RDA 400S

27.06.2011

ver.2 5

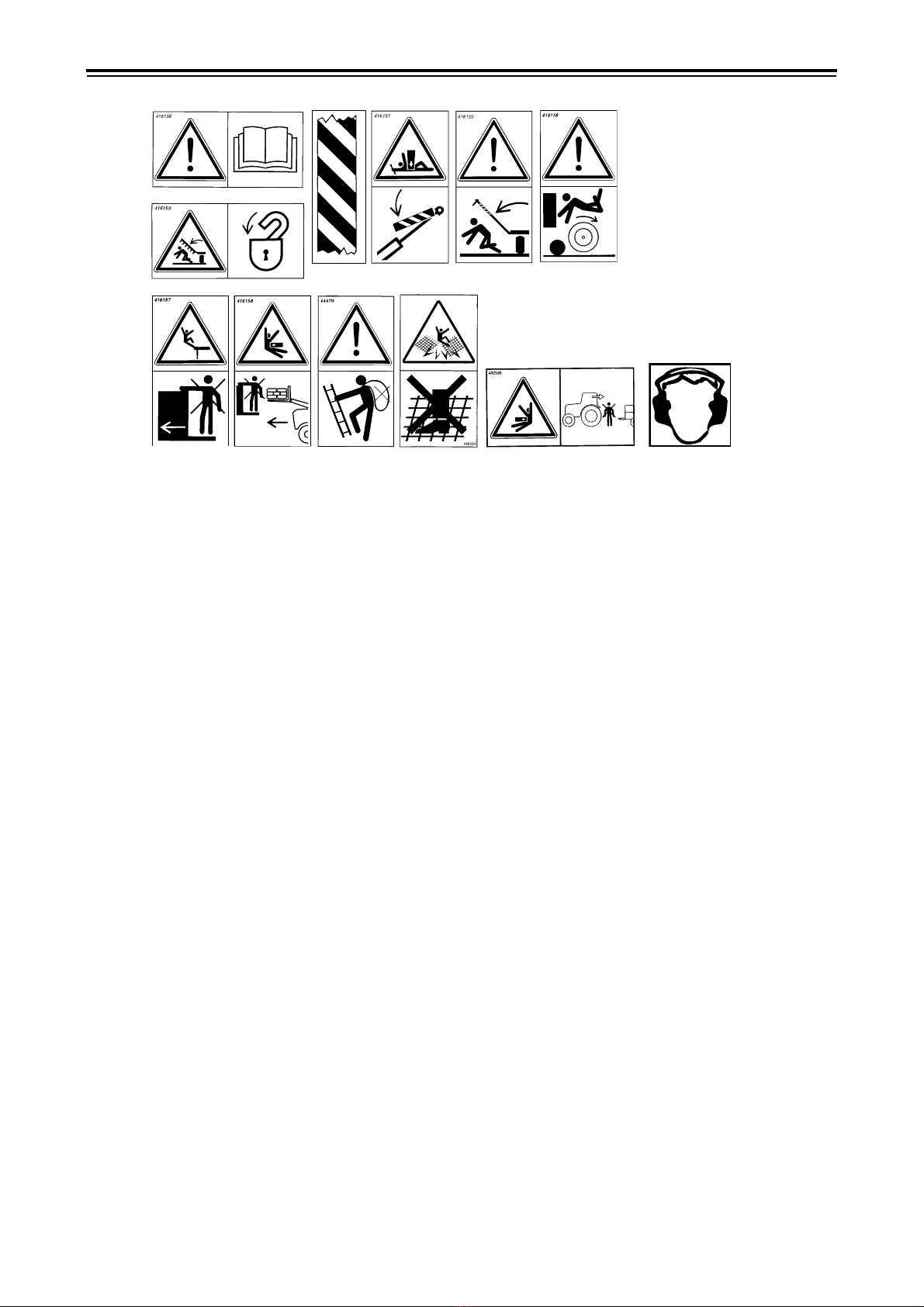

1 Safety regulations

1.1 Before using the drill ............................................................................ 9

1.2 Warning decals ................................................................................. 10

1.3 Location of warning decals on the achine ........................................... 11

1.4 Other safety precautions .................................................................... 12

1.5 Data plates ....................................................................................... 13

1.6 Moving the achine when not hitched to a tractor ................................. 15

2 Installation instru tions

2.1 Installation of the Control Station on the tractor .................................... 17

3 Instru tions and settings

3.1 Tractor ............................................................................................. 18

3.2 Hitching and unhitching the seed drill without an inter ediate packer ...... 19

3.3 Hitching and unhitching the seed drill with an inter ediate packer ........... 21

3.4 Connecting the hydraulic hoses and electrical cables .............................. 22

3.5 Hose length and hose holder adjust ent .............................................. 24

3.6 Wheel retraction echanis (only achines with the hydraulic depth

adjust ent option) ............................................................................ 25

3.7 Changing between transport position and working position ...................... 26

3.8 Horizontal align ent .......................................................................... 28

3.9 Mechanical adjust ent of sowing depth ................................................ 30

3.10 Hydraulic adjust ent of sowing depth (option 15582-) ........................... 31

3.11 Adjusting the wing sections ................................................................ 34

3.12 Adjusting the changeover valve ........................................................... 35

3.13 Adjust ent of the pre-i ple ents ....................................................... 36

3.14 Adjusting the following harrow ............................................................ 38

3.15 Adjusting Low lift height ..................................................................... 39

3.16 Locking the lifting ra s during service .................................................. 39

3.17 Adjusting the seed coulters ................................................................. 40

3.18 Scraper ............................................................................................ 42

3.19 Bout arker adjust ent ..................................................................... 43

3.20 Track eradicators, tines (option) .......................................................... 43

3.21 Track eradicators, Syste Disc ............................................................ 44

3.22 Wing packers (option) ........................................................................ 44

3.23 Setting the radar ............................................................................... 45

3.24 Adjusting the air-flow ......................................................................... 46

3.25 Seed box setting ............................................................................... 47

3.26 Calibration ........................................................................................ 48

3.27 Prior to filling the hopper .................................................................... 53

3.28 E ptying the seed hopper .................................................................. 54

3.29 Operation test ................................................................................... 55

3.30 Control station .................................................................................. 56

3.31 Interactive Depth Control function, IDC (option 15582-) ......................... 67

3.32 Tra lining ........................................................................................ 71

3.33 Adjusting the pre-e ergence bout arker ............................................ 75

3.34 Hydraulic brakes (accessories) ............................................................ 76

3.35 Maintenance of hydraulic brake syste ................................................ 78

3.36 Pneu atic brakes (accessories) ........................................................... 79

3.37 Maintenance of pneu atic brake syste .............................................. 82