Stara Hercules 10000 Instruction Manual

WARRANTY CERTIFICATE

(CLIENT’S COPY)

DEALERSHIP INFORMATION

CLIENT INFORMATION

PURCHASED UNIT INFORMATION

INVOICE NUMBER:

TECHNICAL DELIVERY DATE: / /

IMPORTANT!

Warranty issues will only be address if this certificate is properly

filled-out at the time of delivery by technician. This certificate must be

presented with every warranty claim, along with the sales invoice.

NAME:

NAME PHONE:

MODEL:

MANUFACTURED DATE:

SERIAL NUMBER:

STAMP AND SIGNATURE:

ADDRESS

:

:

cut and send

TECHNICAL DELIVERY TERMS (self-propelled)

(this form must be completed by the technician and sent to Stara)

INSTRUCTIONS AND DIRECTIVES

TECHNICIAN FUNCTIONS: Machines with variable rate systems:

Technician Functions:

( ) Check general conditions of the machine

(defects, dents and others). ( ) Evaluate all machine sensors positionings.

Note: ( ) verify speed sensor and adjust as needed.

( )lign-up pump with the tractor PTO.

( ) inspect goose-neck coupling pin and secure using ( ) check oil levels.

a cotter-pin.

( ) calibrate the machine.

( ) mount tires and adjust wheel axle widths.

Operator directives regarding:

( ) fixed rate, mount conveyor start-up lever and

adjust spring tension. ( ) general machine lubrication.

( ) verify and mount the left/right disc on its specified ( ) tightening nuts & bolts daily.

side.

( ) proper working speeds.

( ) mount and adjust the header cardan/u-joint.

( ) general machine cleanliness.

( ) check and adjust the slide-gade.

( ) instruction manual, warranty certificate & warranty

( ) level the machine. claims.

( ) deliver the instruction manual.

CUSTOMER DATA:

PURCHASED PRODUCT DATA:

MODEL:

MANUFACTURED DATE:

SERIAL Nº:

NAME: PHONE:

ADDRESS:

TECHNICIAN/DELIVERY AGENT:

INVOICE Nº:

DELIVERY DATE: / /

I:ADDITIONAL INFORMATION

cut and send

We declare that the implement referenced in this document, is being delivered under normal

conditions of use, as described and, with the various adjustments and instructions.

Location______________________________Date, ______ / _______ / _______.

CUSTOMER SIGNATURE TECHNICIAN OR DEALER’S SIGNATURE

Instructions for Warranty Claims

Technical Delivery

A) Stara, claims the right of a Technical Delivery to the original owner/purchaser of the equipment, touching

on the following items like: assembly, adjustments, operations, maintenance and warranty.

B) The owner of the machine should designate one or more operators to be trained.

C) It shall be up to the owner, that all instructions listed in the Operation and Maintenance Manual be adhered

to and be rigorously followed.

D) Maintain the equipment and all respective manuals in a perfect state of conservation, and on a regular

maintenance schedule, thus preserving the right to warranty claims.

Warranty Terms

1) The warranty here expressed is the responsibility of the equipment dealership along with the

owner/purchaser of said equipment. Thus, it is understood, that there is no direct dealings between the said

owner/purchaser and the factory.

2) It is here defined that the first purchaser of the equipment is the DEALERSHIP, and the second ownership

will be here established as the CLIENT.

3) The following conditions are basic and will be that, the dealership will submit to Stara's judgment all

warranty claims.

Warranty

A) Stara guarantees its product “only to” the DEALERSHIP, and for the period of six months, starting on the

day of delivery to the CLIENT, along with the original invoice and warranty certificate, which must be

presented at the time of claim.

B) Stara restricts its responsibility strictly to the terms herewith contained in this warranty, which will become

non-transferable an will terminate automatically, in case of the resale of the equipment by the second owner,

the CLIENT or warranty termination by the CLIENT.

C) The warranty covers exclusively material defects and/or of fabrication defects, being that, labor, freight,

and other expenditures are not covered by the Warranty, for they are the responsibility of the DEALERSHIP.

D) Requested revisions by the CLIENT, even though the equipment is still under warranty, will be subject to

charges.

E) The warranty of parts and components which were replaced, will end herewith the warranty of the

equipment.

F) In cases of warranty service delays, those will not warrant the purchaser the right to indemnity for

damages, or extension of the warranty.

Items Excluded from the Warranty

Not included are such items as: hydraulic oils and lubricants, filters, greases and the like,charges for

roadside assistance or help, on-site assistance and any equipment maintenance or help by Stara

personnel; all these are the responsibility of the purchaser.

Also not inclusive, where applicable, are: tires, inner tubes, electrical and electronic equipment, batteries,

engine, starter motor, alternator, fuel injection pump, these again are not inclusive of Stara's warranty since

they have specific manufacturer's warranty on each of said components.

Other charges or expenses such as: transportation or travel expenses, towing services, material damages

or damages against the owner or his agents , these are the sole responsibilities of the purchaser, until

otherwise proven through the results of investigations done by qualified and certified agents of the state or

government.

Conditions of the

Constant Evolution

HÉRCULES 10000/

STAINLESS

INSTRUCTION MANUAL

AND

PARTS CATALOG

SEEDER & FERTILIZER

TRAILER

STARA S.A. - Agricultural Machinery and Implements Industry

AV. STARA, 519

Não-Me-Toque,RS - Brazil

CEP 99470-000

Phone/Fax:+55 54 3332-2800

e-mail: [email protected]

Home page:

Nov./2010 - Revision 06

www.stara.com.br

TABLE OF CONTENTS

INTRODUCTION..

