GAZ lomain KGL P Series Manual

Visit us at www.enersys.com

Battery Installation,

Operation and

Maintenance Instructions

NEXT GENERATION

OF BATTERIES

KGM...P

KGL...P

Visit us at www.enersys.com

1. Receiving the battery

Cells must not be stored in their packaging, therefore, unpack the

battery immediately upon receipt. Do not tilt the package or turn

it upside down. The battery cells are equipped with a blue plastic

transport plug. battery cells will be delivered filled and

charged. The battery is ready for installation. Replace the transport

plug with the red vent cap included in the accessories just before

use (see section 7).

The battery must not be charged with the transport plug installed

as this can damage the battery.

2. Storage

The rooms provided for storing the batteries must be clean, dry,

cool (+10°C to +30°C) and well ventilated. Cells must not be stored

in the transport packaging and must not be exposed to direct

sunlight or UV-radiation.

If the cells are delivered in plywood boxes, open the boxes before

storage and remove the packing material on the top of the cells. If

the cells are delivered on pallets, remove the packing material on

the top of the cells.

Filled cells can be stored up to 12 months from the day of

delivery.

Storage of filled cells at a temperature above +30°C will result in a

loss of capacity of approximately 5% per 10 degrees per year. It is

very important that the cells are sealed with the plastic transport

plugs tightly in place. This is to be checked after receiving the

goods. In case of electrolyte loss during transport, refill the cell up

to the “MAX” mark with genuine electrolyte before storage.

3. Installation

The installation should be carried out in accordance with the

requirements of IEC 62485-2:2010, Part 2 “Safety Requirements

for secondary batteries and battery installations – Part 2: Stationary

batteries” . For non-stationary installations, specific standards may

also apply.

3.1 Location

Install the battery in a dry and clean room. Avoid exposure to direct

sunlight and heat. The battery will give the optimal performance

and maximum service life if the ambient temperature range is

between +10°C and +30°C.

3.2 Ventilation

During the last phase of charging, battery gases are released (a

mixture of oxygen and hydrogen). Ventilation is necessary, even if

the generation of gas is very low during float charging.

Compliance with local regulations as to ventilation may be

necessary for certain applications. If there are no special

regulations, standard IEC 62485-2:2010, Part 2 must be met.

3.3 Setting up

Always follow the assembly drawings, circuit diagrams and other

separate instructions. In the case of parallel string connection

only use battery cells of the same capacity, design and age up to a

maximum of two parallel strings. For parallel connection of more

than two strings, please contact the manufacturer for technical

approval. Use nickel-plated cable lugs for cable connections.

The transport plugs must be replaced with the red vent caps

included in the accessories.

Tighten the terminal screws with corresponding tightening torque

as per table 1.

It is recommended to use a calibrated torque wrench.

Table 1: Torque loading for terminal screws:

2

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

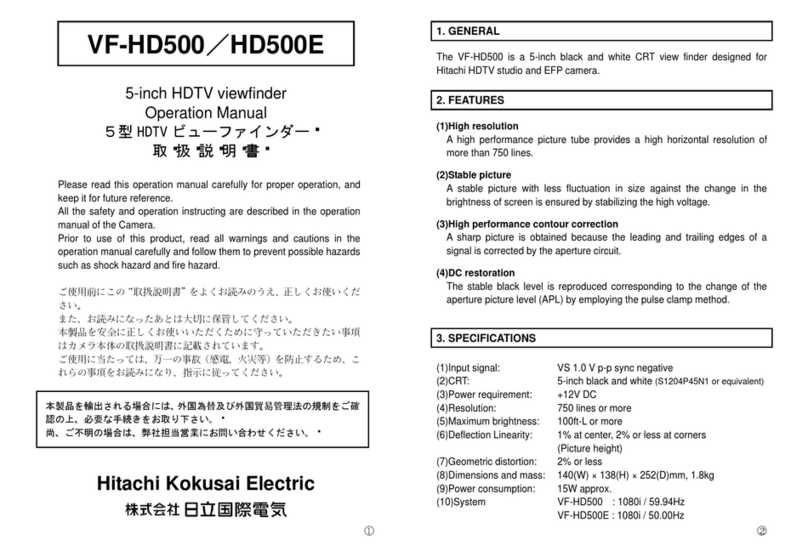

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Warning!

The gases emitted during charging are explosive. The electrolyte (potassium hydroxide, KOH) is highly corrosive. Exposed metal parts of

the battery always conduct a voltage and are electrically active parts. Precautions in accordance with IEC 62485-2:2010 must be observed.

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Handling

DataSafe®XE batteries are supplied in a charged

condition and are capable of extremely high short

circuit currents. Take care to avoid short-circuiting

terminals of opposite polarity.

California Proposition 65 Warning - Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm. Wash hands after handling.

Care for your safety

Keep flames away

Discharge any possible static electricity from clothes

by touching an earth connected part.

Tools

Use tools with insulated handles.

Do not place or drop metal objects on the battery.

Remove rings, wristwatch and articles of clothing

with metal parts that may come into contact with

the battery terminals.

No smoking, no naked flames, no

sparks

Shield eyes Read instructions

Electrical hazard Danger Re-cycle scrap batteries.

Contains lead

Electrolyte is corrosive

Clean all acid splash in eyes or on skin

with plenty of clean water.

Then seek medical help.

Acid on clothing is to be washed with

water

Warning: Risk of fire, explosion, or

burns. Do not disassemble, heat above

60ºC, or incinerate. Avoid any short

circuit. Metallic parts under voltage on

the battery, do not place tools or items

on top of the battery

Observe the instructions for use and place them

visibly close to the battery! Work only on batteries

after receiving instruction from qualified personnel!

