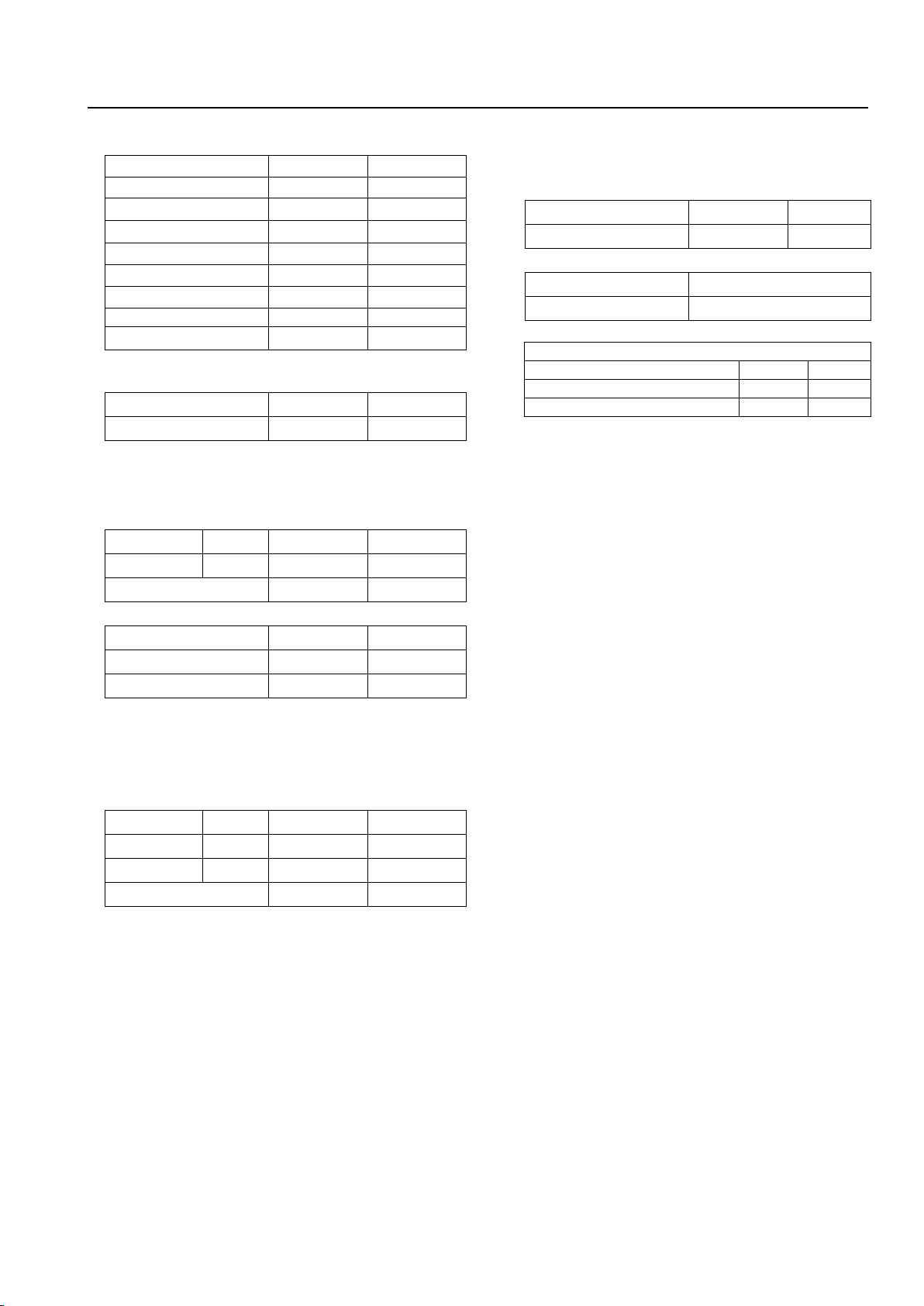

SPECIFICATIONS –2120 SR SERIES

Page 11

10/09

Dimensions

2120FT

2120RT

Overall width

4010

4010mm

Overall height*

3415

3415mm

Top of bin height

3305

3305mm

Overall length^

7245

11,200mm

Seeder length

7245

7020mm

Front wheel centres

-

3000mm

Rear wheel centres

3240

3240mm

Step height

540

540mm

Ground Clearance

380

595mm

*Worklight stand folded down. ^Includes hitch but no options.

