TABLE OF CONTENTS

SECTION DESCRIPTION ................................................ PAGE

GENERAL INFORMATION

Application ........................................................................................... 1

Symbols ................................................................................................. 1

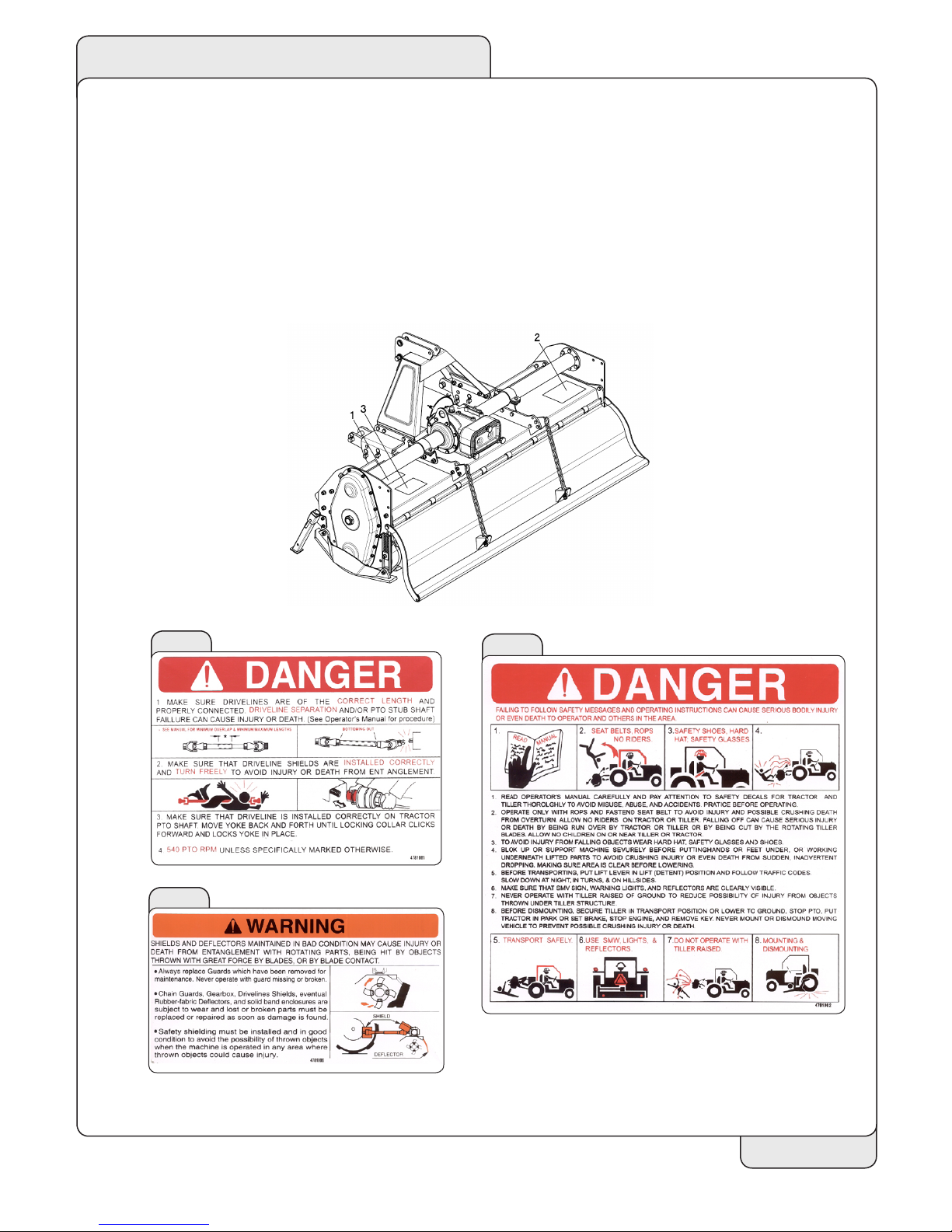

Safety labels .......................................................................................... 2