When working on batteries wear safety glasses and

protective clothing. All metallic personal objects, such

as rings, watches, bracelets etc. shall be removed

before starting work on the battery! Only use insulated

tools! Comply strictly with the accident prevention

regulations and your national Health and Safety

standards as well as IEC 62485-1:2010

Electrolyte is harmful to skin and eyes. Therefore, after

an accidental contact with the electrolyte flood the

eyes immediately with large quantities of clean water

for an extended period of time of at least 15 minutes.

In all cases, consult a doctor immediately! Clothing

contaminated with electrolyte should be washed in

water immediately!

Warning: Risk of fire, explosion, or burns! Avoid any

short circuit! Metallic parts of the battery are always

under voltage on the battery, do not place tools or

items on top of the battery!

Electrolyte is highly corrosive!

Cells are heavy! Make sure they are safely installed!

Only use suitable transport equipment!

No smoking! Do not allow naked flames, embers or

sparks near the battery due to the risk of explosion

or fire!

The Installation, Operation and Maintenance Instructions

must be strictly observed.

Non-compliance with the Installation, Operation and

Maintenance Instructions, use of nongenuine spares and

the usage of other than by EnerSys/GAZ specified parts,

use of additives to the electrolyte and unauthorised

tampering will invalidate any entitlement to warranty.

Used batteries with this

symbol are recyclable products

and have to be put into

a recycling system. Used

batteries must be disposed of

as special waste in accordance

with all standards.

WARNING!

Never use sulphuric acid or

acidic water.

Acid will damage the battery!

Male terminal Female terminal

M10 : 8 Nm

Connectors and terminals should be protected by a thin layer

coating of anti-corrosion grease.

M8 : 20-25 Nm

M10 : 25-30 Nm

Ni-Cd

Cd

3

3.4 Electrolyte

The electrolyte for NiCd batteries consists of a diluted

potassium hydroxide (KOH) solution (specific gravity 1.20 kg/litre

+/-0.01 kg/litre) with a lithium hydroxide component, in accordance

with IEC 60993:1989. The potassium hydroxide solution is prepared

in accordance with factory regulations. The specific gravity of the

electrolyte does not indicate the state of charge of the battery. The

specific gravity changes very little during charging and discharging,

and has limited relationship to the temperature.

When checking the electrolyte levels, a variation in level between

cells is not unusual and is due to the different quantity of gas held

in the separators of each cell. Before the battery is put into service

for the first time, check that the electrolyte level is not lower than

10mm below the “MAX” mark. There is usually no need to adjust

it.

If the electrolyte level is lower than the “MIN” level during service,

the battery should not be disconnected from the charger for a time

longer than 12 hours.

If visual inspection is not possible, due to restricted view, use

an electrolyte level testing tube to check the electrolyte level.

For further instructions, please contact your GAZ/EnerSys

representative.

GAZ cells fulfil the requirements of IEC 62259:2003, para

7.9 for gas recombination efficiency.

3.5 Commissioning

The following instructions are valid for commissioning between

+20°C and +30°C. For different conditions please contact GAZ.

Charging with constant current is the preferred method.

If a site test is requested, it must be carried out in accordance with

IEC 62259:2003.

According to IEC 62259:2003, 0.1 C5A is also expressed as 0.1 ItA.

The reference test current It is expressed as:

Example:

0.1 ItA means:

10 A for a 100 Ah battery or

50 A for a 500 Ah battery

3.5.1 Commissioning with contant current

cells stored up to 6 months:

A commissioning charge is normally not required and the cells

are ready for service. If full performance is necessary immediately,

a commissioning charge of 10 hours at 0.1 ItA is recommended.

This procedure is carried out without the red low-pressure vents

installed.

During the charge the temperature should be checked

(see section 5).

cells stored for more than 6 months up to 1 year:

A commissioning charge of 15 hours at 0.1 ItA is necessary.

This procedure is carried out without the red low-pressure vents

installed.

During the charge the temperature should be checked

(see section 5).

3.5.2 Commissioning with constant voltage

A commissioning charge is normally not required and the cells are

ready for service. If the charger´s maximum voltage setting is too

low to supply constant current charging, divide the battery into two

parts and charge them individually.

cells stored up to 6 months:

A commissioning charge is normally not required and the cells

are ready for service. If full performance is necessary immediately,

a commissioning charge of 20 hours at 1.65 V/cell with current

limited to 0.1 ItA is recommended.

This procedure is carried out without the red low-pressure vents

installed.

During the charge the temperature should be checked

(see section 5).

cells stored more than 6 months and up to 1 year:

A commissioning charge of 30 hours at 1.65 V/cell with current

limited to 0.1 ItA is necessary.

This procedure is carried out without the red low-pressure vents

installed.

During the charge the temperature should be checked

(see section 5).

In the case of variable charging conditions, please consult your

GAZ®representative.

3.5.3 Commissioning at ambient temperature above +30°C

Constant current charging is the only appropiate method for

commissioning under such temperature conditions. During the whole

process the electrolyte temperature must be monitored.

The electrolyte temperature should never exceed +45°C.

On exceeding +45°C the charging should be temporarily interrupted

until the electrolyte temperature drops to +40°C.

Duration: 20 hours

Charging current: 0.1 ItA

In case of any interruption during the commissioning process, the total

charge time must be extended by the duration of the downtime.

4. Charging in operation

Do not open or remove the low pressure vent caps during

operation. The charging current limit should be 0.1 It A maximum in

general.

In order to reduce the water consumption it is recommended, but

not obligatory to adjust the charge voltage.

Operation in high

temperature area (>35°C): Temperature coefficient of -2 mV/K

Operation in low

temperature areas (<20°C): Temperature coefficient of -3mV/K

Recommended charging voltages for ambient temperatures from

+20°C to +35°C are:

Two step charge

Float charge: 1.40-1.42 V/cell

Boost charge: 1.45-1.46 V/cell

Current limitation: 0.1 ItA

Single step charge

Charging voltage: 1.42-1.44 V/cell

Current limitation: 0.1 ItA

5. Periodic maintenance

GAZ®cells require a minimum amount of maintenance.