Air Seeder Weight*

Unloaded

4400

4700kg

Loaded

16,800

17,375kg

(material in all 3 bins at 1000kg/1000 litres)

*Weights for 3 bin model not including an Auger

Bin Capacity 2 Bin

By volume:

Front bin

44%

5500

5500 L

Rear bin

56%

6900

6900 L

Total capacity

12,400

12,400L

By weight:

Front bin (wheat)

4675

4675kg

Rear bin (super)

8000

8000kg

Total weight

12,675

12,675kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Bin Capacity 3 Bin (Non-packed)

By volume:

Front bin

43.5%

5500

5500 L

Middle bin

25%

3150

3150 L

Rear bin

31.5%

3950

3950 L

Total capacity

12,600

12,600L

Wheels

Size:

2120FT

2120RT

Front tyre (quad)

----

18.4-30

Rear tyres

30.5L-32

30.5L-32

Type:

Front tyres

R1 Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

18.4-30 (8pr) Gripster

140

20

30.5L-32 (12pr) Gripster

180

26

Refer to page 13 for Hydraulic, Variator

and Drive System Specifications.

SPECIFICATIONS –2120 LQ SERIES

Page 12

10/09

Dimensions

2120FT

2120RT

Overall width

4010

4010mm

Overall height*

3415

3415mm

Top of bin height

3305

3305mm

Overall length^

7245

11,200mm

Seeder length

7245

7020mm

Front wheel centres

-

3000mm

Rear wheel centres

3240

3240mm

Step height

500

500mm

Ground Clearance

380

595mm

*Worklight stand folded down. ^Includes hitch but no options.

Air Seeder Weight*

Unloaded

4350

4800kg

Loaded

18,460

18,910kg

(material in all 3 bins at 1000kg/1000 litres)

*Weights for 3 bin model not including an Auger

Bin Capacity 1 Tank (2 X2500L) & 2 Bin

By volume:(Non-packed)

Front tank

41%

5000 L

5000 L

Middle bin

26%

3150 L

3150 L

Rear bin

33%

3950 L

3950 L

Total capacity

12,100

12,100L

By weight:

Fresh Water Tank

500

500kg

Front tank

6600

6600kg

Front bin (super)

3650

3650kg

Rear bin (wheat)

3360

3360kg

Total weight

14,110

14,110kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

(UAN=1320/1000 litres)

Wheels

Size:

2120FT

2120RT

Front tyre (quad)

----

18.4-30

Rear tyres

30.5L-32

30.5L-32

Type:

Front tyres

R1 Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

18.4-30 (8pr) Gripster

140

20

30.5L-32 (12pr) Gripster

180

26

Refer to page 14 for Hydraulic, Variator

and Drive System Specifications.

SPECIFICATIONS –2150 SR SERIES

Page 13

10/09

Dimensions

2150FT

2150RT

Overall width

4300

4300mm

Overall height*

3700

3700mm

Top of bin height

3590

3590mm

Overall length^

7245

11,200mm

Seeder length

7245

7020mm

Front wheel centres

-

3000mm

Rear wheel centres

3390

3390mm

Step height

580

580mm

Ground Clearance

380

595mm

*Worklight stand folded down. ^Includes hitch but no options.

Air Seeder Weight*

Unloaded

4750

5300kg

Loaded

20,560

20,600kg

(material in all 3 bins at 1000kg/1000 litres)

*Weights for 3 bin model not including an Auger

Bin Capacity 2 Bin

By volume:

Front bin

44%

6700

6700 L

Rear bin

56%

8450

8450 L

Total capacity

15,150

15,150L

By weight:

Front bin (wheat)

5700

5700kg

Rear bin (super)

9800

9800kg

Total weight

15,500

15,500kg

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Bin Capacity 3 Bin (Non-packed)

By volume:

Front bin

44%

6700

6700 L

Middle bin

25%

3800

3800 L

Rear bin

31%

4800

4800 L

Total capacity

15,300

15,300L

Wheels

Size:

Front tyre (quad)

----

23.1-30

Rear tyres

900/60-R32

900/60-R32

Type:

Front tyres

R1 Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

23.1-30 (8pr) Gripster

140

20

900/60-R32 Radial

240

35

Hydraulics

Fan Motor type....... fixed displacement

........................ axial-piston

Connections........... pressure inlet/main

return outlet/case drain

outlet

Hydraulic capacity.. 44.3 I/min. @ 4500rpm

(Ground Drive) (4 outlet meterbox)