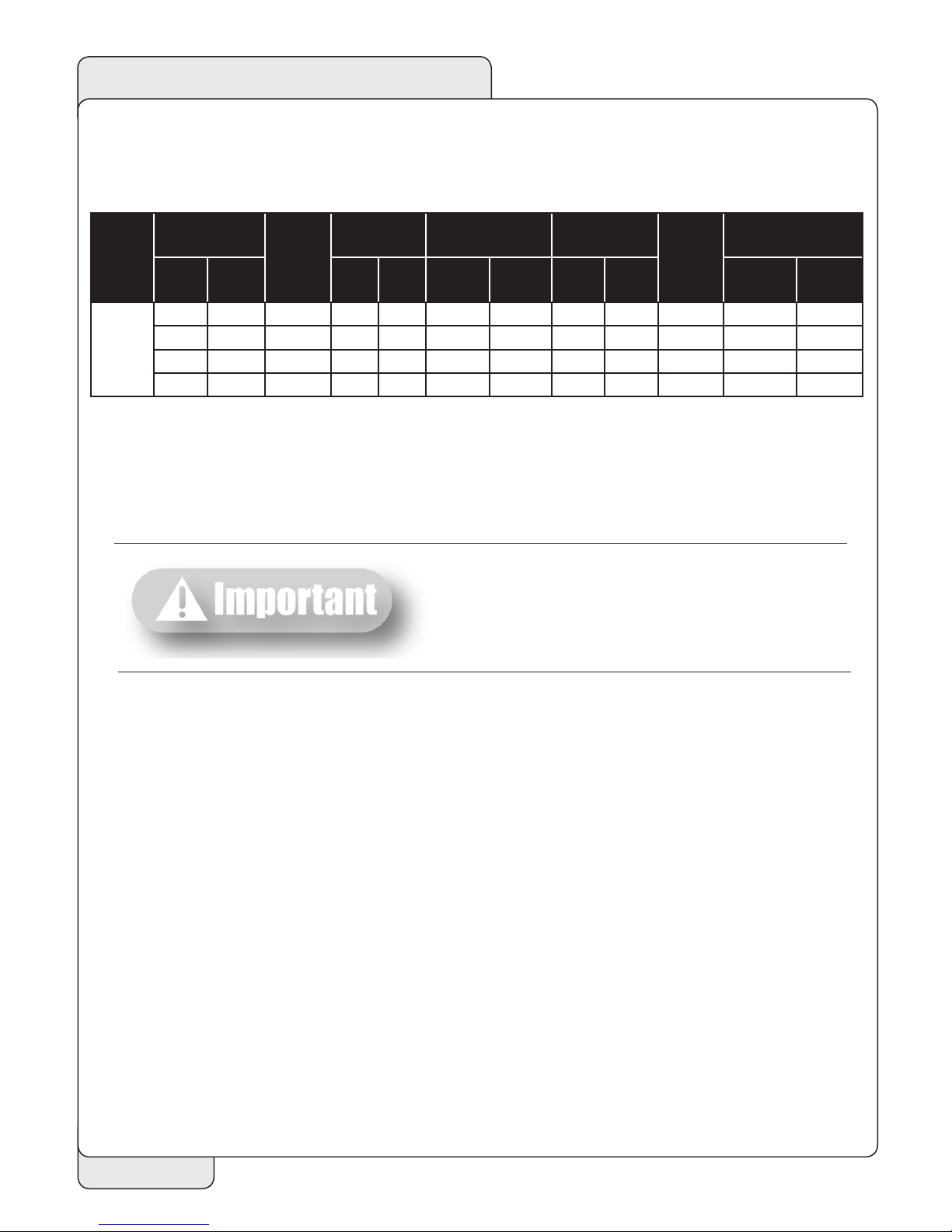

Technical data....................................................................................... 3

