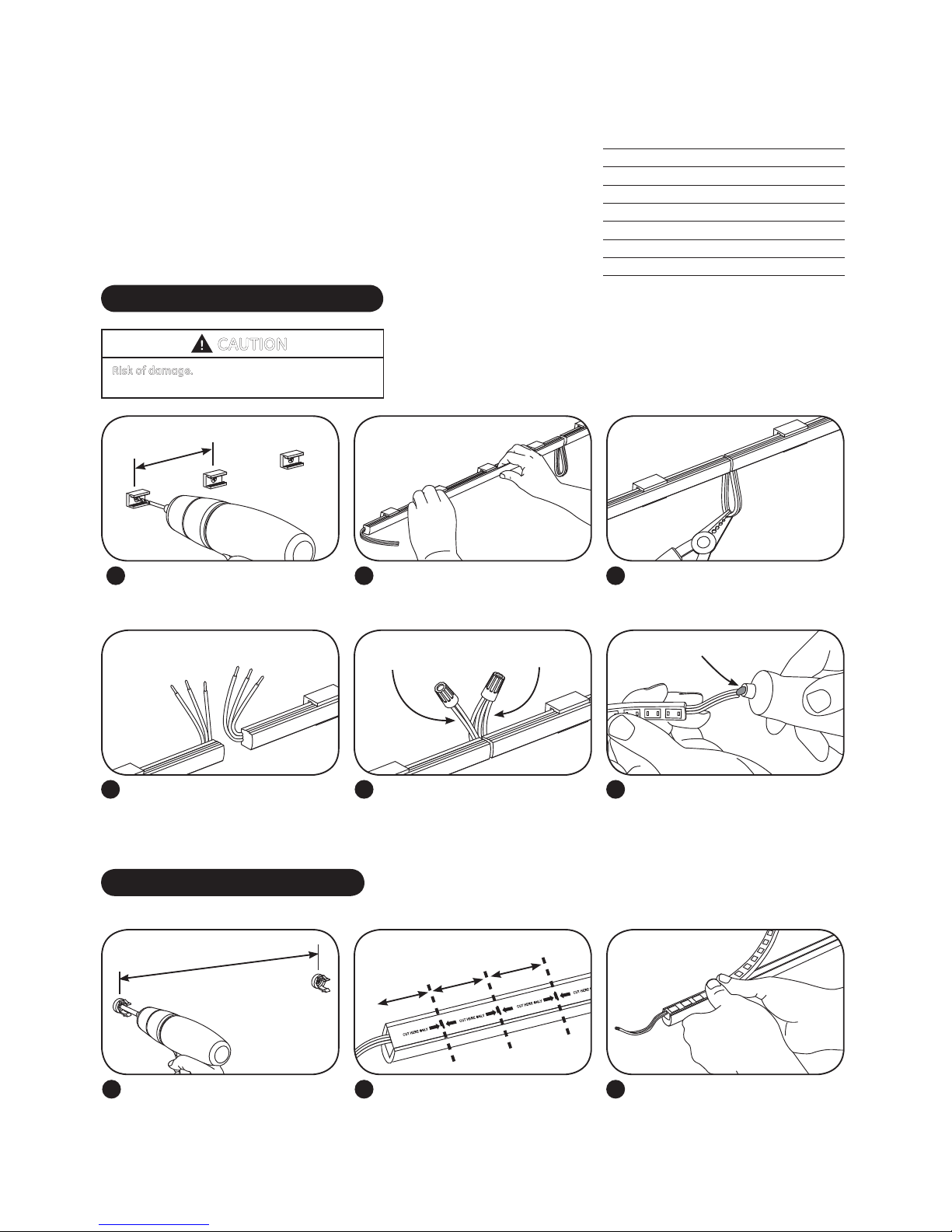

Connect the two outer wires (+) from

the LED strip to the red wire (+) of the

power supply. Connect the middle

wire (-) from the LED strip to the black

wire (-) of the power supply.

NOTE: Grounding and bonding must

be done in accordance with National

Electrical Code (Article 600). See

power supply instructions.

