PartNo.82784 GenieGS-2032andGenieGS-2632 7

Operator's Manual

Second Edition • Second Printing

Component Damage Hazard

Do not use the machine as a ground for welding.

Explosion and Fire Hazard

Donotoperate the machine in hazardous locations

orlocationswherepotentiallyflammableor

explosive gases or particles may be present.

Damaged Machine Hazards

Donot use a damaged or malfunctioning machine.

Conductathoroughpre-operationinspectionofthe

machine and test all functions before each work

shift. Immediately tag and remove from service a

damagedormalfunctioningmachine.

Besureall maintenance has been performed as

specified in this manual and the appropriate service

manual.

Be sure all decals are in place and legible.

Be sure the operator’s, safety, and responsibilities

manualsarecomplete, legible and in the storage

containerlocated on the platform.

Bodily Injury Hazard

Do not operate the machine with a hydraulic oil or

air leak. An air leak or hydraulic leak can penetrate

and/orburnskin.

Impropercontact with componentsunderany cover

will cause serious injury. Only trained maintenance

personnel should access compartments. Access

by the operator is only advised when performing a

pre-operationinspection.Allcompartmentsmust

remainclosedandsecuredduringoperation.

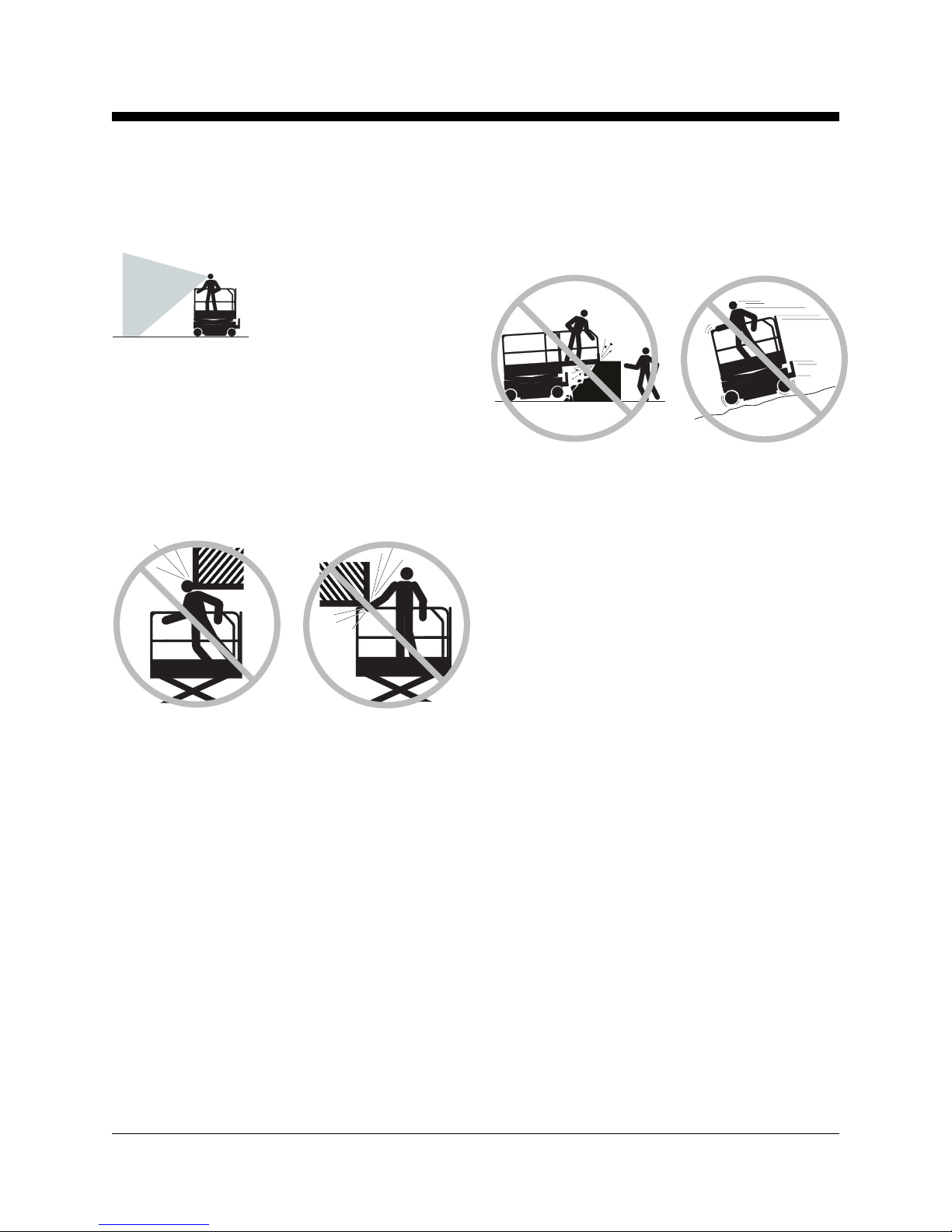

SAFETY RULES

Decal Legend

Genie product decals use symbols, color coding

and signal words to identify the following:

Safety alert symbol—used to alert

personneltopotentialpersonal

injury hazards. Obey all safety

messages that follow this symbol

to avoid possible injury or death.

Red—usedtoindicatethe

presence of an imminently

hazardous situation which, if not

avoided, will result in death or

seriousinjury.

Orange—usedtoindicatethe

presence of a potentially

hazardous situation which, if not

avoided, could result in death or

seriousinjury.

Yellow with safety alert symbol—

used to indicate the presence of a

potentiallyhazardoussituation

which, if not avoided, may cause

minorormoderateinjury.

Yellow without safety alert

symbol—used to indicate the

presence of a potentially

hazardous situation which, if not

avoided, may result in property

damage.

Green—usedtoindicateoperation

ormaintenanceinformation.