GGM gastro GFK481-16 User manual

Gas Style Fryer

Instruction Manual

GFK481-16 GFK591-40

Model

Description

Dimensions LWH(mm)

Power (KW)

GFK481-16

American Style 3 Tubes

Fryer

405*770*1160mm

9KW*3

Robertshaw Gas Valve Made in USA

Material 439 1.5 Oil Tank

Two Red Handle Baskets

Adjustable Stainless Steel Feet

Oil Capacity: 20 Liters=45LBS

Power: 90,000 BTU, 9KW*3=36KW (9KW for each burner)

Model

Description

Dimensions LWH(mm)

Power (KW)

GFK591-40

American Style 5 Tubes

Fryer

545* 770*1160mm

9KW*5

Robertshaw Gas Valve Made in USA

Material 439 1.5 Oil Tank

Two Red Handle Baskets

Adjustable Stainless Steel Feet

Oil Capacity: 30 Liters=65LBS

Power: 150,000 BTU, 9KW*5=45KW (9KW for each burner)

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

GAS EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UPAND

IMPORTANT

IN THE EVENTA GAS ORDOR IS DETECTED, SHUT DOWN UNITS AT THE MAIN

SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER

FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

This fryer was carefully inspected before leaving the factory. Upon acceptance of the

shipment, the transportation company assumes full responsibility for safe delivery.

Immediately after unpacking the fryer, check for possible shipping damage. If the fryer is

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Check that the following have been included:

Crumb Rack

Basket Hanger

Adjustable Legs (4)

Drain Pipe Extension

Twin Fry Baskets (2)

Manual and Warranty –Retain for future reference.

Do not use the door or its handle to lift the fryer.

INSTALLATION

Before installing the fryer, verify that the type of gas (natural or propane) agrees with the

specifications on the fryer data plate, which is located on the inside of the door panel. Make

sure the fryer is configured for the proper elevation.

Clearances

Minimum clearance from combustible construction:

6” (15 cm) from the sides of the fryer

6” (15 cm) from the back of the fryer

The fryer may be installed on combustible floors

Minimum clearance from noncombustible construction:

0” from the sides of the fryer

0” from the back of the fryer

Between the fryer and any open-top flame units:

16” (41 cm)

Allow space for servicing and operation.

Location

Install fryer in an area with sufficient air supply for gas combustion at fryer burners.

Do not obstruct the flow of combustion and ventilation air.

Provide adequate clearance for air openings into the combustion chamber.

Do not permit fans to blow directly onto fryer.

Avoid wall-type fans, which create cross-currents within a room. Avoid

open windows next to sides or back.

Electrical diagram located on inside of door.

CODES AND STANDARDS

The fryer must be installed in accordance with:

ASSEMBLY

The fryer must be restrained to prevent tipping and the splashing of hot liquid. The means

of restraint may be the manner of installation, such as connection to a battery of appliances,

installing the fryer in an alcove, or by separate means such as adequate ties.

FLUE EXHAUST

Comply with Vapor Removal from Cooking Equipment, ANSI-NFPA

Standard #96 (latest edition), available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

Locate the fryer under a hood with adequate connection to an exhaust

duct. The hood must extend 6” (15 cm) beyond fryer on both sides.

Clearance above the fryer should be adequate for combustion byproducts

to be removed efficiently.

An 18” (46 cm) minimum clearance should be maintained between the flue

vent and the filters of the hood venting system.

Never make flue connections directly to the fryer.

Do not obstruct the flow of the gases from the appliance. Proper air balance should

be maintained in the room.

Ensure that your ventilation system does not cause a down draft at the fryer’s flue

opening. Down draft will not allow the fryer to exhaust properly and will cause

overheating which may cause permanent damage. Damage caused by down

draft will not be covered under equipment warranty. Never allow anything to

obstruct the flue or ventilation exiting from the fryer flue. Do not put anything on

top of flue area.

TESTING THE GAS SUPPLY PIPING SYSTEM:

When test pressures exceed ½ PSI (3.45 kPa), the fryer and its individual shutoff valve must

be disconnected from the gas supply piping system.