............ or 54 l/min. @ 4500rpm

(6 outlet meterbox)

Hydraulic capacity…65 I/min. @ 4500rpm

(VRT Hydraulic) (4 outlet meterbox)

or………75 I/min. @ 4500 rpm

(6 outlet meterbox)

Fan Speed control.. pressure compensated

flow control valve

Filter capacity......... 100 I/m @ 10 microns

absolute med. viscosity

Maximum case

drain pressure........ 5 Bar (72.5 psi)

Maximum motor

pressure................. 350 Bar (5075 psi)

Maximum return

line oil temp............ 90° C max.

Hydraulic fluid ........ Mobil fluid 424 or

equivalent High quality

High VI multigrade

transmission and

hydrostatic tractor oil.

Drive System - (Ground Drive)

Clutch .........................electro-magnetic

Chain .........................½ ASA 40

Sprockets....................Nylon/steel

Bearing

lubrication ...................Mobil HP grease

.............................(general purpose)

Variator –(Ground Drive)

Type............................Stepless variable

speed

Oil .............................Mobil Delvac 1240 D

or SAE 40 motor oil

Oil capacity.................1.27 litres

(level with centre of top shaft)

SPECIFICATIONS –2150 LQ SERIES

Page 14

07/13

Dimensions

2150FT

2150RT

Overall width

4300

4300mm

Overall height*

3700

3700mm

Top of bin height

3590

3590mm

Overall length^

7245

11,200mm

Seeder length

7245

7020mm

Front wheel centres

-

3000mm

Rear wheel centres

3390

3390mm

Step height

580

580mm

Ground Clearance

380

595mm

*Worklight stand folded down. ^Includes pull but no options.

Air Seeder Weight*

Unloaded

4850

5400kg

Loaded

18,950

19,500kg

(material in all tanks/bins at 1000kg/1000 litres)

*Weights not including an Auger

Bin Capacity 1 Tank (2x2500L) & 2 Granular Bins

By volume:(Non-packed)

Front tank

37%

5000

5000 L

Middle bin

28%

3800

3800 L

Rear bin

35%

4800

4800 L

Total capacity

13,600

13,600L

By weight:

Fresh Water Tank

500

500kg

Front tank

6600

6600kg

Middle bin (super)

4400

4400kg

Rear bin (wheat)

4080

4080kg

Total weight

15,580

15,580kg

(UAN=1320/1000 litres)

(wheat = 850kg/1000 litres

(super = 1160kg/1000 litres)

Wheels

Size:

2150FT

2150RT

Front tyre (quad)

----

23.1-30

Rear tyres

900/60-R32

900/60-R32

Type:

Front tyres

R1 Gripster

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

23.1-30 (8pr) Gripster

140

20

900/60-R32 Radial

240

35

Hydraulics

Fan Motor type........fixed displacement

........................ axial-piston

Connections............pressure inlet/main

return outlet/case drain

outlet

Hydraulic capacity…

Blower………………(VRT Hydraulic)

max.75 I/min. @ 4500 rpm

(6 outlet meterbox)

Plus

Liquid Pump Drive….30 I/min. @ 500 rpm

(on separate circuit)

Total…………………105 I/min. (max.)

Fan Speed control ..pressure compensated

flow control valve

Filter capacity..........100 I/m @ 10 microns

absolute med. viscosity

Maximum fan case

drain pressure.........5 Bar (72.5 psi)

Maximum fan motor

pressure..................350 Bar (5075 psi)

Maximum return

line oil temp ............90° C max.

Hydraulic fluid.........Mobil fluid 424 or

equivalent High quality

High VI multigrade

transmission and

hydrostatic tractor oil.

