– 4 –

PartsIncluded

PART QUANTITY

Brass orifices 4

Stick-on rating label 1

Installation instructions 1

GasSupply

Withtheinstallationofthisconversionkit,the

cooktopshouldoperateonLPgasat10in.of

watercolumnpressure.

Thepressureregulatormustbeconnectedin

serieswiththemanifoldofthecooktopandmust

remaininserieswiththesupplyline.Forproper

operation,themaximuminletpressuretothe

regulatormustbenomorethan14in.water

columnpressureforLPgas.

Whencheckingtheregulator,theinletpressure

mustbeatleast1in.greaterthantheregulator

outputsetting.Iftheregulatorissetfor10in.of

watercolumnpressure,theinletpressuremustbe

atleast11in.

Note:Disconnectthecooktopandtheindividual

shutoffvalvefromthegassupplypipingsystem

duringanypressuretestingofthatsystemattest

pressuresgreaterthan1/2psig.Isolatethe

cooktopfromthegassupplypipingsystemby

closingtheindividualmanualshutoffvalvetothe

cooktopduringanypressuretestingofthegas

supplypipingsystemattestpressuresequaltoor

greaterthan1/2psig.

ConversiontoLP(Propane)Gas

Note:Beforeyou begin, readthese

instructions completely and carefully.

Thecooktopisfactorysetfornaturalgas

operation.To useLP(propane)gas,theregulator

andburnerorificesmustbeconverted.TheLP

orificespudsforthecooktopburnerscanbe

locatedwithintheliteraturepackageshippedwith

theunit.

IfyouconverttoLPgas,keepinstructionsand

naturalgasorificestoconvertbackforusewith

naturalgas.

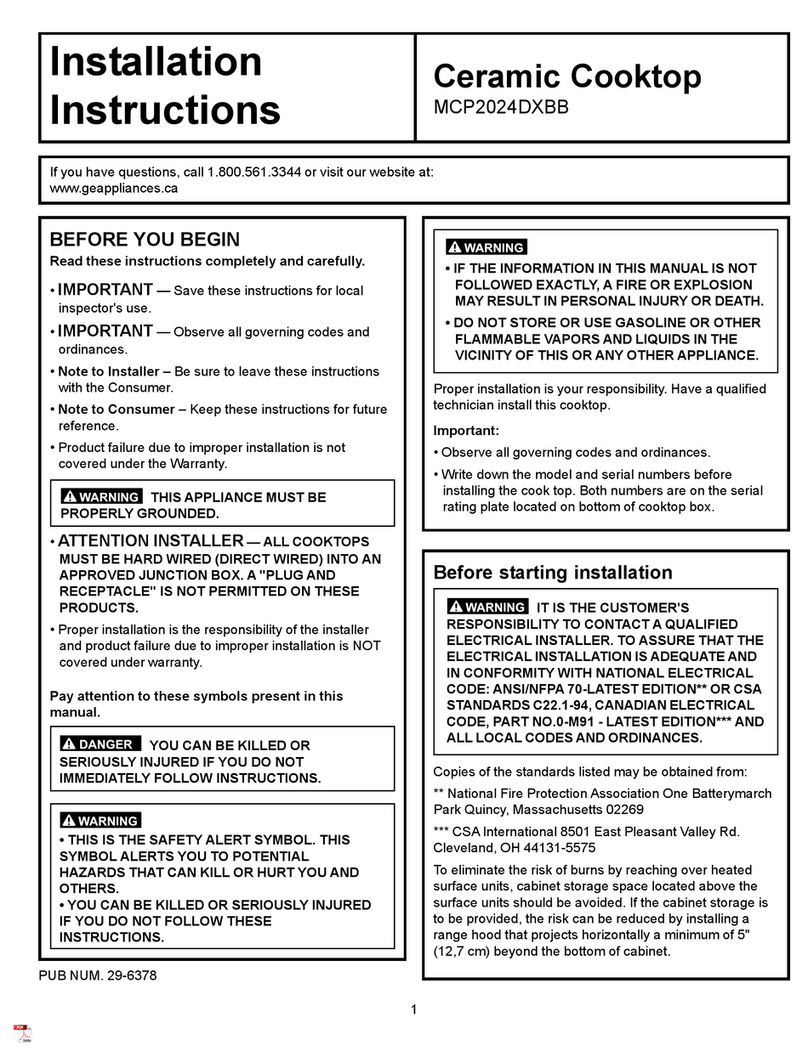

Productfailureduetoimproperinstallationisnot

coveredundertheGEAppliancesWarranty.

WARNING:IfyouareusingLP(propane)gas,all

adjustmentsdescribedinthefollowingstepsmust

bemadebeforeattemptingburneradjustmentsor

usingthecooktop.

WARNING: Thisconversionkitshallbeinstalled

byaqualifiedserviceagencyinaccordancewith

themanufacturer’sinstructionsandallapplicable

codesandrequirementsoftheauthorityhaving

jurisdiction.Iftheinformationintheseinstructions

is notfollowedexactly, afire,explosion,or

productionofcarbonmonoxidemayresult,

causingpropertydamage,personalinjury, or loss

oflife.Thequalifiedserviceagencyisresponsible

fortheproperinstallationofthiskit.Theinstallation

isnotproperandcompleteuntiltheoperationof

theconvertedapplianceischeckedasspecifiedin

themanufacturer’sinstructionssuppliedwiththe

kit.

ToolsYouWillNeed

Adjustable wrench 9/32″(7 mm) Nutdriver T15 Torx driver

Small, thin-blade flat screwdriver with approximately 1/8″

blade width is needed to access the calibration screw.