Gate1Access GA2000 User manual

1

SlidingGateOpener

User’sManual

Gat Model:GA2000

Gate1Access, LLC.

www.gate1access.com

Email: support@gate1access.com

2

Thank you for purchasing GA2000 chain drive sliding gate opener. We are sure that the products will be greatly

satisfying as soon as you start to use it. The product is supplied with a user’s manual which encloses installation and

safety precautions. These should be read carefully before installation and operation as they provide important

information about safety, installation, operation and maintenance. This product complies with the recognized technical

standards and safety regulations.

General Safety

WARNING! An incorrect installation or improper use of the product can cause damage to persons,

animals or properties.

• Scrap packing materials (plastic, cardboard, polystyrene etc.) according to the provisions set out by current

standards. Keep nylon or polystyrene bags out of children’s reach.

• This product was exclusively designed and manufactured for the use specified in the present

documentation. Any other use not specified in this documentation could damage the product and be

dangerous.

• The factory declines all responsibility for any consequences resulting from improper use of the product, or

use which is different from that expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The factory declines all responsibility for any consequences resulting from failure to observe Good

Technical Practice when constructing closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect

any buffer batteries, if fitted.

• Check that a differential switch with a 0.03A threshold is fitted just before the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for closure (doors, gates etc.) and all

system components provided with an earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are needed to protect the area from any

danger caused by squashing, conveying and shearing.

• Position at least one luminous signal indication device (blinker) where it can be easily seen, and fix a

Warning sign to the structure.

• The factory declines all responsibility with respect to the automation safety and correct operation when

other supplier’s components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorized by the factory.

• Instruct the product user about the control systems provided and the manual opening operation in case of

emergency.

• Do not allow persons or children to remain in the automation operation area.

• Keep radio control or other control devices out of children’s reach, in order to avoid unintentional

automation activation.

• The user must avoid any attempt to carry out work or repair on the automation system, and always request

the assistance of qualified personnel.

• Anything which is not expressly provided for in the present instructions is not allowed.

• Installation must be carried out using the safety devices and controls prescribed by the EN 12978

standard.

3

PARTS CHECKLIST

Gate Opener(1pc)

Base Plate(1pc)

Square Bolt(4pcs) Round Bolt(4pcs)

6.5m Chain(1pcs)

Master Link(2pcs)

"L" Chain

Bracket(2pcs)

M10*45Hex

bolt(4PCS)

10 Plain

Washer(4pcs)

10Sprin

Washer(4pcs)

Chain Box(1pc)

M6X30 Stainless Steel

AllenScrew(4pcs)

M12 Chain Bolt(2pc)

M12 Hex Nut(4Pcs)

12 Spring

Washer(4pcs)

12 Plain Washer(4pcs)

8 Plain Washer(8pcs)

8 Spring

Wahser(8pcs)

8 Hex Nut(8pcs)

M10*80 Ground

Expansion Bolt(4pcs)

4

Technical Specifications & Features

Specifications:

•Power supply: 120V/50HZ

•Motor: 110VAC

•Absorbed motor power: 370W

•Gate moving speed: (7.9“/second) 20 cm/second

•Max gate weight: 800KGS

•Max torque:: 35Nm

•Environmental conditions: From -15°C to +40°C

•Protection class: IP44

•Dimensions: 30cmX19.5cmX49.6cm (L*W*H)

Features:

•Easy to install and low maintenance.

•Quick selection for gate open/close direction.

•Get the desired chain tension by adjusting the chain bolts.

•Homelink compatible technology.

•Emergency release key in case of power failure

•Stop/Reverse in case of obstruction during gate opening/closing

•Built in adjustable auto-close (0, 12.5, 25, 45 seconds).

•Reliable inner mechanical limit switch brings easy and accurate setting.

•Can be equipped with wide range accessories.

