Aesculap GB176R Manual

Aesculap®Acculan 4

Aesculap Power Systems

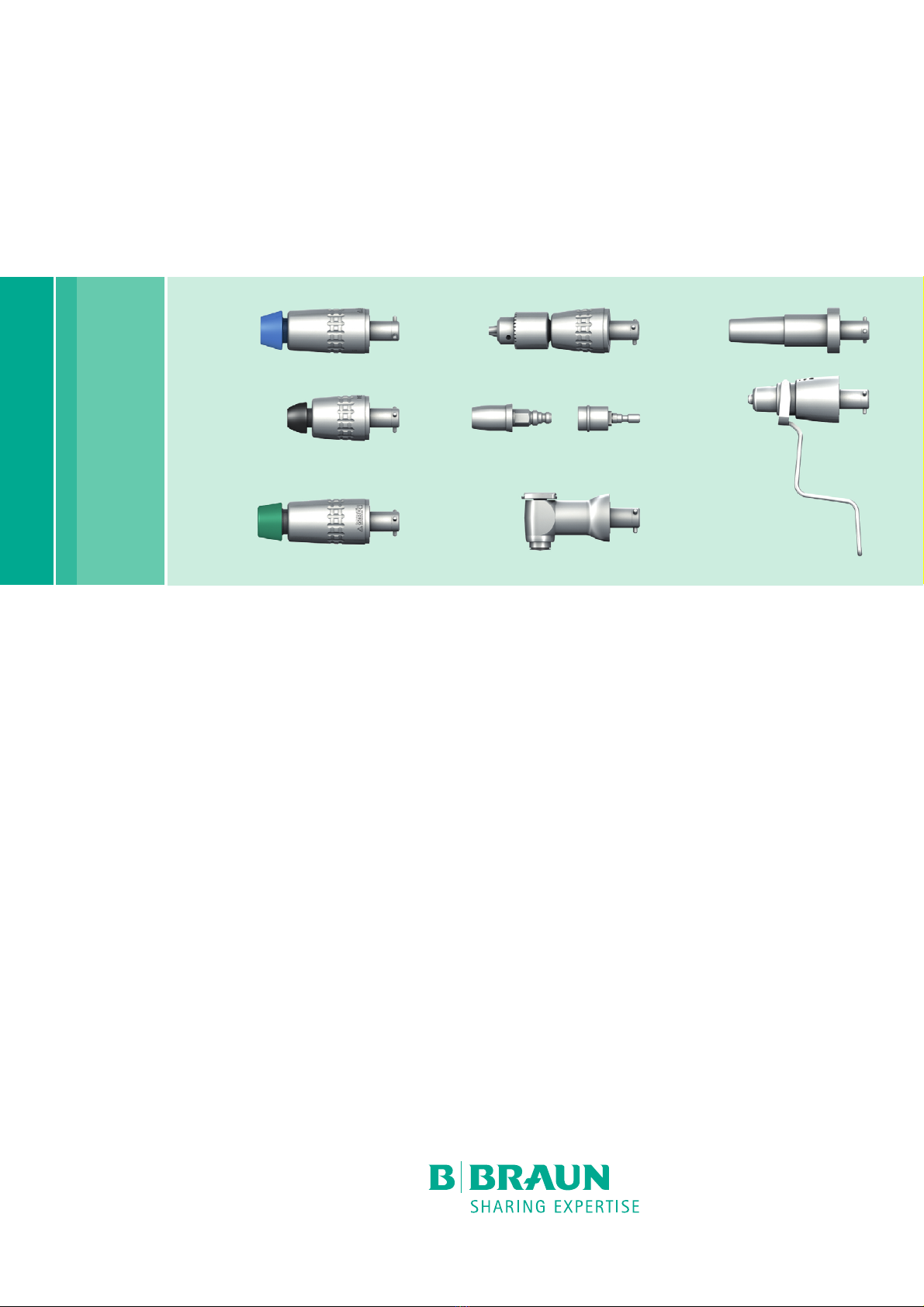

en Instructions for use/Technical description

Attachments

USA Note for U.S. users

This Instructions for Use is NOT intended for United States users. Please

discard. The Instructions for Use for United States users can be obtained

by visiting our website at www.aesculapusa.com and clicking the "Prod-

ucts" menu. If you wish to obtain a paper copy of the Instructions for Use,

you may request one by contacting your local Aesculap representative or

Aesculap's customer service at 1-800-282-9000. A paper copy will be

provided to you upon request at no additional cost.

