Gast 120R User manual

Part No. 6190761 (Rev A)

120R-40M, 120R-40MQ3

2x120R-40MQ6, 2x120R-40M

6190761 | REV A

® Registered Trademark/™ Trademark of JUN-AIR Inc. ©Copyright 2022 JUN-AIR Manufacturing Inc. All Rights Reserved.

WWW

.

JUN

-

AIR

.

COM

ISO 9001 CERTIFIED

A BRAND OF

®

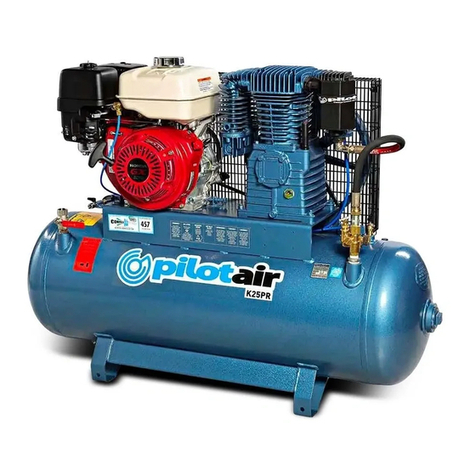

Compressor

A BRAND OF

®

2

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Table of Contents

DB Operating Manual ................................................................................................. 5

DE Betriebsanweisung ............................................................................................... 5

FR Mode d’emploi .................................................................................................... 5

ES Modo de empleo................................................................................................... 5

NL Gebruiksaanwijzing ................................................................................................ 5

DK Betjeningsforskrift ................................................................................................ 5

Technical specifications

Technische Daten

Caracteristiques techniques

Detalles téchnicos

Technische gegevens

Tekniske specifikationer

Diagrams

Zeichnungen

Dessins

Diagramas

Tekeningen

Diagrammer

Spare parts

Ersatzteile

Pieces detachées

Piezas de recambio

Onderdelenlijst

Reservedele

Symbols

Abbildungen

Symboler

3

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

Warranty

Provided that the instructions for operation, maintenance and

service have been carried out, your JUN-AIR compressor is

guaranteed against faulty material or workmanship for 2 years.

The air receiver is guaranteed for 5 years.

The guarantee does not cover damage caused by violence,

misuse, incorrect repairs or use of unoriginal spare parts. Costs

of transportation of parts/equipment are not covered by the

guarantee.

JUN-AIR’s Conditions for Sale and Delivery will generally apply.

JUN-AIR International A/S reserves the right to change technical

specifications/constructions.

DE – Garantie

Vorausgesetzt, dass die Anweisungen für Betrieb und

Wartungerfüllt sind, gewährt JUN-AIR 2 Jahre Garantie bei

Materialoder Fertigungsfehlern.

Auf den Druckbehälter gewährt JUN-AIR 5 Jahre Garantie.

Ausgenommen von Garantieleistungen sind Schäden die durch

Gewalt, falsche Bedienung, nicht fachgerechte Reparaturen oder

durch Verwendung nicht originaler Ersatzteile verursacht wurden.

Transportkosten sind von der Garantie ausgeschlossen.

Es gelten die allgemeinen Geschäfts- und Lieferbedingungen von

JUN-AIR.

JUN-AIR behält sich das Recht von technischen Änderungen vor.

DK – Garanti

Under forudsætning af at alle betjenings- og serviceforskrifter

overholdes, ydes der 2 års garanti for alle materiale- og

fabrikationsfejl.

Dog ydes der 5 års garanti for beholdergennemtæring.

Garantien omfatter ikke skader, som skyldes vold, misbrug,

fejlagtige reparationer eller uoriginale reservedele.

Transportomkostninger er ikke omfattet af garantien.

For Skandinavien gælder i øvrigt NL 92 Salgs- og

Leveringsbetingelser.

JUN-AIR International A/S forbeholder sig retten til ændringer i

tekniske specifikationer og konstruktion.

4

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

SAFETY

Important - read this first!

Please read the following information and operating instructions

included with this product before use. This information is for your

safety and it is important that you follow these instructions. It will

also help prevent damage to the product. Failure to operate the unit

in accordance with the instructions or using JUN-AIR unauthorized

spare parts can cause damage to the unit and could cause serious

injury.