1 - ...............................................................................................07/08

2 - ......................................................................................................08

3 - TECHNICAL SPECIFICATIONS.........................................................................................09/10

4 - SAFETY INSTRUCTIONS..................................................................................................10/11

5 - .............................................................................................................11/12

5.1 - ..........................................................11/12

5.2 - Tire Pressure....................................................................................................................12

6 - MOUNTINGS AND ADJUSTMENTS..................................................................................13/25

6.1 - Montagem dos Cubos, dos Aros e Pneus no Eixo Rodado...????............................13

6.2 - .......................................................................13/14

6.2.1 - .............................................................................13/14

6.2.2 - .................................................................................14

6.3 - Goose-neck Mounting.................................................................................................15/16

6.4 - ............................................................................................16

6.5 - ...............................................................................16

6.6 - Component Mounting for Specific Configurations........................................................16/20

6.6.1 - Configuration for Powdered products (limestone).................................................17/18

6.6.1.1 - Mounting and adjusting the discs for limestone..............................................17/18

6.6.2 - Configuration for granular products (fertilizer)......................................................18/20

6.6.2.1 - Mounting and adjusting the discs for granular applications............................19/20

6.7 - Adjusting the deflector......................................................................................................21

6.8 - Adjusting the conveyor gear box.......................................................................................22

6.9 - Adjusting the Drive-Wheel and the Conveyor Gear Box................................................23/24

6.10 - Using and adjusting the cardan/drive-shaft.....................................................................25

6.11 -Positioning and adjusting the triple box............................................................................25

6.12 - Optional...............................................................25

7 - .......26

8 - INSTRUCTIONS AND USAGE OF THE CALCULATION SCALE.......................................27/29

9 - FLOW-RATE CALCULATIONS USING THE TRAYS...............................................................29

9.1 - .........................................................................................................................29

9.2 - Required Material.............................................................................................................29

9.3 - Procedure....................................................................................................................29/30

9.4 - Verifying the row distribution and overlap..........................................................................31

9.5 - Verifying product flow-rates..............................................................................................32

9.6 - Adjusting the disc vanes..............................................................................................32/33

9.7 - Adjusting the flow-rates(kg/ha) using the sample collection set...................................33/34

10 - ADJUSTING THE DISTRIBUTION DISCS.......................................................................35/48

10.1 - Adjusting the distribution discs 18-24 - FERTILIZERS................................................35/36

10.2 - Adjusting the distribution discs 18-24 - SEEDS...............................................................37

10.3 - Adjusting the distribution discs 24-36 - FERTILIZERS. ................................................38

10.4 - Adjusting the distribution discs 24-36 - SEEDS...............................................................39

11 - PARTS CATALOG...........................................................................................................40/158

11.1 - .......................40/41

11.2 - .....................................................................................42

11.3 - .......................................................................43

11.4 - ..........................44

11.5 - .................................................................................................................45

11.6 - ..................................................46/47

11.7 - ...................................................48

11.8 - . ..........................................................49

.......................................................................................................................06

MAIN COMPONENTS.........

IDENTIFICATION PLATE..

MAINTENANCE....

.

Wheel axle adjustments(options)..........

Wheel axle adjustments/Width

Wheel axle adjustments/Height

Braking System Adjustments

Conveyor Mounting and Adjustments

Conveyor Mounting and Adjustments/

PROBLEMS, POSSIBLE CAUSES AND/OR SOLUTIONS OF THE HYD.SYSTEM........

Objective.

....

Hércules 10000/S.S. Feeder/Fertilizer Trailer Assembly ....................

Protector Package.....................

Ladder Assembly- Hércules 7000/10000

Minor Deflector Package.......................................................................

Support Stand

Distribution Set; f/ Fertilizers- Hércules 7000/10000

Disc Assembly/Complete - 24-36................................

Disc Assembly 24-36/Right & Left .......................

Filter and oil change of the transmission system

11.9 - ........................50

11.11 - ......................................................52

11.12 - ................................................................................53

11.13 - ... .....................................................................54

11.14 - . ................................................................55

11.15 - D ... ...................................................56

11.16 - .......................................................................................57

11.17 - .......................................................58

11.18 - ..........................................................................59

11.19 - .............................................................................................................60

11.20 - .................................................................................................61

11.21 - ......................................................................62/63

11.22 - ..........................................................64/65

11.23 - ......................................................................66/67

11.24 - ..................................................................................68

11.25 - ......................................................................69

11.26 - .............................................................................................70

11.27 - ..............................................................................................71

11.28 - .....................................................72/73

11.29 - ..................................................................74

11.30 - .....................................................................75

11.31 - ..........................................................76

11.32 - .........................................................................77

11.33 - .........................................................................................78

11.34 - .................................................................................................79

11.35 - .........................................................................................80

11.36 - ..............................................................................................81

11.37 - ...........................................................82/83

11.38 - ..............................................................84/85

11.39 - .........................................................................................86/87

11.40 - ..........................................................................88

11.41 - .........................................................89

11.42 - .....................................................................................................................90

11.43 - .....................................................................................91

11.44 - ...............................................................................92

11.45 - ......................................................................................................93

11.46 - ...................................................................................94/95

11.47 - ................................................................96

11.48 - ......................................................................97

11.49 - ..............................................................................................98

11.50 - ........................................................99

11.51 - ....................................................100/101

11.52 - ..................................................................102/105

11.53 - ..........................................................106/108

11.54 - ..........................................................................109/111

Disc Assembly- 18-24; w/Vane 1

Disc Assembly- 18-24/Complete............................

Disc Assembly 18-24/Right & Left

Fertilizer Deflector Assembly .................

