2

IMPORTANTSAFETYINSTRUCTIONS

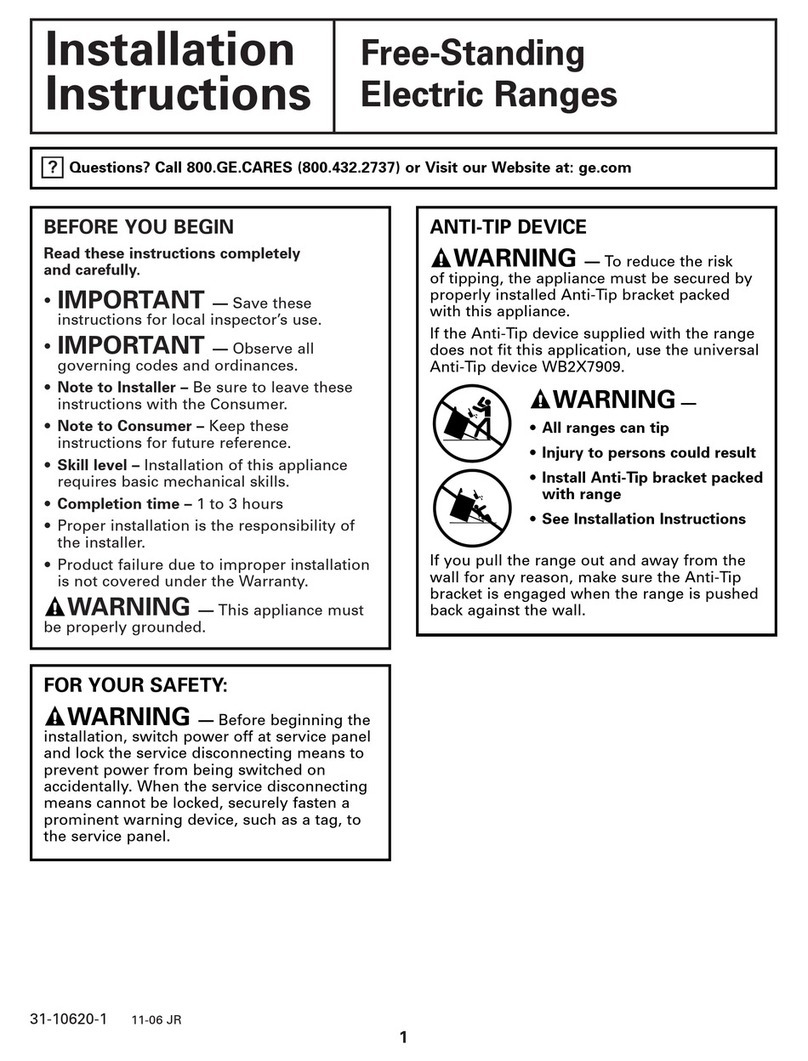

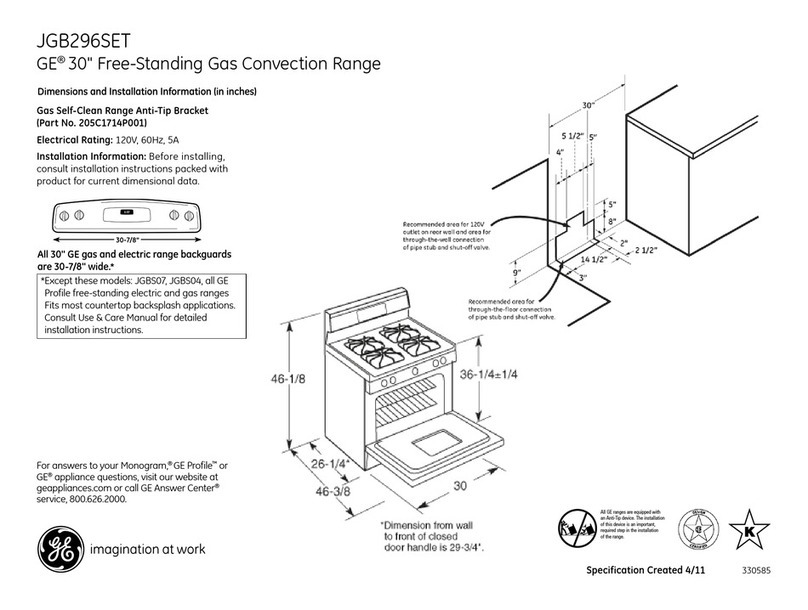

Installation Instructions

ForYourSafety

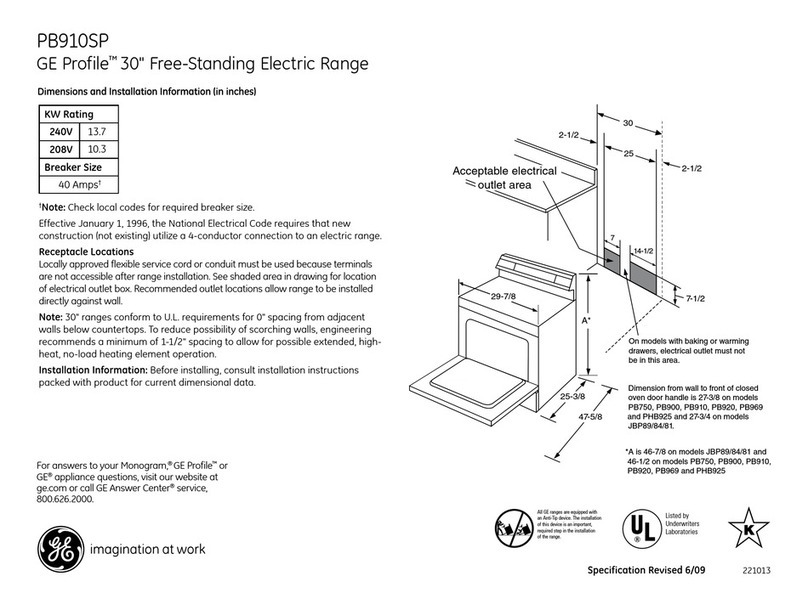

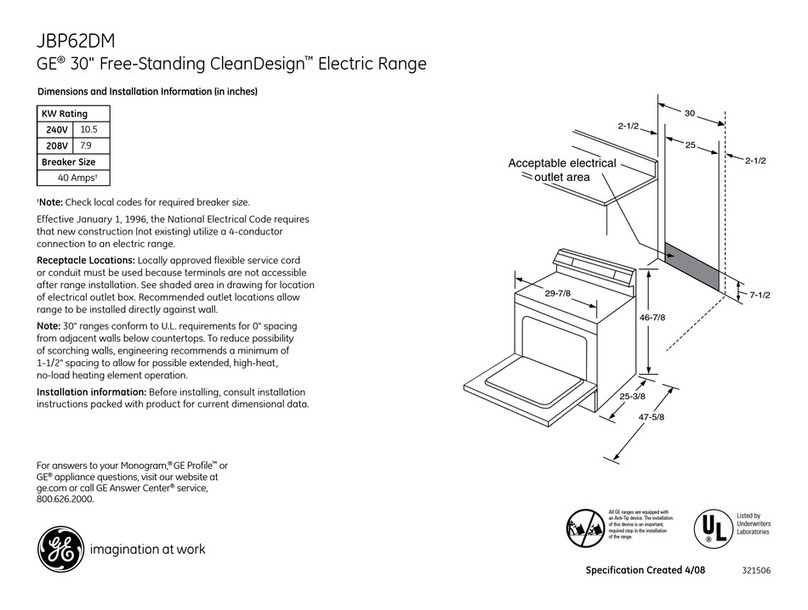

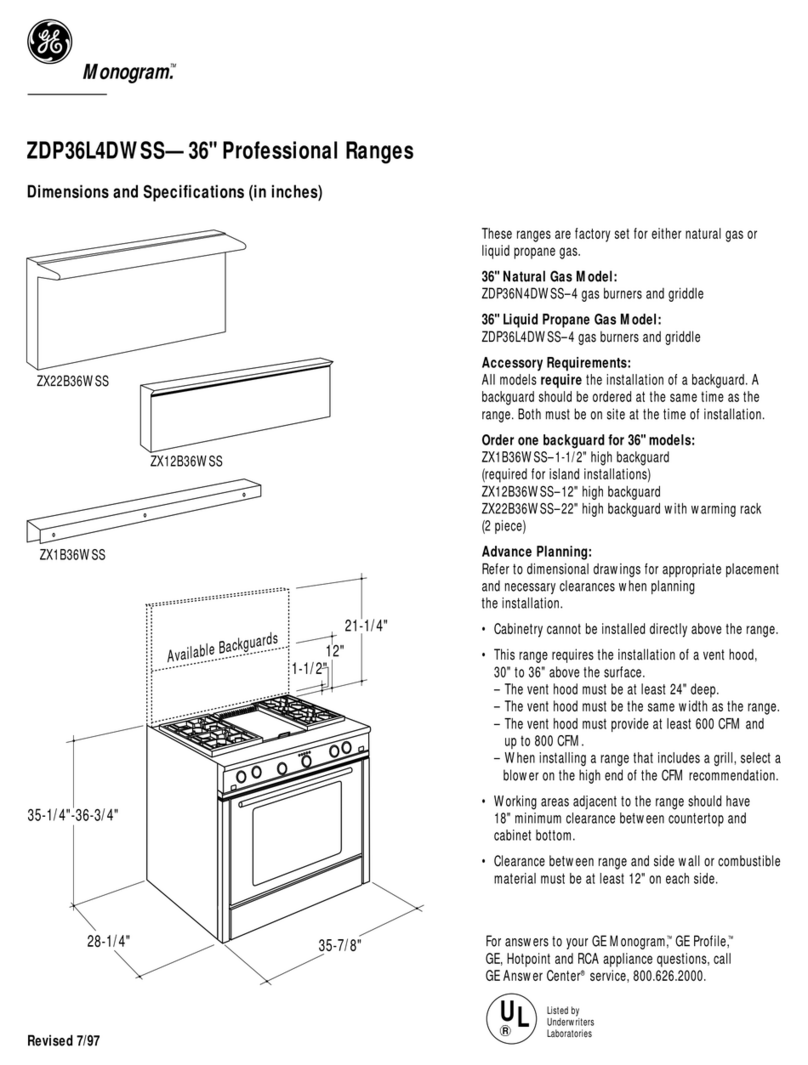

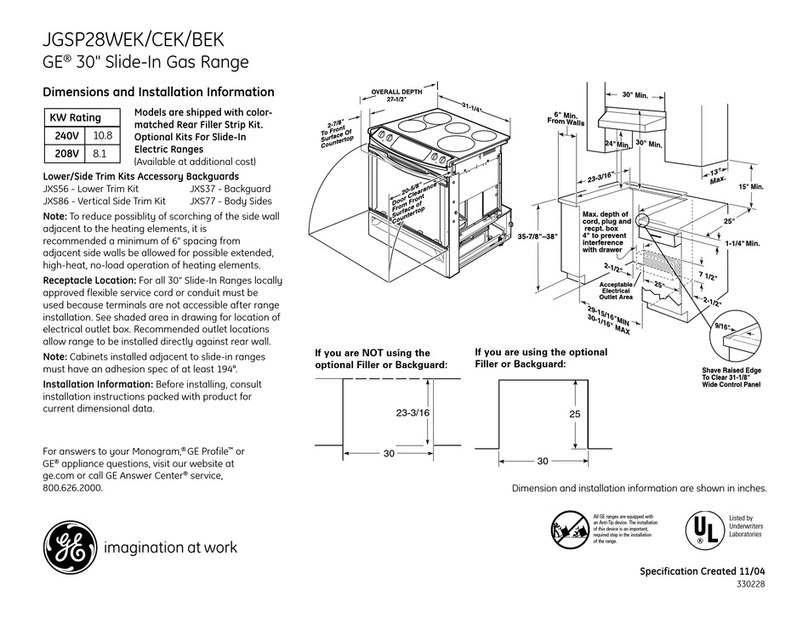

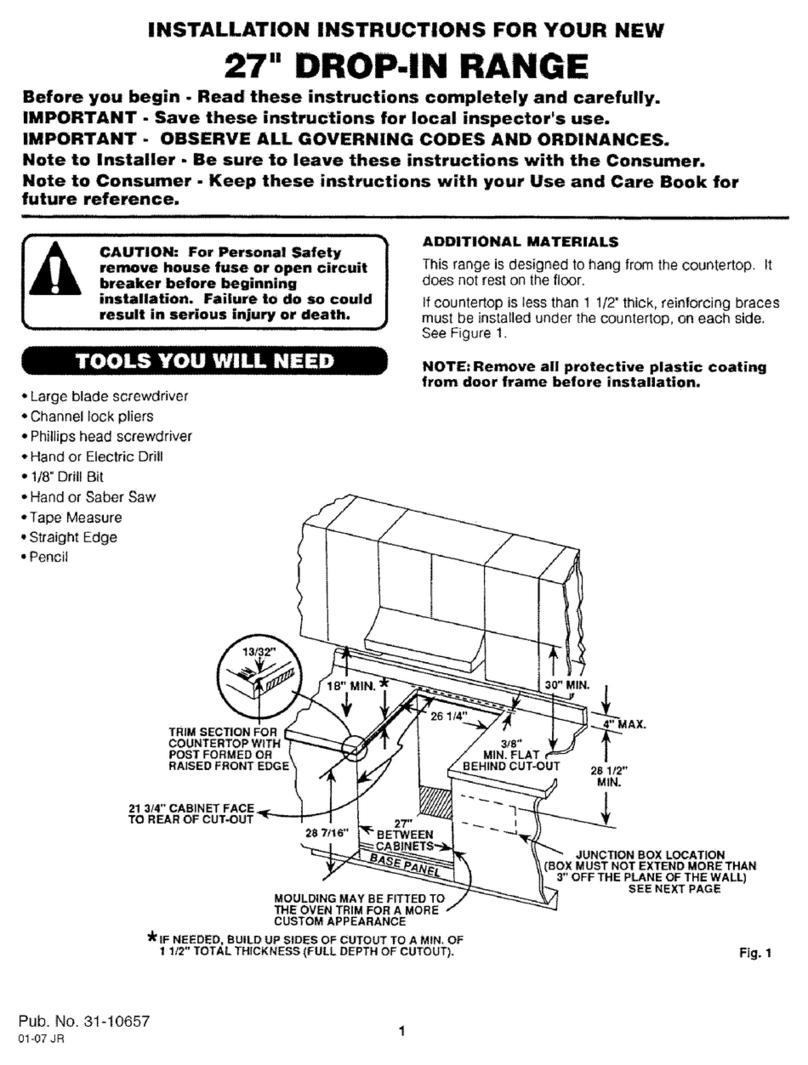

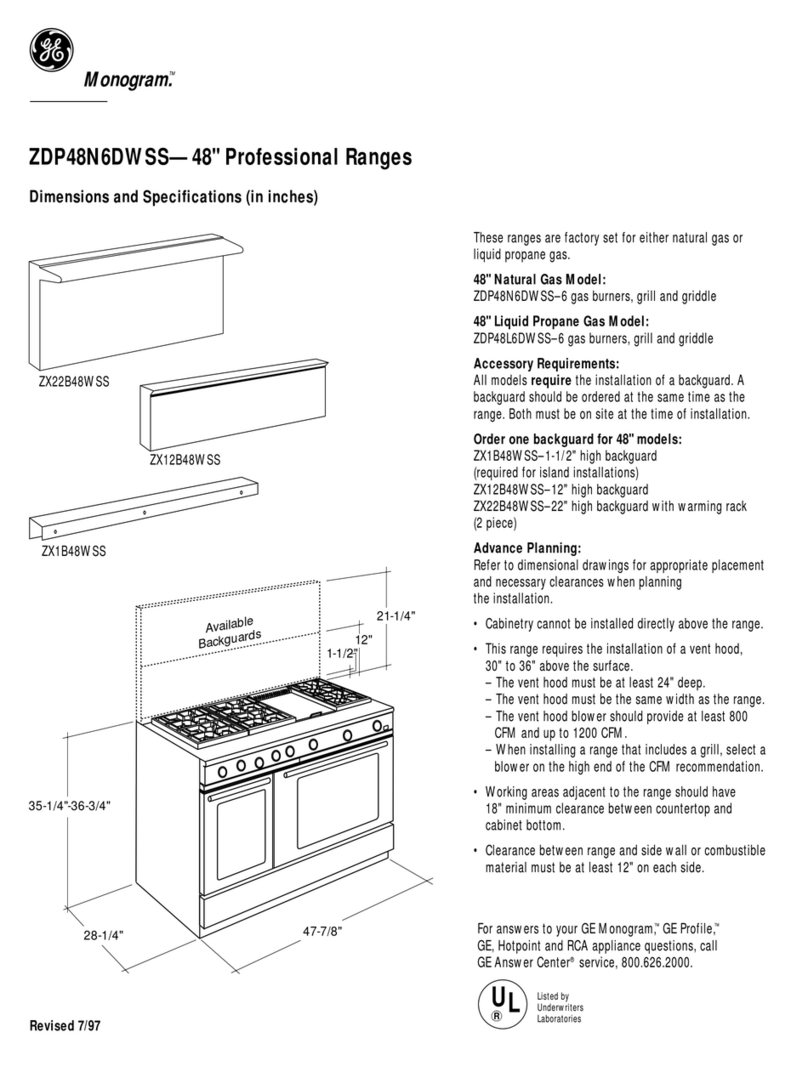

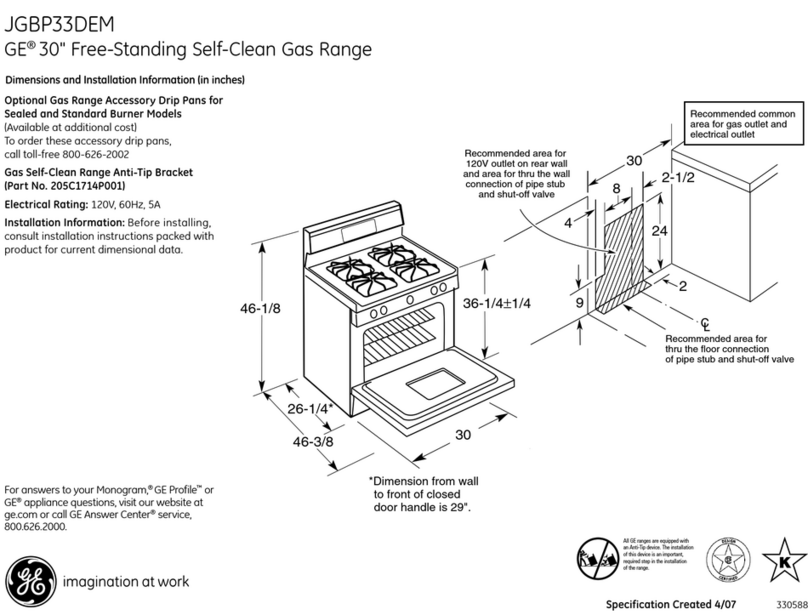