When test pressures are ½ PSI (3.45 kPa) or less, the fryer must be isolated from the gas

supply piping system by closing its individual shutoff valve.

Fryers with Casters: (Restraining device does not come supplied with fryer or casters).

Separate instructions for installing casters are included with the casters:

disconnect device that complies with the Standard for Quick-Disconnect Devices

for Use with Gas Fuel, ANSI z21.41 or Quick-Disconnect Devices for Use with

Gas Fuel, CANI-6.9.

If an overheating situation persists, contact your local Vulcan-Hart authorized service office.

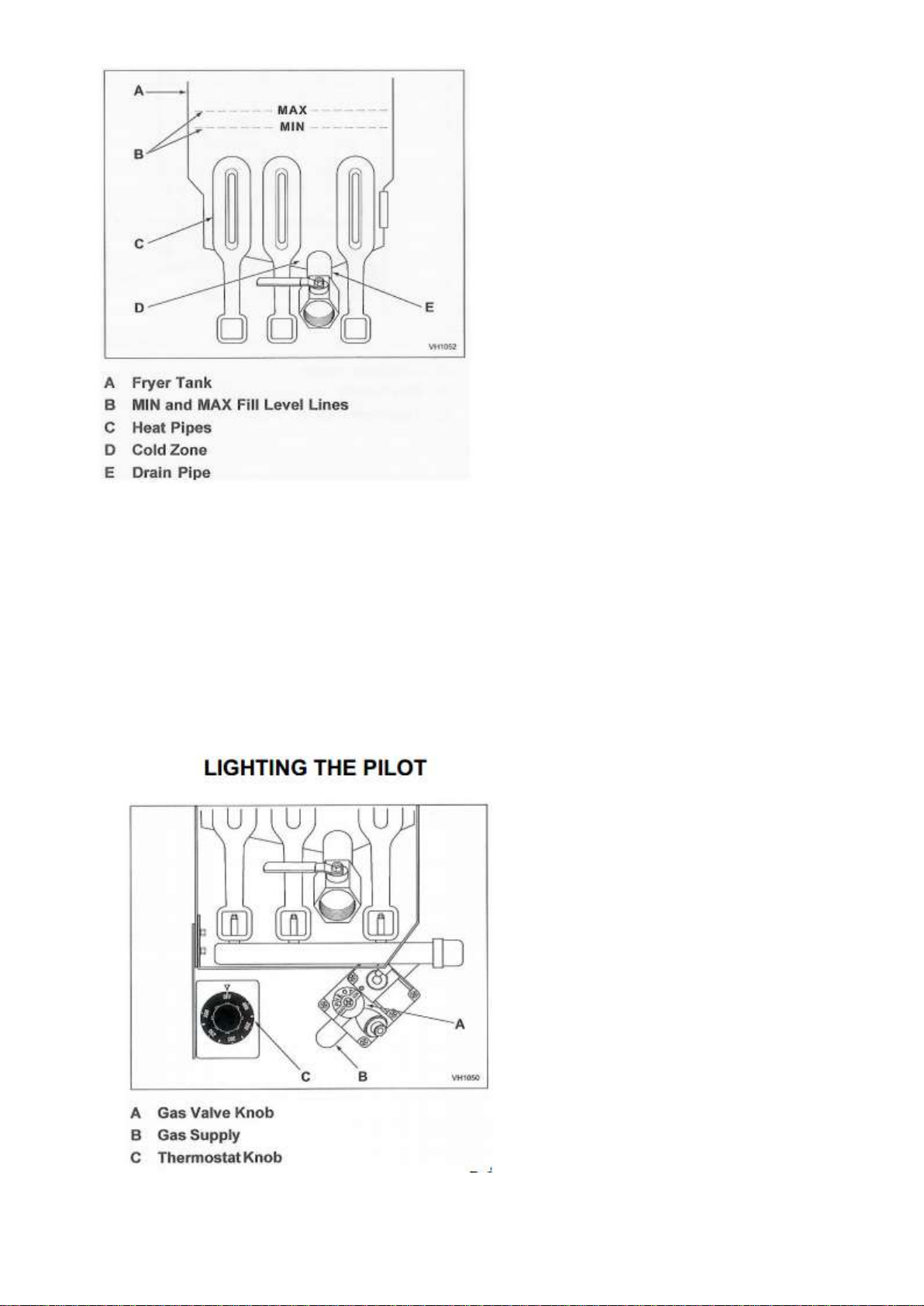

FILLING TANK WITH SHORTENING

Solid shortening should NOT be used with LG300 or LG400 fryers. Melting solid

shortening will damage the tank and void your warranty.