de Gebrauchsanweisung/Technische Beschreibung

Aufsätze

fr Mode d’emploi/Description technique

Embouts

es Instrucciones de manejo/Descripción técnica

Cabezales

it Istruzioni per l’uso/Descrizione tecnica

Terminali

pt Instruções de utilização/Descrição técnica

Cabeçotes

nl Gebruiksaanwijzing/Technische beschrijving

Opzetstukken

sv Bruksanvisning/Teknisk beskrivning

Tillsatser

fi Käyttöohje/Tekninen kuvaus

Istukat

et Kasutusjuhend/Tehniline kirjeldus

Otsakud

ru Инструкция по примению/Техническое описание

Насадки

cs Návod k použití/Technický popis

Násadce

pl Instrukcja użytkowania/Opis techniczny

Nasadki

sk Návod na použitie/Technický opis

Nadstavec

tr Kullanım Kılavuzu/Teknik açiklama

Başlıklar

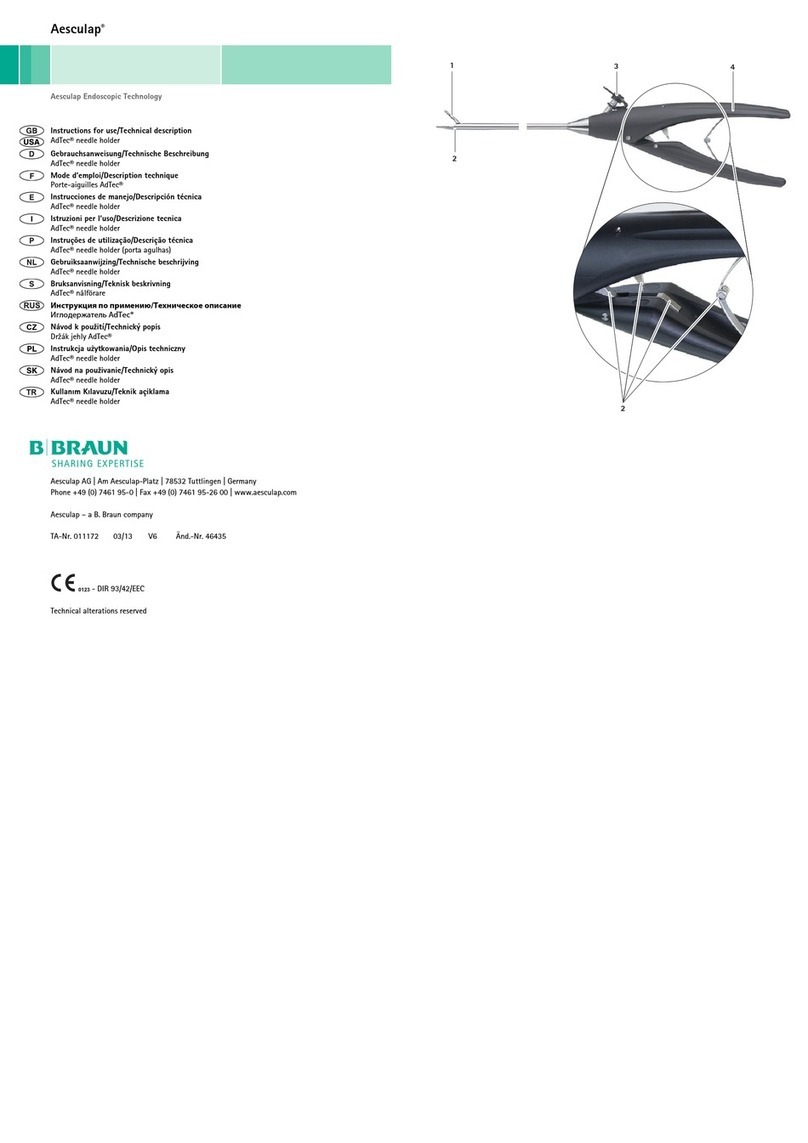

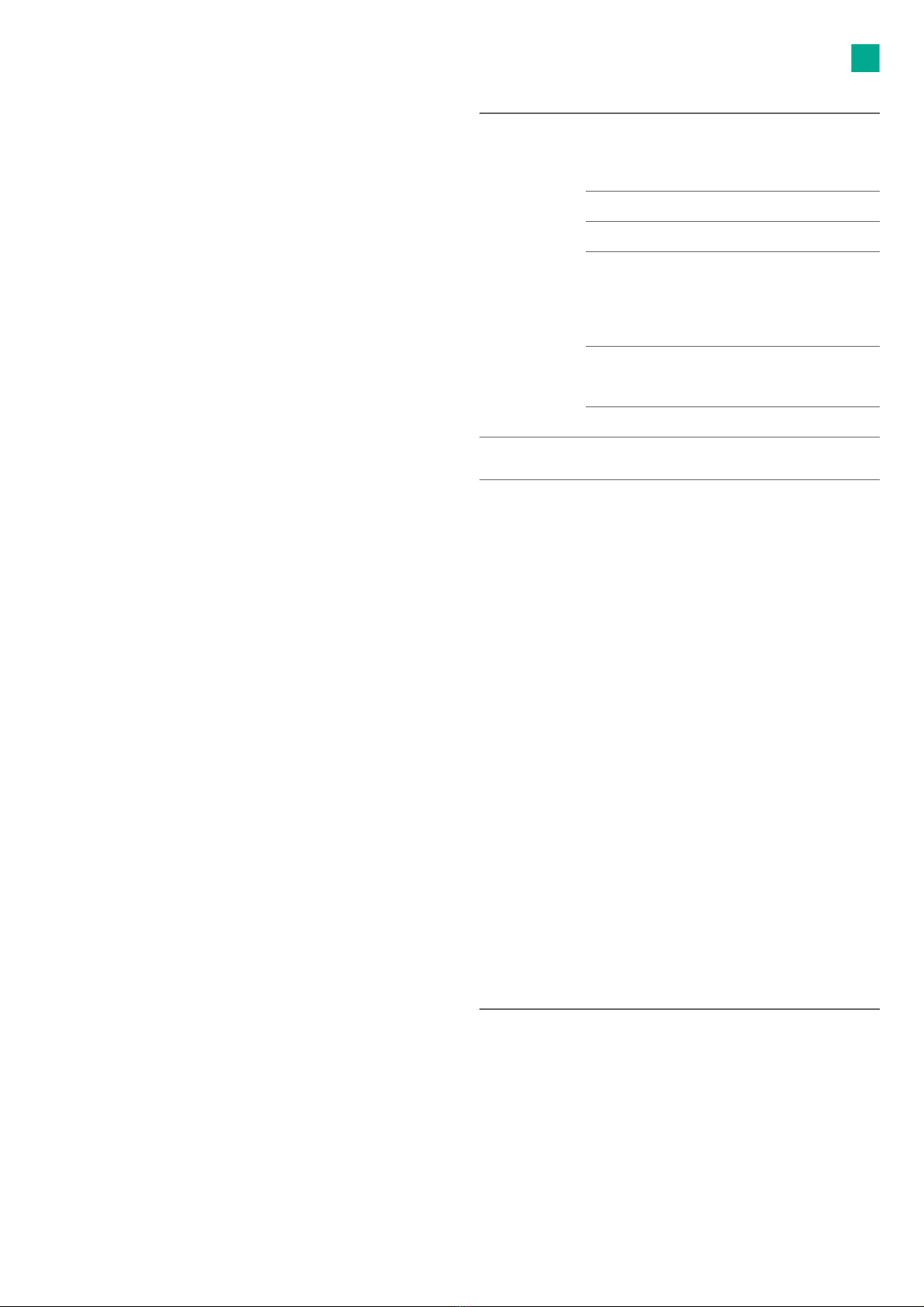

1

2 3

4 567

8

97

8

12

8

13

17

20

8

21

22

23

24

19

18

8

1011

14

16

15

15

8

8

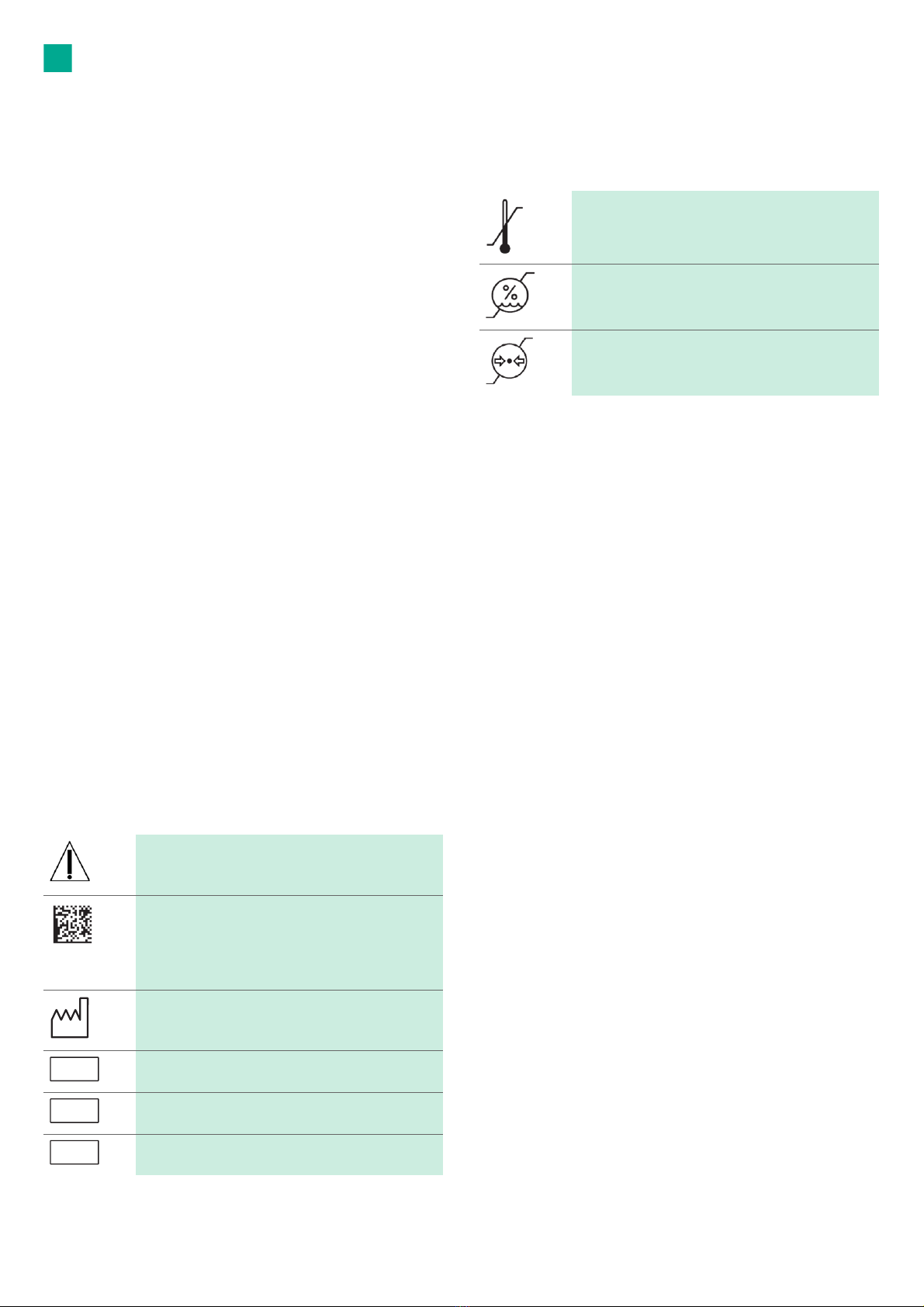

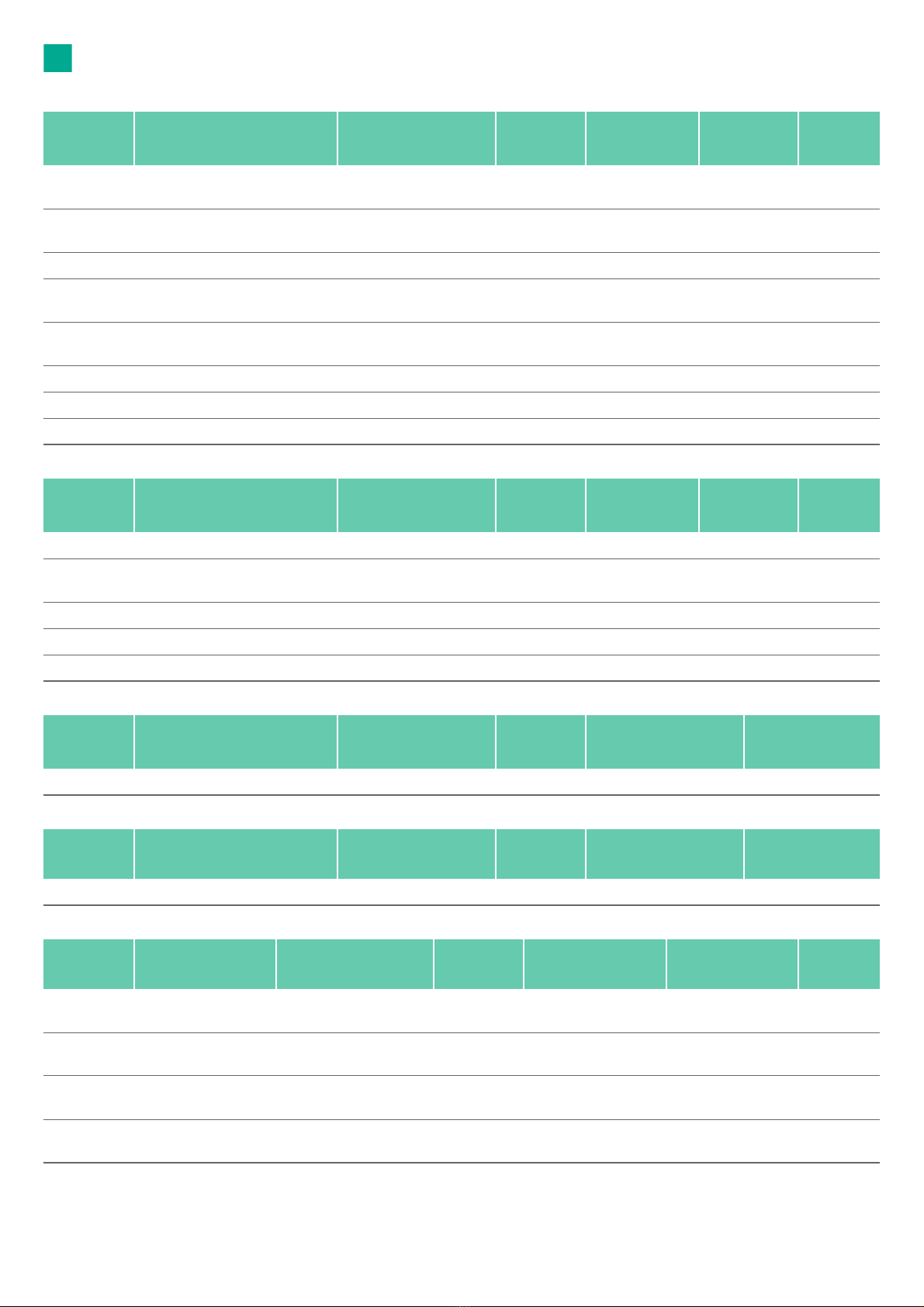

GB621R

GB641R

GB660R

A

B

C

25

18

19

17

26

GB184R

XF457R

GB667R

GB657R

GB628R

GB176R

GB623R

GB663R

GB664R

GB665R

GB620R

GB639R

GB645R GB668R

GB669R

GB670R

2

en

Aesculap®Acculan 4

Attachments

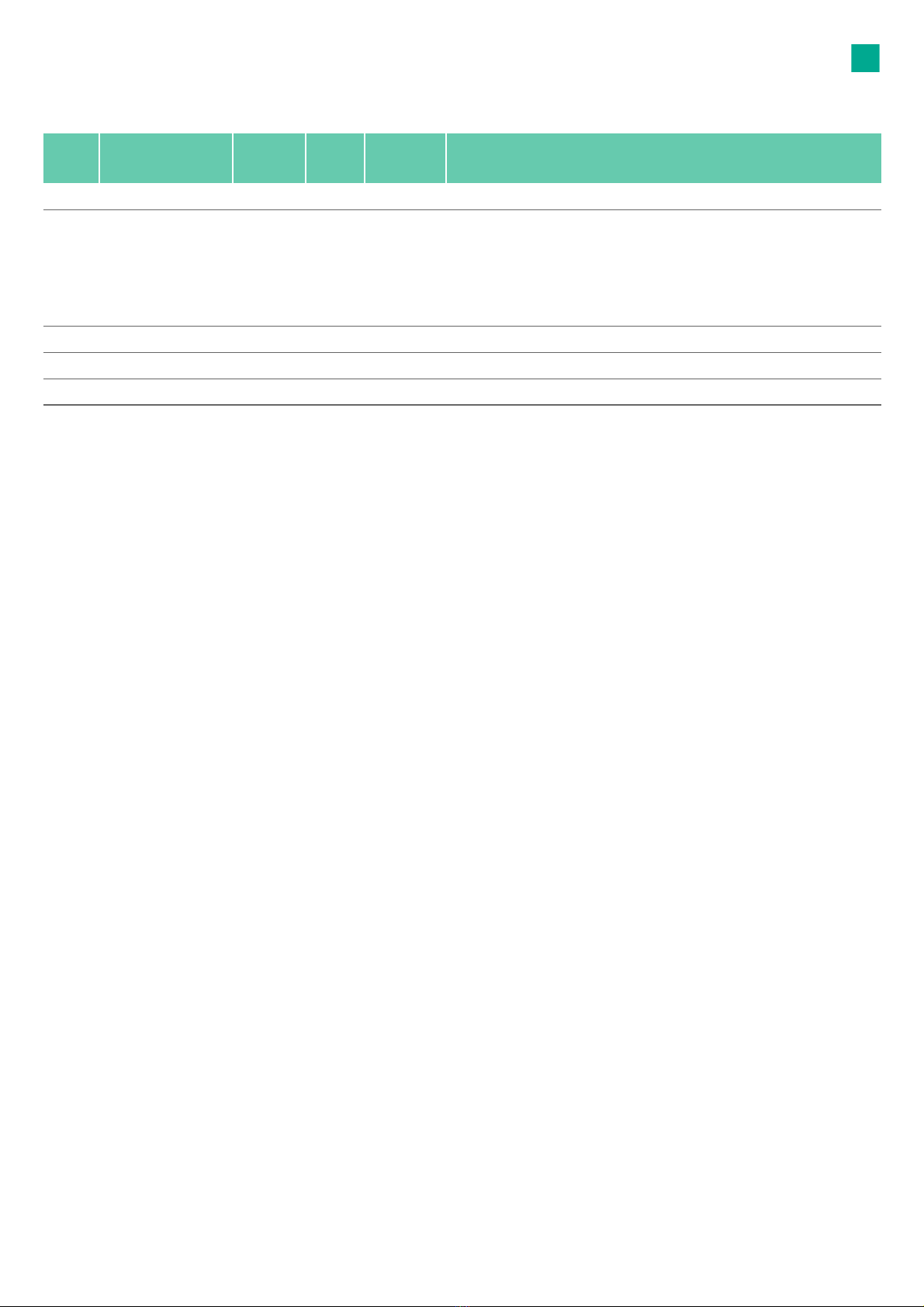

Legend

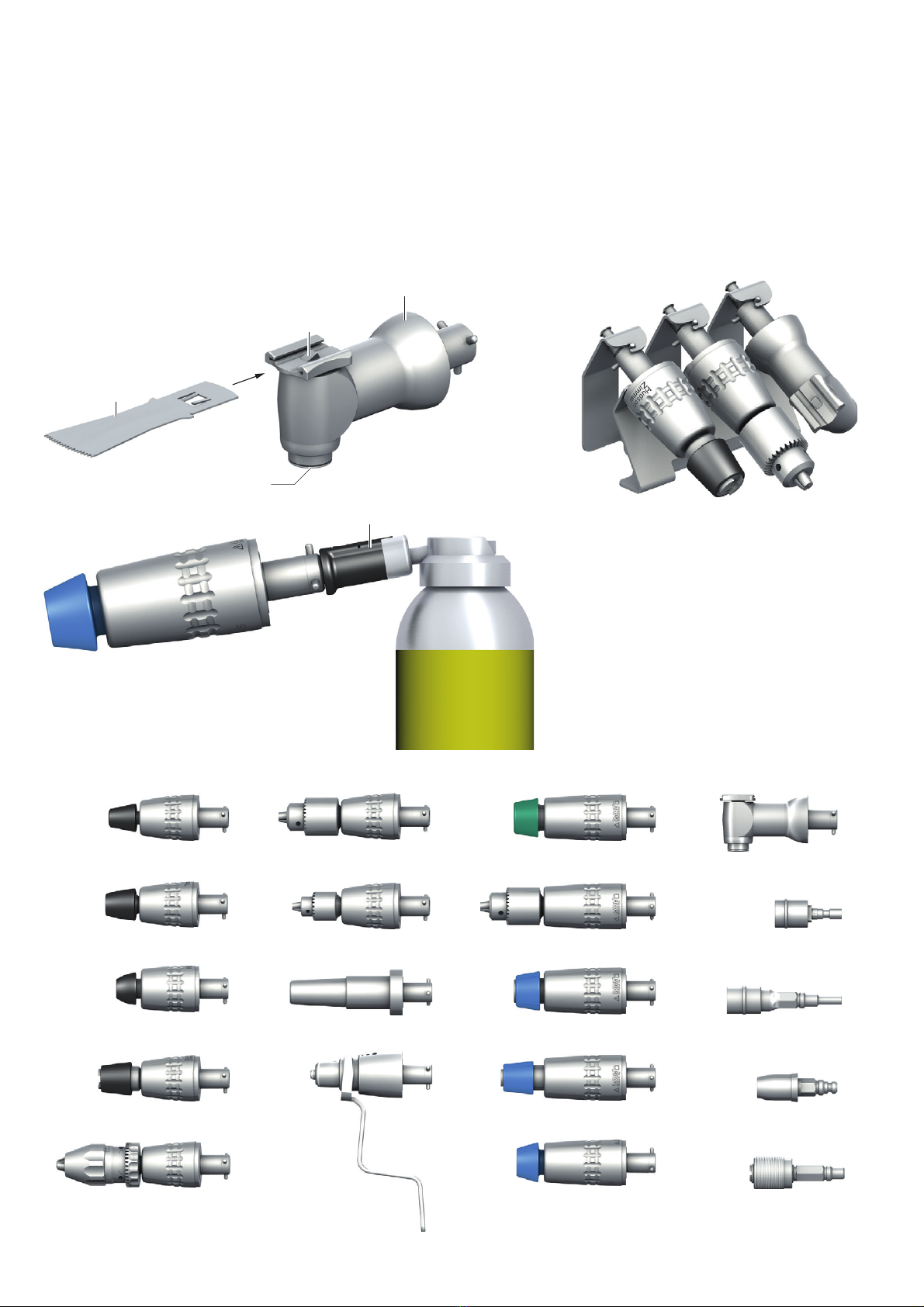

1Drill

2Knob (for speed control)

3Safety catch

4Rotating sleeve

5Arrow

6Reamer attachment with quick-action chuck adapter

7Unlocking sleeve

8Tool coupling

9Drill attachment with quick-action chuck adapter

10 Drill attachment keyless Jacobs chuck

11 Locking sleeve

12 Attachment with Jacobs chuck

13 Tightening key

14 Zimmer chuck with Hudson/Zimmer coupling

15 Unlocking sleeve

16 Adapter AO large to DHS/DCS step drill

17 Sagittal saw attachment

18 Tool attachment with L sagittal tool coupling

19 Knob for tool release

20 Drill attachment for Synthes radiolucent angle transmission

21 Kirschner wire attachment

22 Clamping lever

23 Adjustment sleeve

24 Kirschner wire chuck

25 L sagittal saw blade

26 Oil spray adapter

The diagrams are only schematic.

Symbols on product and packages

Contents

1. Applicable to . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Main functions and design characteristics. . . . . . . . . . . . . . . . 3