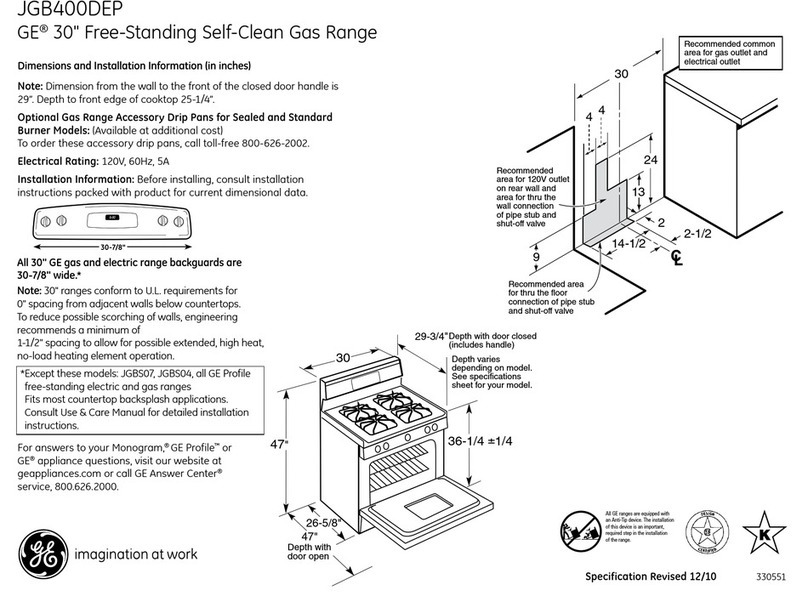

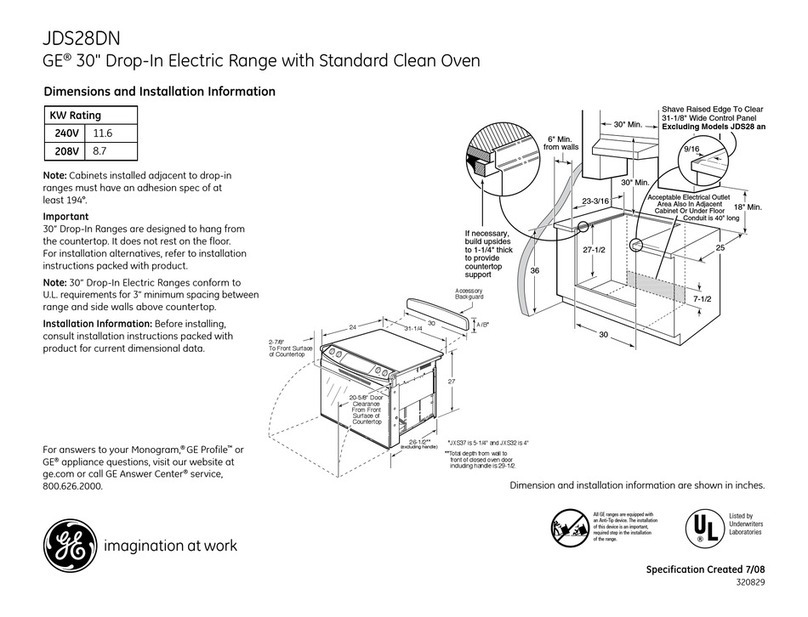

•Allrough-inandspacingdimensionsmustbe

met for safe use of your range.

•Toreducetheriskofburnsorrewhen

reaching over hot surface elements, cabinet

storagespaceabovethecooktopshouldbe

avoided. If cabinet storage space is to be

providedabovethecooktop,theriskcanbe

reducedbyinstallingarangehoodthatsticks

out at least 5” beyond the front of the cabinets.

Cabinetsinstalledabovethecooktopmustbe