In order to maintain maximum performance, the following is

recommend:

Standard service inspection:

In a regular twelve month period, carry out a check-up under

normal float conditions. Depending on site location, local

regulations, or special application requests, these check-ups can

vary in frequency or period.

When performing the standard service inspections please be sure

to carry out the following:

• General appearance and cleanliness of all the batteries and the

battery room.

The battery must be kept clean using only water. Do not use a

wire brush or solvents/additives of any kind. Ventilation must

fulfill the requirements of section 3.2.

CnAh

1h

ItA=

4

6. Additional warning notes

Lead-acid and NiCd batteries shall preferably be accommodated

in separate rooms. Where both battery types are located in the

same room, the charging gases from the lead-acid batteries must

be kept away from the NiCd batteries. Tools for lead-acid batteries

must not be used for NiCd batteries.

Risk of short circuit and fire:

Do not place electrically conductive objects such as tools etc. on

top of the battery!

Risk of injury:

No rings or metal bracelets should be worn during the assembly

of the battery.

Risk of explosion:

Open the doors of the battery cabinet during charging so that the

charging gases can escape.

The charging gases from batteries are explosive. Do not allow

naked flames, sparks or other sources of ignition in the vicinity of

the battery!

Caution – potassium hydroxide solution is corrosive!

A potassium hydroxide solution is used as electrolyte. It is a

highly corrosive liquid which can cause severe damage to health

if it comes into contact with eyes or skin (risk of blinding). Even

swallowing a small quantity may cause internal injuries.

When working with the electrolyte, and on the cells or batteries,

rubber gloves, safety glasses with side guards, and protective

clothing must always be worn!

Contact with the eyes:

Flood eyes immediately with large quantities of water for 10 to 15

minutes. Consult a doctor immediately.

Contact with the skin:

Remove contaminated clothing immediately and wash the

affected skin areas with large quantities of water. In case of

discomfort seek medical advice.

Swallowing:

Rinse the mouth immediately with large quantities of water and

keep drinking large amounts of water. Do not provoke vomiting.

Call an emergency doctor immediately.

In the event of injuries:

Rinse thoroughly for a long time under running water. Consult a

doctor immediately.

• Electrolyte level

Visually check the electrolyte level. Refilling is recommended

when the electrolyte level reaches the “MIN“ mark. However it

must never drop below the “WARNING LEVEL” mark. Adjust

the electrolyte level only in fully charged conditions. Only use

distilled or deionized water to top-up the cells in accordance

with IEC 60993:1989.

NOTE: Once the battery has been filled with the correct electrolyte

at the factory, there is no need to regulary check the electrolyte

density. Interpretation of density measurements is difficult and

could lead to misunderstandings.

• Electrical parameters

Check the float voltage measurements of every single cell and

the battery charging current.

It is important that the recommended charging voltage remains

unchanged. High water consumption of the battery is usually

caused by improper voltage settings of the charger. If a single-

cell voltage of below 1.35V is detected during float charging, it

is recommend to charge the cell(s) separately in accordance to

section 3.5.1 Commissioning with constant current

If a battery is connected in parallel, the charging current in the

strings should also be checked to ensure equality.

• Electrolyte temperature:

Check the electrolyte temperature from one of the cells in the

middle of the battery from time to time. The temperature of the

electrolyte should never exceed +45°C, as higher temperatures

have a detrimental effect on the performance and lifetime of

the cells. During charging, the electrolyte temperature should

be ≤35°C. In the case of the temperature exceeding +45°C, the

charging should be temporarily interrupted until the electrolyte

temperature has dropped to +35°C. In the case of low ambient

temperatures or electrolyte temperatures that reduce to –25°C,

this does not have a detrimental effect on the battery, and only

causes a temporary reduction of capacity.

Extended service inspection:

Regular check every 24 months

In addition to the standard service inspection the following

measures are required:

• Connector torque and corrosion protection:

Check that all connectors, nuts and screws are correctly

torqued. All metal parts of the battery should be coated with a

thin layer of anti-corrosion grease supplied by GAZ. Do not coat

any plastic parts of the battery, for example cell cases.

Measurement readings - battery log book:

It is recommended to utilize a battery log book. This log book

should record all significant events such as power cuts, service

activities, inspections, discharge tests, equalizing charges, topping

5

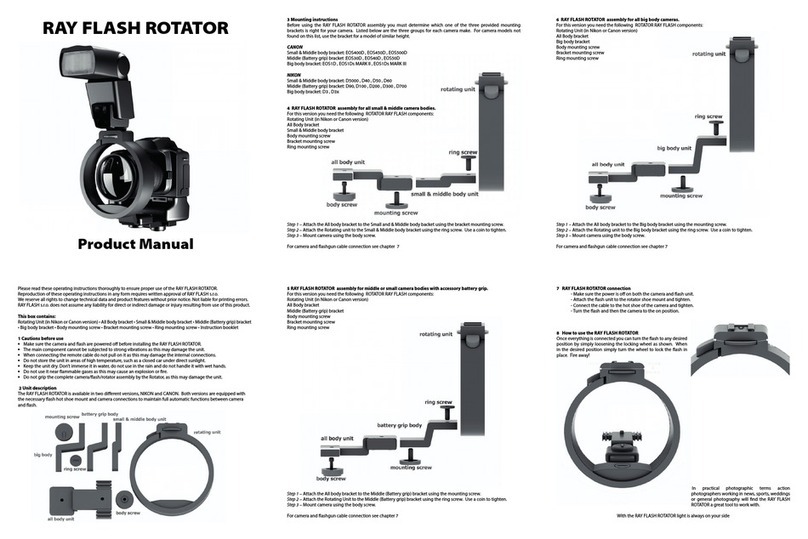

7. Removal of the Transportation Plugs and Fitting of Vent Caps

KGL 12-440 P

KGM 11-400 P

KGL 500-1570 P

KGM 450-1560 P

Step 1

(before commissioning charge)