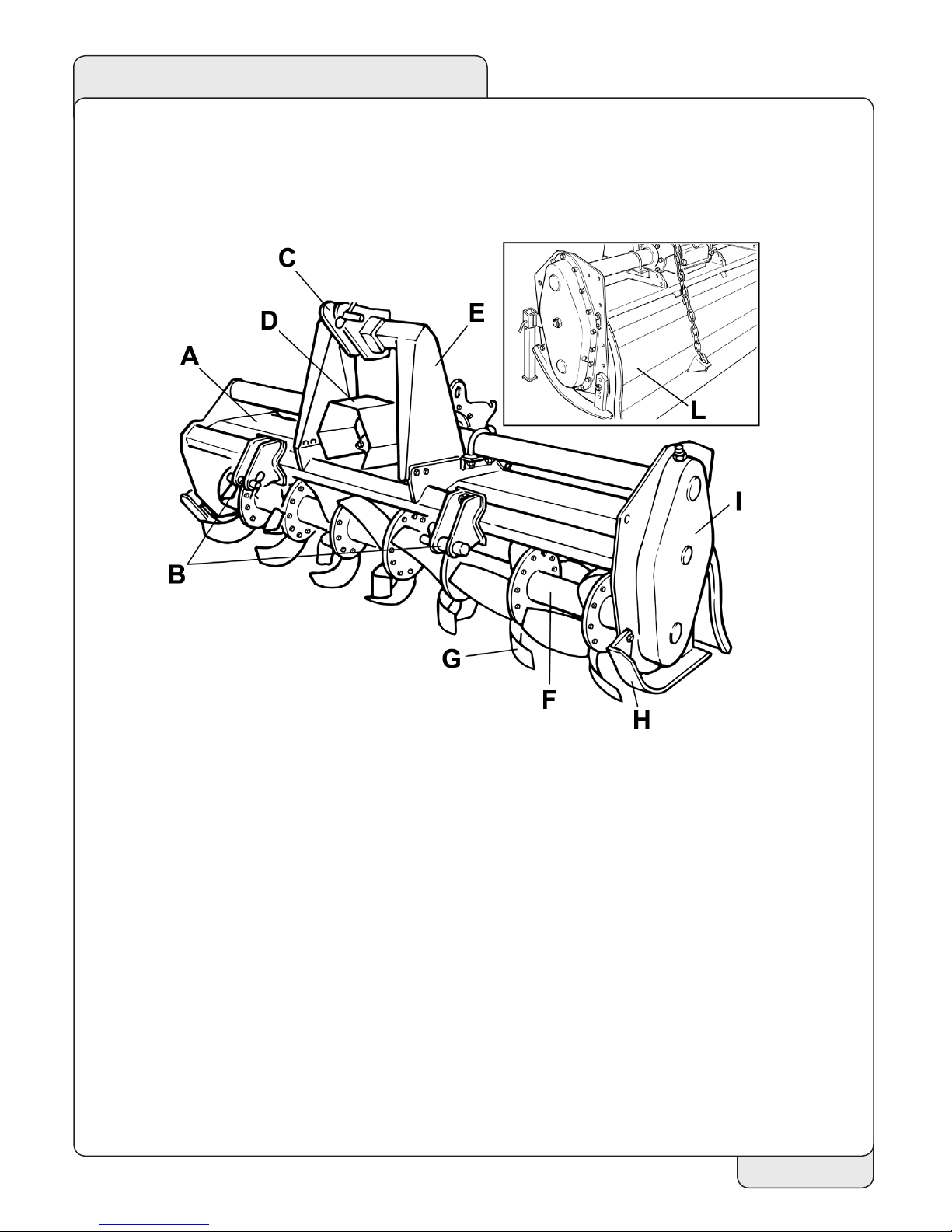

Main parts terminology ...................................................................... 4

Identication plate............................................................................... 5

Recommended use .............................................................................. 5

Inappropriate use................................................................................. 5

Torque Specication............................................................................ 5

SAFETY

Safety in the workplace ....................................................................... 6

User's requirements............................................................................. 6

Work clothing....................................................................................... 6

General safety norms .......................................................................... 6

Preparation ........................................................................................... 7

SET UP

Attachment to the tractor................................................................... 8

PTO shaft connection ....................................................................... 11

Slip clutch drive shaft......................................................................... 11

Working depth adjustment............................................................... 12

Leveling board adjustment............................................................... 13

MAINTENANCE

Road transport ................................................................................... 14

Shut down........................................................................................... 14

First check........................................................................................... 14

Every 8 working hours...................................................................... 15

Every 20 working hours ................................................................... 15

Every 50 working hours ................................................................... 15

Every 500 working hours ................................................................. 15

Replacing clutch linings .................................................................... 16

SPARE PARTS

How to order spare parts ................................................................. 17

Troubleshooting chart....................................................................... 18

Tiller Assembly T230, T280 & T305.............................................. 19

Drive Assembly.................................................................................. 21

Gearbox Assembly ............................................................................ 23

Rotorshaft Assembly......................................................................... 25

Rotorshaft ........................................................................................... 27

Main Deck Assembly ........................................................................ 29

Tailboard Assembly............................................................................ 31

Tiller Assembly T355......................................................................... 33

Gearbox Assembly T355................................................................... 37

Driveshaft EYE81074-2255............................................................339

Driveshaft YE01074-13747 .............................................................. 40

Slip Clutch Assembly ......................................................................... 41

OPTIONS

Rear Roller ........................................................................................... 42

Cutting Disc......................................................................................... 43

LIMITED WARRANTY .................................................................................................. 44