Instruction Manual

© GE Grid Solutions

ATTENTION! The CVT has fragile par s

(insula or, bellows, e c.) ha can be

damaged during ranspor a ion, by sea,

air or by road (being he road paved or

no ). The ranspor a ion and handling

shall be made wi h care. Sudden

movemen s can cause impac and

damage o he equipmen .

2.2. Reception

Whe her he shipmen is on

manufac urer’s or cus omer’s

responsibili y, he cus omer inspec or or

he service agen has o check he

following on receip of delivery:

If he cra es show any signals of impac ,

blows or frac ures, or if he ransformers

have any signal of damage, or oil

leakage, he cus omer inspec or or he

service agen in charge of receip shall

make a wri en remark on shipmen

documen s. The receip con rol, mainly

for he porcelain insula ors and he

secondary erminal box, shall be done in

he presence of he forwarding agen , if

possible. The remarks regarding he

condi ion of he goods shall clearly s a e

de ails of he damages found a he ime

of recep ion.

In case of damages, he cus omer

inspec or in charge of receip shall no ify

GE and he insurance represen a ive. All

con ac informa ion shall be indica ed on

shipmen insurance documen s. This

declara ion shall be made wi hin

maximum of eigh days af er receip of

he ma erial.

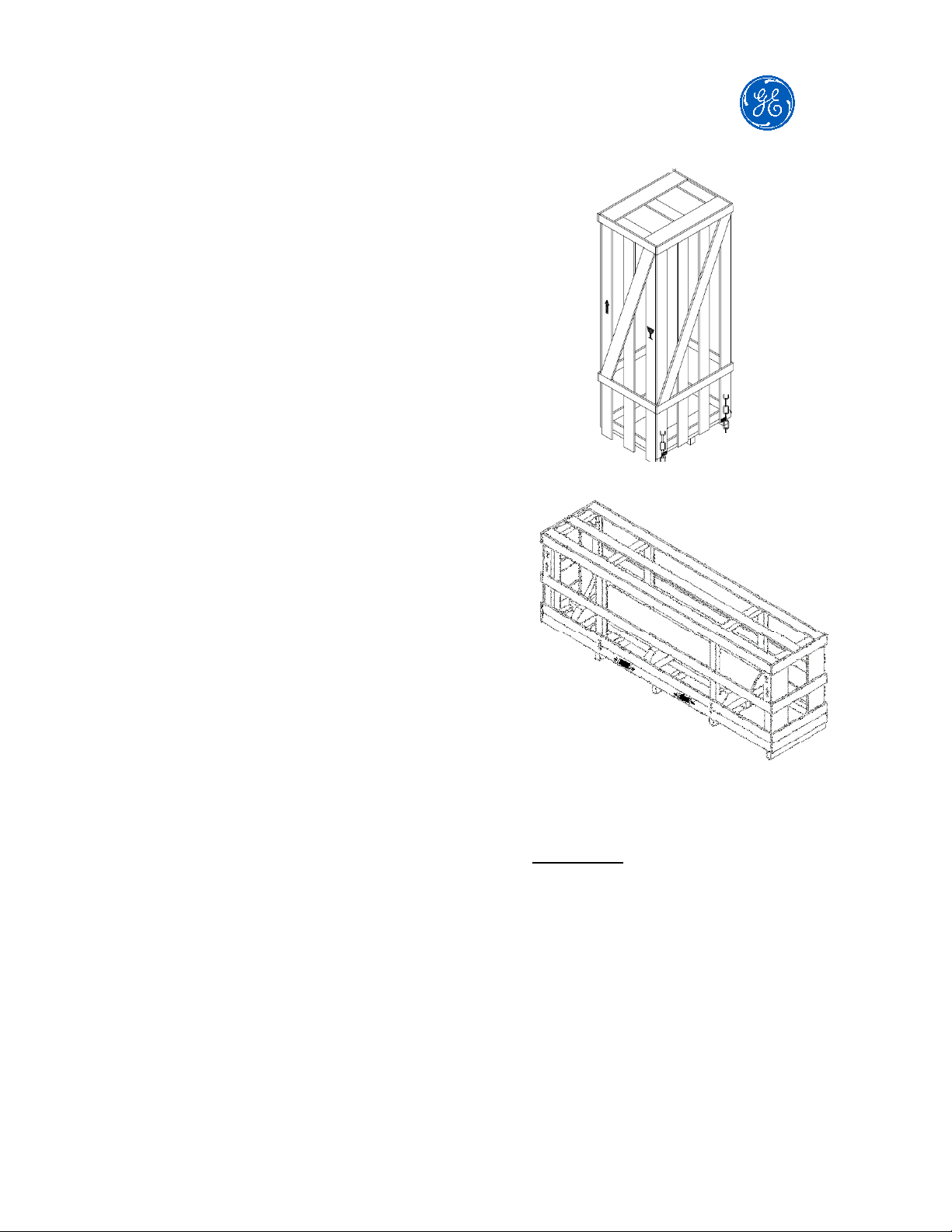

2.3. Unpacking

Ma erial required for unpacking, lif ing

and pu he ransformer in o service:

Q y Descrip ion

2 Crane, munck or hois .

1 Con ac grease ype PENETROX or

equivalen .