Drive System - (VRT)

Meterbox Drive ...........Hydraulic motors

Chain .........................½ ASA 40

Sprockets....................Nylon

Bearing

lubrication...................Mobil HP grease

............................(general purpose)

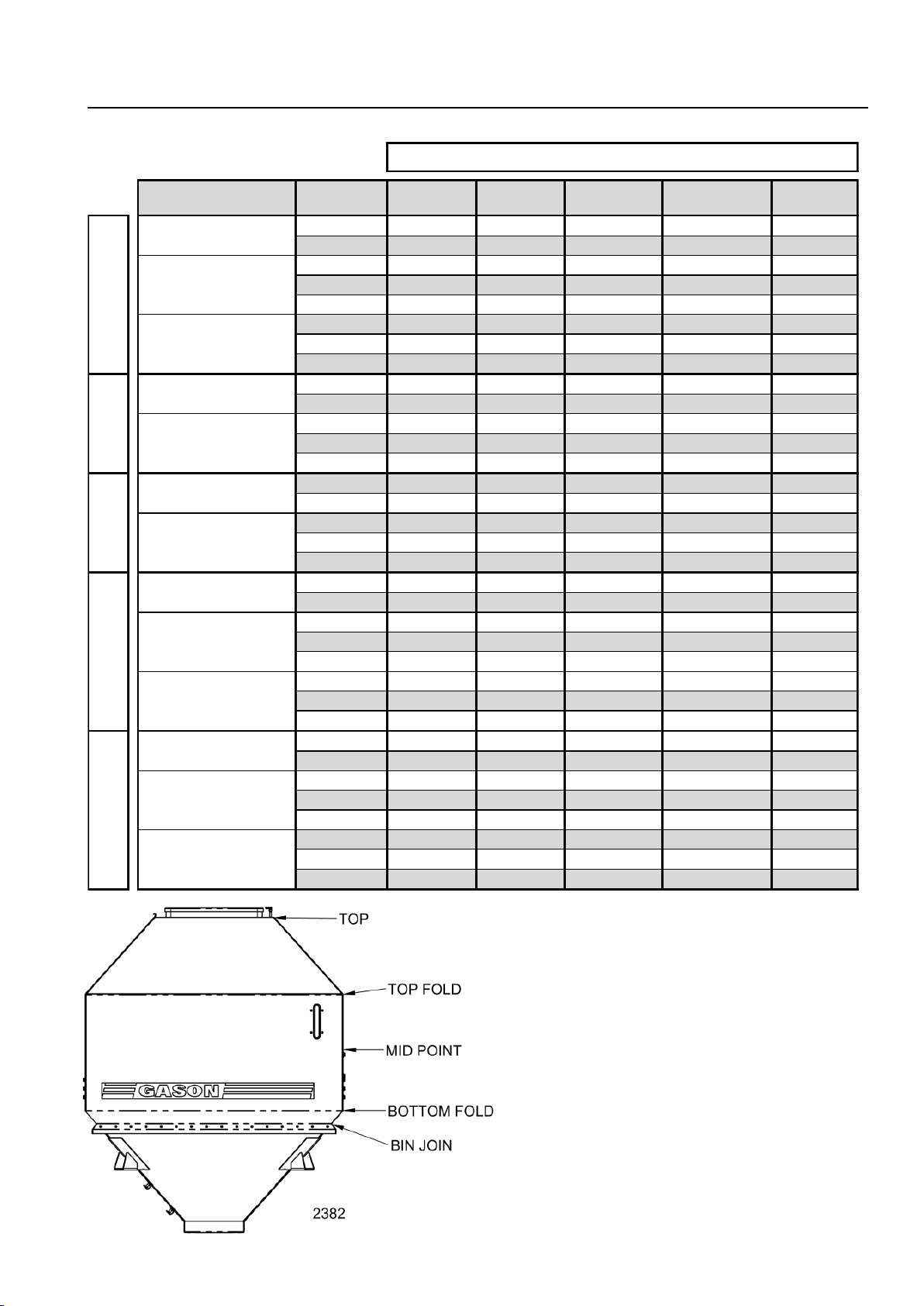

SPECIFICATIONS –LEVEL BIN VOLUME

Page 15

03/12

CONFIGURATION BIN TOP TOP FOLD MID POINT BOTTOM FOLD BIN JOIN

FRONT 2770L 2215L 1456L 700L 535L

REAR 3450L 2783L 1821L 860L 655L

FRONT 2770L 2215L 1456L 700L 535L

MIDDLE 1824L 1404L 923L 442L 340L

REAR 1926L 1506L 1025L 544L 442L

FRONT 2770L 2783L 1456L 700L 535L

MIDDLE 1702L 1282L 862L 442L 340L

REAR 2048L 1628L 1086L 544L 442L

FRONT 3629L 2627L 1848L 890L 517L

REAR 4647L 3410L 2358L 1127L 646L

FRONT 3629L 2627L 1848L 890L 517L

MIDDLE 2099L 1732L 1176L 586L 347L

REAR 27034L 1994L 1335L 692L 450L

FRONT 4064L 3062L 2066L 890L 517L

REAR 5206L 2627L 2638L 1127L 646L

FRONT 4064L 3062L 2066L 890L 517L

MIDDLE 2370L 1842L 1316L 586L 347L

REAR 2987L 2278L 1472L 692L 450L

FRONT 5534L 3766L 2672L 1519L 1005L

REAR 6911L 4744L 3378L 1916L 1263L

FRONT 5534L 3766L 2672L 1519L 1005L

MIDDLE 3177L 2295L 1746L 1049L 719L

REAR 3980L 2695L 1877L 1113L 789L

FRONT 5000L - - - -

MIDDLE 3177L 2295L 1746L 1049L 719L

REAR 3980L 2695L 1877L 1113L 789L

FRONT 6728L 4960L 3287L 1519L 1005L

REAR 8468L 6301L 4156L 1916L 1263L

FRONT 6728L 4960L 3287L 1519L 1005L

MIDDLE 3859L 2984L 2109L 1049L 719L

REAR 4854L 3563L 2293L 1113L 789L

FRONT 5000L - - - -

MIDDLE 3859L 2984L 2109L 1049L 719L

REAR 4854L 3563L 2293L 1113L 789L

2 BIN

3 BIN

(FLAT PANEL)

1+2 BIN (LIQUID)

3 BIN

1+2 BIN (LIQUID)

3 BIN

(DISHED PANEL)

2 BIN

3 BIN

2 BIN

2 BIN

3 BIN

2 BIN

POSITION ON BIN (REFER FIG. BELOW)

3 BIN

1860

1880

1890

2120

2150