IMPORTANT: General instructions for installation

• If the compressor is not fitted with a supply plug, a circuit

breaker must be incorporated in the fixed wiring.

• If this unit is supplied with a three-pin plug, connect with a

properly earthed outlet only.

CAUTION: To reduce risk of electric shock

• Only authorized service agents should carry out service.

Removing parts or attempting repairs can create an electric

shock. Refer all servicing to qualified service agents.

WARNING: To reduce risk of electrocution

• Do not use this unit with electrical voltages other than stated

on the rating plate.

• Always unplug this unit immediately after use and store in a dry

place.

• Do not use this product in or near liquid or where it can fall or

be pulled into water or other liquids.

• Do not reach for this product if it has fallen into liquid. Unplug

immediately.

• This unit is not weatherproof. Never operate outdoors in the

rain or in a wet area.

DANGER: To reduce risk of explosion or fire

• During spraying with combustible liquids, risk of explosion may

arise, particularly in closed rooms.

• Do not use this product in or near explosive atmospheres or

where aerosol products are being used.

• Do not pump any other gases other than atmospheric air.

• Do not pump combustible liquids or vapours with this product;

do not use it in or near areas with combustible or explosive

liquids or vapours.

• Do not use this unit near open flames.

CAUTION: To prevent injury

• Compressed air can be dangerous; do not direct airflow at

a person’s head or body.

• Always keep the system out of reach of children.

• Never operate this product if it has a damaged power lead or

plug, if it has been dropped or damaged, or if it has fallen into

water. Return the product to a service center for examination

and repair.

• Keep the electrical cable away from hot surfaces.

• Ensure all openings are kept free of restriction, and never

place the motor on a soft surface where the openings may

be blocked. Keep all openings free from dust, dirt and other

particles.

• Never leave this product unattended when plugged in.

• Never insert fingers or any other objects into fans.

• This unit is thermally protected and can automatically restart

when the overload resets.

• Wear safety glasses, when servicing this product.

• Use only in well ventilated areas.

• This product may only be connected to units or tools with a

max. pressure rating higher or equal to that of the compressor.

• The surface of the compressor can get hot. Do not touch

compressor motor during operation.

Failure to observe the safety precautions could result in severe

bodily injury, including death in extreme cases.

IMPORTANT: General directions for use

• Protect compressor against rain, moisture, frost and dust.

• The compressor is constructed and approved for a max.

pressure as stated under Technical Specifications.

• Do not operate the compressor at ambient temperatures

exceeding 40°C/104°F or falling below 0°C/32°F.

• If the supply power lead on the compressor is defective, an

authorized Jun-Air distributor or other qualified personnel

must carry out the repair.

5

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

INSTALLATION

Your JUN-AIR compressor is easy to operate. Observe the

instructions and you will get many years service from your

compressor.

• Visually inspect unit for shipping damage, contact your supplier

immediately if you think the unit may have been damaged.

• Check that the performance of the compressor matches the

actual air consumption, please refer to Technical Specifications.

• Check that the rating plate of the compressor corresponds with

the electrical voltage offered and check that fusing is adequate.

Placing

Place the compressor in a dust-free, dry and cool, yet frost-free room.

Sufficient cooling from the surroundings is important.

• Ambient temperature: 0°C to 40°C, 32°F to 104°F

• Relative humidity: Max 90%

Mount the two distance bolts (1) on the back of the cabinet to ensure

sufficient ventilation.

Installation

• Mount the drain bottle (2) visibly outside the cabinet and mount

the hose at the back of the cabinet (3).

• Connect the cable at the back of the cabinet (5).

• Plug the compressor into a standard outlet switch.

• Connect equipment at the back of the cabinet (4).

• The front wheels are delivered with brakes. Brake the wheels

before starting the compressor (6).

Thermo Switch

The fans are controlled by a Stego thermo switch adjusted to 30°C

from the factory – do not alter this setting. Check that the setting is

correct and adjust if necessary.

The fans will start when the temperature inside the cabinet exceeds

30°C and will run continuously until the temperature drops below

30°C.

6

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

OPERATION

• If the compressor has been stored at an extremely low

temperature, allow it to heat to room temperature before

switching it on.

• The cut-in and cut-out pressure is preset from the factory and

it is normally not necessary to change this. However, if it is

necessary to change the preset settings, the instructions of this

manual shall be followed carefully.