2.3 Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Absolute contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Relative contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Safe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.1 Scope of supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.2 Components required for operation . . . . . . . . . . . . . . . . . . . . . 4

4.3 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Working with the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.1 System set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.1.1 Connecting the accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6.2 Protection against inadvertent activation . . . . . . . . . . . . . . . . 5

6.3 Coupling and uncoupling of attachment to drill and reamer . 5

6.4 Attaching and detaching the tool from the attachment. . . . . 5

6.4.1 Attachments with quick-action chuck GB623R/GB657R/

GB663R/GB664R/GB665R/GB668R/GB669R/GB670R. . . . . . . 5

6.4.2 Drill attachment keyless Jacobs chuck GB620R. . . . . . . . . . . . 5

6.4.3 Attachments with three-jaw chuck GB621R/GB639R/GB667R 6

6.4.4 Zimmer chuck with Hudson/Zimmer shaft GB176R. . . . . . . . . 6

6.4.5 Harris chuck with AO large shaft GB184R and DIN chuck with

AO large shaft XF457R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.4.6 Adapter AO large to DHS/DCS step drill GB628R. . . . . . . . . . . 6

6.4.7 Sagittal saw attachment GB660R . . . . . . . . . . . . . . . . . . . . . . . 6

6.4.8 Drill attachment for Synthes radiolucent angle transmission

GB645R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.4.9 Insert and clamp Kirschner wire attachment GB641R. . . . . . . 6

6.5 Function checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.6 Safe operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Validated reprocessing procedure . . . . . . . . . . . . . . . . . . . . . . . 8

7.1 General safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3 Preparations at the place of use . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4 Preparation before cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.5 Cleaning/disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

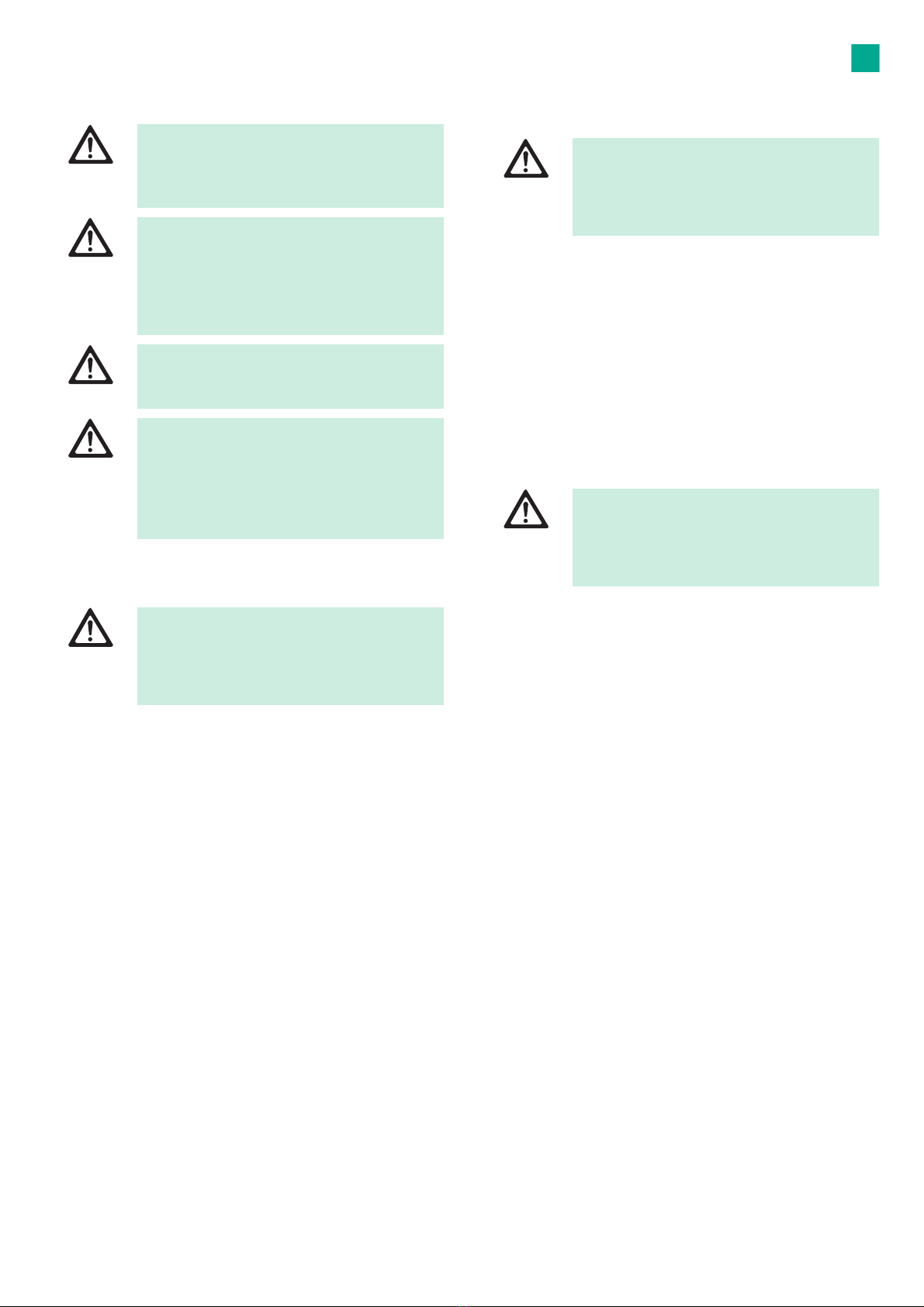

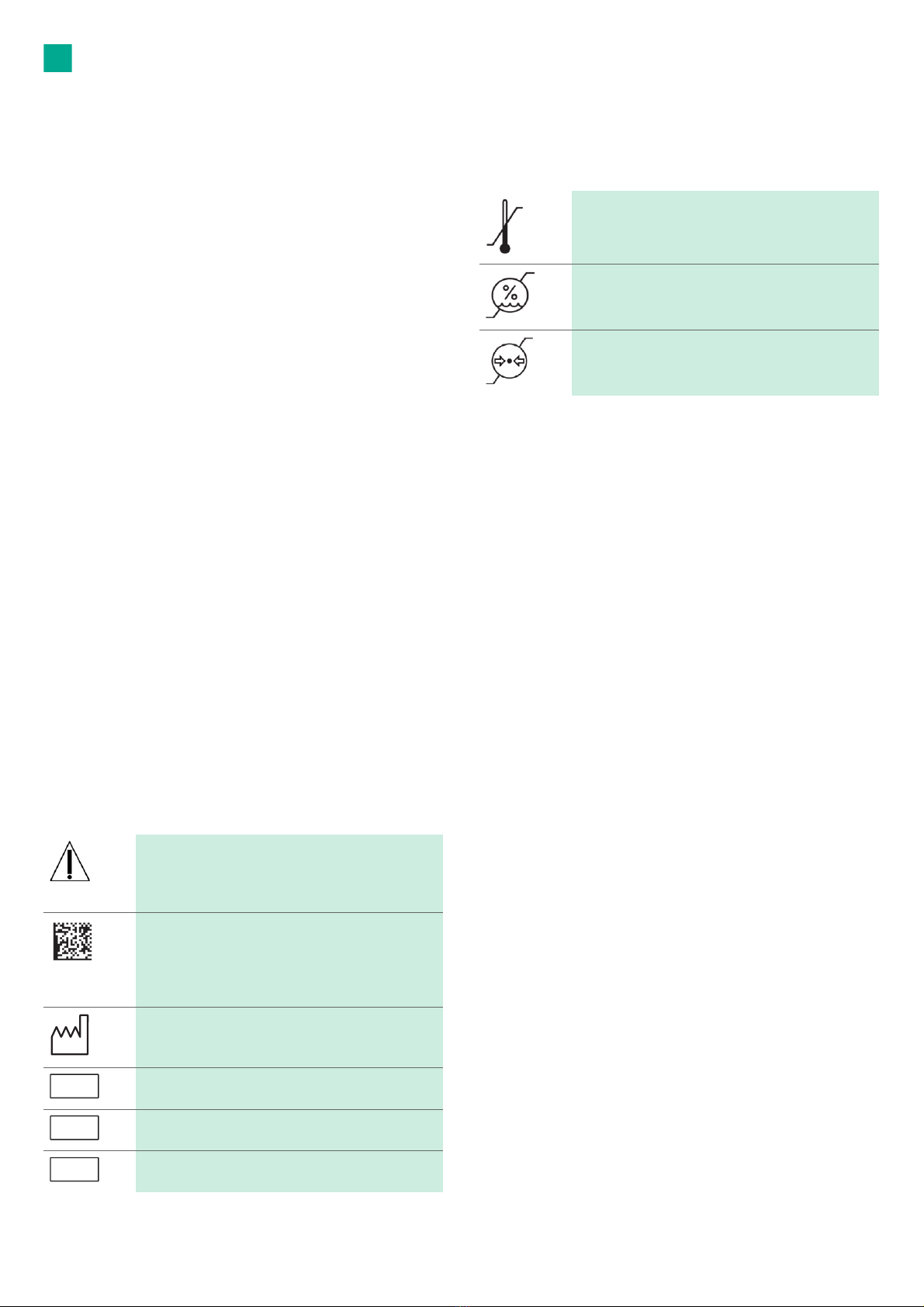

Caution

Observe important safety information such as warn-

ings and precautions in the instructions for use.

