EPM 4500 SUB METER – INSTRUCTION MANUAL TOCTOC–I

Table of Contents

1: OVERVIEW GETTING STARTED ........................................................................................................................... 1-1

DESCRIPTION ........................................................................................................................ 1-1

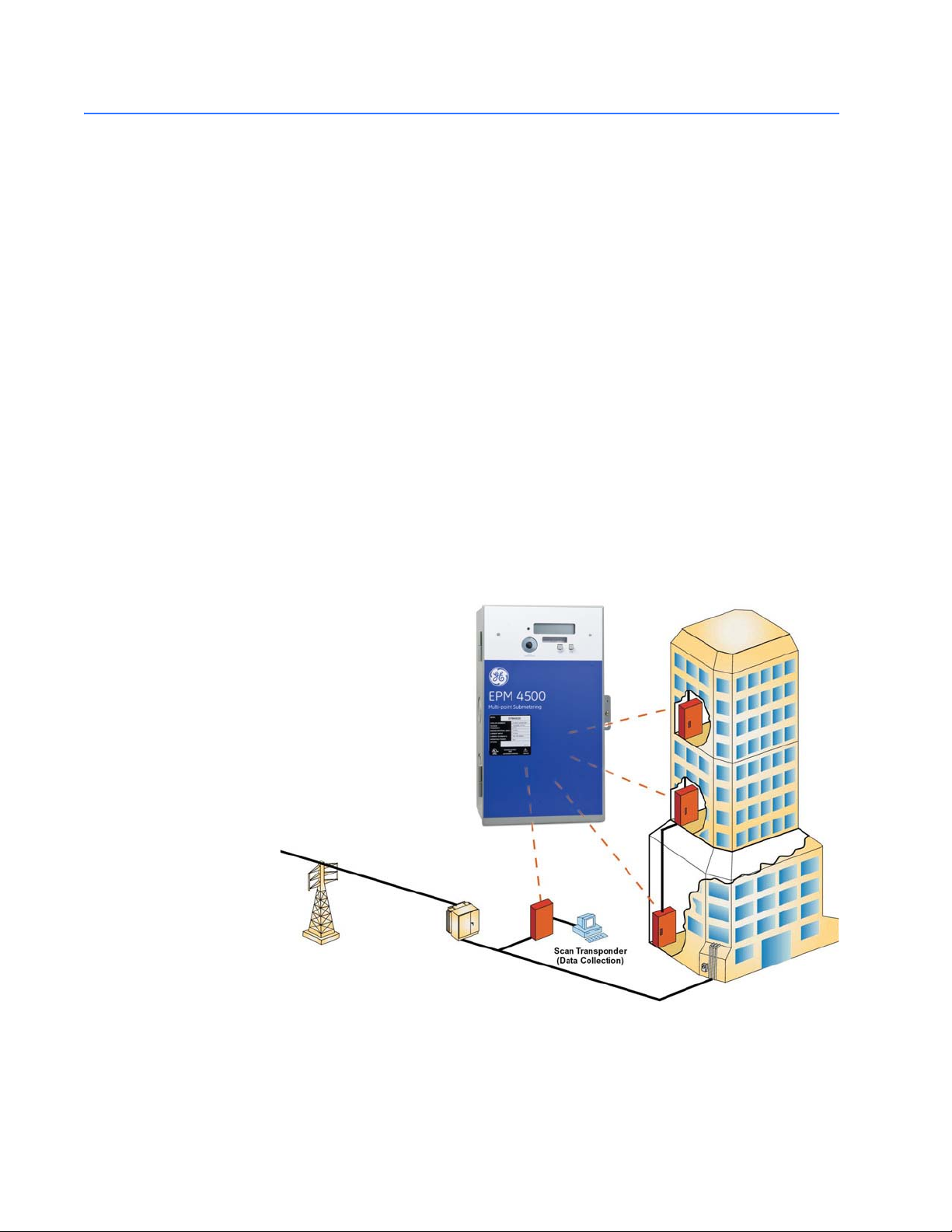

APPLICATIONS ................................................................................................................................... 1-2

STAND-ALONE METER ........................................................................................................ 1-2

METERING SYSTEM .............................................................................................................. 1-2

INTERIOR VIEW .................................................................................................................... 1-3

CAUTIONS AND WARNINGS ............................................................................................... 1-3

PROTECTIVE CONDUCTOR TERMINAL ............................................................................... 1-4

PREVENTIVE MAINTENANCE ............................................................................................... 1-4

SPECIFICATIONS ............................................................................................................................... 1-5

MONITORING ........................................................................................................................ 1-5

POWER SUPPLY ................................................................................................................... 1-5

METERING ............................................................................................................................. 1-5

INPUTS .................................................................................................................................. 1-6

COMMUNICATIONS .............................................................................................................. 1-6

PHYSICAL .............................................................................................................................. 1-6

TYPE TESTS AND APPROVALS ............................................................................................ 1-6

ORDERING ........................................................................................................................................... 1-8

EPM4500 RESIDENTIAL .................................................................................................... 1-8

EPM4500 COMMERCIAL ................................................................................................... 1-8

OPTIONS ...............................................................................................................................1-8

CURRENT TRANSFORMERS (0.1 A SECONDARY) ............................................................. 1-9

TRANSPONDER MODELS ..................................................................................................... 1-9

PULSE INPUTS ...................................................................................................................... 1-9

2: INSTALLATION GETTING READY ................................................................................................................................ 2-1

DETERMINATION OF METERING SYSTEM REQUIREMENTS .............................................. 2-1

PHASE ASSOCIATION ........................................................................................................... 2-1

WIRING ................................................................................................................................................. 2-2

OVERVIEW OF METER WIRING .......................................................................................... 2-2

WIRING OVERVIEW ............................................................................................................. 2-2

THREE-PHASE FOUR-WIRE WYE WIRING ....................................................................... 2-3

SINGLE-PHASE, THREE-WIRE 120 V WIRING ............................................................... 2-6

THREE-PHASE, THREE-WIRE DELTA WIRING ................................................................. 2-9

SINGLE-PHASE, THREE-WIRE WIRING ............................................................................. 2-12

INSTALLATION OF METER, MCI BOARD, AND CTS ............................................................. 2-15

PROCEDURE .......................................................................................................................... 2-15

INSTALLING THE SCAN TRANSPONDER ................................................................................. 2-18

PROCEDURE .......................................................................................................................... 2-18

3: USING THE METER MENU NAVIGATION ........................................................................................................................ 3-1

USER INTERFACE .................................................................................................................. 3-1

CT MULTIPLIER TABLE .................................................................................................................... 3-4

CT MULTIPLIERS .................................................................................................................. 3-4

VERIFYING METER FUNCTIONALITY ......................................................................................... 3-5

OVERVIEW ............................................................................................................................ 3-5