3

Table of contents

1General safety information .............................................................................................. 4

Safe operation ......................................................................................................................... 4

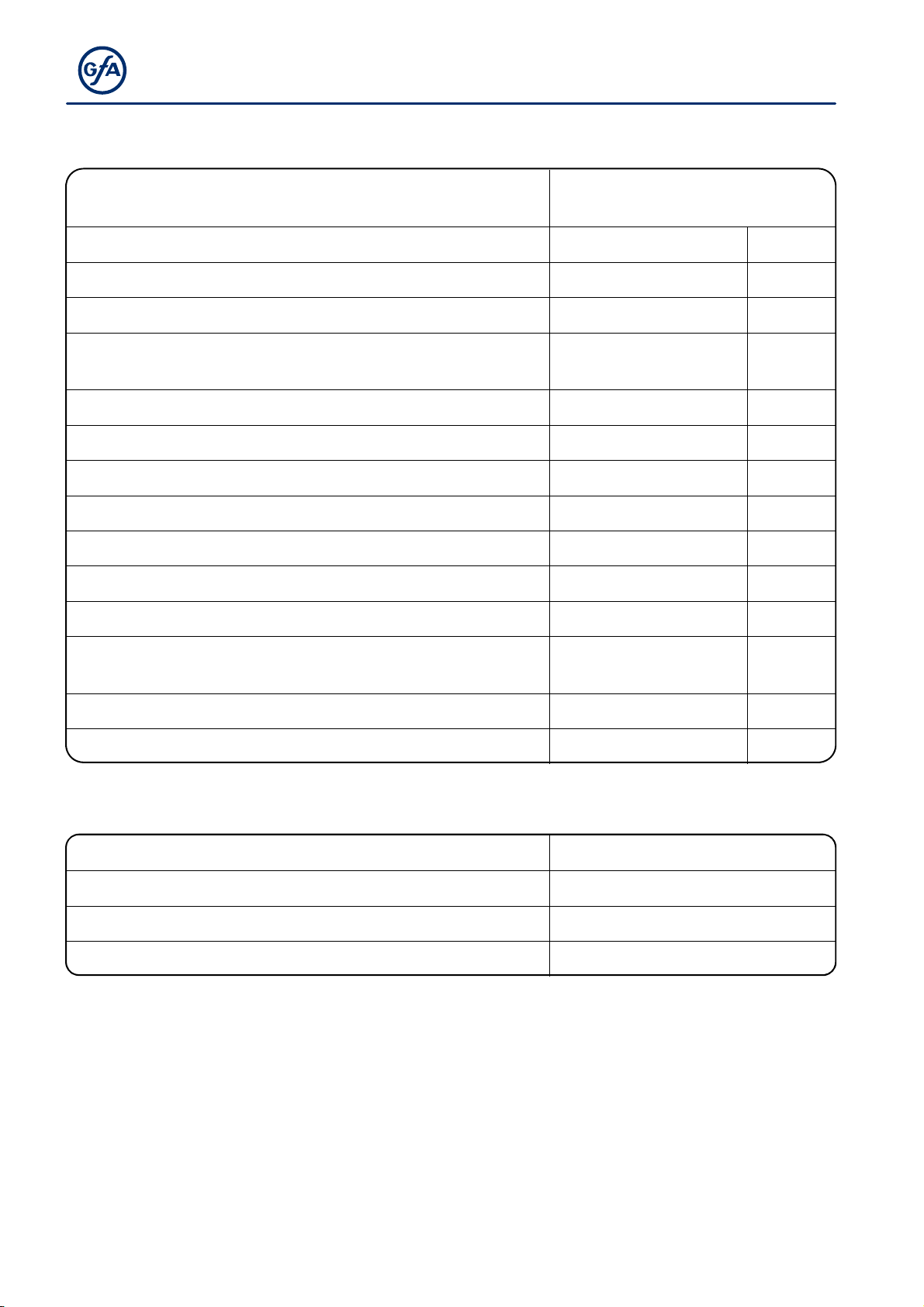

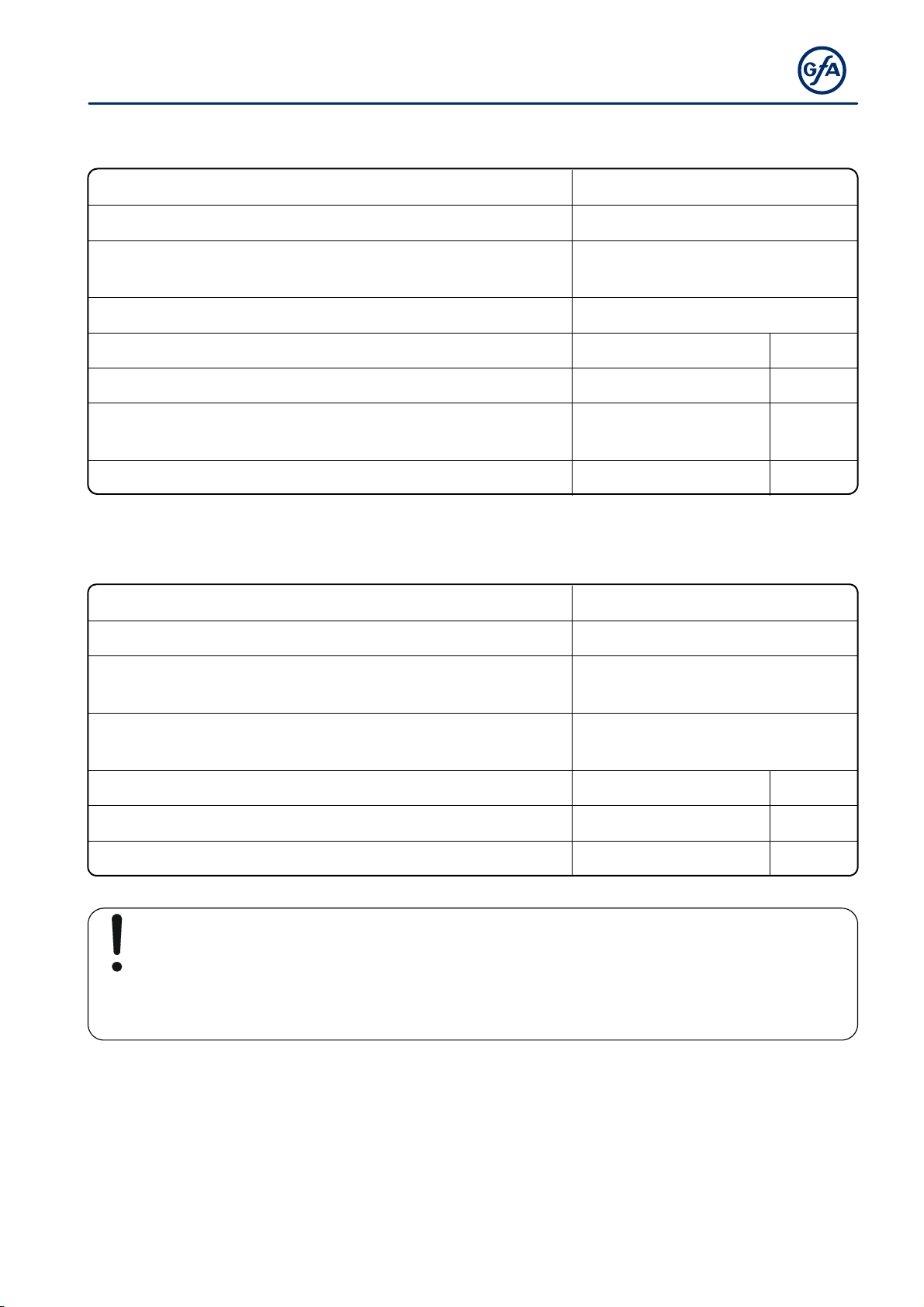

2Technical data of the drive unit ....................................................................................... 6

3Technical data of the gearbox ......................................................................................... 7

4Technical data of the motor ............................................................................................. 8

5Technical data of the terminal box ................................................................................... 9

6Technical data of limit switch / emergency manual operation switch ............................... 9