Deflector Adjustment Support Assembly ......

eflector Package ..................................................

Incline Separator Assembly....

Distribution Package f/Limestone- Hércules 10000

Disc/Vane Assembly- f/Limestone......

Chain Package

Load Reducer Package

Conveyor Package- Hércules 10000

BPN Conveyor Transmission Gear Box.........

GF Conveyor Transmission Gear Box

Conveyor Elongating Roller Assy

Conveyor Centralizing Guide Roller Assy

Conveyor Structure Assy

Load Bearing Roller Assy

Conveyor Centralizing Structure-Hércules10000

Main Tank Sealing- Hércules10000/S.S. ....

Main Tank Chassis- Hércules10000/S.S.

Grating Support Brackets- Hércules 10000/S.S.

Brace Package....................................

Slide-gate Package Assy.....

Measurement Scale.....

Distribution Package Assy....

Butterfly Screw Assembly

BPN Triple Transmission Box Assy................

GF Triple Transmission Assy.....................

Conveyor Mounting Assy

Hose Assy- 1/4x7000;90Deg./straight

Fixed Goose-neck Assy.......................................

Hitch Assy

Hydraulic Lift Brake Lever Assy

Fixed Goose-neck Assy/Tandem...

Hitch Assy / Tandem

Adjustable Goose-neck Assy

Fixed Goose-neck Power Transmission Assy

Fixed Goose-neck Drive Gear Support....

Drive Shaft and Hub Assy

Adjustable Goose-neck Power Transmission Assy

Disc Activation Hydraulic System ( Fixed Rate)

Variable Rate System- Hércules 7000

Variable Rate System-Hércules 10000

Variable Rate System- Plus Hércules 7000

Variable Rate System-

Variable Rate System- Standard

Goose-neck Pump Mounting Pckg

Variable Rate Pump Mounting Pckg

Arm / Wheel Axle Pckg- Hércules 10000 Cross...............................

Conveyor Driver Arm Pckg Assy

Adjustable Wheel Axle Assy(2.10 - 2.70m)

0-18/Complete ....................................

11.10 - ........................................51

................................................................102/105

Plus Hércules 10000.........................................................106/108

11.55 - ..............................................................................112

11.56 - ............................................................................113

11.57 - .............................114

11.58 - .................................................................................115

11.59 - .................................................................116

Disc Assembly 18-24/Right & Left; w/Vane 10-18/Complete

11.60 - ..................................................................................................117

11.61 - ....................................................................................118

11.62 - ...........................................................................119

11.63 - ...................................................................................120

11.64 - ............................................................121/122

11.65 - ............................................................................................123

11.66 - ..........................................................................................124

11.67 - ...........................................................................................................125

11.68 - ........................................................................126

11.69 - ............................................................................127

11.70 - ..............................................................................128

11.71 - ............................................................129

11.72 - ...............................................................130

11.73 - ....................................................................................131

11.74 - ........................................................132/133

11.75 - ................................................134/135

11.76 - .....................................................................136

11.77 - ....................................................................137

11.78 - ......................................................................138

11.79 - ....................................................................139

11.80 - ...........................................................................140

11.81 - .........................................................................................141

11.82 - ................................................................................142

11.83 - .....................................................................................143

11.84 - .........................................................................................144

11.85 - Sample Collector Kit (Buckets/Screen/Tray)(Optional)...............................................145

11.86 - ........................................................................................................................146

11.87 - ..................................................................................................147

11.88 - .........................................................................................148

11.89 - .................................................................................149

11.90 - ......................................................................................150/151

11.91 - .......................................................................152

11.92 - .........................................................................153

11.93 - ....................................................................154

11.94 - .........................................................................................155

11.95 - .............................................................................156/157

11.96 - ...................................................................158

11.97 - ....................................................159

11.98 - ..................................................160

11.99 - ........................................................161

11.100 - .....................................................162

11.101 - .....................................................163

11.102 - ......................................................164

11.103 - ................................165

11.104 - ......................................................166

11.105 - 800 /1900/1200 RPM- Hidrodinâmica..........................................167/168

11.106 - 800 RPM- Hidrodinâmica............................................................169/170

11.107 - ........................................................171

11.108 - ..................................................................172

11.109 - .....................................................................173

11.110 - ....................................................................................175

11.111 - ....................................................................................176

Rear Hub/Shaft Assy

Spring/Cylinder Package Assy

Wheel/Axle Drive- Tandem 12.4 x 24

Conveyor Drive Pckg- Tandem

Hydraulic Conveyor Drive Pckg- H.10000

Spring/Cylinder Package

Tandem Package 12.4x24

Hub/Shaft Assy

Tandem Drive/Axle Package-14.9 x 26

BPN Wheel Axle Transmission Box

GF Wheel Axle Transmission Box

Adjustable Tandem Package/ 1.8-2.7-Tire 400

Adjustable Tandem Axle Drive Package-400

Axle w/Flange for Tandem 400

Adjustable Tandem Drive Package- Tire 400

Adjustable Tandem Drive Package- Tire 12/4x24

Drive Gear Mounting Fixture for Tandem

Adjustable Tandem- 1.8-2.7/Tire 12.4x24

Drive Axle/ Adjustable Tandem 12.4x24

Drive Axle w/Flange for Tandem 12.4x24

Height Extender/Adjustable Tandem

Second Stage Ladder Assy

Goose-neck Elongating Bracket

Height Extender Kit for Cotton

Drive Axle Height Extender

Tray Kit

Measurement Vessel

Main Tank Cap/Grating Set

Sample Collector Pckg(buckets)

Row Spreader(Optional)

Upper Box Assy- Hercules 10000/S.S.