Machine-readable, two-dimensional code

The code contains a unique serial number which can be

used for electronic tracking of the individual instru-

ment. The serial number is based on the global stan-

dard sGTIN (GS1).

Date of manufacture

Manufacturer’s batch designation

Manufacturer’s serial number

Manufacturer’s article number

LOT

SN

REF

Temperature limits during transport and storage

Air humidity limits during transport and storage

Atmospheric pressure limits during transport and stor-

age

3

en

7.5.1 Product-specific safety instructions for the reprocessing

procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.6 Manual cleaning with wipe disinfection . . . . . . . . . . . . . . . . . . 9

7.7 Automatic cleaning/disinfection with manual pre-cleaning . . 10

7.7.1 Manual pre-cleaning with a brush. . . . . . . . . . . . . . . . . . . . . . . 10

7.7.2 Mechanical alkaline cleaning and thermal disinfection. . . . . . 11

7.8 Inspection, maintenance and checks . . . . . . . . . . . . . . . . . . . . . 11

7.9 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.10 Steam sterilization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.11 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9. Troubleshooting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10. Technical Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11. Accessories/Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

12.1 Classification acc. to Directive 93/42/EEC. . . . . . . . . . . . . . . . . 13

12.2 Performance data, information about standards . . . . . . . . . . . 13

12.3 Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.4 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

13. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1. Applicable to

►For item-specific instructions for use and information on material

compatibility, see also the Aesculap Extranet at

https://extranet.bbraun.com

2. General information

2.1 Intended use

Task/Function

The drill and milling machines GA330, GA671 and GA672, combined with

the corresponding attachments and tools, are used to process hard tissue,

cartilage, cognate and bone replacement materials, inserting and remov-

ing bone pins as well as for inserting transfixion wires.

Application Environment

The product is used in operating rooms in sterile zones outside of the

explosion risk zone (such as areas with pure oxygen or anesthesia gases).

2.2 Main functions and design characteristics

Speed GB667R

GB668R

GB669R

GB670R

0 min-1 to max. 250 min-1

GB657R 0 min-1 to max. 370 min-1

GB645R 0 min-1 to max. 900 min-1

GB620R

GB621R

GB663R

GB664R

GB665R

0 min-1 to max. 1 000 min-1

GB623R

GB639R

GB641R

0 min-1 to max. 1 250 min-1

GB660R 0 min-1 to max. 17 000 min-1

Rotational direc-

tion

Right and left rotation, oscilla-

tion

Operating mode Operation with non-periodic

load and speed changes (type

S9 pursuant to IEC EN 60034-

1)

Right/left rotation:

■60 second application,

60 second pause

■20 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Milling (clockwise/counter-

clockwise):

■30 second application,

30 second pause

■8 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Drilling (oscillation):

■60 second application,

60 second pause

■4 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Saw mode with GB660R:

■30 second application,

60 second pause

■3 repetitions

■30 min cooling time

■Max. Temperature 48 °C

4

en

2.3 Indications

The type and area of application depend on the tool selected.

2.4 Absolute contraindications

The product is not licensed for use on the central nervous system or central

circulatory system.

2.5 Relative contraindications

The safe and effective use of the product greatly depends on influences

which can only be controlled by the user. Therefore the specifications pro-

vided represent framework conditions only.

Clinically successful use of the product is dependent on the knowledge and

experience of the surgeon. The surgeon must decide which structures it is

sensible to treat and take into account the safety and warning information

contained in these instructions for use.

3. Safe handling

■General risk factors associated with surgical procedures are not

described in this documentation.

■It is the operating surgeon's responsibility to ensure that the surgical

procedure is performed correctly.

■The operating surgeon must have a thorough understanding of both the

hands-on and conceptual aspects of the established operating tech-

niques.

►Remove the transport packaging and clean the new product, either

manually or mechanically, prior to its initial sterilization.

►Prior to use, check that the product is in good working order.

►To prevent damage caused by improper setup or operation, and in order

not to compromise warranty and manufacturer liability:

– Use the product only according to these instructions for use.

– Follow the safety and maintenance instructions.

– Only combine Aesculap products with each other.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

►Keep the instructions for use accessible for the user.

►Always adhere to applicable standards.

►Ensure that the electrical installation of the room is consistent with the

requirements of IEC/DIN EN.

►Do not operate the product in explosion-hazard areas.

►Sterilize product before use.

►When handling, observe instructions for use that are relevant to

Aesculap holder systems TA009721, see Aesculap Extranet at

https://extranet.bbraun.com

4. Product description

4.1 Scope of supply

4.2 Components required for operation

■Drill and reamer GA330 (ready)

–or-

■Acculan 3Ti Drill and milling machine GA672 (ready for operation)

–or-

■Acculan 3Ti Small drill GA671 (ready for operation)

■Tool (depending on indication)

4.3 Operating principle

The attachment can be coupled to the drill and reamer in three different

positions, each offset by 120°.

The attachment locks automatically when attached to the drill and reamer.

The attachment can be removed by operating a rotating sleeve on the drill

and reamer.

The attachments have various integrated couplings on the working end, to

enable attachment of various tools, Kirschner wires or adapters.

5. Preparation

Aesculap assumes no liability if the following rules are not followed:

►Do not use products from open or damaged sterile packaging.

►Prior to use, inspect the product and its accessories for any visible dam-

age.

►Use the products and their accessories only if they are in perfect tech-

nical condition.

WARNING

Risk of injury and material damage due to inappro-

priate use of the product!

►Use the product only in accordance with the

intended purpose.

WARNING

Risk of injury and damage to property due to

improper handling of the product!

►Follow the instructions for use of all products

used.

Art. no. Designation

GB176R

GB184R

GB620R

GB621R

GB623R

GB628R

GB639R

GB641R

GB645R

GB657R

GB660R

GB663R

GB664R

GB665R

GB667R

GB668R

GB669R

GB670R

XF457R

One of the following attachments/adapters:

Zimmer chuck with Hudson/Zimmer shaft

Harris chuck with AO large shaft

Drill attachment keyless Jacobs chuck

Drill attachment large Jacobs chuck

Drill attachment AO small

Adapter AO large to DHS/DCS step drill

Drill attachment small Jacobs chuck

Kirschner wire attachment

Drill attachment for Synthes radiolucent angle trans-

mission

Medullary reamer attachment AO large

Sagittal saw attachment

Drill attachment Trinkle

Drill attachment Aesculap hexagon

Drill attachment Hudson/Zimmer

Reamer attachment large Jacobs chuck

Reamer attachment AO large

Reamer attachment Hudson/Zimmer

Reamer attachment Harris

DIN chuck with AO large shaft

GA031R Chuck key for large Jacobs chuck (GB620R, GB621R

and GB667R)

GA062R Key for small Jacobs chuck (GB639)

TA014541 Instructions for use for Acculan 4 attachments (flyer)

5

en

6. Working with the device

6.1 System set-up

6.1.1 Connecting the accessories

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically intended

for the respective application, and if they do not compromise the perfor-

mance and safety characteristics of the products.

All configurations must fulfill the fundamental standard

IEC/DIN EN 60601-1. The person connecting the devices with each other

is responsible for the configuration and must ensure that the fundamental

standard IEC/DIN EN 60601-1 or relevant national standards.

►Follow the instructions for use of individual accessories.

►Please address your B. Braun/Aesculap partner or Aesculap Technical

Service with any inquiries in this respect; for a contact address, see

Technical Service.

6.2 Protection against inadvertent activation

The rotational speed control button can be locked to prevent inadvertent

activation of the drill and reamer during a tool/attachment change.

Locking the knob for speed control 2:

►Twist the safety catch 3to position OFF.

The speed control knob 2is blocked and the product 1cannot be oper-

ated.

Unlocking the knob for speed control 2:

►Twist the safety catch 3to position ON.

The speed control knob 2is unlocked and the product 1can be oper-

ated.

Note

For further information on the drill and reamer, see TA014538 or TA014539

(flyer).

6.3 Coupling and uncoupling of attachment to drill

and reamer

►Secure drill and reamer 1against inadvertent activation with the

safety catch 3, see Protection against inadvertent activation.

Coupling

►Push the attachment onto drill and reamer 1until it engages with a

click.

►Pull at attachment to check that it is securely coupled.

Uncoupling

►Turn the sleeve 4in the direction of the arrow 5and simultaneously

remove the attachment from the drill and reamer 1.

6.4 Attaching and detaching the tool from the attach-

ment

►Ensure that the tool connector and attachment type are compatible.

6.4.1 Attachments with quick-action chuck GB623R/GB657R/

GB663R/GB664R/GB665R/GB668R/GB669R/GB670R

Coupling

►Pull back on the unlocking sleeve 7.

►Insert the tool shaft in the correct position up to the stop in the tool

holder 8of the attachment 6/9.

►Release the unlocking sleeve 7.

Tool is attached.

►Pull at tool to check that it is securely coupled.

Uncoupling

►Pull back the unlocking sleeve 7.

►Remove tool.

6.4.2 Drill attachment keyless Jacobs chuck GB620R

Note

The drill attachment keyless Jacobs chuck GB620R may open during left-

hand rotation of tools (e.g. when pulling out tools).

To operate tools in left-hand rotation, use the Jacobs chuck with key

GB621R, GB639R or GB667R.

Note

If necessary, the key GA031R can be used for coupling and decoupling.

Coupling

►Rotate the locking sleeve 11 clockwise and open Jacobs chuck.

►Insert the tool shaft in the correct position up to the st op in the tool

holder 8of the attachment 10.

►Rotate locking sleeve 11 counterclockwise and close Jacobs chuck.

►Pull at tool to check that it is securely coupled.

WARNING

Risk of infection and contamination!

Product is delivered unsterilized!

►Sterilize the product before use pursuant to the

operating instructions.

WARNING

Risk of injury and material damage due to inappro-

priate use of tools!

►Always follow the safety advice and information

given in the instructions for use.

►When coupling/uncoupling, handle tools with

cutting edges with care.

WARNING

Damage to the product if dropped!

►Use the products only if they are in perfect tech-

nical condition, see Function check

WARNING

Risk of burns to skin and tissue through blunt tools

or if product has not been maintained properly!

►Use tools only if they are in perfect condition.

►Replace blunt tools.

►Maintain the product properly, see maintenance

guide.

DANGER

Risk of injury due to unapproved configuration

using additional components!

►Ensure that the classification of all components

used is consistent with the classification of the

product (such as type BF or type CF).

WARNING

Risk of injury when attaching/removing attach-

ments/tools in the ON position through inadvertent

activation of the product!

►Only attach/remove attachments/tools in the

OFF position.

WARNING

Risk of injury when attaching/removing attach-

ments/tools in the ON position through inadvertent

activation of the product!

►Only attach/remove attachments/tools in the

OFF position.

6

en

Uncoupling

►Rotate the locking sleeve 11 clockwise and open Jacobs chuck.

►Remove tool.

►Rotate the locking sleeve 11 counterclockwise and close Jacobs chuck.

6.4.3 Attachments with three-jaw chuck

GB621R/GB639R/GB667R

Coupling

►Open the Jacobs chuck with the key 13.

►Insert the tool shaft in the correct position up to the st op in the tool

holder 8of the attachment 12.

►Close the Jacobs chuck with the key 13 and pull tight.

►Pull at tool to check that it is securely coupled.

Uncoupling

►Open the Jacobs chuck with the key 13.

►Remove tool.