• All AC compressors are designed for 100% duty, but 50%

operation is recommended to prolong the lifetime.

• The fans on the back of the cabinet will start when the

temperature exceeds 30°C. It will run continuously even if the

compressor may have switched of until the temperature is below

30°C again.

• Do not lubricate the oil-less motor with oil, as it will destroy

important components.

Start

Start the compressor by pressing the green button.

The green lamp for compressor in operation is now

alight.

Read the outlet pressure on the pressure gauge.

Adjust the pressure on the regulator.

Read the receiver pressure on the pressure gauge.

The green lamp is alight when the fans are in operation.

Read on the hour counter the elapsed service time.

If the compressor does not start, there might be pressure in

the receiver. The compressor will automatically start when the

pressure drops.

The compressor will automatically stop when the preset cut-out

pressure is reached.

Stop

Turn off the compressor by pushing the green button.

The green light for compressor in operation switches off.

7

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

MAINTENANCE

To ensure a long lifetime of the compressor, it is important that

inspection and maintenance is carried out regularly as described in

the following.

Read the elapsed operation time on the hour counter.

Opening of cabinet

Turn the four () locks clockwise with a screwdriver or sim. to

open the cabinet.

Preventive maintenance

Activity Weekly Monthly

One a year,

or every

2000 hours

aDrain condensate •

bCheck filter regulator •

cCheck for leaks •

dClean the unit •

eCheck safety valve •

fCheck inlet filter •

gCheck non-return

valve •

hCheck fans •

iCheck dryer •

a) Drain condensate

If drain bottle is installed, empty when necessary. ().

b) Check outlet filter

Check and change the filter and filter element in accordance with

the instructions in ”Installation and maintenance instructions” for

the filter in question.

c) Check for leaks

Check motor, hoses and equipment for leaks. Check the pumping

time.

d) Clean the unit

Clean the unit when needed with a soft, damp cloth. If necessary,

use paraffin to remove adhesions. Dust and dirt prevent cooling.

e) Check safety valve

Check the safety valve with pressure in the receiver. The safety valve

is operated by pulling the ring (1) or turning the screw (2) depending

on the valve type.

f) Check intake filter

Check the intake filter and change it if necessary.

g) Check the non-return valve

Turn off the compressor on the mains switch and pull out the

plug.

Empty the receiver for compressed air by operating the safety

valve. When the receiver is empty, the reading of the pressure

gauge is bar.

Dismount the non-return valve from the receiver.

8

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Disassemble the non-return valve and remove the O-ring () part

no. from the piston.

Clean the non-return valve.

Mount a new O-ring and re-assemble the non-return valve.

Re-install the non-return valve.

h) Check the fans

Check that the fans at the back of the cabinet work. They

will start when the temperature exceeds °C and will run

continuously until the temperature falls below °C.

i) Check dryer

If a dryer is installed refer to the operating manual for the dryer.

Please note that all service must be carried out by a qualified

person.

Adjustment of pressure switch

The working presure has ben preset from the factory, and it is

normally not necessary to change this.

However, if it is necessary to change the preset settings, the

instructions mentioned below should be followed carefully.

Warning

The compressor is constructed and approved for a max.

pressure as stated under Technical Specifications - do not

adjust to a higher pressure.

Higher working pressure will reduce the lifetime of the

compressor.

The compressor will stop at max. pressure (stop pressure) and

start again at min. pressure (start pressure). The difference

between max. and min. pressure is the differens pressure.

Unscrew the lid of the pressure switch. Adjust max. pressure

adjusting the two springs marked A (clockwise: higher pressure).

Adjust the two springs identically.

Adjust the differens pressure adjusting the spring marked B

(clockwise: higher differens pressure, start pressure maintained).

Test of pumping time

The pumping time indicates the condition of the compressor.

. Check that there are no leaks in the system.

. Empty the air receiver of compressed air so that the

pressure gauge shows bar.

. Close the filter regulator and check that the drain valve is

closed.

. Start the compressor and note the time it takes until it is

turned off again by the pressure switch. Check that the

pumping time agrees with the technical specifications for

the actual compressor system.

Please note that the pumping time in this manual is given for to

max pressure. Deviations from this result in deviating results.