Row Spreader for Adjustable Tandem

Wheel Drive Axle with Pneumatic Brakes

Hub/Pneumatic Brake Assy

Pneumatic Brake System Assy

Wheel/Tire Assy- 4.5x8 / 18x8-5-8 (Drive)

Wheel/Tire Pckg- 13x15.5 / 400 / 60-15.5/Right/Left

Wheel/Tire Pckg-W 10x24; 8Ply / 12.4x24/Right/Left

Wheel/Tire Pckg- DW 13x26 / 14.9x26-Right/Left

Wheel/Tire Pckg- DW 20x26 / 23.1x26 -Right/Left

Wheel/Tire Pckg- DW 16x30 / 18.4x30-Right/Left.

Wheel/Tire Pckg-DW 15x34 / 18.4x34-Right/Left.

Wheel/Tire Pckg- DW15x34 / 18.4 / 15x34- for Right/Left Brake

Wheel/Tire Pckg- DW 11x38 / 13.6x38-Right/Left

Simple Pump/

Double Pump/

Adjustable Tandem/l1.8-2.7- Tire 400/ H.10000

Adjustable Tandem Drive Axle Assy- 400

Tandem Drive Pckg- Tire 400/ H.10000

Decals- Hércules 10000/S.S.

Decals,Operational Warnings

INTRODUCTION

You've just become the proud owner of an implement developed and produced with the

highest cutting-edge technology, which had the direct involvement of clients and farmers in its

development.

It is the first spreader made in Brazil, which combines a, rubberized conveyor and an

exclusive self-aligning conveyor belt unit. It is driven by the implement’s tires, which maintain a

constant distribution at any working speeds.

There are two distribution discs, which are product specific for granular or powdered

products, which will provide greater accuracy, uniformity and greater job widths.

Also, available on the main distribution tank is the Chinese Cap, which avoids the

overloading of product and product built-up in the tank chambers, thus contributing to proper

conveyor functionality and uniform distribution.

Additionally, it has a wheel drive train system which allows height adjustment and various

wheel base widths. Thus allowing for the job operations to proceed even after the vegetation has

sprouted or grown, without damaging the harvest. Its distribution main tank is made of Stainless

Steel, which has a high resistance to the distributed corrosive products , guaranteeing the durability

of the equipment.

The Hercules 10000/SS, being used properly and maintaining a scheduled maintenance

program, will have an extended longevity, thus increasing the financial returns of your investment.

So, with that in mind, it is extremely important that the operational manual be read thoroughly, and

should be consulted always when doubts or questions arise.

Stara offers its after-market sales services, to assist you and your dealer, in the hopes of

achieving the highest profitability and yield of your machine.

Note: This manual is available on our website: , and also additional

information on our complete line of products.