6.4.4 Zimmer chuck with Hudson/Zimmer shaft GB176R

Coupling

►Push unlocking sleeve forward 15 and hold.

►Insert the tool shaft in the correct position up to the st op in the tool

holder 8of the attachment 14.

►Release the unlocking sleeve 15.

►Pull at tool to check that it is securely coupled.

Uncoupling

►Push unlocking sleeve forward 15 and hold.

►Remove tool.

6.4.5 Harris chuck with AO large shaft GB184R and DIN chuck with

AO large shaft XF457R

Coupling

►Push unlocking sleeve back 15 and hold.

►Insert the tool shaft in the correct position up to the st op in the tool

holder 8of the attachment 14.

►Release the unlocking sleeve 15.

►Pull at tool to check that it is securely coupled.

Uncoupling

►Push unlocking sleeve back 15 and hold.

►Remove tool.

6.4.6 Adapter AO large to DHS/DCS step drill GB628R

Coupling

►Push unlocking sleeve back 15 and hold.

►Insert the tool shaft in the correct position up to the st op in the tool

holder 8of the attachment 16.

►Release the unlocking sleeve 15.

►Pull at tool to check that it is securely coupled.

Uncoupling

►Push unlocking sleeve back 15 and hold.

►Remove tool.

6.4.7 Sagittal saw attachment GB660R

Coupling

►Insert saw blade 25 into the slot of the tool holder 18, see Fig. A.

Ensure that the side stops of the saw blade are aligned with the tool

holder.

The tool engages.

►Pull on the attachment 22 to ensure a secure fit.

Uncoupling

►Press kjnob for tool release 19 and pull saw blade 25 out of the tool

holder 18.

6.4.8 Drill attachment for Synthes radiolucent angle transmission

GB645R

The drill attachment allows connecting a radiolucent angle transmission

for applying drill holes in the bone under radiographic control.

The drill attachment is only suitable for use of the radiolucent angle trans-

mission 511.300 from the Synthes company.

►Follow the instructions for the radiolucent angle transmission 511.300

in the operating instructions of the Synthes company.

Coupling the angle transmission

►Push the radiolucent angle transmission up to the stop on holder 8of

the drill attachment 20.

►If necessary, slightly move the radiolucent unit.

Decouple angled handpiece

►Forcefully pull out the radiolucent angle transmission from the drill

attachment 20.

Couple/decouple the tool

►Follow the instructions for the radiolucent angle transmission 511.300

in the operating instructions of the Synthes company.

6.4.9 Insert and clamp Kirschner wire attachment GB641R

Note

The special Kirschner wire chuck is recommended for the placement of

guide wires. This quick-action chuck adapter allows quick and easy ten-

sioning of drilling wires.

For further information see TA014535 or TA014539 (flyer).

The following diameters can be set on the Kirschner wire attachment:

■0.6 mm to 1.8 mm

■1.8 mm to 3.0 mm

■3.0 mm to 4.0 mm

Insert Kirschner wire

►Ensure that the clamping lever 22 is in the starting position (deacti-

vated status).

►Set the adjusting sleeve 23 of the Kirschner wire attachment to the

desired diameter range:

– Push back the adjusting sleeve 23 and turn until the desired diam-

eter range has been reached.

– Release adjustment sleeve 23, making certain that adjustment

sleeve 23 clicks into position.

►Insert the Kirschner wire into the Kirschner wire chuck 24 until the

desired exposed length is achieved.

The Kirschner wire is held in the intended position in the attachment

by an automatic clamping mechanism.

WARNING

Risk of injury when using long guide wires!

►Use Kirschner wire protection sleeve when using

long guide wires.

7

en

Clamping the Kirschner wire

►Pull on the clamping lever 22 and hold in the desired position.

The further the clamping lever is pulled back, the higher the tension of

the Kirschner wire.

Note

The Kirschner wire will only remain tensioned with the clamping lever

pulled back. If the clamping lever is released, it will move back into the

starting position and the Kirschner wire is freely mobile.

6.5 Function checks

The function test must be performed before each use and after each intra-

operative change of attachment and tool.

►Check that the attachment is coupled properly. To test this, pull on the

attachment.

►Check that the tool is coupled properly. To do this, pull on the tool.

►Ensure that the tool blades are not mechanically damaged.

►Release drill and reamer for use (ON position).

►Briefly run the drill and reamer at maximum speed in clockwise and

counterclockwise mode.

►Make certain that the rotational direction is correct in each case.

►Check the product for damage, abnormal operation noises, heavy vibra-

tion and excessive heat.

►Do not use the product if it is damaged or defective.

►Set aside the product if it is damaged.

6.6 Safe operation

Operating the product

Note

For further information on the drill and reamer, see TA014538 or TA014539

(flyer).

►Start the drill and reamer at moderate speed.

►Apply moderate pressure to prevent slipping.

►Do not bend the tool, otherwise there is a danger of breakage.

►When screwing bone screws and bone pins in and out: ensure correct

torque setting.

Use the following attachments for drilling:

■GB620R

■GB621R

■GB623R

■GB639R

■GB663R

■GB664R

■GB665R

Use the following attachments for milling (medullary reaming):

■GB667R

■GB668R

■GB669R

■GB670R

Use the following attachment for medullary reaming:

■GB657R

Use the following attachment for the placement of Kirschner wires:

■GB641R

Use only the following attachment for using the radiolucent angle trans-

mission 511.300 from the Synthes company:

■GB645R

Use the following attachment for drilling:

■GB660R

WARNING

Coagulation of patient tissue or risk of burns for

patients and user through hot product!

►Do not use drill attachments to operate reamer

tools such as the acetabulum reamer and the

medullary reamer.

►Operate any reamer tool only with a reamer

attachment.

►Cool the tool during operation.

►Keep product/tool out of the reach of patients.

►Let the product/tool cool down.

►Use a cloth to protect against burns when

changing the tool.

WARNING

Risk of infection or injury through aerosol forma-

tion or particles ejected from the tool!

►Use suitable protection (such as waterproof pro-

tective clothing, face mask, safety gases, suc-

tion).

WARNING

Risk of injury and/or malfunction!

►Always carry out a function check prior to using

the product.

WARNING

Risk of injury when using the product beyond the

field of view!

►Apply the product only under visual control.

WARNING

Risk of injury and damage to the tool/system!

The rotating tool may get caught in drapes (such as

textiles).

►Do not let the tool come into contact with

drapes (such as textiles) during operation.

8

en

7. Validated reprocessing procedure

7.1 General safety notes

Note

Adhere to national statutory regulations, national and international stan-

dards and directives, and local, clinical hygiene instructions for reprocess-

ing.

Note

For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD, or possi-

ble variants of CJD, observe the relevant national regulations concerning

the reprocessing of products.

Note

Mechanical reprocessing should be favored overmanual cleaning as it gives

better and more reliable results.

Note

It should be noted that successful reprocessing of this medical device can

only be guaranteed following prior validation of the reprocessing method.

The operator/reprocessing technician is responsible for this.

The recommended chemistry was used for validation.

Note

If there is no final sterilization, then a virucidal disinfectant must be used.

Note

For up-to-date information about reprocessing and material compatibility,

see also the Aesculap Extranet at https://extranet.bbraun.com

The validated steam sterilization procedure was carried out in the Aesculap

sterile container system.

7.2 General information

Dried or affixed surgical residues can make cleaning more difficult or inef-

fective and lead to corrosion. Therefore the time interval between applica-

tion and processing should not exceed 6 h; also, neither fixating pre-

cleaning temperatures >45 °C nor fixating disinfecting agents (active

ingredient: aldehydes/alcohols) should be used.

Excessive neutralizing agents or basic cleaners may result in a chemical

attack and/or fading and the laser marking becoming unreadable either

visually or by machine.

On stainless steel, residues containing chlorine or chloride (such as surgi-

cal residues, drugs, saline solutions in water for cleaning, disinfection and

sterilization) may lead to corrosion (pitting corrosion, tensile corrosion)

and thus to the destruction of the product. These must be removed by rins-

ing thoroughly with demineralized water and then drying.

Perform additional drying, if necessary.

Only process chemicals that have been tested and approved (e.g. VAH or

FDA approval or CE mark) and which are compatible with the product’s

materials according to the chemical manufacturers’ recommendations

may be used for processing the product. All the chemical manufacturer's

application specifications must be strictly observed. Failure to do so can

result in the following problems:

■Visual material changes (such as fading or color changes in titanium or

aluminum). For aluminum, the application/process solution only needs

to be pH >8 to cause visible surface changes.

■Material damage (such as corrosion, cracks, breaks, premature aging or

swelling).

►Do not use metal cleaning brushes or other abrasives that would dam-

age the product surface and could cause corrosion

►For further detailed information on hygienically safe and material-pre-

serving/value-preserving reprocessing, see www.a-k-i.org, link to Pub-

lications, Red Brochure – Proper maintenance of instruments.

7.3 Preparations at the place of use

►Remove all attached components from the product (tool and accesso-

ries).

►Remove the attachment from drill and reamer.

►Remove any visible surgical residues as much as possible with a damp,

lint-free cloth.

►Place the dry product in a sealed waste container and forward it on for

cleaning and disinfection within 6 hours.

7.4 Preparation before cleaning

►Before the first automatic cleaning/disinfection: attach ECCOS fixa-

tions in a suitable sieve basket.

►Insert the products in the correct position into the ECCOS fixations, see

Fig. B.

Kirschner wire attachment GB641R

►Turn adjustment sleeve 20 to setting for largest Kirschner wire diame-

ter.

7.5 Cleaning/disinfection

7.5.1 Product-specific safety instructions for the reprocessing pro-

cedure

Note

The indicated drying time is a guide time only. It must be checked taking

into account the specific conditions (e.g. load) and if applicable adjusted.

CAUTION

Damage to the product due to inappropriate clean-

ing/disinfecting agents and/or excessive tempera-

tures!

►Use cleaning and disinfecting agents according

to the manufacturer’s instructions which

–are approved for plastic material and high-

grade steel,

–do not attack softeners (e.g. in silicone).

►Do not use cleaning agents that contain ace-

tone.

►Observe specifications regarding concentration,

temperature and exposure time.

►Do not exceed the maximum temperature of

60 °C during chemical cleaning and/or disinfec-

tion.

►Do not exceed the maximum temperature of

96 °C during thermal disinfection with FD

water.

►Dry the product for at least 10 minutes at a

maximum of 120 °C.