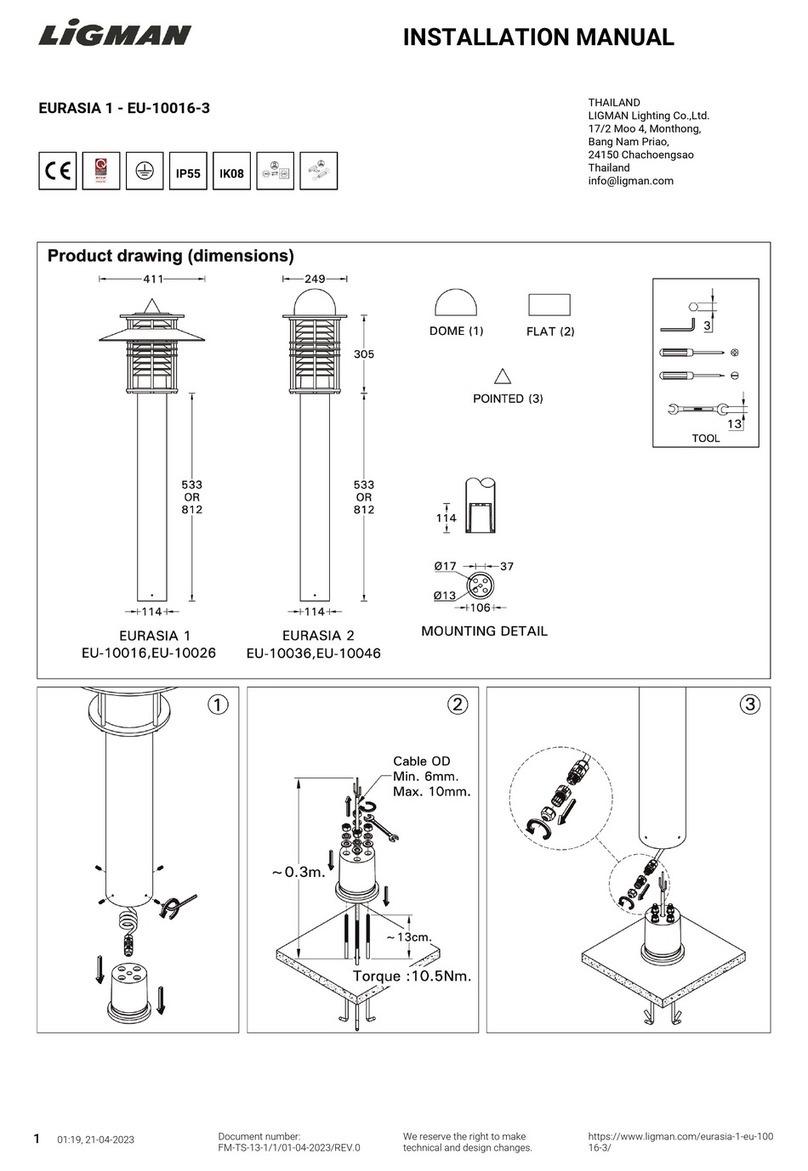

4 Attach Tetra Contour to the mounting

clips, leaving a 3/8 in. (10mm) gap

between sections to allow for expansion

or contraction. Secure light guide by

twisting tie-wire around the mounting

clip and light guide.

8 At any open end, apply electrical

grade silicone and press fit a

GExxLGEC15 light guide end cap to

the Tetra Contour.

9

Electrical grade silicone

At each gap between Tetra Contour

sections, snap on a GExxLGC15 light

guide connector.

3/8in. (10mm)