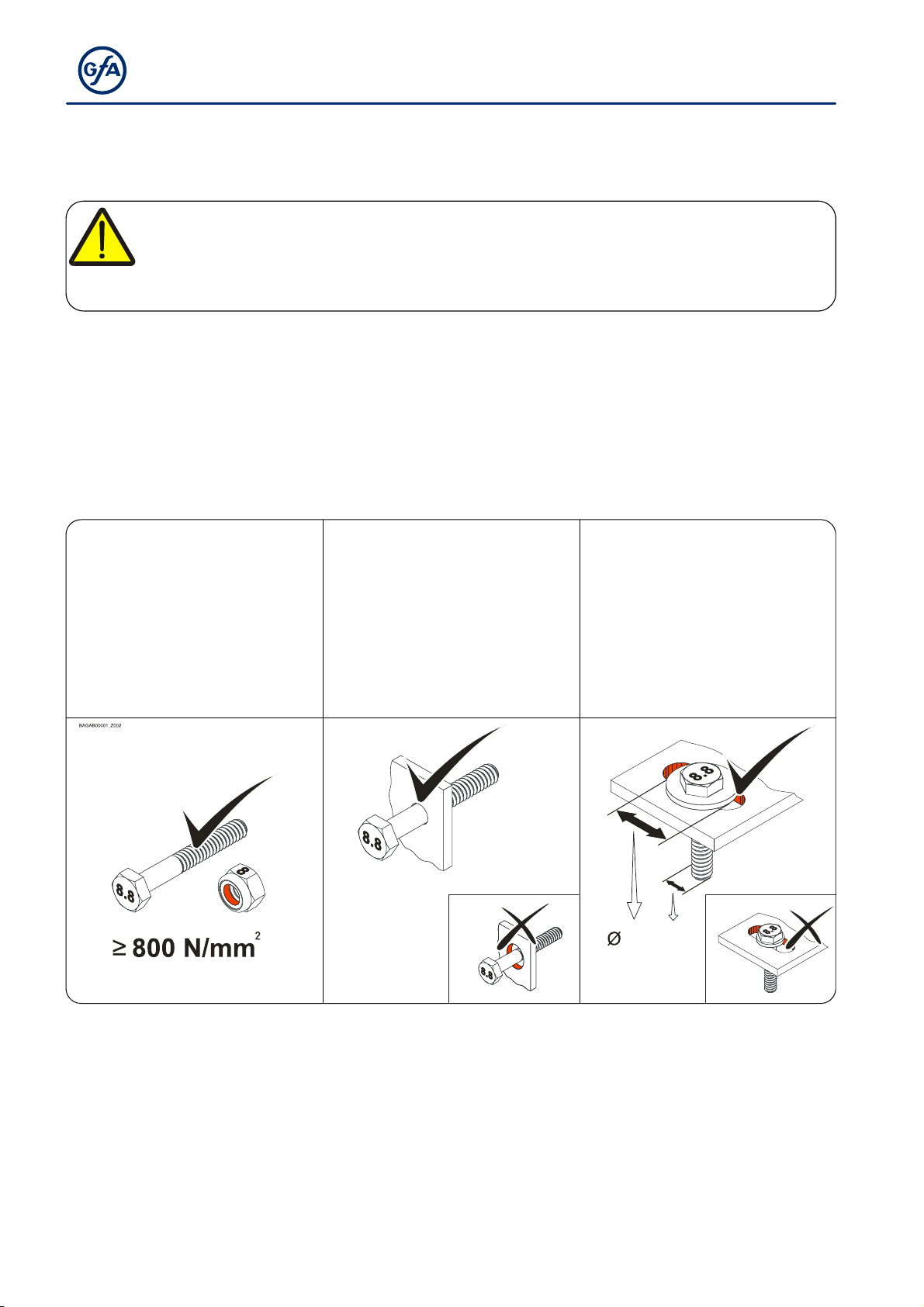

7Mechanical installation .................................................................................................. 10

8Electrical installation ..................................................................................................... 15

9Limit switch setting ........................................................................................................ 18

10Motor connection .......................................................................................................... 20

11Limit switch connection ................................................................................................. 20

12Emergency manual operation (emergency hand crank) ................................................ 21

13Completion of initial operation / inspection / operation ................................................... 23

14Declaration of conformity, Motor .................................................................................... 28

15Declaration of conformity, Accessories .......................................................................... 29

16Declaration of incorporation / Declaration of conformity ................................................. 31

Symbols

Warning - Potential injury or danger to life!

Warning - Danger to life from electric current!

Note - Important information!

▶ Requirement - Required action!

Schematic representations are based on product examples. Deviations from delivered

products are possible.