5

TABLE OF CONTENTS

Important Safety Instructions…………………………………….……6

Safety Instructions for Installation………………………..…………...7 - 8

Installation Overview and Instructions……………………..………...9 – 10

Manual Operation…………………………………………………….10

Installation of chain and chain brackets……………………..……..11 – 13

Limit Switch Settings………………………………………………….14

Control Board ………………………………………………………...15 – 20

Wiring Instructions……………………………………………..15

Setting the DIP Switches……………………………………...16 – 17

Direction of gate opening…………………………………......17

Potentiometer Overload Adjustments…………………….…18

Programming the Remote Control……………………..…....19

Wiring Diagram………………………………………………..20

Troubleshooting…………………………………………………..….21 - 22

Maintenance…………………………………………………………22

6

Important Safety Instructions

WARNING – To reduce the risk of injury or death:

READ AND FOLLOW ALL INSTRUCTIONS.

1) Never let children operate or play with gate controls. Keep the remote control

away from children.

2) Always keep people and objects away from the gate. NO PERSON SHOULD

CROSS THE PATH OF THE MOVING GATE.

3) Test the gate opener monthly. The gate MUST reverse on contact with a rigid

object or stop when an object activates the non-contact sensors. After adjusting

the force or the limit of travel, retest the gate opener. Failure to adjust and retest

the gate opener properly can increase the risk of injury or death.

4) Use the emergency release only when the gate is not moving.

5) KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a

qualified service person make repairs to gate hardware.

6) The entrance is for vehicles only. Pedestrians must use separate entrance.

7) SAVE THESE INSTRUCTIONS.

7

Safety Instructions for Installation

A. Install the gate opener only when:

1) The opener is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum

of 4 feet (1.22 m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the

openings anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3) All exposed pinch points are eliminated or guarded.

4) Guarding is supplied for exposed rollers.

B. The opener is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a

separate access opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate

the gate such that persons will not come in contact with the vehicular gate during the entire path of travel of the

vehicular gate.

C. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of entrapment.

D. The gate must be properly installed and work freely in both directions prior to the installation of the gate opener.

Do not over-tighten the opener clutch or pressure relief valve to compensate for a damaged gate.

E. For gate openers utilizing Type D protection:

1) The gate opener controls must be placed so that the user has full view of the gate area when the gate is moving.

2) The placard provided marked in letters at least 1/4-in (6.4-mm) high with the word ″WARNING″ and the

following statement or the equivalent: “ Moving Gate Has the Potential of Inflicting Injury or Death – Do Not

Start Gate Unless Path is Clear” shall be placed adjacent to the controls,

3) An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed.

4) No other activation device shall be connected.

F. Controls intended for

user activation must be

located at least ten feet

(10’) away from any moving

part of the gate and where

the user is prevented from

reaching over, under,

around or through the gate

to operate the controls.

Outdoor or easily

accessible controls shall

have a security feature to

prevent unauthorized use.

G. The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall

not cause the opener to start.

H. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

8

1) See instructions on the placement of non-contact sensors for each Type of application,

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the

gate is still moving in the opening direction.

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

I. For a gate opener utilizing a contact sensor in accordance with Usage Class:

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the

leading edge, trailing edge, and post-mounted both inside and outside of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4) A hardwired contact sensor shall be located and its wiring arranged so that the communication between the

sensor and the gate opener is not subjected to mechanical damage.

5) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate opener for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall function

under the intended end-use conditions.

6) One or more contact sensors shall be located on the inside and outside leading edge of a sliding gate.

Additionally, if the bottom edge of a sliding gate is greater than 6 inches (152 mm) above the ground at any point in

its arc of travel, one or more contact sensors shall be located on the bottom edge.

9

Installation Overview

Installation of the Opener

Caution

Be sure that the opener is installed in a level and paralleled position and is

properly secured.

Improper installation could result in property damage, severe injury, and/or

death.

Before starting installation, ensure that there is no point of friction during

the entire movement of the gate and there is no danger of derailment.

Ensure that the Warning Signs are present.

Necessary Tools:

The following tools may be necessary to install the Gate Opener.

Screwdrivers

Electric drill

Wire cutters

Wire stripper

A socket set

10

The installation procedures are as follows:

1. The limit default setting is for gate in close

position. Before installation, please make sure

gate is closed.

2. Prepare one or more conduits for the electrical

cables. Cable conduits have to pass through the

hole in the base plate.