9

en

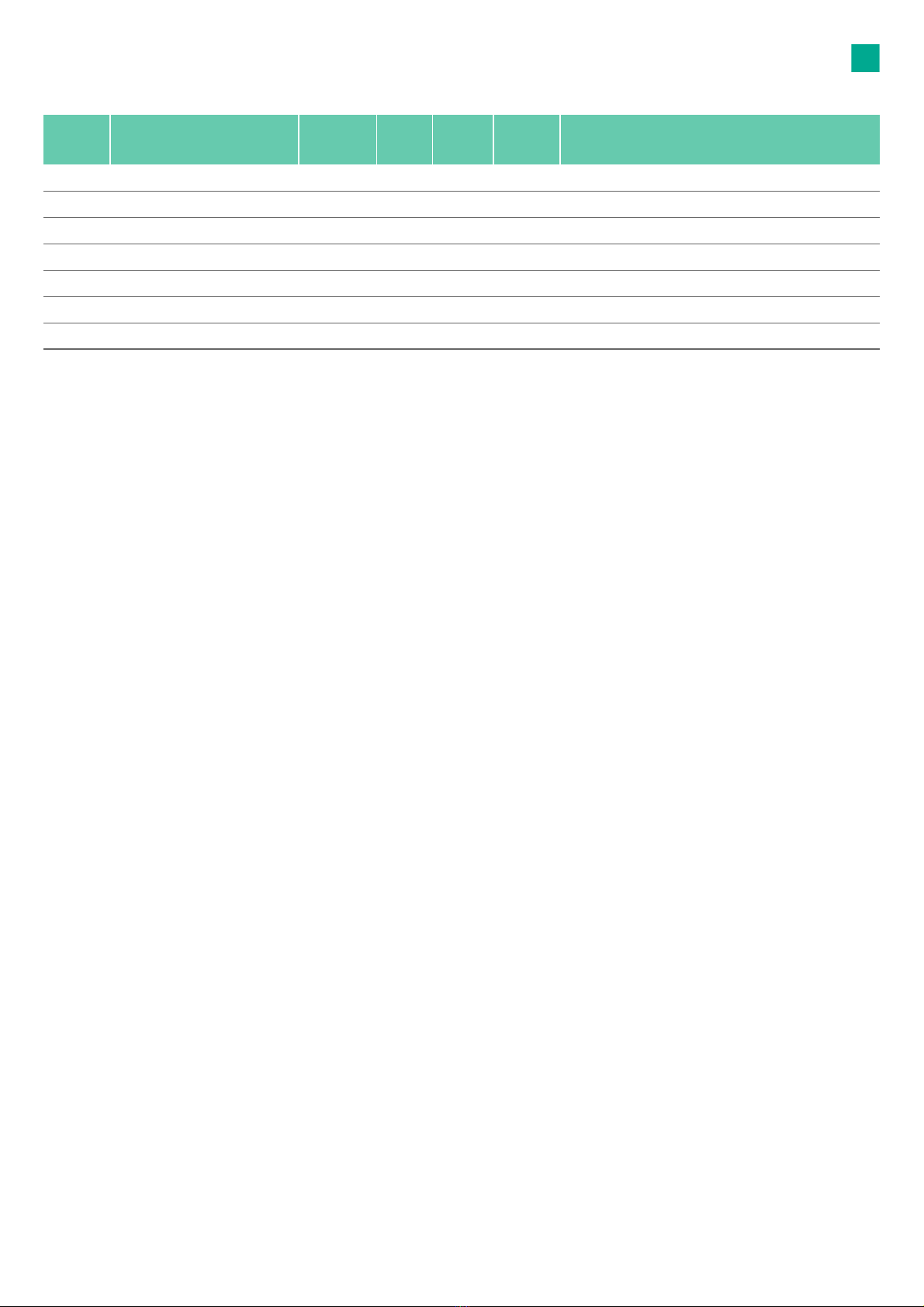

7.6 Manual cleaning with wipe disinfection

D–W: Drinking water

FD–W: Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least)

RT: Room temperature

* Validated with enzyme cleaner “Cidezyme Johnson & Johnson”

►Do not clean the product in a ultrasonic bath and do not immerse the

product in any fluids. Let any fluid incursions drain out immediately,

otherwise there is a danger of corrosion and loss of function.

Phase I

►Mobilize non-rigid components during cleaning.

►Clean the product under running water, using a suitable cleaning brush

until all visible residues have been removed from the surfaces.

►Brush cannulation with cleaning brush TA011944 and difficult to

access surfaces with a suitable cleaning brush made of plastic for at

least 1 min.

Note

For details on difficult to access surfaces, see Acculan pre-cleaning and

care information TA016000 (available on Aesculap Extranet at

https://extranet.bbraun.com).

Phase II

►Follow the operating instructions of the enzyme cleaner with regard to

correct concentration, dilution, temperature and water quality.

►Spray products with a pH neutral enzyme solution, let soak in for at

least 2 minutes and then wipe off.

Phase III

►Mobilize non-rigid components during cleaning.

►Rinse product under running tap water for at least 5 minutes.

►Follow the operating instructions of the enzyme cleaner with regard to

correct concentration, dilution, temperature and water quality.

►Contamination should be removed with a lint-free cloth or soft brush

moistened with enzyme cleaner.

►Flexible components (such as sleeves) and cannulations should be

rinsed for 20 seconds with the water pistol (cold water, at least

2.5 bar).

►After manual cleaning, check visible surfaces and areas of flexible com-

ponents for residues.

►If necessary, repeat the cleaning process (phase 1 to 3).

Phase IV

►Dry the product in the drying phase with suitable equipment (such as

lint-free cloths, pressurized air).

Phase V

►Wipe all surfaces of the product with a single-use disinfecting wipe.

Phase VI

►Rinse disinfected surfaces after the prescribed reaction time for at least

1 minute under running demineralized water.

►Drain any remaining water fully.

Stage VII

►Dry the product in the drying phase with suitable equipment (such as

lint-free cloths, pressurized air).

Phase Step T

[°C/°F] t

[min] Conc.

[%] Water

quality Chemicals

I Pre-cleaning RT (cold) ≥2 - D-W Until visually clean

II Cleaning with enzyme solution RT (cold) ≥20.8 D–W pH-neutral*

III Intermediate rinse RT ≥5- D-W –

IV Drying RT - - - -

VWipedisinfection - >1 - - Meliseptol HBV wipes 50 % Propan-1-ol

VI Final rinse RT (cold) 0.5 - FD–W -

VII Drying RT - - - -

10

en

7.7 Automatic cleaning/disinfection with manual pre-cleaning

Note

The cleaning and disinfection device must fundamentally have a tested

efficacy (such as FDA approval or CE label pursuant to DIN EN ISO 15883).

Note

The cleaning and disinfection machine used for processing must be serviced

and checked at regular intervals.

7.7.1 Manual pre-cleaning with a brush

D–W: Drinking water

RT: Room temperature

►Do not clean the product in a ultrasonic bath and do not immerse the

product in any fluids. Let any fluid incursions drain out immediately,

otherwise there is a danger of corrosion and loss of function.

►For Kirschner wire attachment GB641R: Set the adjustment sleeve 20

to the greatest Kirschner wire diameter.

Phase I

►Mobilize non-rigid components during cleaning.

►Thoroughly clean the product under running water.

Phase II

►Mobilize non-rigid components during cleaning.

►Brush cannulation with cleaning brush TA011944 and difficult to

access surfaces with a suitable cleaning brush made of plastic for at

least 1 min.

►After manual preparation, check visible surfaces for residue and repeat

the pre-cleaning process as needed.

Note

For details on difficult to access surfaces, see Acculan pre-cleaning and

care information TA016000 (available on Aesculap Extranet at

https://extranet.bbraun.com).

Phase Step T

[°C/°F] t

[min] Conc.

[%] Water

quality Chemistry/Note

IRinsing RT (cold) - - D–W Until visually clean

II Brushes RT (cold) - - D–W Until visually clean

11

en

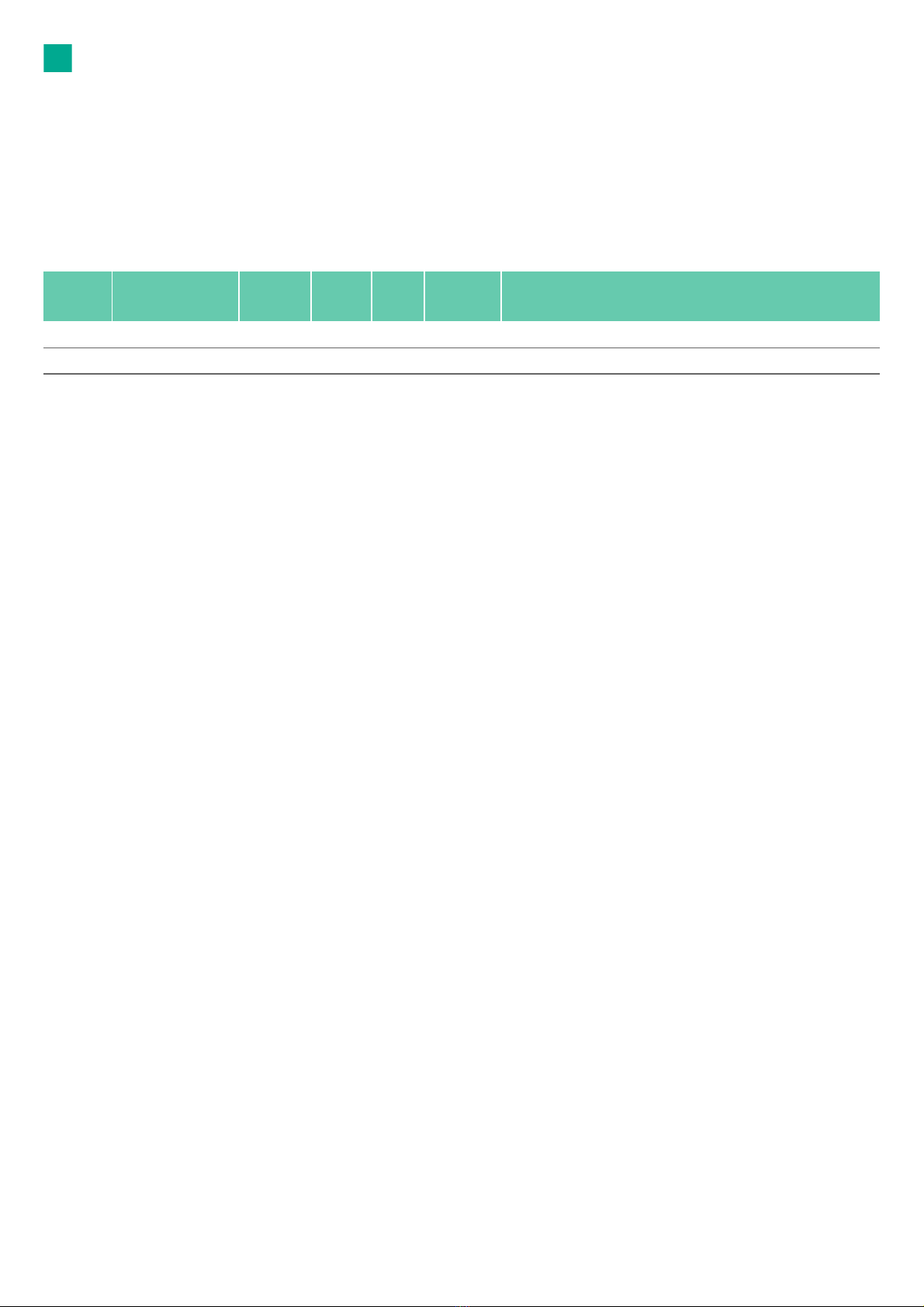

7.7.2 Mechanical alkaline cleaning and thermal disinfection

Machine type: single-chamber cleaning/disinfection device without ultrasound

D-W: Drinking water

FD–W: Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least)

*Recommended: BBraun Helimatic Cleaner alkaline

►For Kirschner wire attachment GB641R: Set the adjustment sleeve 20

to the greatest Kirschner wire diameter.

►Insert the product in its proper position in the ECCOS fixation.

►Then connect the interior rinse device to the ECCOS fixation and con-

nect to the rinse connector of the cleaning/disinfection device/rinse

cart.

►After automatic cleaning/disinfection, check visible surfaces for resi-

dues and repeat the cleaning/disinfection process as needed.

7.8 Inspection, maintenance and checks

►Allow the product to cool down to room temperature.

►Inspect the product after each cleaning and disinfecting cycle to be

sure it is: clean, functional, and undamaged.

►Spray product after every cleaning and disinfection with Acculan 4 oil

spray adapter 23 GB600840 (black) for approx. 2 sec. with Aesculap

STERILIT Power Systems oil spray GB600, see Fig. C.

Note

Aesculap recommends occasional spraying of moving parts (such as knobs,

couplings, cover caps) with the Aesculap STERILIT-Power-Systems oil spray.

►Check the product for any damage, abnormal running noise, overheat-

ing or excessive vibration.

►Set aside the product if it is damaged.

7.9 Packaging

►Always follow the instructions for use of the respective packaging and

storage devices (e.g. instructions for use TA009721 for Aesculap-

ECCOS holder system).

►Insert the products in the correct position into the ECCOS fixations,

see Fig. B.

►Pack trays appropriately for the sterilization process (e.g. in Aesculap

sterile containers).

►Ensure that the packaging will prevent a recontamination of the prod-

uct.

7.10 Steam sterilization

Note

Remove all attached components from the product (tools, accessories)

before sterilization.

►Check to ensure that the sterilizing agent will come into contact with

all external and internal surfaces (e.g. by opening any valves and fau-

cets).

►Use a validated sterilization method:

– Steam sterilization using fractional vacuum process

– Steam sterilizer DIN EN 285 and validated pursuant to

DINENISO17665

– Sterilization using the fractionated vacuum process at 134 °C,

holding time 5 min

When sterilizing multiple products in one steam sterilizer:

►Ensure that the maximum permitted load specified by the manufac-

turer for the steam sterilizer is not exceeded.

7.11 Storage

►Store sterile products in germ-proof packaging, protected from dust, in

a dry, dark, temperature-controlled area.

8. Maintenance

To ensure reliable operation, the product must be maintained at least once

a year.

For technical service, please contact your national B. Braun/Aesculap

agency, see Technical Service.