1 Graphi e grease MOLYKOTE ype

P37 or equivalen .

4 Slings of 4,5m of leng h (capaci y

10.000 N)

1 Sling of 1,5m of leng h (capaci y

1.000 N), for cases wi h equipmen

packaged a horizon al posi ion only.

Unpacking of he ransformer should be

made wi h care.

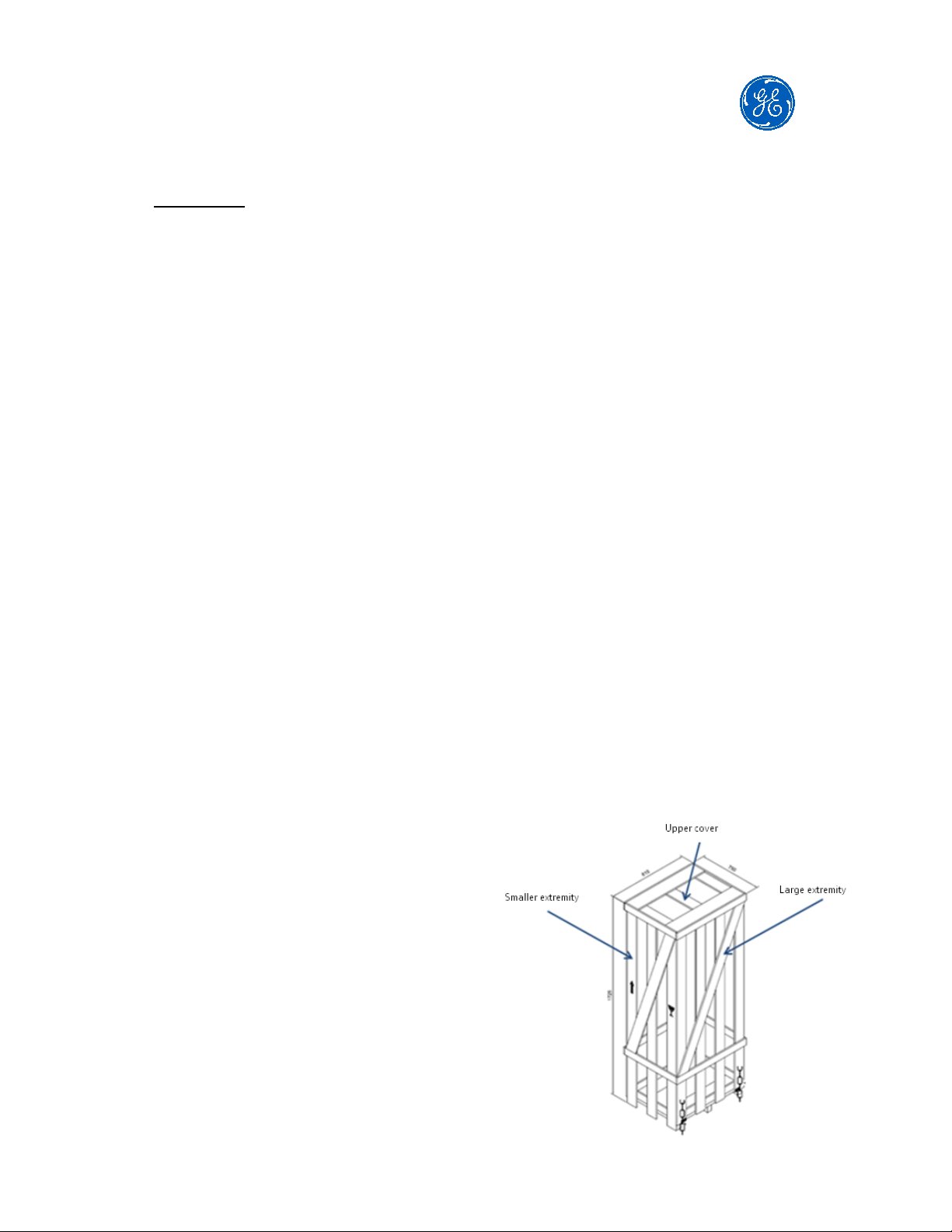

Ver ical packaging

1) Remove upper cover.

2) Remove he smaller ex remi ies.

3) Remove he wood blocking pieces.

4) Remove he larger ex remi ies

5) Remove he four screws a he

equipmen fee and, when applicable,

screws ha anchor he modules o he

package

6) Lif each par of he CVT