Important

Always test the pumping time when cold. If the compressor is

warm, the pumping time will be considerably longer.

FAULT FINDING AND REPAIR

Important

Switch off and isolate from electrical supply before removing

any parts from the pump. Empty air receiver of air before

performing any operation on the compressors’ pressure

system.

1. Compressor does not start

a. The air receiver is pressurized. The motor will start when

the pressure has dropped to the preset start pressure.

Empty the receiver.

b. Check that the mains supply agrees with the motor

label.

c. No power from mains. Check fuses and plug.

d. Bad connection or broken cable.

e. The motor is overheated and the thermal protection

has switched it off. When cooled the motor will turn on

automatically. Go to section .

f. The compressor has not been unloaded and there

is back pressure on the piston. Ensure that the

compressor is unloaded each time it stops.

g. The motor is blocked.

h. Defective capacitor.

2. The compressor makes a buzzing sound but does not start

a. Leaky non-return valve. Dismount the pressure pipe and

check if air leaks from the non-return valve. Clean and

replace.

b. The motor is blocked.

9

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

3. The compressor runs but the pressure does not increase

a. Intake filter clogged. Replace.

b. Non-return valve is clocked. Clean or replace.

c. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

d. Check the piston gaskets. Replace if necessary.

e. Defective valve plate. Contact your JUN-AIR distributor.

4. The motor gets very hot

a. The ambient temperature is too high. If the motor is

installed in a cabinet, sufficient ventilation must be

ensured.

b. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

c. The compressor is overloaded.

5. The compressor runs even if no air is tapped

a. Leaks in fittings, tubes or pneumatic equipment. Check

with soapy water or by letting unit stay over night

disconnected from mains. Pressure drop should not

exceed bar.

6. The compressor does not start at min pressure or does not

stop at max pressure.

a. Defective pressure switch. Replace.

PRESSURE VESSEL

Pressure tested at 4-25 litre 24 bar

40-50 litre 18.3 bar

Directions for use

Application Receiver for compressed air

Receiver specifications See name plate

Installation Tubes, etc. must be installed with

suitable materials

Placement

Observe the working temperature of

the receiver

Ensure sufficient room for

inspection and maintenance

The receiver must be kept in a

horizontal position

Corrosion protection

The surface treatment must be

maintained as required

Internal inspection at least every

five years

Drain condensate at least once a

week

Alternation/repair No welding must be made on

pressurized parts

Safety valve

Ensures that PS will not be

exceeded

Never adjust to a higher pressure

than PS

The capacity of the valve must

be calculated in accordance with

teh volume of air supplied by the

compressor

PS - Maximum working pressure of

the receiver

10

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Technical Data & Specifications

Specifications 120R-40M 120R-40MQ3 2x120R-40M 2x120R-40MQ6

Tank size liter 40 40 40 40

U.S. gallon 10.6 10.6 10.6 10.6

Weight kg 111 116 152 169

lbs 245 256 335 373

Dimensions

(LxWxH)****

mm 720 x 650 x 860 720 x 780 x 860

in 28.0 x 25.5 x 34.0 28.0 x 30.5 x 34.0

Pumping time @ 50 Hz 90 sec. 96 sec. 52 sec. 80 sec.

@ 60 Hz 78 sec. 88 sec. 45 sec. 65 sec.

Noise level @

1 m

@ 50 Hz 66 dB(a) 66 dB(a) 69 dB(a) 69 dB(a)

@ 60 Hz 69 dB(a) 69 dB(a) 72 dB(a) 72 dB(a)

Technical modifications reserved.

11

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

English German French Spanish Dutch Dansk

Voltage Spannung Voltage Voltaje Voltage Spænding

Frequency Frequenz Fréquence Frequencia Frequentie Frekvens

Power Motor HP Moteur CV Motor CV Motor HP Effekt

Displacement Ansaugleistung Débit Aire aspirado Capaciteit Ydelse

Max. pressure Max. Druck Pression de service

max.

Presión de régimen

máx.

