PRODUCT MANUAL

Version 1.4

PELLET BOILER STOVE – AMANDA Diva 16,1 kW

6

2: IMPORTANT INFORMATION

2.1: GENERAL INFORMATION

Requesting information

If information is requested from the manufacturer of the

stove, always refer to the serial number and other

identifying data shown on the product’s identification

label.

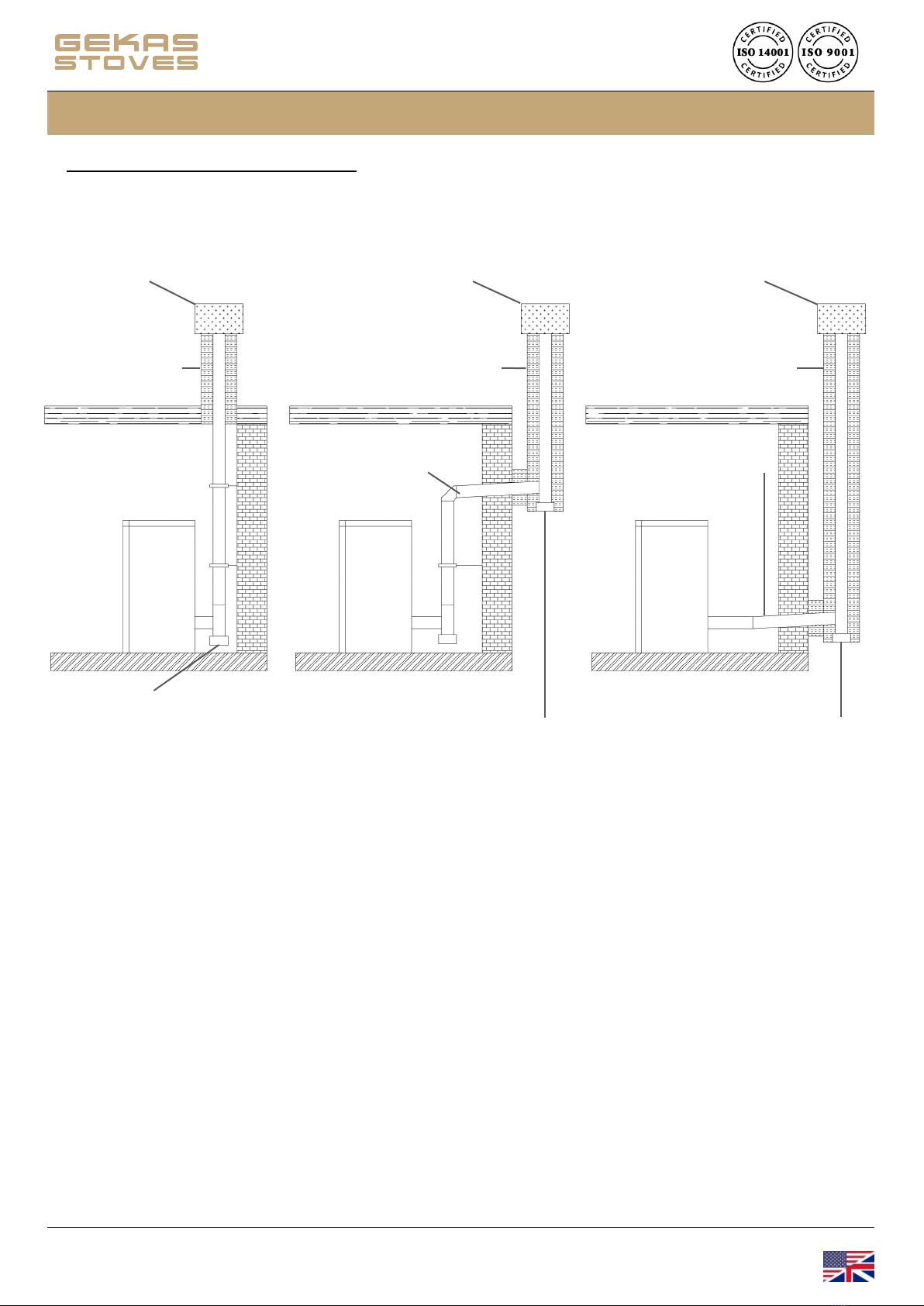

Responsibility for installation

Gekas Metal Group accepts no responsibility for the work

carried out to install the stove, such responsibility lies with

the installer, who is required to carry our checks on the

flue and air intake and ensure installation is completed

correctly. Furthermore, all safety standards required by

relevant legislation in force in the country where the stove

is installed must be complied with.

Use

The stove must only be used in compliance with the

instructions provided in this manual, as well as with all

safety standards required by relevant legislation in force in

the country where the stove is installed.

2.2: GENERAL WARNING AND SAFETY INFORMATION

Observance of the introductory general warning

information is imperative.

•Read the entire manual thoroughly before installing

and putting the stove into service. Observe the

national provisions and laws as well as the

regulations and rules applicable locally.

•Gekas Stoves should only be installed in rooms with

normal humidity.

•Only approved transport equipment with enough

load carrying capacity may be used with your heating

appliance.

•Your heating appliance is not suitable for use as a

ladder or stationary scaffolding.

•The burning of fuel releases heat energy that lead to

extensive heating of the stove surfaces, doors, door

and operating handles, glass, flue pipes and possibly

the front wall and side walls. Refrain from touching

these parts without appropriate protective clothing

or equipment e.g. heat-resistant gloves or means of

operation.

•Make your children aware of this danger and keep

them away from the stove during heating.

•Only burn approved heating materials.

•The combustion or introduction of highly flammable

or explosive materials such as empty spray cans etc.

in the combustion chamber and storing them near

the stove is strictly prohibited due to the danger of

explosion.

•Use heat-resistant gloves to open the door of your

stove.

•Make sure that no embers fall out of the combustion

chamber onto inflammable material.

•Placing non-heat resistant objects on the stove or

near it is prohibited.

•Do not place clothing on the stove to dry.

•Laundry racks etc. must be placed at enough distance

to the stove – ACUTE DANGER OF FIRE!

•When your stove is burning, the use of highly

inflammable and explosive materials in the same or

adjacent rooms is prohibited.

•If the stove is heated in continuous operation, the

cleaning intervals are shorter. Increased wear,

especially of the thermally stressed parts, is the

result. Please therefore strictly follow the

requirements for cleaning and maintenance!

Warning

Waste and liquids may not be burnt in the stove!

Note

To prevent your stove’s internal components from

overheating, do never cover the convection fins.

Note

CAUTION when filling the pellet hopper. The opening of

the pellet hopper is sufficiently dimensioned to ensure

easy filling. Take great care that no pellets drop to the

convection fins and the hot stove body. This can cause a

lot of smoke.

Tip

We recommend refilling the pellet hopper when the stove

is inactive and still cold.

Note

Your stove will expand and contract during the heating

and cooling phase, respectively, which can sometimes lead

to slight bending or cracking noises. This is normal and

there is no reason to worry or complain.