Technical Characteristics / Technical Data

Warranty term

This product was designed and manufactured to fully meet the

technical specifications described in the accompanying booklet.

ÉIt is IMPORTANT that this termbe read, as well as theentire User

Manual and the product's technical specifications and instructions

for its correct installation.

INDÚSTRIAS ROSSI ELETROMECÂNICA EIRELI, in accordance

with the Law 8078/90, certifies that the product is in perfect

condition for use and fit for its intended purpose, warranting it

against any defect in design, manufacture, or material quality

defects that make it unsuitable or inadequate for its intended use,

for a period of 1 (one) year, including the legal warranty period of

90 days, from the date of issue of the Invoice to the consumer.

When the consumer faces an eventual manufacturing defect within

the warranty period, he/she must present the product, along with

the respective purchase Invoice, to a Rossi Distributor so that the

product can be evaluated and, if necessary, repaired.

The warranty will be totally void if any of the following events occur:

a) If it is found that the defect is not a manufacturing defect;

b) If it is found that the product defect was caused by misuse or

inappropriate use, unforeseeable circumstances or force majeure

(lightning, floods, floods, landslides, etc.), defect in the electrical network.

c) If it is found that the product defect is due to exposure to

chemicals, electromagnetic interference, salt spray, excessive

humidity and/or intense heat and cold;

d) If it is found that the product defect was caused by accidents,

falls, disasters, pest attacks or agents of nature;

e)If the manufacturing label has been removed from the product;

f) If the product has been tampered with and/or has been modified

by third parties not authorized by INDÚSTRIAS ROSSI

ELETROMECÂNICA EIRELI;

g) If the product suffers natural wear, due to not having been

followed correctly, and in full, the instructions for use and

maintenance contained in the User Manual;

h) If it is found that the unsatisfactory performance of the product

originates from inadequate installation, in disagreement with NBR

5410:1997 - ABNT - Brazilian Association of Technical Standards and

with the instructions that accompany the product, or in the electrical

network where it is connected (see technical specifications of the

equipment)

i) If the product is being used in an application for which it was not

designed or if it exceeds the maximum operating cycle causing the

operator to burn out or wear out internal components;

CAUTION! The installation of the product must follow the

instructions that come with the product, otherwise this warranty will

be invalidated. The expenses necessary for the installation, as well

as the purchase of materials necessary for the installation, in

addition to optional features, will be the sole responsibility of the

consumer.