Note:

Volumes are for reference only.

Volumes refer to flat water capacity at the

various levels shown. When filling, material

may peak and not flow into rear bin corners.

Volume of 23 L removed from under centre

platform on 2120/50 & 1880/90 to account for

material repose.

Volumes do not include meterbox capacity.

CONVERSION FORMULAE

Page 16

10/09

Useful Conversions –Formulae

LENGTH:

1 km = 0.621371 mile

1 mile = 1.609344 km

1 m = 3.280840 ft.

1 ft = 0.304800 m

1 mm = 0.039390 inch

1 inch = 25.400 mm

SPEED:

1km/h = 0.625 mph

AREA:

1 ha = 10,000 m2= 2.471054 acres

1 acre = 10 sq. chain = 4840 sq. yd. = 0.404685ha = 4840 sq. yd. = 0.404685 ha

1 km2= 0.386102 sq. mile

1 sq. mile = 2.589988 km2

VOLUME:

1 m3 = 35.31476 cu. Ft.

1 cu. ft. = 0.028317 m3

1 L = 0.26418 US gal.

1 US gal. = 3.78531 L

1 UK gal = 1.201 US gal.

1 UK Bushel = 8.00 UK gal. = 1.2843 cu. Ft. = 8.00 U.K. gal. = 1.2843 cu. ft. = 1.2843 cu. ft.

1 L = 0.0274962 UK Bushels

1 UK Bushel = 36.369 L

1 L = 0.0283785 US Bushels

1 US Bushel = 35.2379 L

TORQUE:

1 Nm = 0.7375624 lbft.

1 lbft. = 1.3558175 Nm

FORCE:

1 lbf = 4.4482 N

1N = 0.22481 lbf

PRESSURE:

1 psi = 6.89476 kPa = 0.0689476 Bar

1 kPa = 0.145038 psi = 0.01 Bar

1 Bar = 14.5 psi

MASS:

1 kg = 2.204622 lb

1 lb = 0.453592 kg

1 kg = 1000 grams

POWER:

1 kW = 1.341 hp

1 hp = 745.7 W

DENSITY:

1 kg/m3 = 0.0624 lb/ft3

1 lb/ft3 = 16.0185 kg/m3

APPLICATION RATE:

1 kg/ha = 0.892 lb/acre

1 lb/acre = 1.121 kg/ha

HYDRAULIC HORSE POWER:

1 hp = FLOW (US GPM) x PRESSURE (psi)

1714

MASS FLOW RATE:

kg/min = Application Rate (kg/ha) x Area Rate (ha/hour)

60

lb/min = Application Rate (lb/acre) x Acre Rate (acre/hour)

60

This manual suits for next models

5

Table of contents

Other Gason Seeder manuals