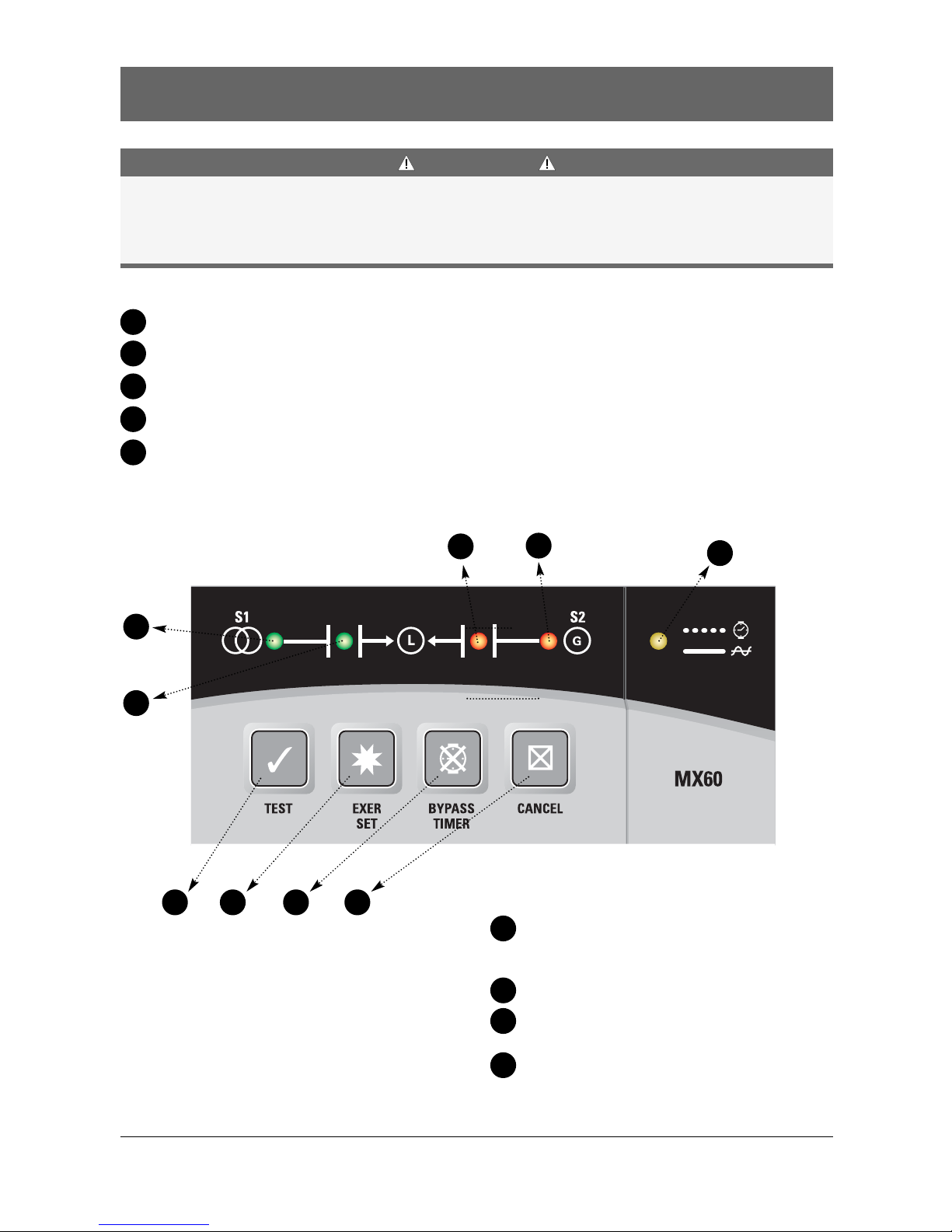

■■GE Zenith Controls 1■■

ZTX Operation and Maintenance Manual (72R-1000)

Each GE Zenith transfer switch is factory wired and

tested. A complete information package is furnished

with each switch which includes:

a. Sequence of operation.

b. Description and operation of

all accessories supplied.

c. Power panel connection diagram

and schematic.

d. Description and identification of

all customer field connections.