no deeper than 13”.

•Besureyourapplianceisproperlyinstalledand

groundedbyaqualiedtechnician.

We recommend you have the electrical wiring

andhookupofyourrangeconnectedbya

qualiedelectrician.Afterinstallation,havethe

electrician show you where your main range

disconnect is located.

Checkwithyourlocalutilitiesforelectricalcodes

which apply in your area. Failure to wire your

range according to governing codes could result

in a hazardous condition. If there are no local

codes, your range must be wired and fused to

meet the requirements of the National Electrical

Code,ANSI/NFPANo.70–LatestEdition.Youcan

get a copy by writing:

NationalFireProtectionAssociation

BatterymarchPark

Quincy,MA02269

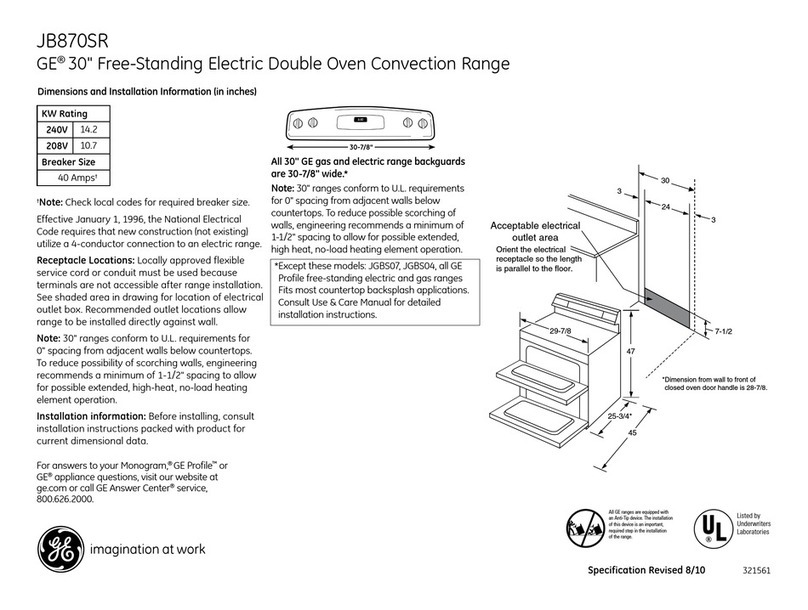

EectiveJanuary1,1996,theNational

Electrical Code requires that new, but not

existing, construction utilize a four-conductor

connection to an electric range. When installing

an electric range in new construction, a mobile

home, recreational vehicle or an area where

local codes prohibit grounding through the

neutral conductor, follow the instructions in the

sectiononNEWCONSTRUCTIONANDFOUR-

CONDUCTORBRANCHCIRCUITCONNECTION.

Youmustuseathree-wire,single-phase

A.C.208Y/120Voltor240/120Volt,60hertz

electrical system. If you connect to aluminum

wiring, properly installed connectors approved

for use with aluminum wiring must be used.

WARNING:Forpersonalsafety,

removehousefuseoropencircuit

breakerbeforebeginninginstallation.

Failuretodosocouldresultinserious

injuryordeath.

Rating Plate

Location

Electrical

Requirements

This appliance must be supplied with the

proper voltage and frequency, and connected

to an individual, properly grounded branch

circuit,protectedbyacircuitbreakerorfuse

having amperage as noted on rating plate.

(Rating Plate is located behind the oven door

on the range.)