Max. druk Max. driftstryk

Max. current Stromverbrauch Consommation Corriente máxima Max. stroom Strømforbrug

Tank size Behältervolumen Volume réservoir Volumen de tanque Tankvolume Beholderstørrelse

Weight Gewicht Poids Peso Gewicht Vægt

Dimensions

(l x w x h)

Abmessungen

(l x b x h)

Dimensions

(l x p x h)

Dimensiones

(l x a x h)

Afmetingen

(l x w x h)

Dimensioner

(l x b x h)

Noise level Schallemissionen Niveau sonore Nivel de ruido Geluidsniveau Lydniveau

Pumping time Pumpzeit Temps de refoule-

ment

Tiempo de bombeo Pomptijd Oppumpningstid

Neutral is required Null-leiter ist er-

forderlich

Neutre nécessaire Neutro necesairo Neutraal noodza-

kelijk

Nul-leder kræves

Available for opera-

tion at a maximum

pressure of 10

barg/145 psig upon

request. Please

note that operation

at higher pressure

will influence the

life time.

Auf Anfrage er-

hältlich bis zu einem

Betriebsdruck

von max. 10 bar.

Höherer Druck hat

Auswirkungen auf

die Lebensdauer.

Kan leveres til max.

driftstryk på 10 bar.

Bemærk at øget

driftstryk reducerer

levetiden.

Displacement is

reduced by approx.

18-20% on units

with dryer (D).

Min. pressure

required to operate

dryer: 6 bar.

Bei Kompressoren

mit Adsorption-

strockner reduziert

sich die effektive

Luftliefermenge um

18-20% (D). Mind-

estarbeitsdruck für

den Lufttrockner

beträgt 6 bar

Le débit est réduit

de 18-20% pour les

unités avec sécheur

d’air (D) Pression

min. 6 bar

Le capacidad se

reduce con 18-20%

para las unidades

con secador de aire

(D)

Bij systemen

met droger is de

capaciteit ca. 18-

20% lager (D). Min.

benodigde druk

voor de droger: 6

bar

Ydelsen reduceres

med ca. 18-20% på

kompressorer med

tørrer (D). Min. tryk

til drift af tørrer: 6

bar

3-phase units are

approx. 100 mm

wider than 1-phase

units

3 phasige Anlagen

ca. 100 mm breiter.

3-fasede anlæg er

ca. 100 mm bredere

end 1-fasede anlæg.

Technical modifica-

tions reserved.