Close the drain valve.

Fill the fryer tank with liquid shortening.

Shortening level should be between the min and max lines in the fryer tank.

Shortening will expand when heated. Do not ill the fryer tank past the MAX line.

Add fresh shortening as needed to maintain oil level.

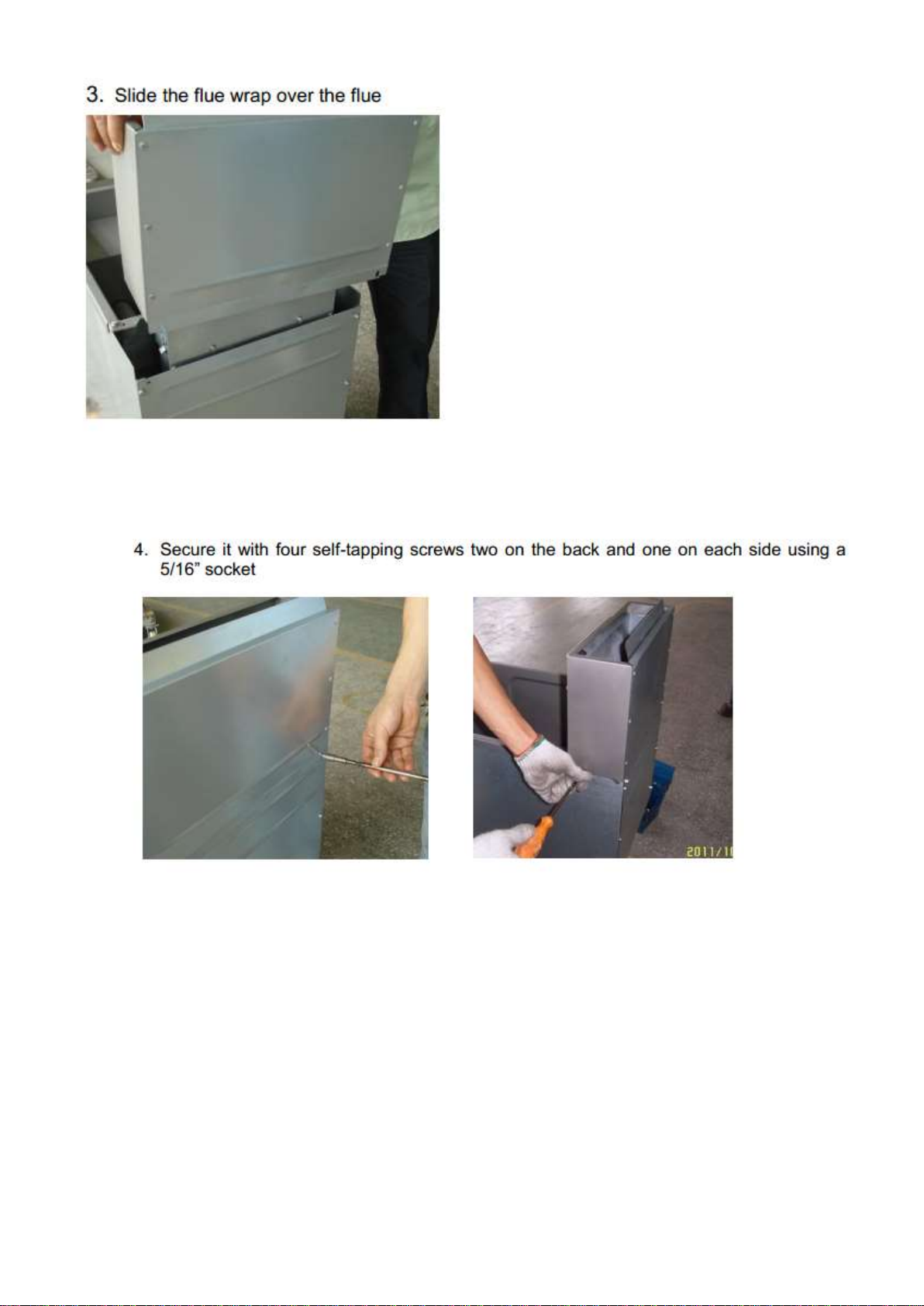

1. Open the door.

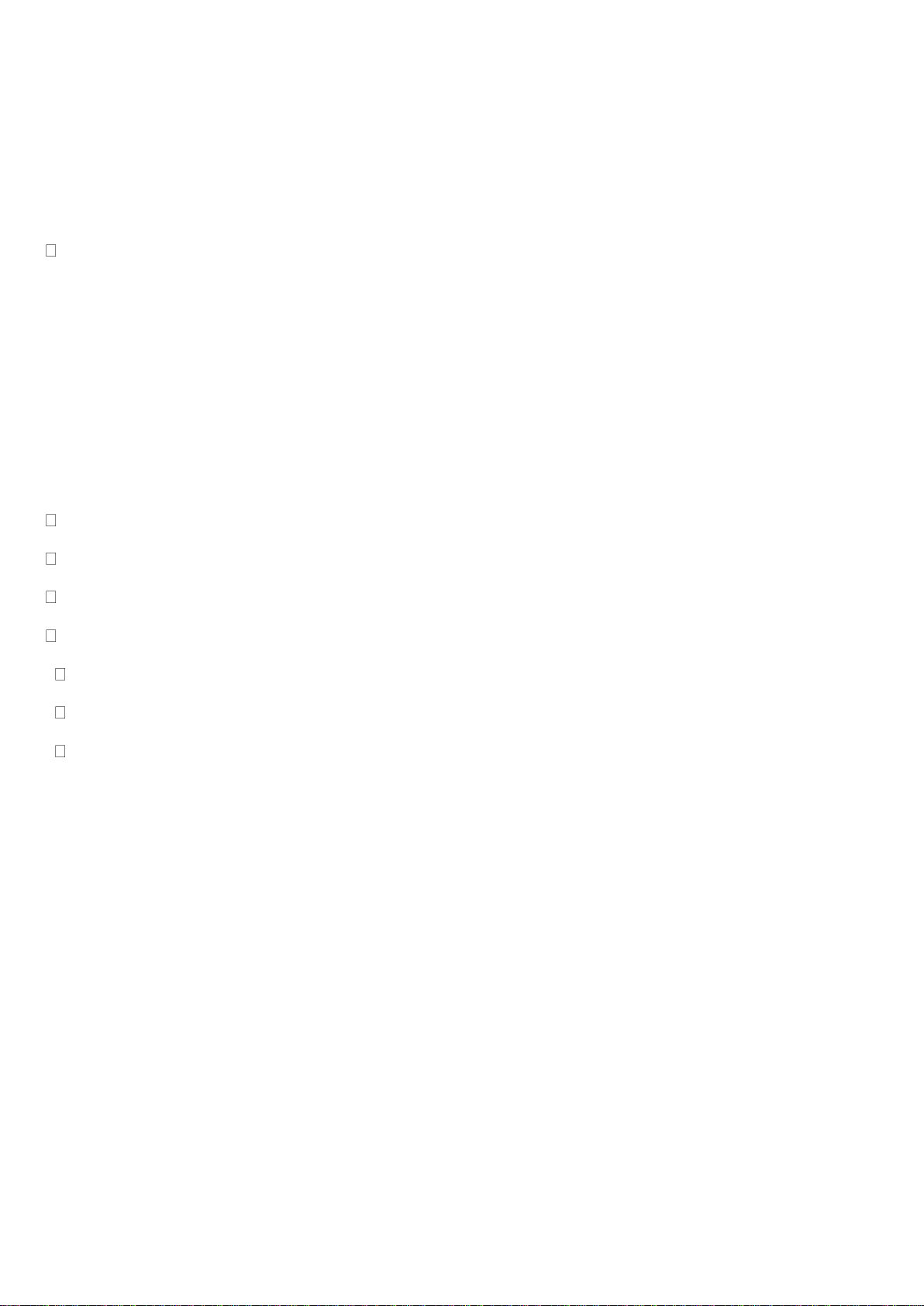

2. Turn the thermostat OFF (see figure below, view A). The thermostat is located

behind the door.