Phase Step T

[°C/°F] t

[min] Water

quality Chemistry/Note

IPre-rinse <25/77 3 D–W -

II Cleaning 55/131 10 FD–W ■Concentrate, alkaline:

–pH~13

– <5 % anionic surfactant

■0.5 % working solution

–pH~11*

III Intermediate rinse >10/50 1 FD–W -

IV Thermal disinfection 90/194 5 FD–W -

VDrying - - - mind. 10 min at max. 120 °C

12

en

9. Troubleshooting list

►Have defective products repaired by Aesculap Technical Service, see Technical Service.

Issue Cause Detection Remedy

Product becomes too hot Excessive use Attachment very hot Follow operating instructions (operating mode).

Defective attachment drive/ball

bearings

Attachment very hot Follow operating instructions (preparation, care).

Preventative: lubricate attachment before every

sterilization.

Have the manufacturer repair the attachment.

Fall damage, product defective Attachment very hot Have the attachment repaired by the manufacturer

Blunt tool Heating of tool and product Change tool.

Insufficient power Product is operating in left rota-

tion mode

Serrated tool run in counterclock-

wise mode

Use serrated tools only in clockwise mode

Attachment defective Attachment very hot Follow operating instructions (preparation, care).

Preventative: lubricate attachment before every

sterilization.

Follow operating instructions (operating mode).

Have the attachment repaired by the manufacturer

Blunt tool Tool blades worn out Change tool.

Loud running noise Defective attachment drive/ball

bearings

Loud, perceptible noise during

operation

Follow operating instructions (preparation, care).

Preventative: lubricate attachment before every

sterilization.

Have the manufacturer repair the attachment.

Attachment does not

attach or detach.

Attachment not compatible Attachment doesn't engage Use the compatible attachment for drill.

Connection on attachment

deformed/defective

Attachment is difficult to couple

or cannot be coupled

Have the manufacturer repair the attachment.

Coupling on drill deformed/defec-

tive

Attachment is difficult to couple

or cannot be coupled

Have the manufacturer repair the drill.

Sleeve on drill hard to move Attachment doesn't engage Turn and hold the drill sleeve, then attach the

attachment. Turn the sleeve back if necessary.

Preventative: lubricate the sleeve on the drill

before each sterilization.

Tool does not attach or

detach.

Incompatible tool Tool does not click into place Use the tool compatible with the attachment.

Tool connector deformed/defec-

tive

Tool is difficult to couple or can-

not be coupled

Use a new tool.

Coupling on attachment

deformed/defective

Tool is difficult to couple or can-

not be coupled

Have the manufacturer repair the attachment.

Tool coupling dirty Tool is difficult to couple or can-

not be coupled

Clean tool or use a new tool.

Clean the attachment.

For GB641R: Kirschner

wire does not insert into

the Kirschner wire chuck

Kirschner wire chuck not set cor-

rectly

Diameter of the Kirschner wire is

not consistent with the scale set-

ting

Set the adjustment sleeve to the right Kirschner

wire diameter.

For GB641R: Kirschner

wire not turning

Kirschner wire chuck not set cor-

rectly

Diameter of the Kirschner wire is

not consistent with the scale set-

ting

Set the adjustment sleeve to the right Kirschner

wire diameter.

Open the clamping lever Open the clamping lever Close the clamping lever.

Clamping lever not pulled back

with sufficient force

Kirschner wire not turning Pull back the clamping lever forcefully and hold it.

13

en

10. Technical Service

Modifications carried out on medical technical equipment may result in

loss of guarantee/warranty rights and forfeiture of applicable licenses.

►For service and repairs, please contact your national B. Braun/Aesculap

agency.

Service addresses

Aesculap Technischer Service

Am Aesculap-Platz

78532 Tuttlingen / Germany

Phone: +49 (7461) 95 -1601

Fax: +49 (7461) 14 -939

E-Mail: ats@aesculap.de

Other service addresses can be obtained from the address indicated above.

11. Accessories/Spare parts

12. Technical data

12.1 Classification acc. to Directive 93/42/EEC

12.2 Performance data, information about standards

The product was subject to 500 preparation cycles as a test by the manu-

facturer and has passed.

The performance data for the individual attachments can be found in the

table below.

Tool not moving Attachment not fully attached to

the drill

Attachment can be pulled out of

the drill

Correctly attach the attachment and perform a

function test.

Tool not fully attached to the

attachment

Tool can be pulled out of the tool

coupling

Correctly attach the tool and perform a function

test.

Attachment defective Drill turning, but attachment is

not turning.

Have the manufacturer repair the attachment.

Drill defective Drill not turning Have the manufacturer repair the drill.

The safety catch of the drill is in

the OFF position

Safety catch is in OFF position Turn the safety catch into the ON position.

Oil spray adapter not

attachable

Oil spray adapter not compatible Oil spray adapter not attachable Use the compatible oil spray adapter for GA344.

Issue Cause Detection Remedy

WARNING

Danger to life of patients and users if the product

malfunctions and/or protective measures fail or are

not used!

►Do not perform any servicing or maintenance

work under any circumstances while the product

is being used on a patient.

►Do not modify the product.

Art. no. Designation

GB243R ECCOS set for 2 large machines

GB600 STERILIT Power Systems oil spray

GB600840 Oil spray adapter

TA011944 Cleaning brush

GB496R ECCOS fixation for 3 attachments

GB497R ECCOS fixation for one attachment

GA031R Key for large Jacobs chuck

GA062R Key for small Jacobs chuck

TA014541 Instructions for use for Acculan 4 attachments

(flyer)

Art. no. Designation Class

GB176R

GB184R

GB620R

GB621R

GB623R

GB628R

GB639R

GB641R

GB645R

GB657R

GB660R

GB663R

GB664R

GB665R

GB667R

GB668R

GB669R

GB670R

XF457R

Zimmer chuck with Hudson/Zimmer shaft

Harris chuck with AO large shaft

Drill attachment keyless Jacobs chuck

Drill attachment large Jacobs chuck

Drill attachment AO small

Adapter AO large to DHS/DCS step drill

Drill attachment small Jacobs chuck

Kirschner wire attachment

Drill attachment for Synthes radiolucent angle

transmission

Medullary reamer attachment AO large

Sagittal saw attachment

Drill attachment Trinkle

Drill attachment Aesculap hexagon

Drill attachment Hudson/Zimmer

Reamer attachment large Jacobs chuck

Reamer attachment AO large

Reamer attachment Hudson/Zimmer

Reamer attachment Harris

DIN chuck with AO large shaft

IIa

Rotational direction Right and left rotation, oscillation

Conforming to stan-

dard

IEC/DIN EN 60601-1

14

en

Drill attachments

Milling attachments

Saw Attachments

Kirschner wire attachment

Adapter

Attachment Connector Dimensions Length x ∅

[mm] ±5 % Weight [g]

±10 % Max. speed

[min-1]

Max. torque

[Nm] Cannula-

tion [mm]

GB620R Jacobs chuck keyless Ø 0.3 mm to

7.4 mm

133 x 35 397 1 000 5 4

GB621R Jacobs chuck with key Ø 0.5 mm to

7.4 mm

118 x 35 300 1 000 5 4

GB623R AO small 90 x 35 210 1 250 4 2.8

GB639R Jacobs chuck with key Ø 0.5 mm to

4.0 mm

105 x 35 243 1 250 4 4

GB645R Synthes radiolucent angle trans-

mission

110 x 35 225 900 5 –

GB663R Trinkle 93 x 35 217 1 000 5 4

GB664R Aesculap hex 86 x 35 225 1 000 5 4

GB665R Hudson/Zimmer 100 x 35 230 1 000 5 4

Attachment Connector Dimensions Length x ∅

[mm] ±5 % Weight [g]

±10 % Max. speed

[min-1]

Max. torque

[Nm] Cannula-

tion [mm]

GB657R AO large 108 x 35 300 370 12 4

GB667R Jacobs chuck with key Ø 0.5 mm to

7.4 mm

133 x 35 280 250 19 4

GB668R AO large 108 x 35 300 250 19 4

GB669R Hudson/Zimmer 118 x 35 300 250 19 4

GB670R Harris 106 x 35 290 250 19 4

Attachment Connector Dimensions L x W x H

[mm] ±5 % Weight [g]

±10 % Max. oscillation fre-

quency [min-1]

Cannulation [mm]

GB660R Rapid Action 89 x 36 x 44 270 17 000 –

Attachment Connector Dimensions L x W x H

[mm] ±5 % Weight [g]

±10 % Max. speed [min-1]Cannulation [mm]

GB641R Kirschner wire ∅0.6 mm to 4 mm 93 x 36 x 137 285 1 250 4

Attachment Connector Dimensions Length x ∅

[mm] ±5 % Weight [g]

±10 % Max. speed [min-1]Max. torque [Nm] Cannula-

tion [mm]

GB184R Harris 88 x 22 85 With GB668R: 250

With GB657R: 370

With GB668R: 19

With GB657R: 12

–

GB176R Zimmer 50 x 22 55 With GB669R: 250

With GB665R: 1 000

With GB669R: 19

With GB665R: 5

3

GB628R DHS/DCS 61 x 22 70 With GB668R: 250

With GB657R: 370

With GB668R: 19

With GB657R: 12

4

XF457R DIN 75 x 25 100 With GB668R: 250

With GB657R: 370

With GB668R: 19

With GB657R: 12

–

15

en

12.3 Operating mode

12.4 Environmental conditions

13. Disposal

Note

The user institution is obliged to process the product before its disposal, see

Validated reprocessing procedure.

►Detailed information concerning the disposal of the product is avail-

able through your national B. Braun/Aesculap agency, see Technical

Service.

Operating mode Operation with non-periodic load and

speed changes (type S9 pursuant to

IEC EN 60034-1)

Right/left rotation:

■60 second application, 60 second

pause

■20 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Milling (clockwise/counterclockwise):

■30 second application, 30 second

pause

■8 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Drilling (oscillation):

■60 second application, 60 second

pause

■4 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Saw mode with GB660R:

■30 second application, 60 second

pause

■3 repetitions

■30 min cooling time

■Max. Temperature 48 °C

Operation Storage and transport

Temperature 10 °C to 27 °C -10 °C to 50 °C

Relative

humidity

30 % to 75 % 10 % to 90 %

Atmospheric

pressure

700 hPa to 1 060 hPa 500 hPa to 1 060 hPa

Adhere to national regulations when disposing of or recy-

cling the product, its components and its packaging!

The recycling pass can be downloaded from the Extranet

as a PDF document under the respective article number.

(The recycling pass includes disassembling instructions for

the product, as well as information for proper disposal of

components harmful to the environment.)

Products carrying this symbol are subject to separate col-

lection of electrical and electronic devices. Within the

European Union, disposal is taken care of by the manufac-

turer as a free-of-charge service.

16

de

Aesculap®Acculan 4

Aufsätze

Legende

1Bohrmaschine

2Drücker (für Drehzahlregulierung)

3Drückersicherung

4Drehhülse

5Pfeil

6Fräsaufsatz mit Schnellspannfutter

7Entriegelungshülse

8Werkzeugaufnahme

9Bohraufsatz mit Schnellspannfutter

10 Bohraufsatz schlüsselloses Dreibackenfutter

11 Verschlusshülse

12 Aufsatz mit Dreibackenfutter

13 Spannschlüssel

14 Zimmer-Spannfutter mit Hudson/Zimmer-Anschluss

15 Entriegelungshülse

16 Adapter AO-groß auf DHS/DCS Stufenbohrer

17 Sagittalsägeaufsatz

18 Werkzeugaufnahme mit L-sagittal-Werkzeugkupplung

19 Knopf zur Werkzeugentriegelung

20 Bohraufsatz für Synthes röntgenstrahldurchlässiges Winkelgetriebe

21 Spickdrahtaufsatz

22 Spannhebel

23 Einstellhülse

24 Spickdrahtfutter

25 Sägeblatt L sagittal

26 Ölspray-Adapter

Die Darstellungen sind nur schematisch.

