2

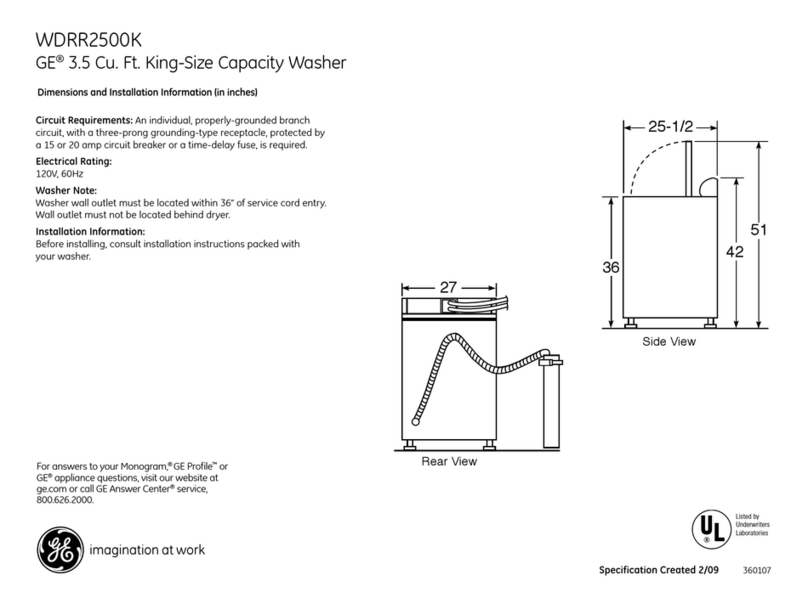

The rating plate containing model and serial number is located on the rear of the control panel in the center. If you

lean over the washer you can see the rating plate without moving the unit.

The full size electronic washer incorporates optimum washability, capacity, quiet operation, and ease of service. The

washer is 100 percent front serviceable, with 40% fewer parts. It features an Auto Balance suspension system, that

allows greater out of balance capacity.

Drive system has a rotating transmission with metal gears and a disc brake, and it comes as a single replaceable

component.The brake is activated when the end of cycle occurs and also, when the lid is lifted.

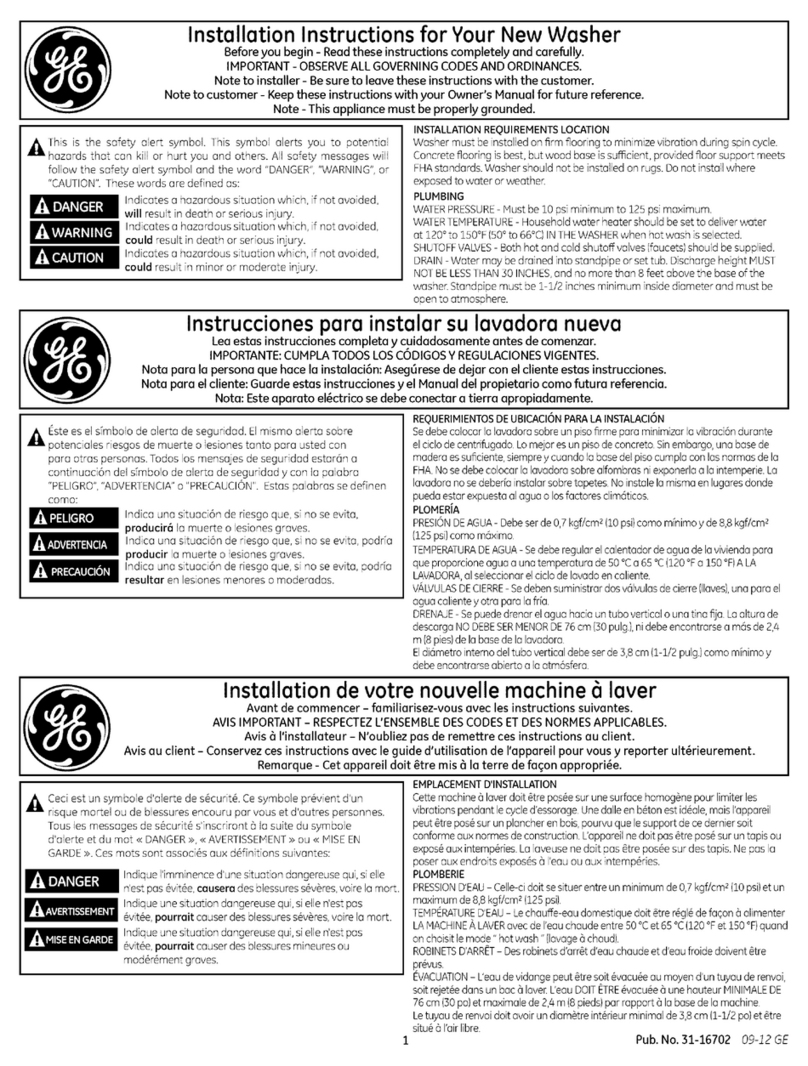

All washers are manufactured and supplied with provisions for proper grounding.The installation instructions advise

on proper grounding. Safety devices should never be removed unless for servicing, and must always be replaced

prior to placing the washer back in active service.

The mini manual is located in the backsplash, and contains service information

Mini Manual Location

Rating Plate

at rear of

backsplash

Rating Plate and Mini-Manual Location

Suggested Tool List:

#2 Philips, small slot blade screwdriver

1/4”, 3/8”, 7/16”, nutdrivers

3/8”, 3/4” open-end wrench

1/2” socket and rachet

Pliers

Special agitator pullerWX5X1326

Special hub nut toolWX5X1325

Hammer

T20HTorx head security screwdriver

Locking pliers

Wire tie to reattach overflow tube