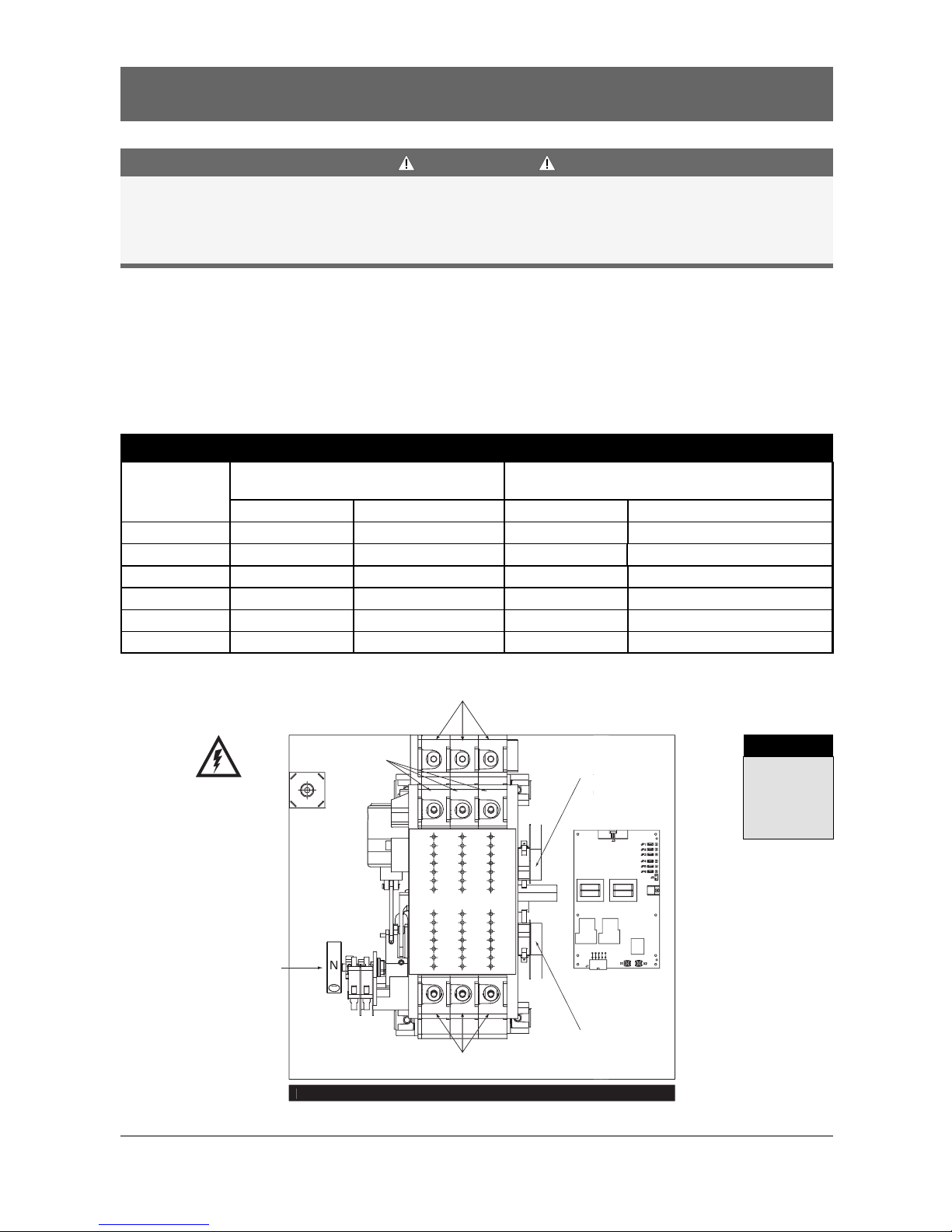

Installation of GE Zenith transfer switches includes:

a. Mounting the transfer switch cabinet.

b. Connection of all Normal, Emergency,

and Load cables or bus bars.

c. Connection of external control

circuits as required.

Mounting

Enough room should be allowed to open the cabinet doors

fully for inspection and servicing of the switch per NEC and

local codes.

Installation

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

The safe operation of your switch is GE Zenith’s focus.

The proper storage, installation, operation and mainte-

nance will help increase the life of the switch.

Equipment Inspection

and Storage

Once you have received the transfer switch, inspect

it for any damage. This includes damage to the enclo-

sure, power panel, control panel and wiring harness. If

any damage is found or suspected, file a claim as soon as

possible with the carrier and notify the nearest GE Zenith

representative.

Before installation, it is necessary to store the transfer

switch in a clean dry place, protected from dirt and

water. Provide ample air circulation and heat, if

necessary, to prevent condensation.

5% to 95%

(non-con-

densing)

-30°C to

+75°C

(-22°F to

+167°F)

-20°C to +65°C

(-4°F to +149°F)

Operating

Storage Temperature

Temperature (Ambient): Humidity

CAUTION

Due to hazardous voltage and current, GE Zenith rec-

ommends that a GE Zenith Certified technician or a

qualified electrician must perform the

installation and maintenance of the switch.