Symbole an Produkt und Verpackung

Inhaltsverzeichnis

1. Geltungsbereich . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Allgemeine Informationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Zweckbestimmung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Wesentliche Leistungsmerkmale . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Indikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Absolute Kontraindikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Relative Kontraindikationen. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Sichere Handhabung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Gerätebeschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2 Zum Betrieb erforderliche Komponenten . . . . . . . . . . . . . . . . . 18

4.3 Funktionsweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5. Vorbereiten . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6. Arbeiten mit dem Produkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 Bereitstellen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.1 Zubehör anschließen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Sicherung gegen unbeabsichtigtes Betätigen . . . . . . . . . . . . . 19

6.3 Aufsatz an Bohr- und Fräsmaschine kuppeln/entkuppeln. . . . 19

6.4 Werkzeug in Aufsatz kuppeln und entkuppeln. . . . . . . . . . . . . 19

6.4.1 Aufsätze mit Schnellspannfutter GB623R/GB657R/GB663R/

GB664R/GB665R/GB668R/GB669R/GB670R . . . . . . . . . . . . . . 19

6.4.2 Bohraufsatz schlüsselloses Dreibackenfutter GB620R. . . . . . . 19

6.4.3 Aufsätze mit Dreibackenfutter GB621R/GB639R/GB667R . . . 20

6.4.4 Zimmer-Spannfutter mit Hudson/Zimmer-Schaft GB176R. . . 20

6.4.5 Harris-Spannfutter mit AO-groß-Schaft GB184R und DIN-

Spannfutter mit AO-groß-Schaft XF457R . . . . . . . . . . . . . . . . 20

6.4.6 Adapter AO-groß auf DHS/DCS Stufenbohrer GB628R . . . . . . 20

6.4.7 Sagittalsägeaufsatz GB660R . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4.8 Bohraufsatz für Synthes röntgenstrahldurchlässiges

Winkelgetriebe GB645R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4.9 Spickdrahtaufsatz GB641R einsetzen und spannen. . . . . . . . . 20

6.5 Funktionsprüfung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.6 Bedienung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7. Validiertes Aufbereitungsverfahren. . . . . . . . . . . . . . . . . . . . . . 22

7.1 Allgemeine Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . 22

7.2 Allgemeine Hinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.3 Vorbereitung am Gebrauchsort . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4 Vorbereitung vor der Reinigung. . . . . . . . . . . . . . . . . . . . . . . . . 22

7.5 Reinigung/Desinfektion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Vorsicht

Wichtige sicherheitsbezogene Angaben wie Warnhin-

weise und Vorsichtsmaßnahmen in Gebrauchsanwei-

sung beachten.

Maschinenlesbarer zweidimensionaler Code

Der Code enthält eine eindeutige Seriennummer, die

zum elektronischen Einzelinstrumententracking ver-

wendet werden kann. Die Seriennummer basiert auf

dem weltweiten Standard sGTIN (GS1).

Herstelldatum

Chargenbezeichnung des Herstellers

Seriennummer des Herstellers

Bestellnummer des Herstellers

LOT

SN

REF

Temperaturgrenzwerte bei Transport und Lagerung

Luftfeuchtigkeits-Grenzwerte bei Transport und Lage-

rung

Atmosphärendruck-Grenzwerte bei Transport und

Lagerung

17

de

7.5.1 Produktspezifische Sicherheitshinweise zum

Aufbereitungsverfahren. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.6 Manuelle Reinigung mit Wischdesinfektion . . . . . . . . . . . . . . . 23

7.7 Maschinelle Reinigung/Desinfektion mit manueller

Voreinigung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.7.1 Manuelle Vorreinigung mit Bürste . . . . . . . . . . . . . . . . . . . . . . . 24

7.7.2 Maschinelle alkalische Reinigung und thermische Desinfektion 25

7.8 Kontrolle, Wartung und Prüfung . . . . . . . . . . . . . . . . . . . . . . . . 25

7.9 Verpackung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.10 Dampfsterilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.11 Lagerung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8. Instandhaltung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9. Fehler erkennen und beheben. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10. Technischer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11. Zubehör/Ersatzteile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12. Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.1 Klassifizierung gemäß Richtlinie 93/42/EWG . . . . . . . . . . . . . . 27

12.2 Leistungsdaten, Informationen über Normen . . . . . . . . . . . . . . 27

12.3 Nennbetriebsart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

12.4 Umgebungsbedingungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

13. Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1. Geltungsbereich

►Für artikelspezifische Gebrauchsanweisungen und Informationen zur

Materialverträglichkeit siehe auch Aesculap Extranet unter

https://extranet.bbraun.com

2. Allgemeine Informationen

2.1 Zweckbestimmung

Aufgabe/Funktion

Die Bohr- und Fräsmaschinen GA330, GA671 und GA672, kombiniert mit

entsprechendem Aufsatz und Werkzeug, werden zum Bearbeiten von

Hartgewebe, Knorpel, Artverwandtem sowie Knochenersatzmaterialien,

Ein- und Ausdrehen von Knochenpins sowie Setzen von Spickdrähten ver-

wendet.

Anwendungsumgebung

Das Produkt wird in OP-Räumen im sterilen Bereich außerhalb des explo-

sionsgefährdeten Bereichs (z. B. Bereiche mit hochreinem Sauerstoff oder

Anästhesiegasen) eingesetzt.

2.2 Wesentliche Leistungsmerkmale

2.3 Indikationen

Anwendungsart und Anwendungsbereich hängen von dem gewählten

Werkzeug ab.

2.4 Absolute Kontraindikationen

Das Produkt ist nicht zur Anwendung im zentralen Nervensystem bzw.

zentralen Kreislaufsystem zugelassen.

Drehzahl GB667R

GB668R

GB669R

GB670R

0 min-1 bis max. 250 min-1

GB657R 0 min-1 bis max. 370 min-1

GB645R 0 min-1 bis max. 900 min-1

GB620R

GB621R

GB663R

GB664R

GB665R

0 min-1 bis max. 1 000 min-1

GB623R

GB639R

GB641R

0 min-1 bis max. 1 250 min-1

GB660R 0 min-1 bis max. 17 000 min-1

Drehrichtung Rechts- und Linkslauf, Oszilla-

tion

Nennbetriebsart Betrieb mit nicht periodischen

Last- und Drehzahländerungen

(Typ S9 gemäß IEC EN 60034-1)

Rechts-/Linkslauf:

■60 s Anwendung, 60 s Pause

■20 Wiederholungen

■30 min Abkühlzeit

■Max. Temperatur 48 °C

Fräsen (Rechts-/Linkslauf):

■30 s Anwendung, 30 s Pause

■8 Wiederholungen

■30 min Abkühlzeit

■Max. Temperatur 48 °C

Bohren (Oszillation):

■60 s Anwendung, 60 s Pause

■4 Wiederholungen

■30 min Abkühlzeit

■Max. Temperatur 48 °C

Sägebetrieb mit GB660R:

■30 s Anwendung, 60 s Pause

■3 Wiederholungen

■30 min Abkühlzeit

■Max. Temperatur 48 °C

18

de

2.5 Relative Kontraindikationen

Der sichere und effektive Gebrauch des Produktes hängt stark von Einflüs-

sen ab, die nur der Anwender selbst kontrollieren kann. Deshalb stellen die

genannten Angaben nur Rahmenbedingungen dar.

Die klinisch erfolgreiche Verwendung des Produkts ist vom Wissen und der

Erfahrung des Chirurgen abhängig. Er muss entscheiden, welche Struktu-

ren sinnvoll behandelt werden können und dabei die in der Gebrauchsan-

weisung genannten Sicherheits- und Warnhinweise berücksichtigen.

3. Sichere Handhabung

■Allgemeine Risiken eines chirurgischen Eingriffs sind in dieser

Gebrauchsanweisung nicht beschrieben.

■Der Operateur trägt die Verantwortung für die sachgemäße Durchfüh-

rung des operativen Eingriffs.

■Der Operateur muss sowohl theoretisch als auch praktisch die aner-

kannten Operationstechniken beherrschen.

►Fabrikneues Produkt nach Entfernung der Transportverpackung und vor

der ersten Sterilisation reinigen (manuell oder maschinell).

►Vor der Anwendung des Produkts Funktionsfähigkeit und ordnungsge-

mäßen Zustand prüfen.

►Um Schäden durch unsachgemäßen Aufbau oder Betrieb zu vermeiden

und die Gewährleistung und Haftung nicht zu gefährden:

– Produkt nur gemäß dieser Gebrauchsanweisung verwenden.

– Sicherheitsinformationen und Instandhaltungshinweise einhalten.

– Nur Aesculap-Produkte miteinander kombinieren.

►Produkt und Zubehör nur von Personen betreiben und anwenden las-

sen, die die erforderliche Ausbildung, Kenntnis oder Erfahrung haben.

►Gebrauchsanweisung für den Anwender zugänglich aufbewahren.

►Gültige Normen einhalten.

►Sicherstellen, dass die elektrische Installation des Raums den Anforde-

rungen nach IEC/DIN EN entspricht.

►Produkt nicht in explosionsgefährdeten Bereichen einsetzen.

►Produkt vor dem Einsatz steril aufbereiten.

►Bei Handhabung der Aesculap-Halterungssysteme relevante

Gebrauchsanweisung TA009721 einhalten, siehe Aesculap Extranet

unter https://extranet.bbraun.com

4. Gerätebeschreibung

4.1 Lieferumfang

4.2 Zum Betrieb erforderliche Komponenten

■Bohr- und Fräsmaschine GA330 (betriebsbereit)

– oder –

■Acculan 3Ti Bohr- und Fräsmaschine GA672 (betriebsbereit)

– oder –

■Acculan 3Ti Kleine Bohrmaschine GA671 (betriebsbereit)

■Werkzeug (je nach Indikation)

4.3 Funktionsweise

Der Aufsatz kann in drei verschiedenen Stellungen, um je 120° versetzt,

mit der Bohr- und Fräsmaschine gekuppelt werden.

Der Aufsatz verriegelt beim Aufstecken auf die Bohr- und Fräsmaschine

selbstständig. Durch Betätigen einer Drehhülse an der Bohr- und Fräsma-

schine kann der Aufsatz wieder gelöst werden.

Die Aufsätze haben am Arbeitsende verschiedene integrierte Kupplungen,

um entsprechende Werkzeuge, Spickdrähte oder Adapter aufnehmen zu

können.

5. Vorbereiten

Wenn die folgenden Vorschriften nicht beachtet werden, übernimmt

Aesculap insoweit keinerlei Verantwortung:

►Kein Produkt aus offenen oder beschädigten Sterilverpackungen ver-

wenden.

►Vor der Verwendung Produkt und dessen Zubehör auf sichtbare Schä-

den prüfen.

►Nur technisch einwandfreie Produkte und Zubehörteile verwenden.

WARNUNG

Verletzungsgefahr und Sachschaden bei Benutzung

des Produkts entgegen seinem Verwendungszweck!

►Produkt nur gemäß Verwendungszweck verwen-

den.

WARNUNG

Verletzungsgefahr und Sachschäden durch falsche

Handhabung des Produkts!

►Gebrauchsanweisungen aller verwendeten Pro-

dukte einhalten.

Art.-Nr. Bezeichnung

GB176R

GB184R

GB620R

GB621R

GB623R

GB628R

GB639R

GB641R

GB645R

GB657R

GB660R

GB663R

GB664R

GB665R

GB667R

GB668R

GB669R

GB670R

XF457R

Einer der folgenden Aufsätze/Adapter:

Zimmer-Spannfutter mit Hudson/Zimmer-Schaft

Harris-Spannfutter mit AO-groß-Schaft

Bohraufsatz schlüsselloses Dreibackenfutter

Bohraufsatz großes Dreibackenfutter

Bohraufsatz AO-klein

Adapter AO-groß auf DHS/DCS Stufenbohrer

Bohraufsatz kleines Dreibackenfutter

Spickdrahtaufsatz

Bohraufsatz für Synthes röntgenstrahldurchlässiges

Winkelgetriebe

Markraumbohraufsatz AO-groß

Sagittalsägeaufsatz

Bohraufsatz Trinkle

Bohraufsatz Aesculap Sechskant

Bohraufsatz Hudson/Zimmer

Fräsaufsatz großes Dreibackenfutter

Fräsaufsatz AO-groß

Fräsaufsatz Hudson/Zimmer

Fräsaufsatz Harris

DIN-Spannfutter mit AO-groß-Schaft

GA031R Spannschlüssel für großes Dreibackenfutter (GB620R,

GB621R und GB667R)

GA062R Spannschlüssel für kleines Dreibackenfutter (GB639)

TA014541 Gebrauchsanweisung für Acculan 4 Aufsätze (Falt-

blatt)

This manual suits for next models

18

Table of contents

Languages:

Other Aesculap Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual