OS Image Installation

If this is the initial installation, re-image the Base with the latest OS Image. This is required for initial

installations only, not for software upgrades such as ISW or firmware. However, re-imaging a Base

to the latest version may be necessary to enable additional ISW features. Consult technical support

to determine site specific necessity.

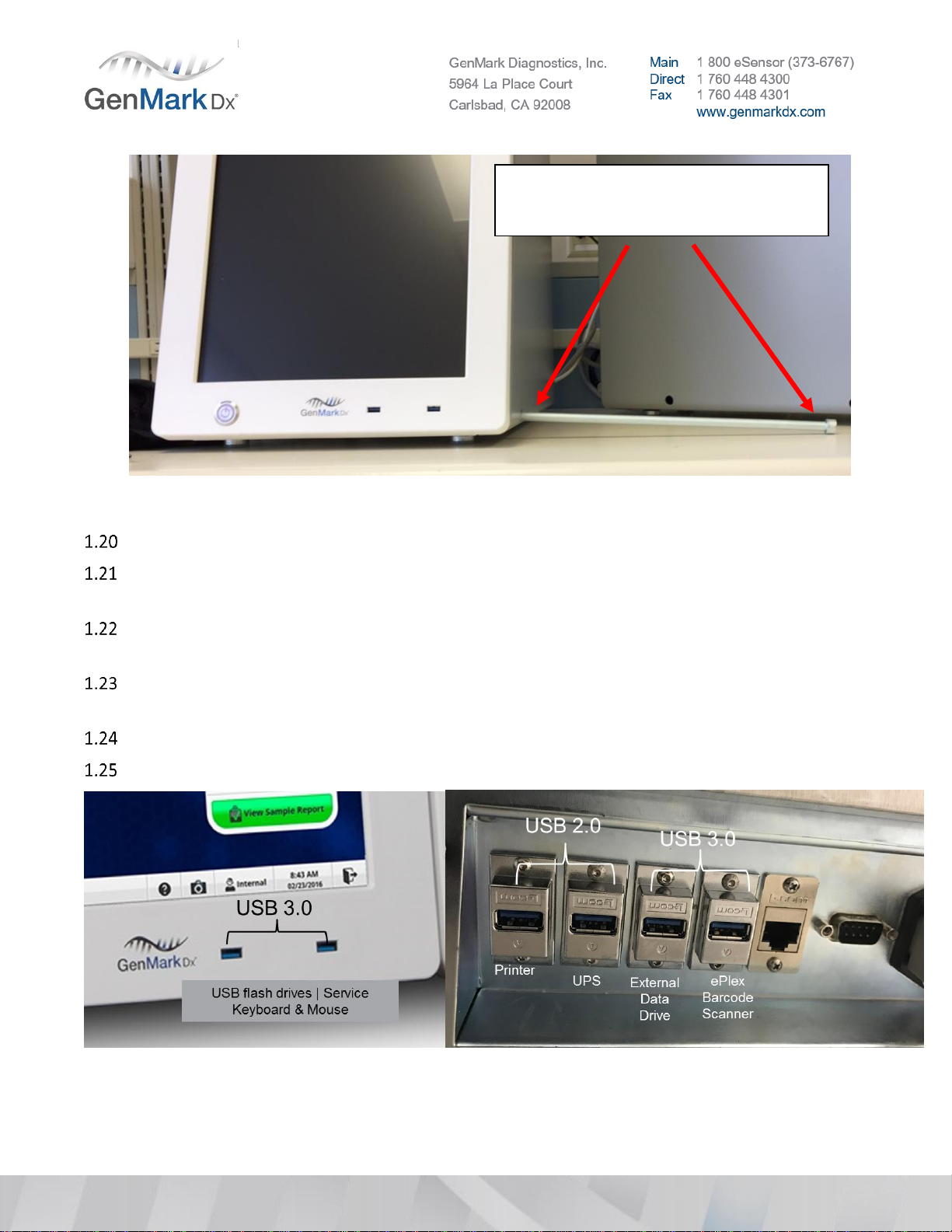

Insert the bootable USB (flash) drive with the Acronis image file into an ePlex USB port.

Power on the ePlex system and press and HOLD the Delete key on the keyboard to enter the BIOS

setup. Type the BIOS password if one has been preset. Otherwise, leave the password box blank and

click the Enter key.

Use the LEFT/RIGHT arrow keys on the keyboard to navigate to the Boot tab.

Use the UP/DOWN arrow keys on the keyboard to navigate to Boot Option #1 under FIXED BOOT

ORDER Priorities.

Press Enter and use the UP/DOWN arrow keys to navigate to USB Key as the Boot Option #1. If the

USB key does not have the description of the device, select the USB Floppy instead (which has the

description).

Press Enter then F4 to save these settings.

Select Yes in the Save & Exit Setup prompt and press Enter to temporarily boot from the USB (flash)

drive.

Note: The ePlex Instrument will reboot and should boot into Acronis True Image Software automatically

In the Acronis True Image screen, select Acronis True Image (select the first option).

Click the Recovery drop-down and select Disk and Partition Recovery.

In the Recovery Wizard, click the Browse button on the bottom right.

Navigate to the USB (flash) drive, browse to the ePlex X.X folder (where X.X is the version of the

image file), select the first volume file which ends with _v1.tib extension, and click the OK button.

Click the Next button once the full backup file is selected.

Select the Recover whole disks and partitions radio button and click the Next button.

Select the Disk 1 or Disk 2 checkbox, ensuring that all checkboxes under it are checked. Click the

Next button, then Next again.

Click the OK button on the Confirmation screen.

Click the Proceed button in the Summary screen.

Once the Data Recovery process has been completed, click OK to close the information prompt.

Remove the USB (flash) drive and click the Xbutton (red button with a white X on the upper right) to

reboot the PC.

As the ePlex system starts, press and HOLD the Delete key on the keyboard to enter the BIOS setup.