3

FACTORY AUTOMATION

Phone: 248-435-0700 Toll Free: 800-635-0289 Fax: 248-435-8120 www.ametekfactoryautomation.com

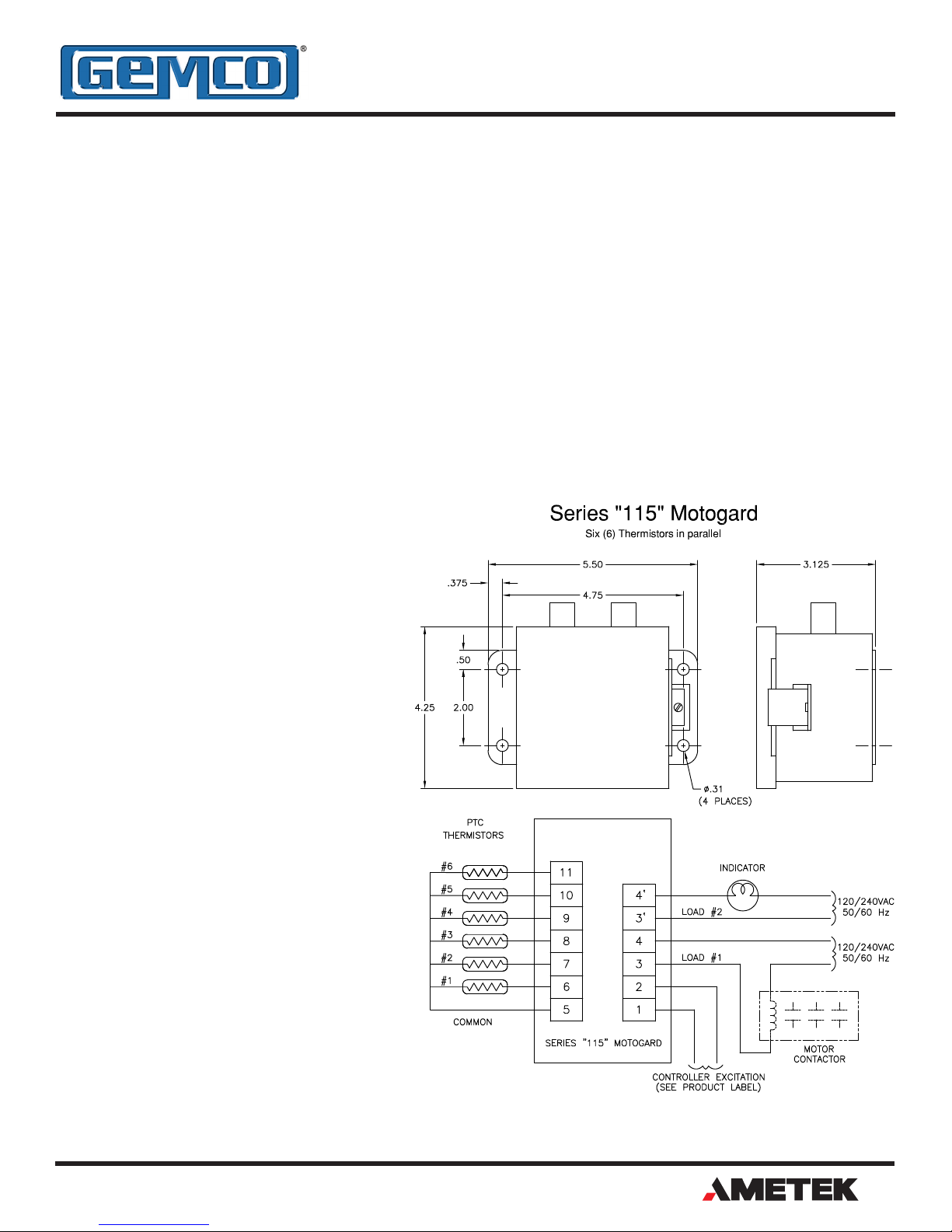

Series 115 Motogard™

The Series 115 Motogard is designed to take in up

to 6 Thermistors wired in Parallel, and has two Triac

output relays.

Connections

Power Connections:

The standard 115 Series Motogard relay is designed

to operate off of 120VAC +/-10%, Single Phase,

50/60Hz, and is sold under part number 115101-

2. There is a special 230VAC input power version

available and sold under part number 115202-2.

On terminals 1 & 2 connect incoming AC

power.

Thermistor Connections:

1. Connect one lead of each Thermistor

to terminals 6, 7, 8, 9, 10, and 11

respectively.

2. Connect other leads of each Thermistor

to Common, terminal 5.

3. Maximum number of Thermistors in

parallel: Six (6)

4. Note: If using less than 6 Thermistors.

Any unused input – Install a 150 Ohm

1/2W resistor from sensor common

(terminal 5) to any unused input.

Output Load Connections:

1. With power applied to the controller

and all input sensors in their low

impedance states. Terminal 3 and 4

become the equivalent to a closed

contact of an electromechanical

relay.

2. With power applied to the controller

and all input sensors in their low

impedance states. Terminal 3’ and

4’ become the equivalent to a open

contact of an electromechanical

relay.

3. Be sure power is never applied directly across

the contact but always in series with the load.

4. Maximum allowable load – 5 Amps at

120/240VAC.

5. The closed output of the Motogard Over

temperature Protection System has been

specifically designed to operate directly in

series with most main line contactors. If a small

interposing relay must be used, the sealed

burden shall be greater than 10VA.

6. The open output of the Series 115 relay can be

used for trip indication.