– 10

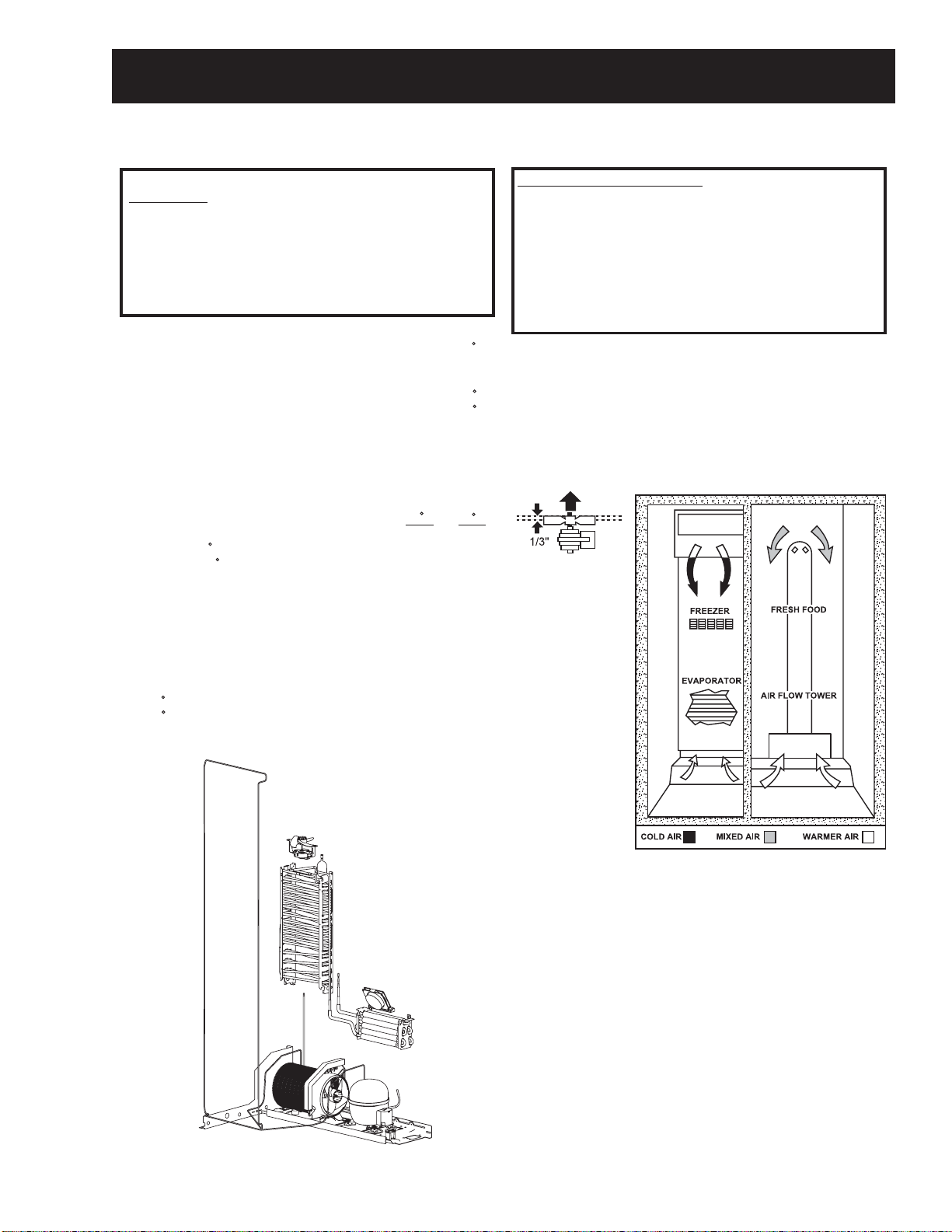

Liner Protection Mode

The dual evaporator model has separate liner

protection modes for each section. The specific

evaporator fan (freezer or fresh food) will start

and run on high speed if the door has been open

for 3 minutes.

This mode is controlled by 2 timers. Timer #1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If 3

minutes elapse before the door is closed, the liner

protection mode will become active. Once the

door is closed, timer #1 resets and liner protection

mode goes into standby. In standby, normal

fan operation resumes and timer #2 begins a

3-minute door-closed count. If 3 minutes elapse

without a door opening, liner protection mode will

completely deactivate. If a door is opened within

the timer #2 door-closed count, the remaining

time in the door-closed count will be deducted

from the timer #1 door-open count.