STARA – AGRICULTURAL MACHINERY and IMPLEMENTS COMPANY

Não- Me-Toque, RS, Brazil

Dear Customer,

www.stara.com.br

7

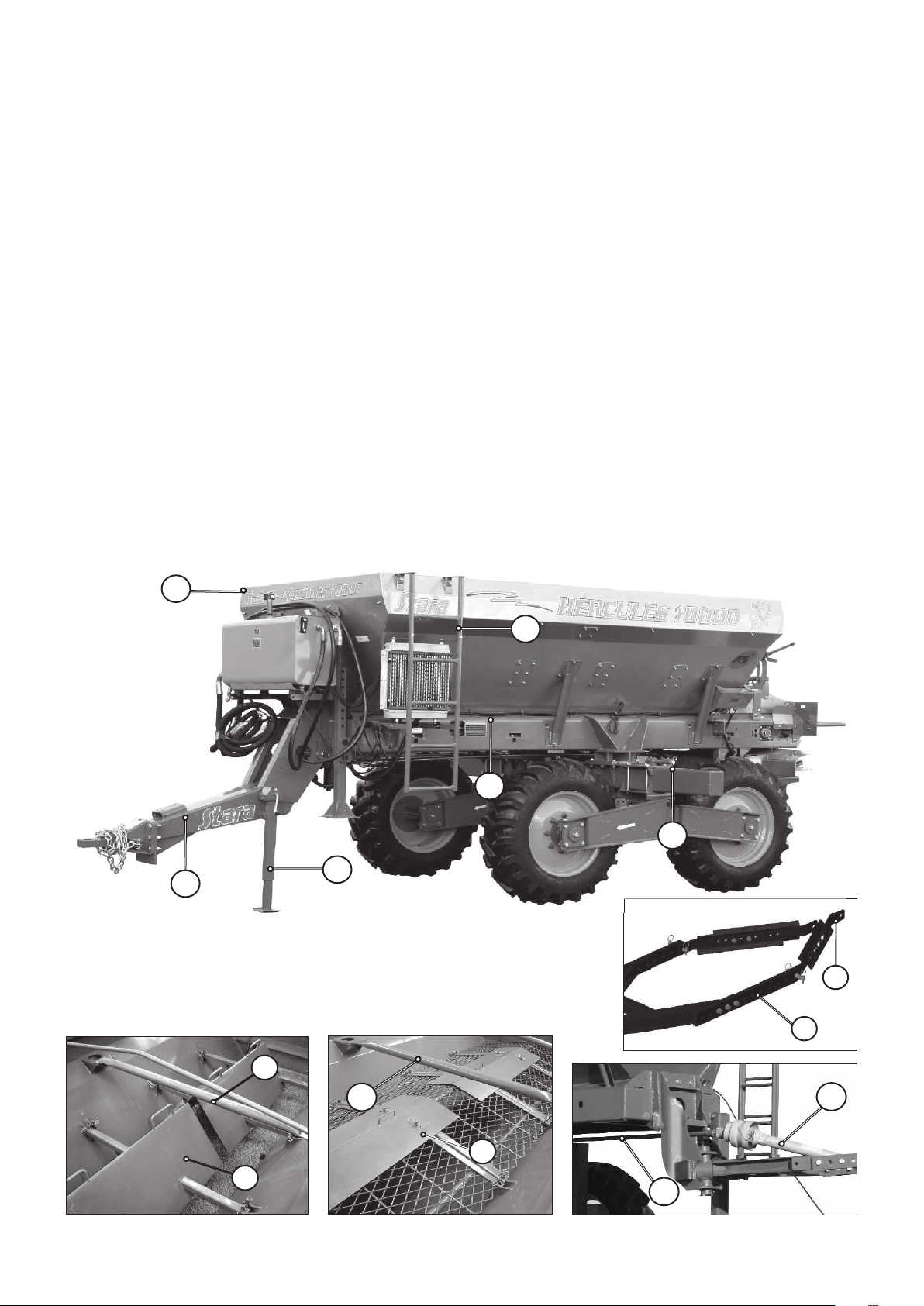

A- Chassis.

B - O -Ladder.

C - Fixed Gooseneck/ hitching arm (optional). P - Main Tank cap for fertilizer (optional).

D - Adjustable Gooseneck/hitching arm(opt.) Q - Deflector for fertilizers.

E - Wheel Axle. R - Chain set for limestone.

F - Conveyor. S - Load reducer for limestone.

G -Conveyor activation lever. T - Tarp support arches.

H - Spring and cylinder(Conveyor activation ). U - Brace.

I - Conveyor activation drive-shaft. V - Transmission.

J - Conveyor Sealing. W - Height extender(optional).

K - Distribution Discs. X - Lifting brake (Adjustable hitching arm ).

L - Distribution unit (transmission gear box). Y - Support stand (Adjustable hitching arm ).

M- Deflector Z - Slide-gate/flood-gate.

N - Tractor drive-shaft. AA- Measurement Scale.

Main Tank.

U

S

Figure 01

X

D

P

T

E

B

CY

A

O

N

V

1 – COMPONENTS

The 10000/Stainless Hercules is equipt with a basic set of components, as shown in figures

01 and 02

8

AA Z

L

K

Q

M

IHF

J

R

Figure 02

W

G

2 – IDENTIFICATION PLATE

The ID plate (Figure 03) shows the model no. of the

machine, weight, serial no., and also the date

manufactured . This information is fundamental in the

traceability of the machine during its life cycle.

Figure 03

MOD.: PESO: kg

Nº

SÉRIE:

FAB.:

MÊS/ANO /

STARA S.A. IND. DE IMPLEMENTOS AGRÍCOLAS

NÃO-ME-TOQUE - RS BRASIL

9

: The é

this rating can be reduced due to operational conditions, and the tires used(see the above item

“Load capacity and Volume”). These limits should be respected for the safety concerns of the

operator and personnel, additionally to extend the life of the equipment.

NOTE H rcules 10000/Stainless chassis was engineered to support up to 10 tons, but,

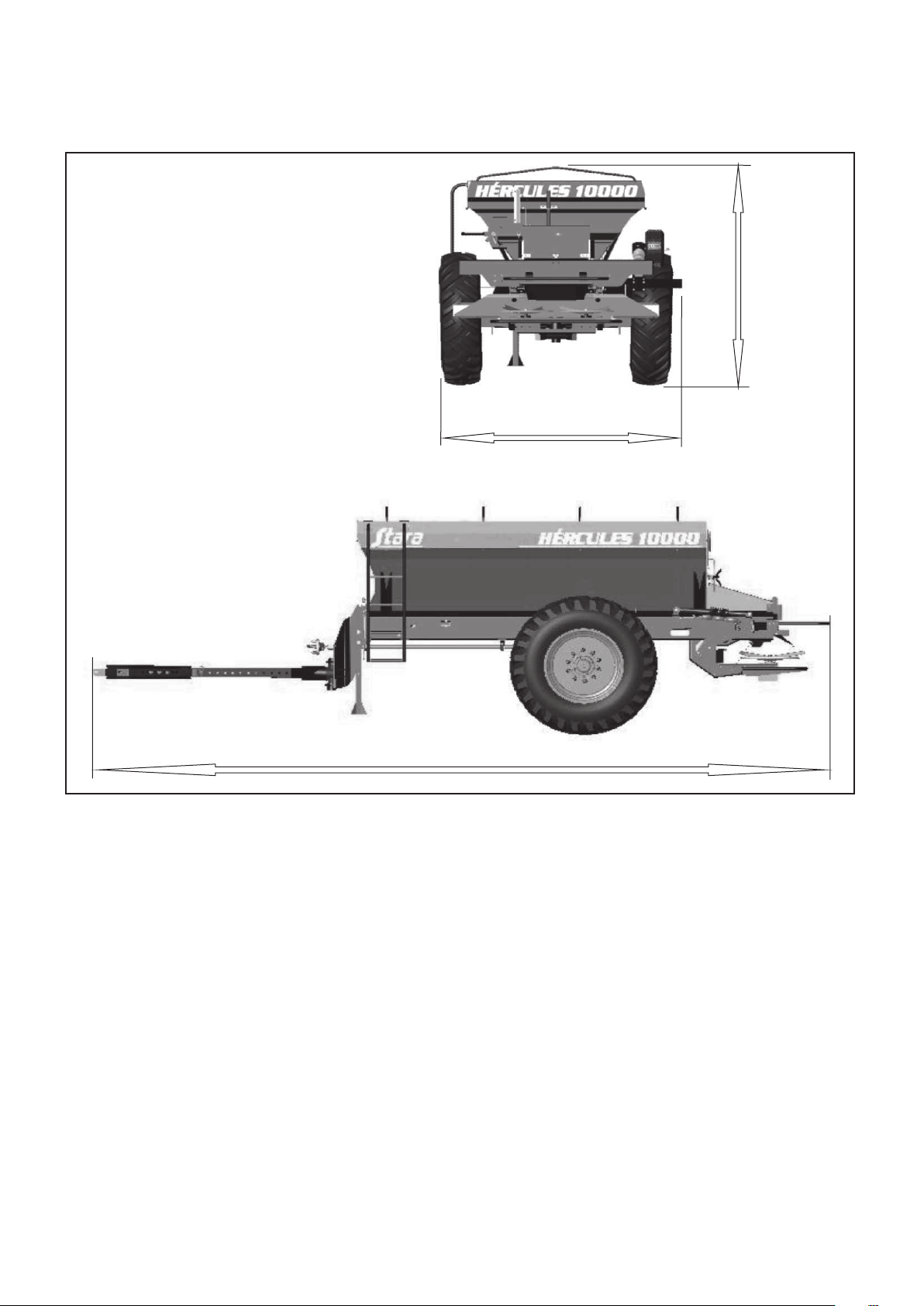

3 - HÉRCULES 10000 STAINLESSTECHNICAL SPECIFICATIONS/

- :Length - w/f : 6,500 mm

- w/adjustable gooseneck/hitching arm: 6,770 mm

ixed gooseneck/hitching arm

- :Height - W/tarp support arches: 2,500mm

- (w/o tires):Width - 1,910mm

- Total weight (w/o tires): - 1,800kg

- Load capacity and Volume - W/standard wheels: 10,000kg or 5,000/l

- W/wheels using options: 5,000kg or 2,500/l

- Output rate: - 13kg/ha to 6,000kg/ha

- Working speeds: - 4km/h to 18km/h

- Power requirements: - Minimum Tractor power rating: 100hp

- Available product Discs: - Discs 18-24 and 24-36, and discs for limestone.

- Distribution width: - Granular Products: up to 36m

- Powdered Products: up to 14m

- Predominant color: - Polyester green

- Wheels/tires: - Wheel 7.00”x8.5” - 5 holes.

- Tire 18”x8.5” - 8ATV MAX (4ply/pressure: 20 lbs/in²)

- Optional:

- Hitches: - Fixed Goose-neck

- Adjustable Goose-neck

- Wheel/tire:

- Cross wheels: (for coverage)

- Wheel- DW 11” x 38”

- Tire- 13.6” x 38”

- Tandem wheels: (adjustable)

- Wheel- W10” x 24”

- Tire- 12.4” x 24’

- Tandem wheels:

- Wheel- DW 13” x 26”

- Tire- 14.9” x 26”

- Transmission: - Cardan/u-joint drive

- Hydraulic actuation

10

6770

2600

2500

Hércules 10000 Stainless with:

- Adjustable Gooseneck

- Tire: TM64/R - 18.4/15-30 - 12PR

3 - (Dimensions)TECHNICAL SPECIFICATIONS/ HÉRCULES 10000 STAINLESS

4 - SAFETY PRECAUTIONS

The Hércules 10000/Stainless Spreader, is like any other piece of equipment, as with any

agricultural implement or machinery, certain precautionary measures are indispensable for the

avoidance of accidents. To do so, follow the these procedures:

- check that the tractor and the spreader are in good working condition;

- check the area around the spreader and the tractor before maneuvering them, so as not to trample

personnel, animals or other objects;

- upon engaging the spreader to the tractor traction bar, or the two hydraulic lift points, place the

engagement locking pin on the coupling gear;

- upon descending with the spreader, use the same required gear to climb(braking motor);

- upon covering the spreader with a tarp, avoid overfilling the main tank, and use the ladder, thus

avoiding any accidents;

- read and follow the instructions on the posted decals of the implement, which will also instruct you

on maintenance issues;

- never go near the drive-shaft while its in operation;

- never go near nor perform any maintenance on discs, without disengaging the PTO;