3. Put the base plate to the ground. It's only

temporary installation. Further adjustment will be

required when installing the chain.

4. Make the chain go through the chain box, Fix

the chain to the gate frame with the chain bolts.

(Bolts and brackets supplied in package.)

5. Mount the chain box to the base plate by using

screws and washers, don’t make the four screws

too tight.

6. Move the opener to the proper position, Fix

the opener to the ground with 4 expansion bolts

supplied in the package.

Manual Operation

The opener comes with an easy operating manual release. It brings the easiest manual release operation just

in case of any emergency.

Insert the manual release key supplied in package to release lock, then turning the key clockwise 90

degrees.

Pull out the release lock part to be more than 90 degrees, now the gear and shaft are disengaged.

Refer to the figures below

11

Installation of chain and chain brackets

1. Chain Brackets

a) Please refer to below chain brackets figure, which shows “U” bolt, “L” bracket and chain bolt. Use

the “U” bolts (square or round) to attach the chain brackets to gate frame.

b) If both the square bolts and round bolts are not fit for the gate frame, use the appropriate bolts to

attach the chain brackets to gate frame.

12

2. How to install the chain

1) The motor comes with 1 foot of chain already placed around the top of the idler wheels and under the drive

sprocket in the chain box….please proceed to step 2

2) Connect one of your 10ft chains (provided) to the right end of the chain coming out of the chain box using a

master link.

a) Measure the length of chain needed to get to the chain bolt that’s connected on the right L-Bracket

(on the gate),

b) cut it & install the end of the chain to the M12 Chain bolt using another master link.

3) Connect the remaining 10ft chain (provided) to the left end of the chain coming out of the chain box using a

master link.

a) Measure the length of chain needed to get to the chain bolt that’s connected on the left L-Bracket

(on the gate),

b) cut it & install the end of the chain to the M12 Chain bolt using another master link.

4) Make sure that the chain is line up exactly with the position where the chain on the chain idler wheel.

5) Get the desired chain tension by adjusting the two chain bolts of the both ends.

Thoroughly fasten the four nuts as well as spring washers onto anchor bolts tightly, ensuring the opener is

firmly secured on the concrete pad during the whole gate travel.

13

3. Check the position of the opener and chain brackets

1).The chain brackets must be mounted to the same height as the chain on the guiding sprockets.

2). The opener must be parallel to the gate.

3). Make sure there is 1” distance at least between the chain box and the gate after you position the

base plate.

14

Inner Mechanical Limit Switch Setting

This newly developed internal mechanical limit switch is much easier and more accurate

compared to the traditional magnetic limit switch. User does not need to mount any external

parts for limits. It is user-friendly and saves on cost and labor

.

Remove the cover, user can see the limit switch is located above the manual release part, there are

2 adjustable screws that can be used to set open/close limit. The Left Hand Screw is for setting the

close limit, the Right Hand Screw is for setting the open limit.

After adjusting the opener with chain and fixing the opener to the ground, check if the gate is still in

close position, then moving the gate to the fully open position and start setting the open limit.

The Right Hand Screw is for setting open limit. Turning clockwise to increase the distance,

turning counter clockwise to decrease the distance. After the control board open limit indicator

light is on, now the opener will stop at the desired position.

After setting the open limit, operate to close the gate, if the gate will not stop at the fully close

position. Fine turning

The Left Side Screw is for closing. Turning clockwise to decrease the distance, turning

counter clockwise to increase the distance.

15

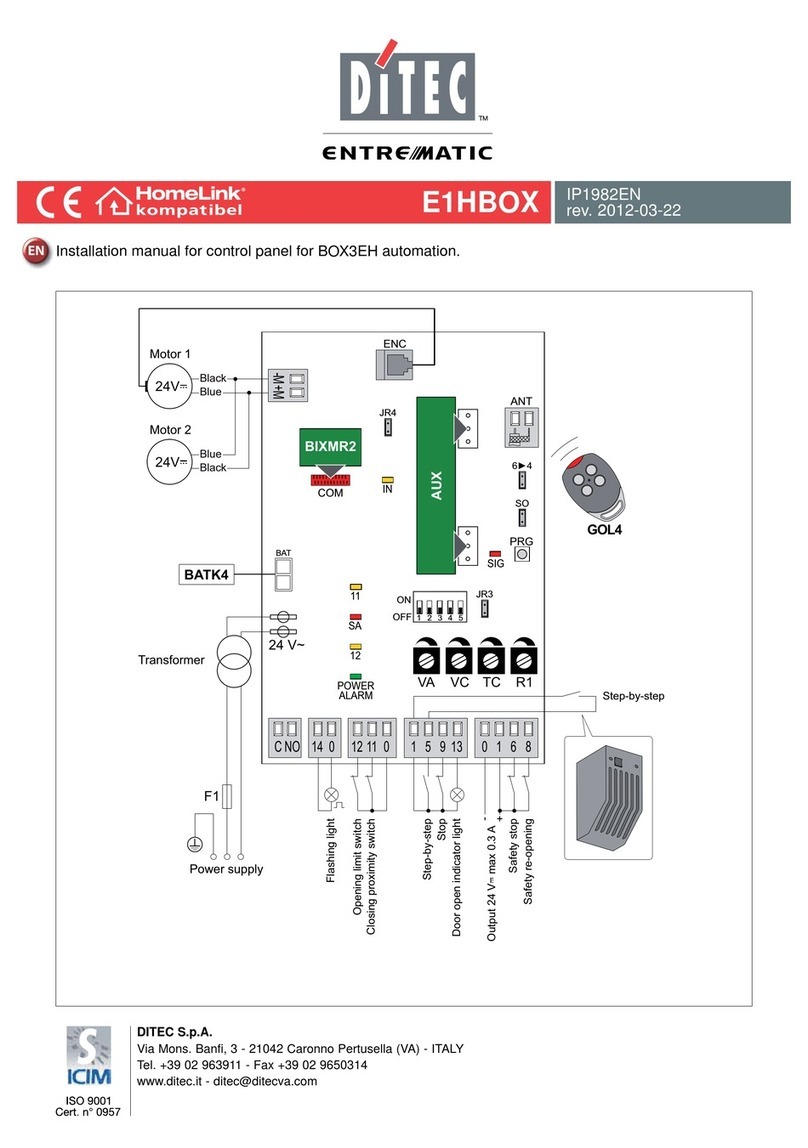

Wiring of the Control Board

1. Motor

The BLUE wire of the motor should be connected into the “3” terminal.

The YELLOW wire of the motor should be connected into the “4” terminal.

The WHITE wire of the motor should be connected into the “5” terminal.

2. Start Capacitor

One pin of the start capacitor should be wired to the “6” terminal, another to “7” terminal.

3. Limit Switches

The YELLOW wire of the limit switches should be connected into the “18” terminal.

The BLACK wire of the limit switches should be connected into the “19” terminal.

The RED wire of the limit switches should be connected into the “20” terminal.

Note: If opening is to the left, the Limit Switch wires on the control board (yellow & red) need to be reversed. The

black wire stays the same.

4. Alarm Lamp

One wire of the alarm lamp should be connected into the “8” terminal, another should be connected into the “9”

terminal.

5. Photocell (Normal Open

)

Use a 2-core cable to connect the “+ ~” terminal of the photocell’s emitter to the “10” terminal, the “- ~”

terminal to the “11” terminal. Also the “+ ~” and “- ~” terminals of the photocell’s receiver should be connected

to the “11” and “12” terminals in parallel. Use another 2-core cable to connect the NO” terminal of the receiver

to the “21” terminal, the “COM” terminal to the “22” terminal.

6. Push Button

The push button should be wired to the “13” and “14” terminals. The gate opener works alternately by pushing

the button (open-stop-close-stop-open)

7. Loop Detector

First insert the LOOP DETECTOR BOARD into the CONTROL BOARD, and then connect the twisted-pair to

the “15” and “16” terminals to realize the auto close function. Or connecting to the “16” and “17” to realize the

auto open function.