Technische Änder-

ungen vorbehalten

Droits réservés

pour modifications

techniques

Reservamos el

derecho a cambiar

estas especifica-

ciones técnicas sin

previo aviso

Technische wijzigin-

gen voorbehouden

Ret til ændringer

forbeholdes

Translations

12

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Performance Curves

13

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

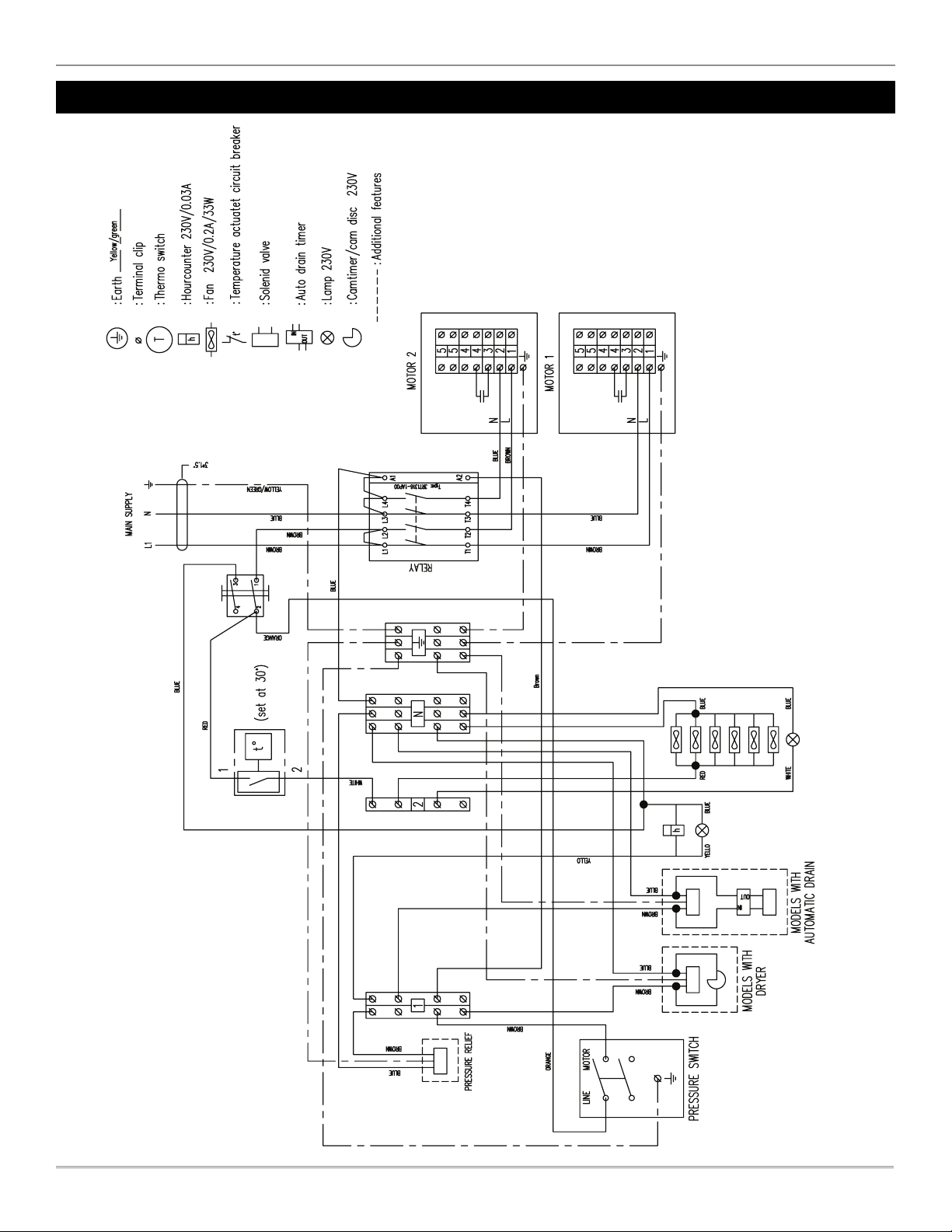

Electrical Drawing Model R-M and R-MQ, V// Hz

14

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Electrical Drawing Model xR-M, xR-MQ, V// Hz

15

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

Compressor system

R-

PM-

NNX

Compressor

Receiver, l silver w/inspection plug internally coated for metal

cabinet ASME

Receiver l with inspection plug f/metal cabinet, silver

Receiver l for metal cabinet w/inspection plug silver internally

coated CE/ASME

Filter um w/automatic drain, complete

Regulator R--RNMG, bar

Panel ring f/regulator and filter regulator

Dryer complete xOF & OF OX Bar

Dryer complete xOF & OF OX Bar

Dryer complete OF C-D type OX Bar

Dryer complete OF C-D type OX Bar

Dryer complete xOF D-D type OX Bar

Dryer complete xOF D-D type OX Bar

Rapid fitting /” internal x Ø mm

Rapid fitting /” external x Ø

Rapid fitting elbow /”xØ

Rapid fitting elbow /”internal x Ø

Rapid fitting elbow /” int. x Ø

Rapid fitting elbow /”xØ

Rapid fitting elbow /”xØ

Rapid fitting /” x Ø

Rapid fitting elbow /”xØ KQL-S

Rapid fitting lead-in /”xØmm

Rapid fitting Ø-Ø mm pipe

Rapid fitting Ømmx/” elbow

Rapid fitting elbow /” nt. x Ø mm

Rapid fitting lead-in /” x Ø mm

Rapid fitting /” ext. x Ømm

Rapid fitting lead-in /” x Ø mm

Kontactor Danfoss C/xV -Hz

Contactor Danfoss C/V

Contact . kW V/V without neutral

Thermo relay .-.A Danfoss

Thermo relay .-.A Danfoss

Connector .Q yellow/green

Connector .Q grey

Plate f/connector

Cage clamp connector

Control lamp V

Control lamp V w/spade plug

Control lamp V

Hour counter V

Hour counter V

Hour counter -V/-Hz

Camtimer V compl.