Figure 04

11

Figure 05

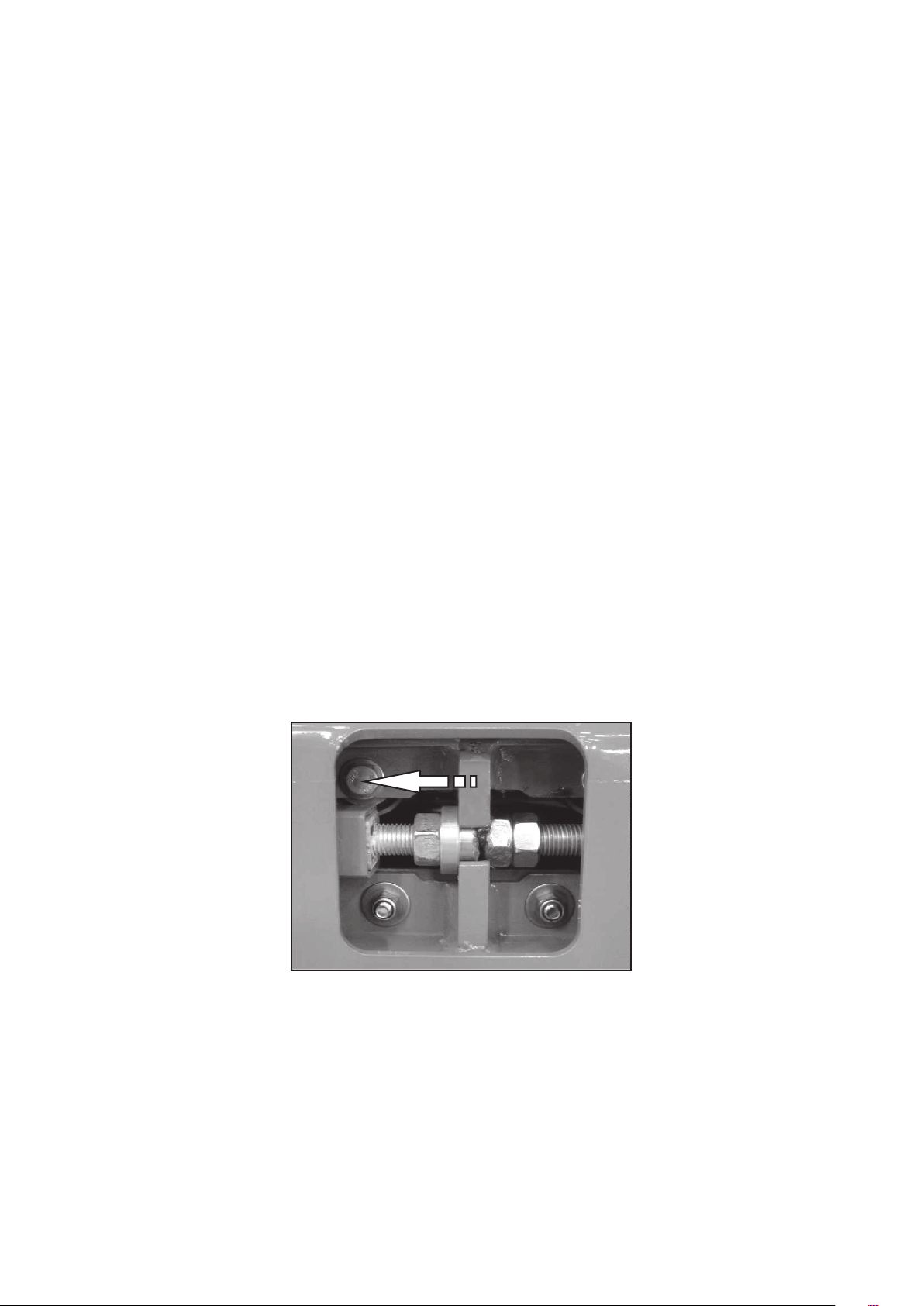

5 - MAINTENANCE

So that all available resources of the implement can be fully appreciated, with durability and

precision in mind, certain precautions should be adhered to:

- Do not allow sharp objects (metallic, rocks and other materials),which could damage the

conveyor belt to mix with the product to be distributed;

- Check for any misalignment of the conveyor belt in relationship to the machine, and/or distension

of the same. The belt uses internal components which maintain it centralized during the job. These

are factory set, and can be damage with excess over-tightening during adjustments (Figure 05) or

poor and careless alignments;

- For prolonged life expectancy and good conveyor belt operations, which are directly related to the

proper use of safety shields/guards to relieve the product load, thus avoiding overloading and

slippage of the same;

- Verify that the conveyor belt rollers are equally spaced thus avoiding product built-up of the same;

- After machine clean-up, be careful not to contaminate the rubber components with oil or similar

products;

- After using the implement, use a high pressure hose to wash it down (be sure not to use chemical

products, which may damage the paint finish of the machine), remove all product residue and bathe

all metalic parts in oil;

- When necessary, touch-up all paint finishes to avoid corrosion of metalic parts.

-do not step on the conveyor while its moving;

- retighten all screws/bolts before using the implement, take special care with the wheel nuts, the

goose-neck engagement and transmission case supports;

- after first 5 working hours, review all nuts and bolts and retighten as needed;

- adopt as a standard procedure to inspect daily all the wheel nuts and bolts and the gooseneck

5.1 - Transmission gear box oil change

Below are the suggested directives for changing the transmission gear box oil :

- The recommended oil for the gear box is the SAE 90 EP(with extreme pressure additives),

available by various manufacturers on the market (using Ipiranga’s Ipergerol EP 90, Ipiranga, or

Castrol’s Maxtron 90EP l).

- Change out the oil regularly (every 500 hrs), check for oil leaks.

- The gear case cannot operate with, low oil level or any contamination.

12

-

axle case- 0.6/l.

- The first time oil change should be done after 50 work hours.

- The gear case has a vent with a dip-stick to monitor the oil levels, which should be refilled when

necessary. On the triple case, the proper oil level line is the midway range of the case, where the oil

level indicator of the container is found.

- Regarding the triple case, when changing out the oil, remove the main oil container of the three

cases, and fill each case with one liter each, which makes up the set, allowing to release of any air

and bathing the whole transmission with oil.

- After harvesting has come to an end, it is recommended to clean all external surfaces of the unit

and to apply oil to contain any corrosion;

- When not in use, the unit should be kept in a covered place, thus avoiding exposure to rain and

solar radiation.

5.2 - Tire air pressure

- Tire, Dw13.6” x 38” ; 14Ply ( Cross wheel)

- 40 lbs/in²

-Tire, 12.4” x 24” ; 10Ply ( Tandem wheel)

-Tire, 14.9” x 26”; 12Ply ( Tandem wheel)

- 34 lbs/in²

The oil quantity of each case is as follows: Triple case - 3/ l; Conveyor belt case - 7/ l;

- 32 lbs/in²

13

Figure 06

6 -MOUNTING AND ADJUSTMENTS

The Hércules 10000/Stainless leaves the factory assembled, with the exception of the

wheel/tire assemblies, the goose-neck and the optional items needed to work with granular or

powdered products.