Step 1

(before commissioning charge)

Step 2

(after commissioning charge)

Step 2

Step 3

(after commissioning charge)

6

6

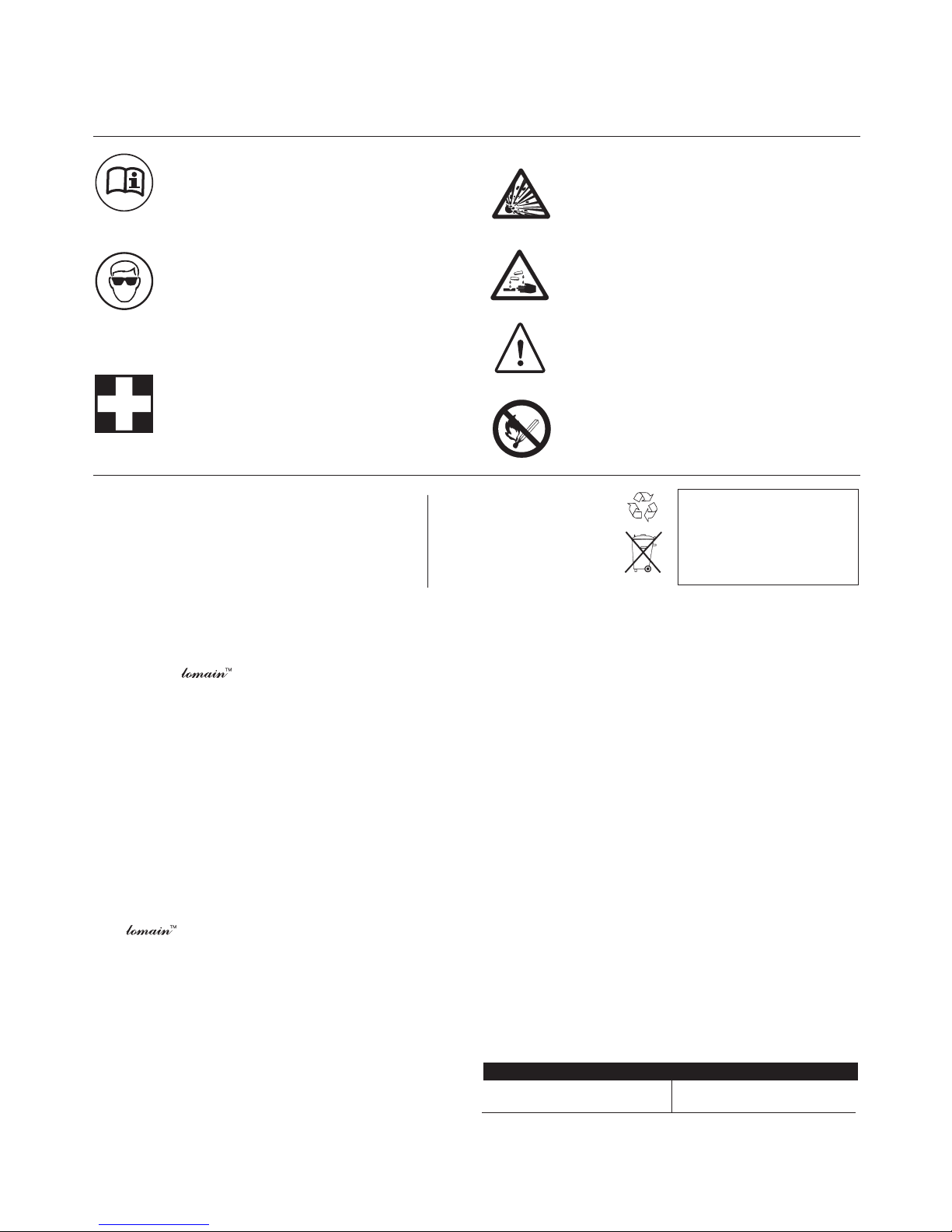

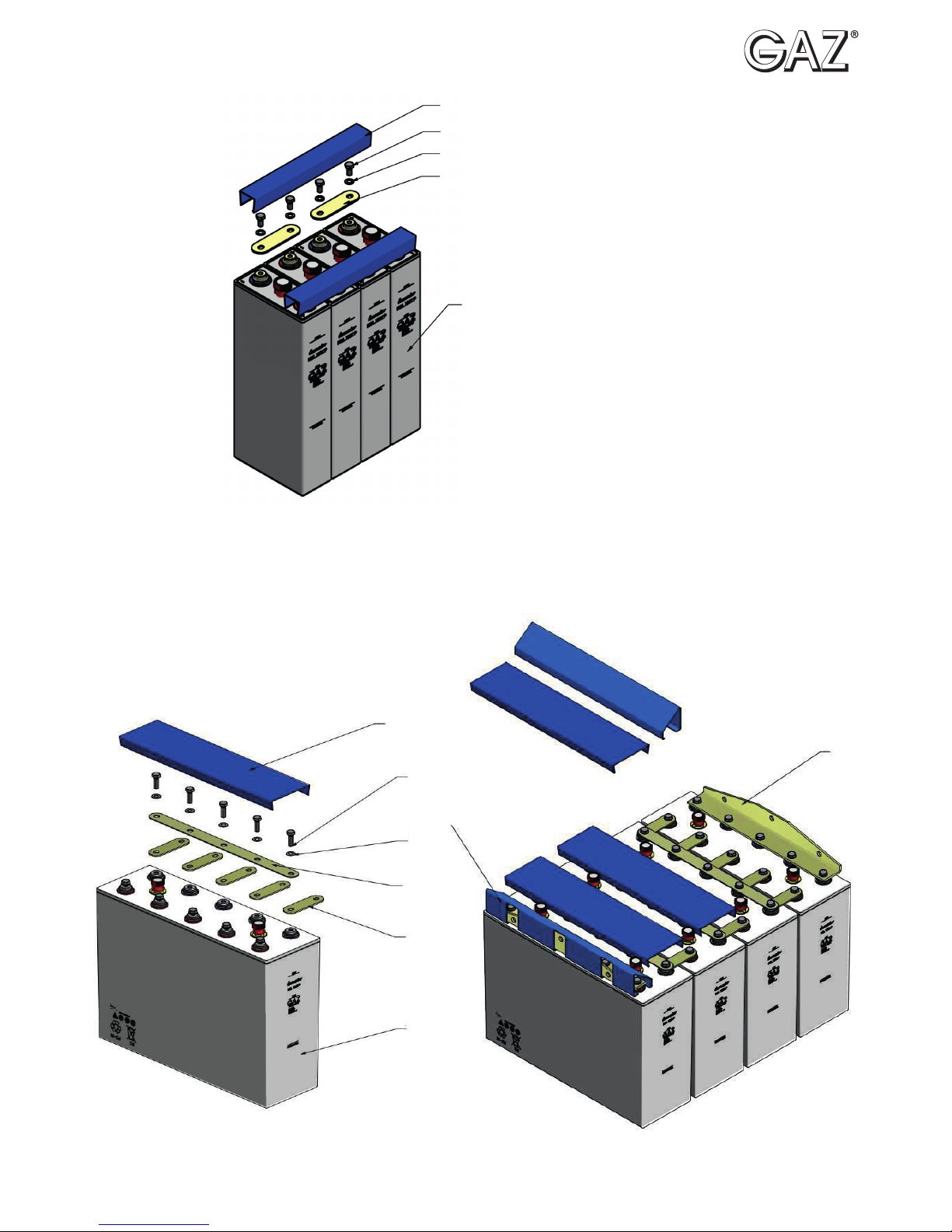

7. Design principals - Exploded view

KGL 12-35 P

KGM 11-30 P

KGL 45-60 P

KGM 40-55 P

1

2

3

4

5

Cell container

Cell connector

Spring washer

Hexagonal screw

Connector cover

1

2

3

4

5

Cell container

Cell connector

Spring washer

Hexagonal screw

Connector cover

6

7. Design principals - Exploded view

KGL 12-35 P

KGM 11-30 P

KGL 45-60 P

KGM 40-55 P

1

2

3

4

5

Cell container

Cell connector

Spring washer

Hexagonal screw

Connector cover

1

2

3

4

5

Cell container

Cell connector