Camtimer V complete

Thermo switch ajustable

Plug male -pole f/metal cabinet

Switch f/metal cabinet (green)

Switch f/metal cabinet (A)

Solenoid valve f/unloader V w/plug

Solenoid valve f/unloader V w/plug

Auto drain -V series

Auto drain V series

Pressure switch MDR / -way UL

Gauge Ø - bar /” built-in

Non return valve

Safety valve bar / psi

Safety valve bar / psi

Drain cock /” l

Safety valve TÜV . bar

Radiator f/radiator & fan box

Fan V x

Fan V x

Drain bottle multi l compl. for metal cabinet

O-ring f/” plug - x mm

O-ring f/plug Ø.x. f/OF

O-ring Øx f/ /” plug

Grommet black ØxØxmm

Cable relief PG

Distance bolt f/metal cabinet

Distance bolt long f/metal cabinet

Unbraco plug /”x

Unbraco plug /”

Unbraco bolt Mx

Unbraco bolt Mx original

Spring washer Ø.xØ.x.

Washer ØxØ.x

Nut /” flat

Star washer type M

Star washer type A M

Teflon hose /” cm

Teflon hose /” cm with elbow

Teflon hose /” cm with elbow

Teflon hose /” cm with elbow

Wheel Ø mm

Wheel Ø mm w/brake

Cabinet plate - complete f/-M(D), OF- M(D),

OF-M(D), -M(D), -M(D) w/wheels

RAL

Cabinet plate complete size C-MD

Cabinet plate complete size D-MD

Back B-M V Snapline

Back B-D V Snapline

Back B-D V Snapline

Door B-MD, C-MD and D-MD Snapline

Back C-MD V Snapline

Back C-MD V Snapline

Back D-MD Snapline

Front complete B-MD V Snapline

Front complete B-MD V Snapline

Front complete C-MD V Snapline

Front D-MD V Snapline

Mounting bracket complete D-D xOF xV Snapline

Mounting bracket complete D-M xOF xV Snapline

Mounting bracket complete D-M OF xV Snapline

Mounting bracket complete C-M OF xV Snapline

Mounting bracket complete C-D OF xV Snapline

Mounting bracket complete C-M OF xV Snapline

Mounting bracket complete C-M V (M V) Snapline

Mounting bracket complete D-M xOF V Snapline

Parts & Accessories List

16

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Mounting bracket complete A-D & BD V Snapline

Mounting bracket complete A-D & BD V Snapline

Mounting bracket complete A-M & B-M V Snapline

Mounting bracket complete A-M & B-M V Snapline

Mounting bracket complete C-D V (M V) Snapline

Mounting bracket complete D-D xOF V Snapline

Mounting bracket complete D-D xOF V Snapline

Mounting bracket complete D-M xOF V Snapline

Mounting bracket complete C-MD V & V Snapline

Mounting bracket complete D-MD xOF Snapline

Mounting bracket complete B-MD OF & M & xOF

V Snapline

Mounting bracket complete B-MD OF & M & xOF

V Snapline

Mounting bracket size f/cabinet

Mounting bracket A & B

Mounting bracket size C

Mounting bracket D

Double nipple /”

Plug /”

Double nipple /” L= mm

Double nipple /” w/o-ring track

Double nipple /”x/”

Bushing f/metal cabinet /”

Bushing f/autodrain f/metal cabinet /”

Bushing nipple

Connection piece f/non-return valve

Coupling /”

Coupling /”

Adaptor -way

Adaptor f/-

Cross connector /”

Plug ” f/inspection

Plug /” f/inspection ASME

Plug /” f/OF

Elbow /” int./ext. KRG

Elbow /”

Bushing /” int. x /” ext.

Bushing /” x /”

Y-connection /” ( x int.)

Compressor motor

Capacitor, run complete uF f/OF/OF ( cm)

Nut M FZB

Nut M square, FZB

Screw Mx PH Torx

Double nipple /” w/o-ring track

Miscellaneous

K Preventative Maintenance Kit

K Service Kit

K Spare Parts Kit

Parts & Accessories List, continued

17

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

Spare Parts: Model R-MQ

6985922

A

7024002

120R689-T102-N800NX

6342250

5074800

6341750

6341750

6390000

6390000

6372600

6372600

7167201

4146200

7167215

4143500

A

B

4141601

6986026

6317100

6390200

7026001

4739340

6341750

2X

4785600

4750700

6342200

2X

7070901

7167102

4143502

6985928

6339900

2X

4146203

2X

478150

5

6342200

2X

4141620

2X

8008511

4146201

7052005

4141620

4094100

5447000

5612306

4783803

475000

2X

4752205

5150000

2X

4141860

4146200

6340500

4071020

4146200

4147000

4141820

4779901

4740400

4X

4750700

6342200

6951201

6951301

4146200

5422702

4146200

7160000

3512102

5451000

5416100

18

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Spare Parts: Model R-M

A

7024002

120R689-T102-N800NX

6342250

A

B

4141601

6986026

6317100

6390200

7026001

6342200

2X

6339900

2X

4146203

2X

4781505

5447000

4783803

475000

2X

4752205

5150000

2X

4141860

4146200

6340500

4071020

4146200

4147000

4141820

4779901

4740400

4X

4750700

6342200

6951201

6951301

4146200

5422702

4146200

7160000

3512102

5451000

5416100

6984878

6984878 DETAIL

6985922

4146200

7167201

507480

0

6295510

7167215

6390000 6341750

4143502

4143500

7070901

4785600

4146200

4740400

4739340

6341800

4750700

6372600

4X

8081112

6314200

2X

6358000

19

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

120 Basic Compressor User Guide 6190761 (Rev A)

Spare Parts: xR-M

4740400

4779901

4750700

4740400

6342200

4146200

7565000

4146800

5414500

7598500

4141820

7025000

4146200

5416100

7160000

6951301

6984523

COMPLETE

6951201

3512102

A-A 6457047

B-B 6457047

6295900

6984935

COMPLETE

6390200

6390200

5447000

5451000

6317001

6390060

5240607

4141601

6317100

6390200

4146203

4146203

6339900

6339900

6340500

407102

0

4146200

4147000

4750001

4783803

4752000

4141820

4141860

5150000

6984919

COMPLETE

5612306

COMPLETE

7026001

6984974

COMPLETE

6984563

COMPLETE

6390025

6342250

A

6341060

B

4146200

6984949

COMPLETE

A

B

6372600

6341750

6390000

4141800

6390000

6342200

4146200

4071009

7024000

7167215

5074800

7167201

4146200

4785600

7020000

7167102

4141800

4147000

7076000

7025000

4799700

4146800

7167102

7083000

4141860

4146200

6221000

7022100

4750700

6341800

4740400

4739312

4740400

7024002

4146459

120R689-T102-N800NX

5414500

20

6190761 (Rev A) 120R Basic Compressor User Guide

© 2022, JUN-AIR

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Spare Parts: Model xR-MQ

4143500

4143502

4785600

7167102

7070901

5447000

4141601

5451000

6390200

6390200

6390060

6317001

6984982

COMPLETE

6295900

6339900

4146203

6339900

5612302

COMPLETE

B-B 6457037

A-A 6457037

6984563

COMPLETE

120R689-T102-N800NX

7167201

6243710 O-RING

7024002

6243710 O-RING

6342250

6355500

6984523

COMPLETE

6951201

6951301

4146200

5422702

5240600

5416100

7160000

4146200

4750700

6342200

4779901

4740400

6984990

COMPLETE

4783803

4750001

4752205

4141820

4141860

5150000

4146200

6340500

4071021

4146200

4147000

6984974

COMPLETE

5451000

4141620

8008511

4094200

7022100

6221000

4141860

4141860

4146200

5414500

7083000

7167102

6342200

6358000

8081112

4740400

4739340

4740400

6341750

4750700

6342200

639000

0

6372600

6341750

6390000

6372600

6341750

6390000

6341750

6390000

6342200

7167215

6243710 O-RING

5074800

7167201

6243710

O-RING

4146200

4146200

4750700

4740400

4739342

4740400

6342200

5240600

6985973

6984919

COMPLETE

A

7026001

6390200

6317100

B

C

C

A

6342200

4146458

4146458

6985948

7052005

4146200

3512102

6372600

Other manuals for 120R

1

This manual suits for next models

3

Other Gast Air Compressor manuals

Popular Air Compressor manuals by other brands

ActiveProducts

ActiveProducts C36A-54 owner's manual

Central Pneumatic

Central Pneumatic 93351 Assembly and operating instructions

MasterFlow

MasterFlow MF-1089 owner's manual

Airmax

Airmax SilentAir G25 installation manual

Delta

Delta A08590 instruction manual

ALLPOWER

ALLPOWER 3.5HP PEAK 6 GALLON owner's manual