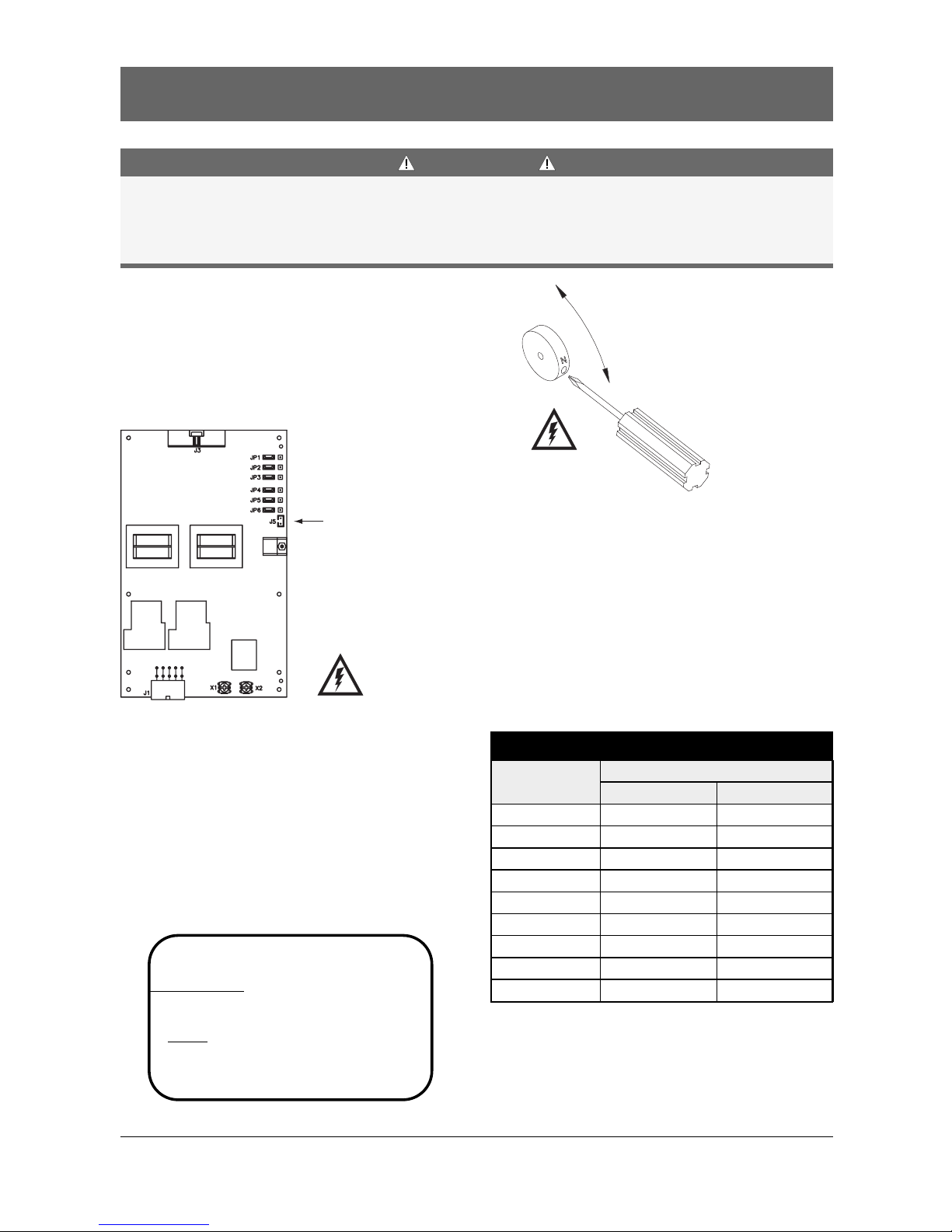

Final Equipment Inspection

Prior to energizing the transfer switch:

1. Remove any debris incurred, with a vacuum,

due to shipment or installation.

WARNING

Do not use a blower since debris may

become lodged in the electrical and

mechanical components and cause damage.

2. Verify that all cabled connections are correct.

3. Check engine start connections and verify

the correct connection of all control wires.

4. Check the lug torque values of the power

connections.

NOTE: Lug torque values are specified

in the power panel manual.

5. Make sure that all covers and barriers are

installed and properly fastened.

NOTE: Power panels ship from GE Zenith

in the Normal Position.

CAUTION

Before drilling conduit entry holes or any

accessory mounting holes, cover and protect

the switch and control panel to prevent dirt

and metal fragments from entering the

mechanical and electrical components.

Failure to do so may result in

damage and malfunction of the switch.

NOTE: When lifting the switch using a spreader bar,

height H must be equal to half of distance D.