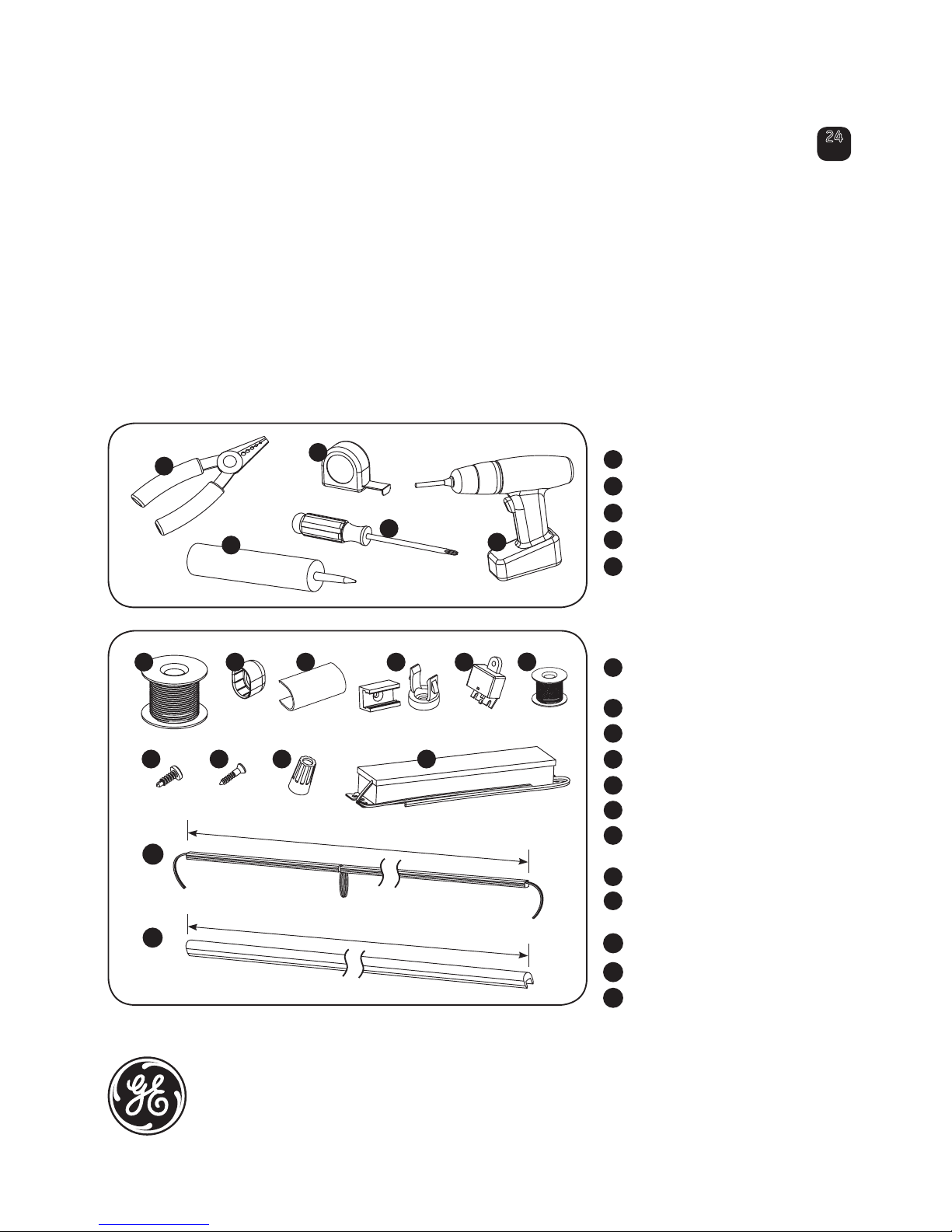

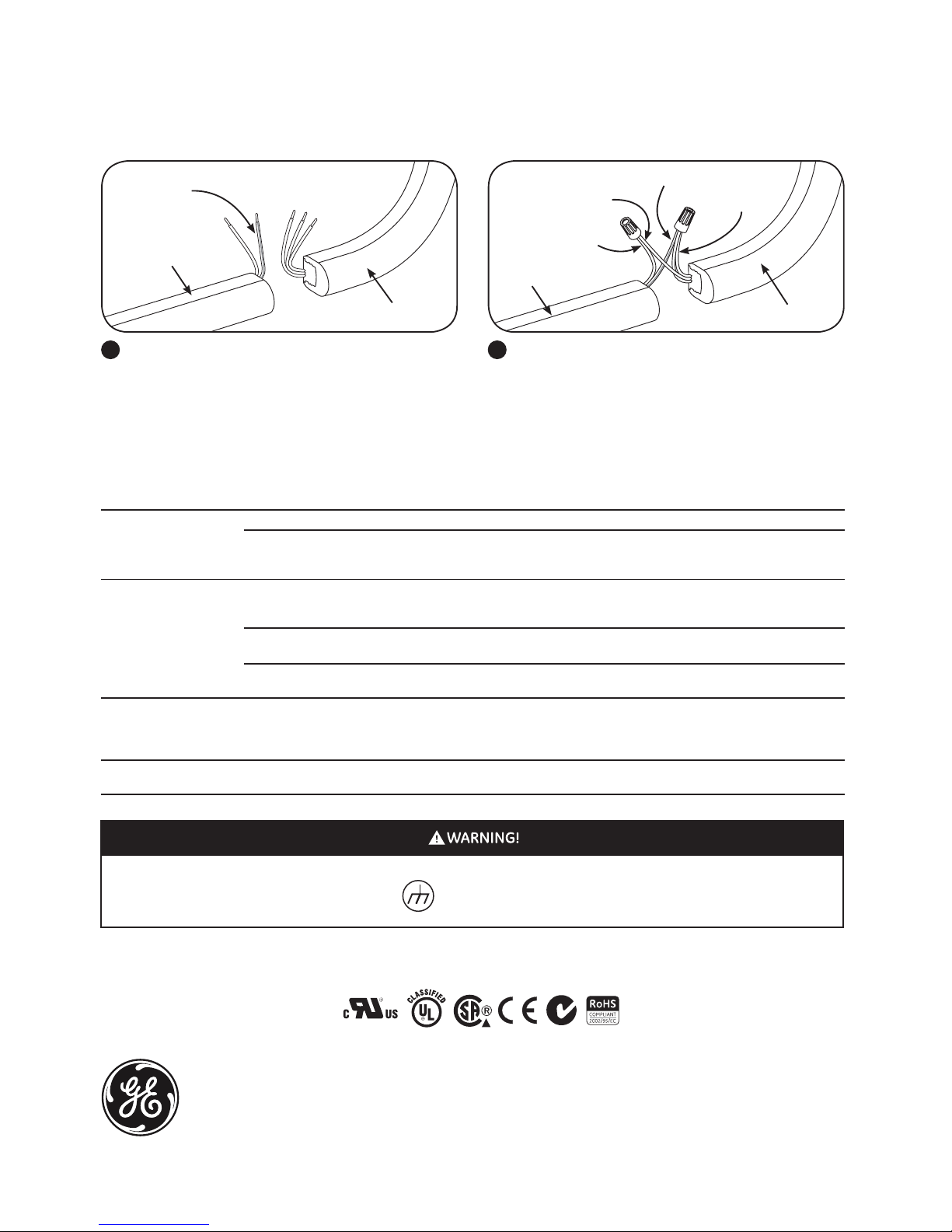

6 Use twist-on wire connectors to join

wires together. Fold wires behind

light engines.

5 Separate wires and identify outer

conductors as positive (+) and

middle conductors as negative (–).

Strip ends back 0.5 in. (13mm).

+ +

+ + –

–

Electrical grade silicone

Connect two

negatives (–)

Connect four

positives (+)

Separate wires

7 Insert wire connectors into weather

box. Fill with electrical grade silicone

and close box. Weather box can be

mounted using #8 (M3) screws.

NOTE: Weather box is required for all

outdoor electrical connections.

Weather box can be painted

Connect Power Supply

Run a wire from the power supply to

a section of Tetra Contour.

NOTE: Power supply connection

must be completed in an acceptable

UL/NEMA enclosure.

NOTE: Power supply loading is

described in the power supply

installation instructions.

Separate wires and identify outer

conductors as positive (+) and middle

conductor as negative (-). Strip ends

back 0.5 in. (13mm).

1 2

WARNING

Risk of electrical shock. Turn power OFF

before inspection, installation or removal.

Example electrical grade silicones include: GE RTV 6700 Series Silicone Rubber Adhesive Sealant, GE White Blanc RTV 162 Silicone

Rubber Adhesive Sealant-Electrical Grade, Dow Corning 3140 - Non-Corrosive Flowable (clear), Dow Corning 3145 - Non-Corrosive

Nonflowable (clear or gray) & Dow Corning RTV 748 Non-Corrosive Sealant-White

+

+

–

Power

supply

To Tetra Contour

Red (+)

Black (-)

3

To power supply

Black (-) Red (+)

Middle wire (-)

Outer wires (+)