8. External Receiver

The BROWN wire of the external receiver should be connected into the “16” terminal.

The BLACK wire of the external receiver should be connected into the “13” terminal.

The RED wire of the external receiver should be connected into the “12” terminal.

9. Wired Keypad (12VDC)

The RED wire of the wired keypad should be connected into the “12” terminal.

The BLACK wire of the wired keypad should be connected into the “13” terminal.

The WHITE wire of the wired keypad should be connected into the “16” terminal.

The BLUE wire of the wired keypad should be connected into the “15” terminal.

16

Setting of

the Control

Board

1. DIP Switches

The DIP switches are

used to set the limit

switch of the opener to

be NO or NC, auto close

time of the gate opener

and fast change the

open/close direction

which is determined by

the position of the gate

opener installed.

Setting of the Control Board

DIP Switch #1: Limit switch NC (normally closed) or NO (normally open)

DIP Switch #1

:

ON –NO /OFF –NC

This mode enables user to set the board to work with motor with NC or NO limit switch

NOTE: Factory default setting is NO

DIP Switch #2–#4: Auto close time of the gate opener

DIP Switch #2: ON – 12.5 Seconds OFF – 0 Seconds

DIP Switch #3: ON – 25 Seconds OFF – 0 Seconds

DIP Switch #4: ON – 45 Seconds OFF – 0 Seconds

NOTE: The auto-close function would be disabled if all 3 dip switches are turned to off (factory default

setting).

17

DIP Switch #5: Direction of gate opening.*

(* Direction from the inside of the property where the opener is installed.)

DIP Switch #5: OFF – Opens to the right.

DIP Switch #5: ON – Opens to the left.

Note: If opening is to the left, the Limit Switch wires on the control board (yellow & red) need to

be reversed. The black wire stays the same.

18

DIP Switch #6: (NOT USED)

DIP Switch #7–#8: Remote Control Button (yellow & blue) Setting

DIP Switch #7: ON – Yellow Button is Working OFF – Yellow Button is Not Working

DIP Switch #8: ON – Blue Button is Working OFF –Blue Button is Not Working

2. Potentiometers

The left potentiometer is to adjust the CLOSE stall force of the gate opener. The right Potentiometer is used to

adjust the OPEN stall force of the gate opener.

Turn the potentiometer clockwise to increase the stall force.

Turn the potentiometer counter-clockwise to decrease the stall force.

19

Test the reversing sensitivity

For the sake of safety, it is very important to test the reversing sensitivity as soon as the control board set is

finished.

The reversing sensitivity adjustment is inverse correlation with stall force adjustment in potentiometer 1 and

potentiometer 2. In other word, the stall force level is higher; the reversing sensitivity level is lower.

Put an immobile object along the gate path, and then operate the gate to strike it during the open and close

cycles. The gate must reverse as soon as object is struck with it. If the gate doesn’t reverse, please increase

the reversing sensitivity by turning the potentiometer in counter-clockwise direction. (Turning the stall force

potentiometer toward to “Light” position to increase the reversing sensitivity)

Note 1: If the sensitivity setting is too higher, the gate will stop or reverses very easy by itself

while there is little obstruction or resistance such as strong wind or heavy snow sometimes.

Note 2: Always check the gate reversing function every each time of control board set or

restart after power off.

How to learn or erase the remote

Learn the remote

Press and release the learn button, the BLUE LED light will be on, then press any button in the remote within

5 seconds, the BLUE LED light will go off. Now the remote has been learnt successfully.

Erase all the remote codes

Press and hold the learn button until the BLUE LED light goes off after flashing 5 times. Now all remote codes have

been erased.

20

Control Board Wiring Diagram

Table of contents

Popular Gate Opener manuals by other brands

Eagle Access Control Systems

Eagle Access Control Systems Eagle-2000 series installation instructions

CENTURION SYSTEMS

CENTURION SYSTEMS D 10 installation manual

Rossi

Rossi DZ GHT9 Installation

Opera

Opera 28720 Installation and use manual

BFT

BFT PHEBE Installation and user manual

CAB

CAB Hydro HD.35 Operating instructions and spare parts catalogue