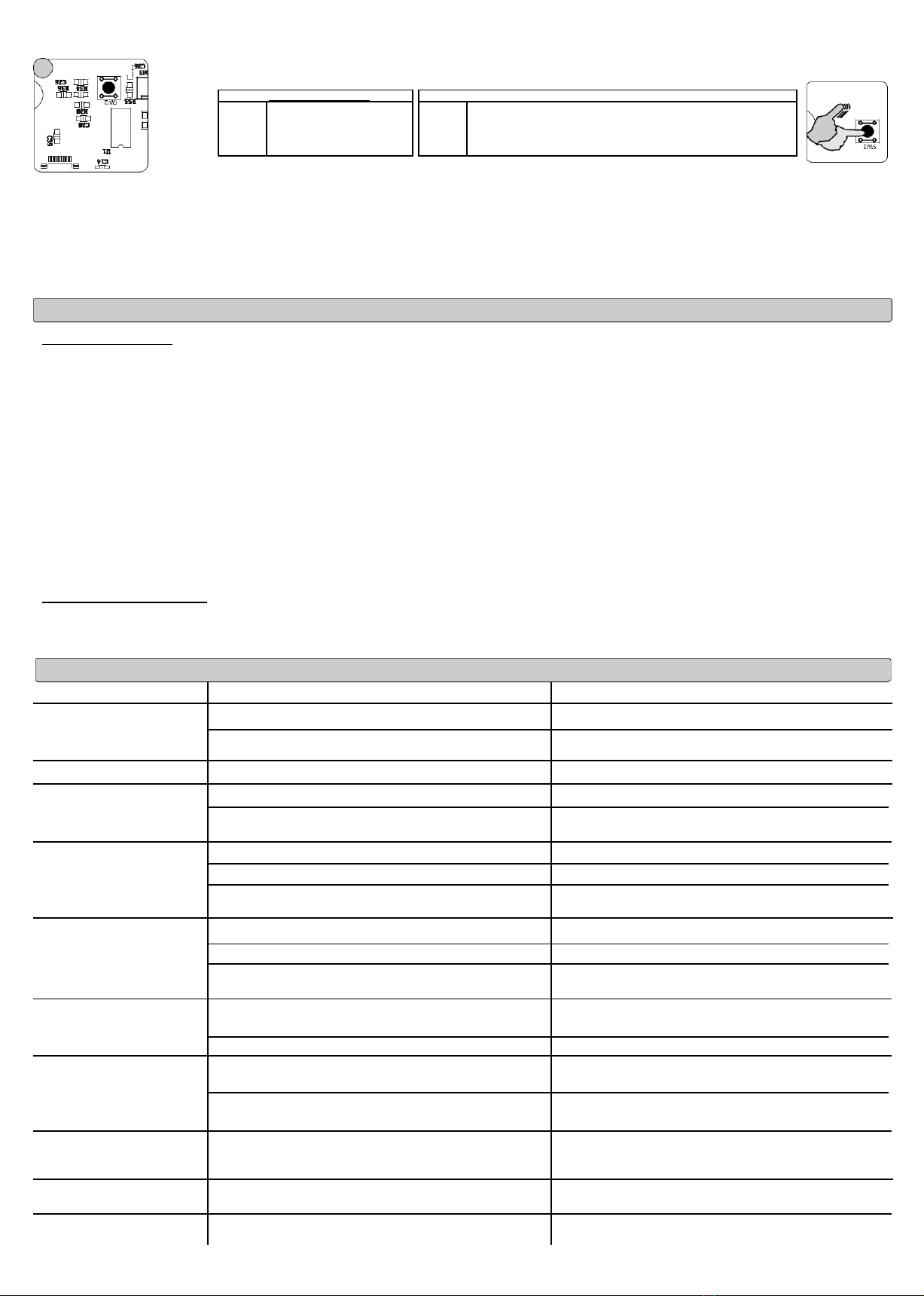

CAUTION! It is essential, under penalty of invalidating this warranty,

the use of the Active infrared sensor - SIA 30 to activate the anti-

trapping protection system. The absence of this sensor can cause

collision with obstacles, accidents with people, animals or material

goods.

CAUTION! Keep children and pets away from the gate when it is

operating.

CAUTION! The product was developed for generic use, and not for

the specific purpose of each consumer. Therefore, this warranty is

limited to serving the purposes set out in the User Manual.

CAUTION! If the equipment is defective, immediately contact the

technician who installed the equipment through the address and

telephone number filled in or stamped on this certificate.

INDÚSTRIAS ROSSI ELETROMECÂNICA EIRELI reserves the

right, at any time, to modify and/or make improvements to this

product, without incurring the obligation to do the same for products

in stock or already sold.

For people's safety it is important that all instructions are followed

Look carefully at each of them:

1th - The installer must follow all the instructions contained in this manual.

2th- Keep the commands of the automatic equipment (command buttons, remote control etc.) out of the reach of children.

3th - Carry out the command operations from points where the automatic gate is visible.

4th - Use the remote controls only if you can see the automatic gate.

5th - Warning: ROSSI does not assume any responsibility for any damage caused by non-observance, at the time of installation, of the safety standards

and the laws currently in effect. NBR 5410:1997 - ABNT - Brazilian Association of Technical Standards.

6th - This manual is intended exclusively for specialized personnel who have knowledge of the manufacturing criteria and the protection devices against accidents related

to gates and motorized doors.

7 If not provided for in the electrical panel, install before this a bipolar circuit breaker type switch with minimum contact opening equal to

3mm, of a brand that complies with international standards and provide the equipment grounding.

8 For the cable section, ROSSI recommends using a minimum section of 2.5mm and also observing the laws in force in the country.

9° Keep this manual for possible future reference

10 This appliance should not be used by people (including children) with reduced physical, sensory or mental abilities, or without experience and knowledge, unless they

are supervised or instructed on use of the appliance by someone who is responsible for their safety.

11 It is recommended that children be supervised to ensure that they are not playing with the appliance.

12° The installer must inform all the information related to automatic operation, emergency unlocking and deliver the user manual with the necessary information.

13 It is mandatory to use the Active infrared sensor - SIA 30 or XP 20W, to activate the anti-trapping protection system and allow the operation of the FS central, avoiding

collision with obstacles and accidents with people or material goods.

14 Before installing the unit, check that the driven part is in good mechanical condition, correctly balanced and opens and closes correctly

15º Frequently examine the installation for imbalances and signs of wear or damage to the cables, springs and assembly. Do not use for repairs or if adjustment is required.

16 Disconnect the equipment from power when cleaning or performing maintenance.

17º Check if the temperature of the equipment is indicated for the place where it will be used.