Spring washer

Hexagonal screw

Connector cover

Note, typical layout only. Refer to section 9 for details

KGL 12-35 P

KGM 11-30 P

1 Cell

2 Cell connector

3 Spring washer

4 Nut

5 Connector cover

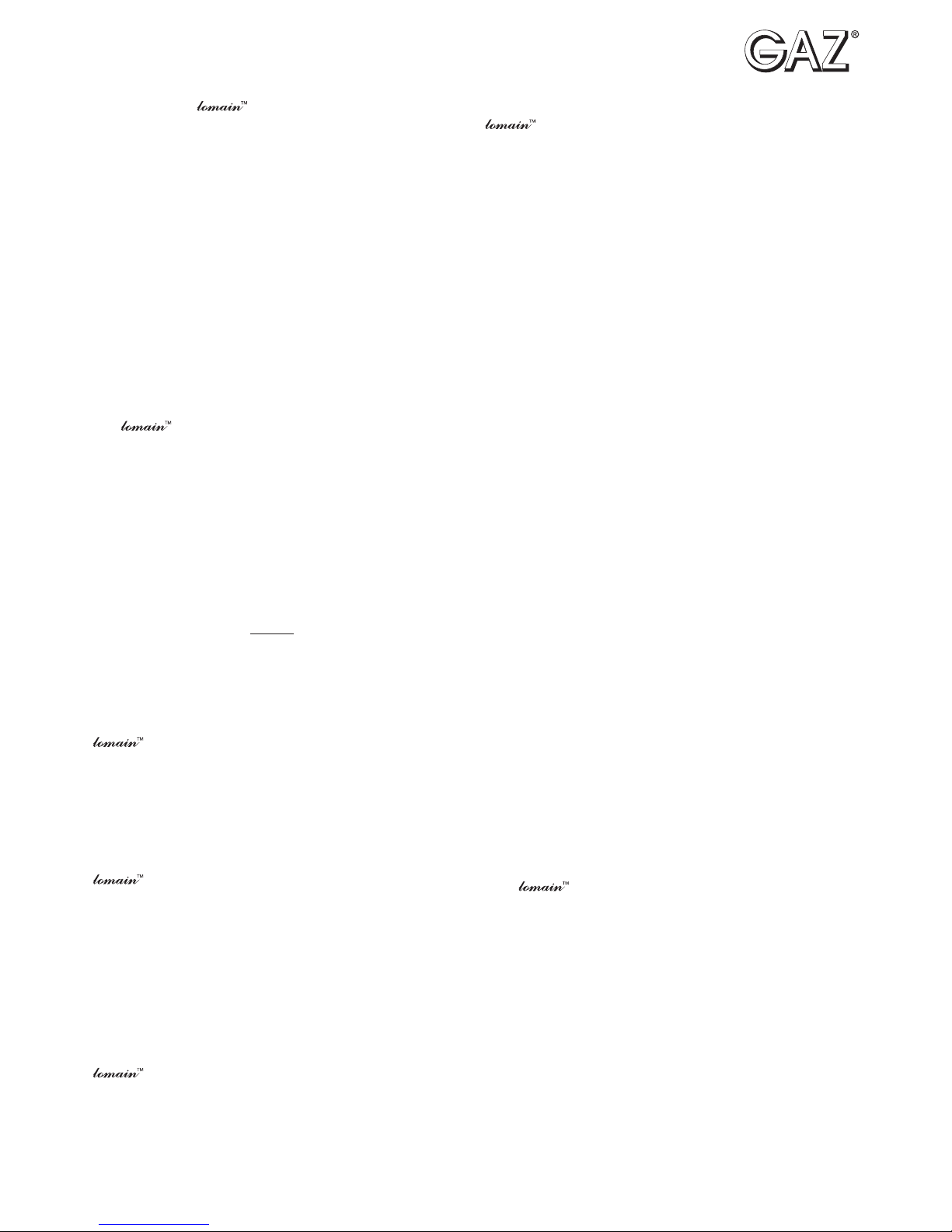

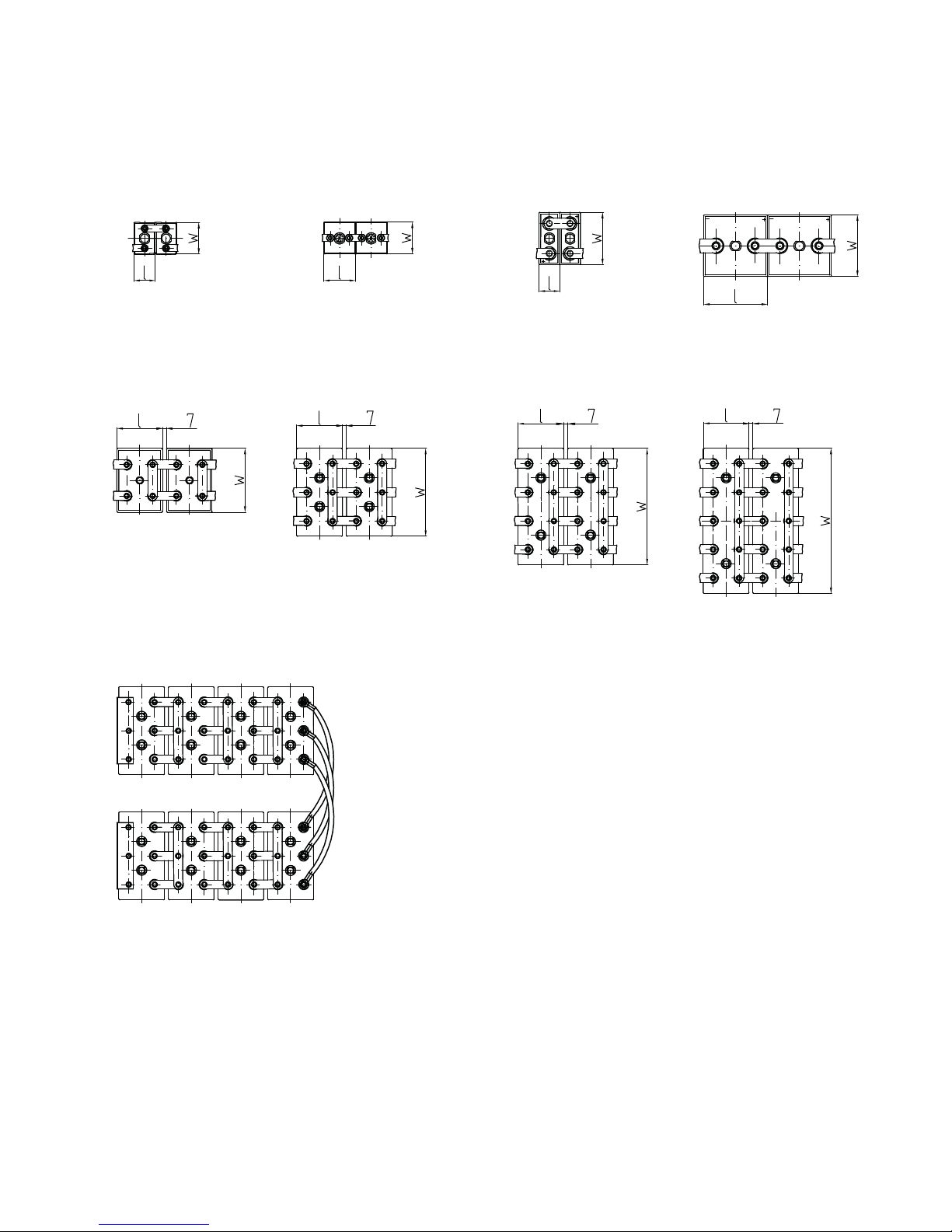

8. Layout details: inter-cell connection

KGL 45-60 P

KGM 40-55 P

1 Cell

2 Cell connector

3 Spring washer

4 Nut

5 Connector cover

1

5

4

3

2

1

5

4

3

2

KGL 500-1570 P

KGM 450-1350 P

1 Cell

2 Cell connector

3 Terminal connector

4 Spring washer

5 Screw

6 Connector cover

7 End terminal connector

8 Cover end terminal

connector

7

Note, typical layout only. Refer to section 9 for details

KGL 70-440 P

KGM 65-400 P

1 Cell

