EN - 1

Gefran spa - Drive & Motion Control Unit - Gerenzano (VA) Italy

1S5L29, EXP-ETH-GD-ADV -IT/EN

(rev. 0.1 - 21.7.17)

Instruction manual

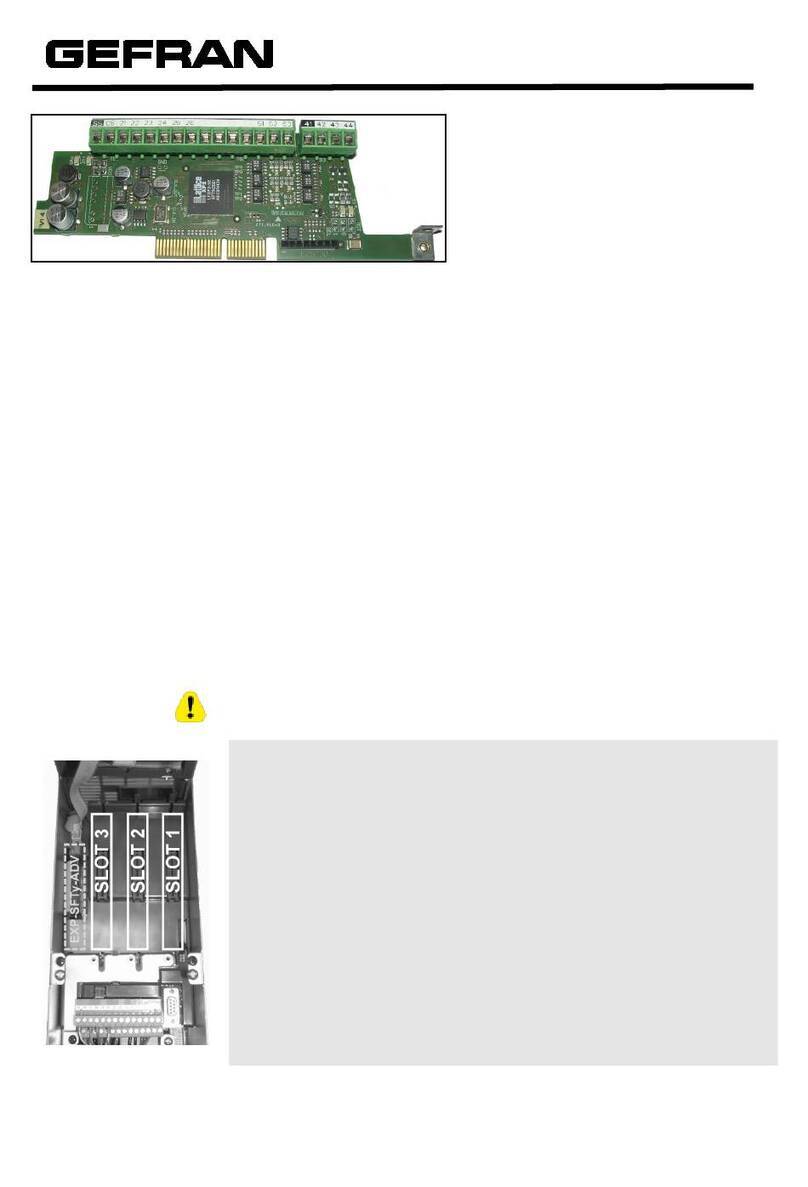

EXP-ETH-GD-ADV

GDNet interface

expansion card

1. Introduction ........................................................................................2

1.1. Reinforced insulation.................................................................................................2

1.2. Features ....................................................................................................................2

1.3. What is GDNet? ........................................................................................................2

1.4. Safety ........................................................................................................................2

1.5. Mounting....................................................................................................................2

1.6. Connections ..............................................................................................................2

1.7. Leds - Rotary switch - Jumper - Terminal..................................................................5

1.8. Optional card recognition ..........................................................................................6

2. Start-up guide.....................................................................................7

2.1. GDNet master device settings (PLC) ........................................................................8

2.1.1. Description of Master -> Slave cyclic input/output data communication................9

2.1.2. Description of Slave -> Master cyclic input/output data communication..............10

2.1.3. Composition of I/O ..............................................................................................11

2.2. ADV200 Conguration.............................................................................................12

2.2.1. Reading states and writing commands to the drive .............................................12

2.2.1.1. FIELDBUS CONFIG menu ...................................................................................................12

2.2.2. Writing Output data ..............................................................................................13

2.2.2.1. Fieldbus M2S Menu..............................................................................................................13

2.2.2.2. REFERENCES Menù ...........................................................................................................15

2.2.3. Writing Input data.................................................................................................15

2.2.3.1. FIELDBUS S2M Menu..........................................................................................................15

2.3. Communication check.............................................................................................18

3. GDNet Protocols ..............................................................................19

3.1. GDNet communication states..................................................................................19

3.2. Database: general description.................................................................................22

3.2.1. Cyclic data exchange ..........................................................................................22

3.2.2. Acyclic data exchange ........................................................................................23

4. Alarm .................................................................................................24

4.1. Drive error messages..............................................................................................24

4.2. Faults.......................................................................................................................26

5. In general ..........................................................................................27

5.1. Glossary ..................................................................................................................27

5.2. Abbreviations...........................................................................................................27

5.3. References..............................................................................................................27