User Manual

UNLOCKING FOR MANUAL OPENING

Insert and turn the key clockwise and pull the lever up to 100º.

Place and turn

the key in the sense

time

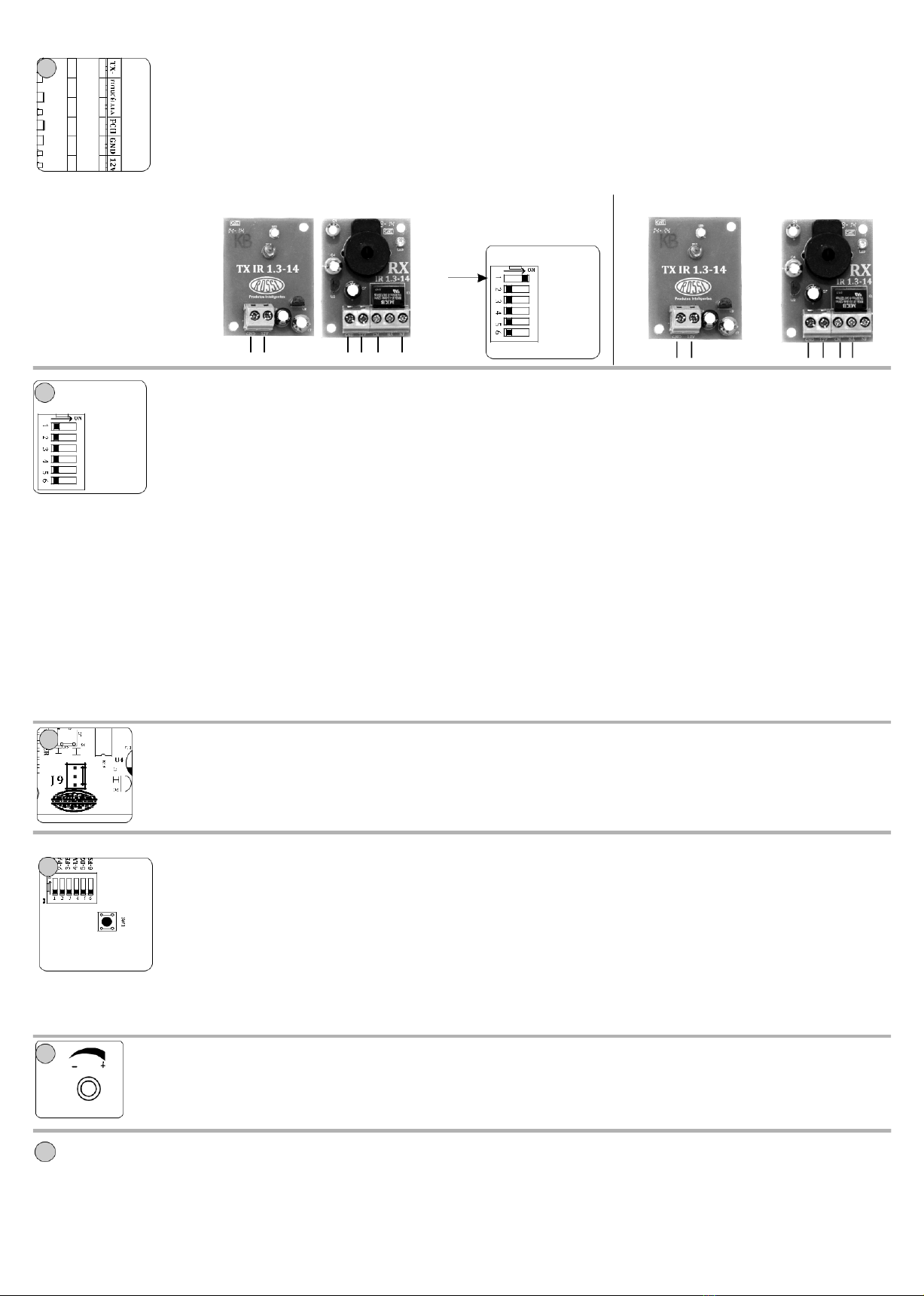

HCS REMOTE CONTROL CONFIGURATION (Rolling Code)

To add the remote control code to the command center, press and release the “LEARN” button on the

command center or Rossi receiver and immediately press one of the control buttons. To record other

buttons, repeat the operation.

Note: buttons 1 and 2 on the controller are independent.

Erase memory - If you want to erase all the codes of the remote controls in the command center, press

the “LEARN” button and keep it pressed until the “ST” led turns off.

Remote Control

1Place the key 2Pull the lever. 3Leave at 100º Control panel

Important Safety Instructions