3. Push the gas control valve knob and turn to OFF. Wait 5 minutes for unburned gas

to vent.

4. Push and turn gas control valve knob to the “L” in PILOT (see figure below, view B).

5. While still holding the knob in, light the pilot with a lit flame. Continue to depress the

knob until pilot remains lit when knob is released. If the pilot does not remain lit,

repeat step 3 through 5.

6. Depress and turn gas control knob to ON (See figure below, view C).

7. If gas supply is interrupted, repeat steps 2 through 6.

TURNING ON THE FRYER

Set the temperature knob to desired temperature.

After the set temperature has been reached, the thermostat shuts off the

gas flow to burners.

The pilot remains lit. The burners will cycle on and off, maintaining the set

temperature.

TURNING OFF THE FRYER

1. Turn the thermostat OFF.

2. To keep the pilot lit, turn the gas valve to “L” in Pilot.

3. To shut off all gas to the system, including the pilot, turn the gas valve

knob to OFF.

EXTENDED SHUTDOWN

1. Turn the thermostat knob to OFF.

2. Push in the pilot knob and turn to OFF.

3. Thoroughly drain the fryer. Refer to DRAINING THE FRYER.

4. Clean the fryer according to CLEANING.

5. Turn off the main gas shutoff valve.

When frying is completed, remove basket or product. Hang basket on rear

hanger.

Fry Basket Capacity:

Basket for 3 and 4 tubes fryer: Recommended pounds per basket are 1.5 lbs. (0.7 kg).

Basket for 5 tubes fryer: Recommended pounds per basket are 3.0 lbs. (1.4 kg).

EXTENDING SHORTENING LIFE

Shortening life can be extended by the following guidelines:

Do not salt foods over the fryer.

Use good-quality shortening.

Filter shortening daily (at a minimum).

Replace shortening if it becomes poorly flavored.

Keep equipment and surrounding clean.

Set thermostat correctly.

Remove excess moisture and particles from food products before placing on fryer.

DRAINING THE TANK

1. Turn the thermostat to OFF.

2. To keep the pilot lit, turn the gas valve to PILOT.

3. Direct the drain spout into the container that you want to drain the shortening into.

4. Open the drain valve. The oil will drain into the container. When the container is full

or the fryer tank is empty, close the drain valve. Repeat this step until the fryer is

empty.

5. If desired, perform the weekly clean-out as described under CLEANING.

6. Once tank is completely empty, add new shortening and set thermostat to desired

temperature.

MAINTENANCE

Hot oil and hot parts can cause burns. Use care when operating,

cleaning, and servicing the fryer.

Spilling hot fryer compound can cause severe burns. Do not

move fryer without draining all frying compound from the tank.

This manual suits for next models

1

Table of contents

Other GGM gastro Fryer manuals

Popular Fryer manuals by other brands

Kogan

Kogan SMARTERHOME KASM12DGFYA user guide

Taurus

Taurus AF1001 manual

Dean

Dean Super Runner Series Service & parts manual

Maxi-matic

Maxi-matic Elite Bistro EUC-1031DB instruction manual

PERFECT FRY COMPANY

PERFECT FRY COMPANY PFC Series Installation-Inspection-Maintenance

Ninja

Ninja FOODI SP100 Series owner's guide

ElectrIQ

ElectrIQ HOV17D user manual

DS Produkte

DS Produkte XJ-2K960S instruction manual

Morphy Richards

Morphy Richards MRAF72BK instruction manual

Wells

Wells WFGA-60FS Operation manual

DeLonghi

DeLonghi RAPID CRISP FH2133 Get started

Lang

Lang CLF-15-E Installation, operation, maintenance, & troubleshooting