2 Cell connector

3 Spring washer

4 Screw

5 Connector cover

1

5

4

3

2

1

5

4

3

2

6

7

8

8

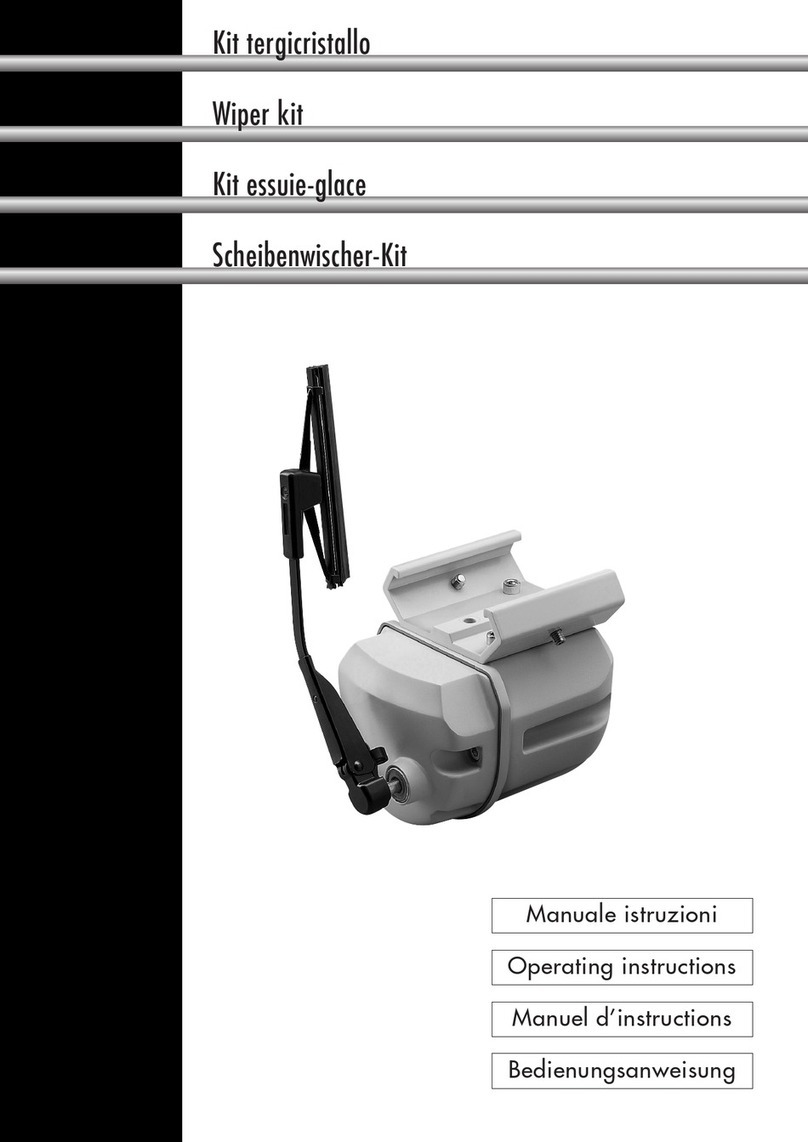

KGL...P

KGL 12 P - KGL 35 P

(Male thread M10)

KGL 500 P - KGL 645 P

(Female thread M10)

KGL 45 P - KGL 60 P

(Male thread M10)

KGL 665 P - KGL 835 P

(Female thread M10)

KGL 70 P - KGL 275 P

(Female thread M8)

KGL 890 P - KGL 1110 P

(Female thread M10)

KGL 300 P - KGL 440 P

(Female thread M10)

KGL 1260 P - KGL 1570 P

(Female thread M10)

Cells assembled in a 2 row

configuration

9. Cell Layout

9

KGL...M

KGM 11 P - KGM 30 P

(Male thread M10)

KGM 40 P - KGM 55 P

(Male thread M10)

KGM 65 P - KGM 250 P

(Female thread M8)

KGM 270 P - KGM 400 P

(Female thread M10)

KGM 450 P - KGM 570 P

(Female thread M10)

KGM 600 P - KGM770 P

(Female thread M10)

KGM 800 P - KGM 1130 P

(Female thread M10)

KGM 1250 P - KGM 1350 P

(Female thread M10)

Cells assembled in a 2 row

configuration

Publication No. EN-GAZ Iomain-IOM-004 - May 2017 - Subject to revisions without prior notice. E.&O.E.

EnerSys Asia

152 Beach Road

Gateway East Building #11-03

Singapore 189721

Tel: +65 6508 1780

EnerSys World Headquarters

2366 Bernville Road, Reading

PA 19605, USA

Tel: +1-610-208-1991 /

+1-800-538-3627

EnerSys EMEA

EH Europe GmbH

Baarerstrasse 18

6300 Zug, Switzerland

© 2017 EnerSys. All rights reserved. Trademarks and logos are the property of EnerSys and its affiliates unless otherwise noted.