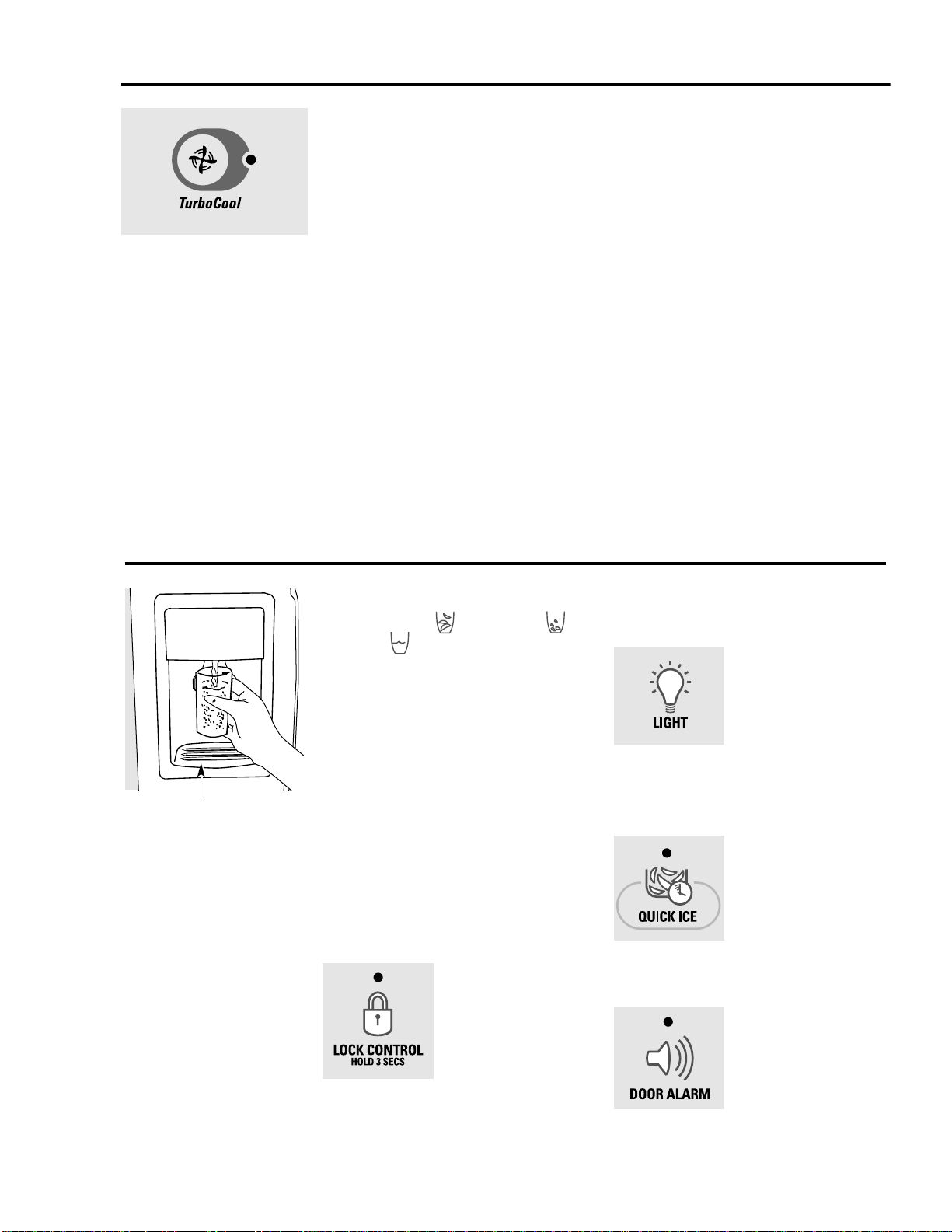

Dispenser Light

The LIGHT pad turns the dispenser light on and

off. When the light is turned off, it will fade out.

The dispenser light will come on automatically

when the dispenser cradle is depressed and will

fade out 5 seconds after it is released. The LIGHT

pad will not turn off the light during dispensing.

Dispensing Functions

The water, crushed ice, and cubed ice functions

are controlled by the main control board. To

select a function, press the appropriate pad on

the dispenser. The LED will light to identify the

selection.

To dispense ice cubes or crushed ice, choose

the appropriate pad and depress the dispenser

cradle. The solenoid and linkage assembly will

open the ice chute duct door to dispense the

ice. If cubed ice is selected, a solenoid located

behind the ice bucket will lift a rod along the side

of the bucket. This rod pulls a flapper away from

the cutter blades, allowing cubes to bypass the

ice crusher. The dispenser duct door will remain

open for 3 seconds after dispensing to allow all

ice to clear the chute.

The dispenser light will come on automatically

when the dispenser cradle is depressed and will

fade out 5 seconds after it is released.

To lock or unlock communication between the

dispenser and main control board, press the

LOCK pad and hold it for 3 seconds. The LOCK

LED will flash while the LOCK pad is pressed.

When the communication is locked, the LOCK

LED will be illuminated.

The status of other functions selected prior to the

initiation of the lock feature will be displayed. If

the lock is engaged while a mode is active, the

LED will remain on until that mode times out.

If the lock is engaged when the filter timer

expires, the LED will come on but cannot be reset

until the lock is turned off.

The lock feature will be restored in the event of a

power disruption.

Dispenser Lock

When the dispenser system is locked, no

dispenser command will be accepted. This

includes the dispenser cradle and will prevent

accidental dispensing that may be caused

by children or pets. If a pad or the cradle is

depressed with the system locked, it will be

acknowledged with three pulses of the LOCK

LED accompanied by an audible tone.