It is important to note in this manual that certain components need special adjustments, be it

in the application of powdered or granular products.

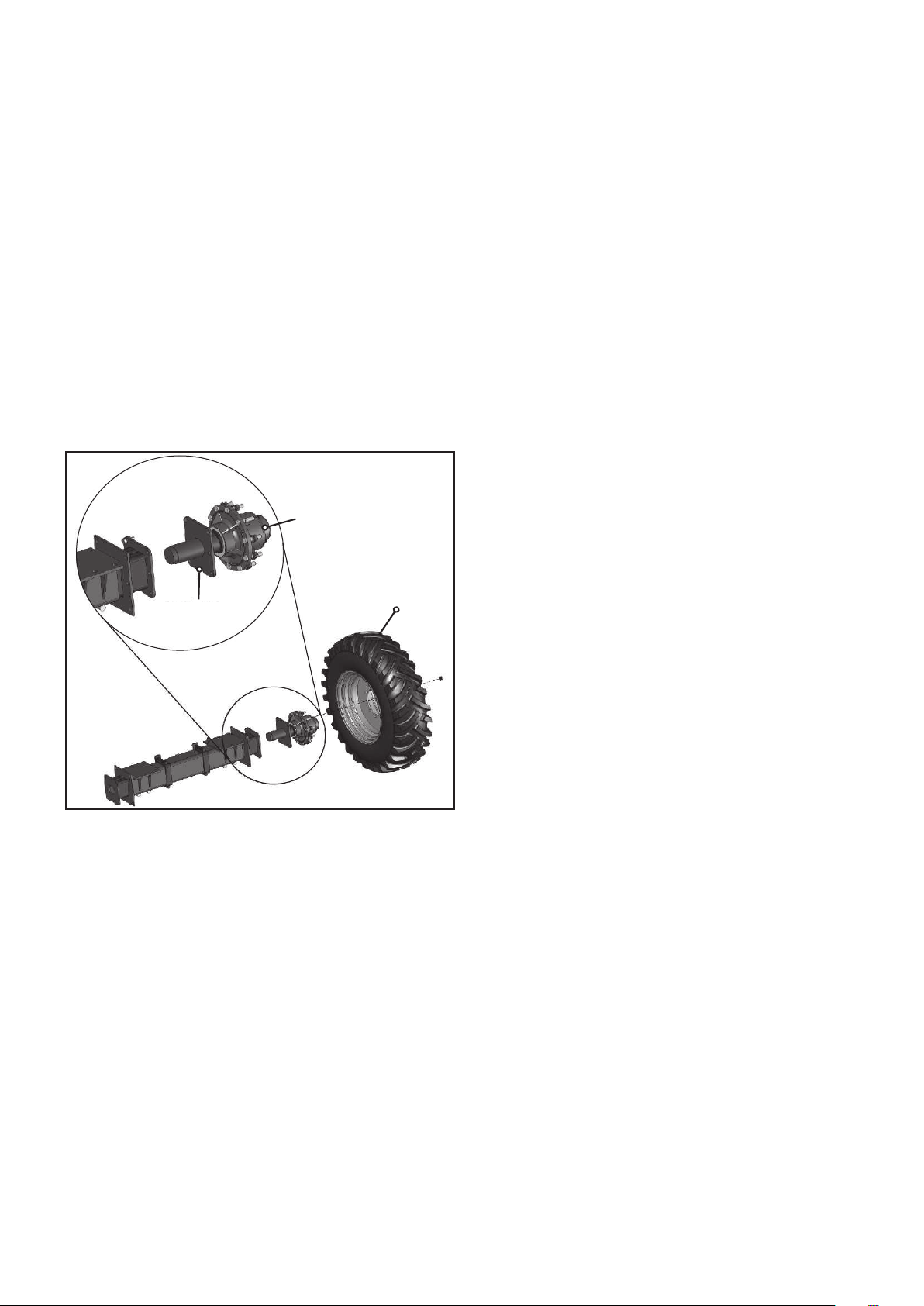

6.1 - Hub/wheel axle mounting

The wheel/tire assemblies come factory ready, thus the only requirement is to align the

mounting holes with the hub screws and to securely tighten them.

In case a height extender is being used (item 6.2.2), it will be necessary to dismount the

HUB/ SH AF T fr om th e WHE EL AXLE

EXTENDER. After re-mounting the hub/shaft, be

sure to mount with the cut side downward

(detailed on Figure 06). Next, tighten the axle

extender screws to the height extenders and the

hub/shaft to the height extender. Finally, tighten

the HUB screws to the WHEELS.

ATTENTION! Securely tighten all wheels

nuts and bolts before starting a job, and re-

tighten after the first work hour.

6.2 - Optional wheel/axle adjustments-

The Hércules 10000/Stainless facilitates the adjustments for the job, with different width

dimensions and 3 height adjustments.

6.2.1 - Wheel/axle width adjustments:

To adjust the wheel axle, place the axle extentions to the desired length and mount the

clamps on the axle, securely tighten the bolts.

There are two options available to adjust the axle width:

1st Option: allows for a wheel base adjustment width between 2,100 to 2,700mm. In its

maximum extended width, do not exceed 5,000 kg of product (figure 07). This still allows for the

hook-up of the height extender kit, as shown on figure 09 of page 14.

HUB

AXLE

CUT POINTED

DOWNWARD

WHEEL/TIRE

14

This manual suits for next models

1

Table of contents