Contact

This manual suits for next models

1

Table of contents

Other GAZ Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Pixapro

Pixapro LECO 500 instruction manual

Videotec

Videotec VIP6A1 operating instructions

IKAR

IKAR 41-50 Log book and instructions for use

Moog

Moog RM7CF2N Assembly, installation and operation instructions

GRASS VALLEY

GRASS VALLEY EyeCatcher EC 744 user guide

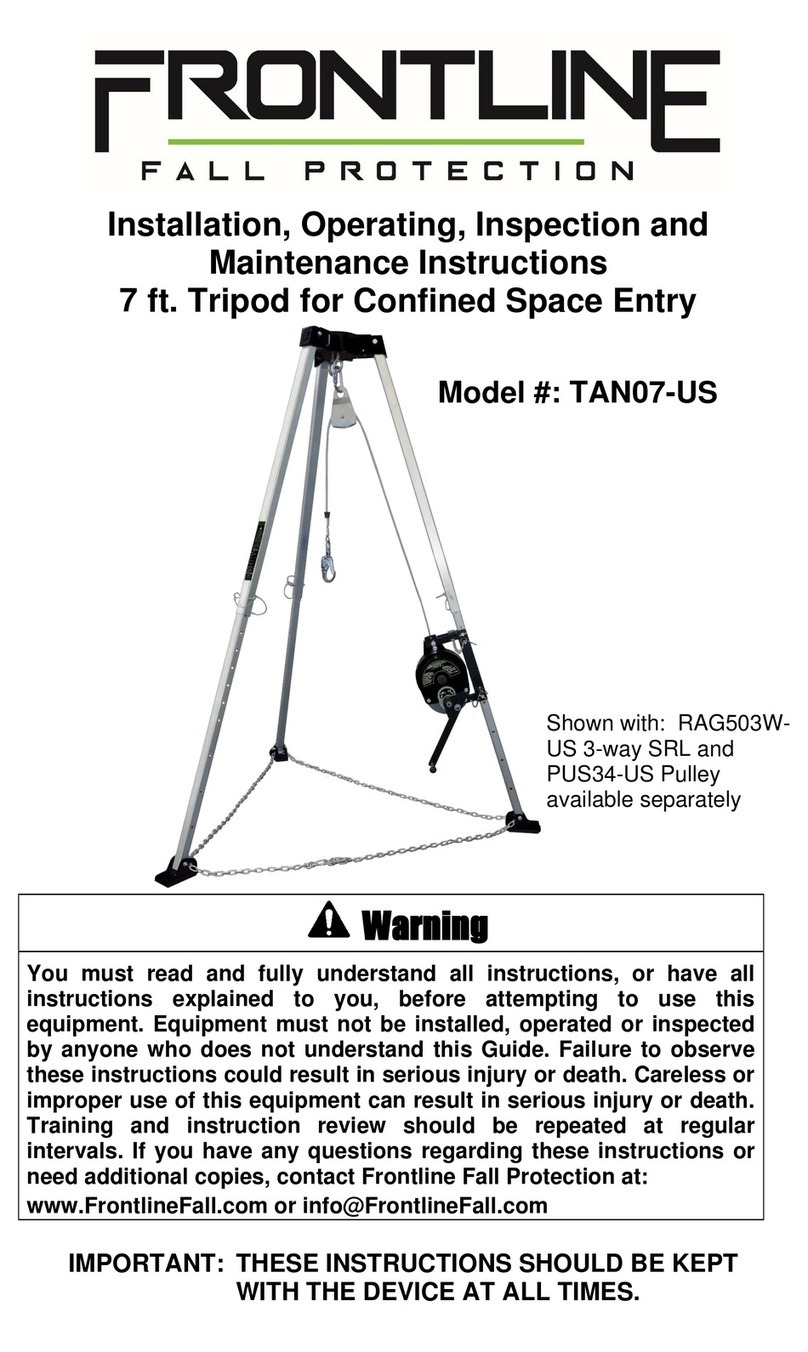

FrontLine

FrontLine TAN07-US Installation, operating and maintenance instructions

Geutebruck

Geutebruck G-Case/WPH-1010 Installation

Maxwell

Maxwell 16 V Series user manual

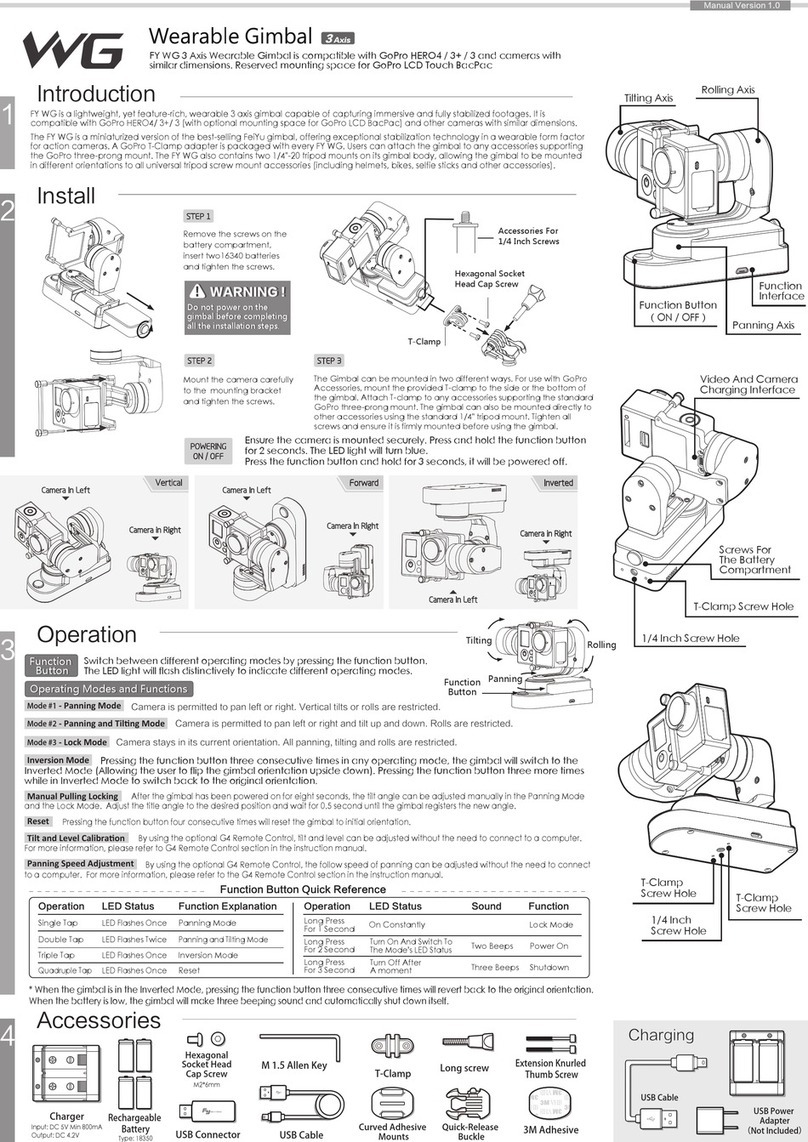

Feiyu

Feiyu FY WG manual

HOLATRON SYSTEMS

HOLATRON SYSTEMS SureFire-1 Operation & maintenance guide

3D Shape Engineering

3D Shape Engineering Motorized Camera Slider v1 Documentation & Instrusctions

Vello

Vello BG-C7 user manual