7 PFC SERIES INSTALLATION, OPERATION, MAINTENANCE

INSTALLATION

ELECTRICAL POWER SUPPLY (NORTH AMERICAN MODELS)

• Your PERFECT FRY PFC must be connected to a dedicated electrical circuit that meets your fryer’s requirements

(see table below).

CAUTION

Improper installation may damage the fryer and void your warranty.

• All electrical connections to comply with local and national standards and codes.

• If your fryer’s plug does not t your wall outlet receptacle, have an electrician install the appropriate NEMA receptacle

within 4 feet of the fryer.

• See the manufacturer’s label on your fryer for the electrical Model No. PFCXXX, then check o your Model Number.

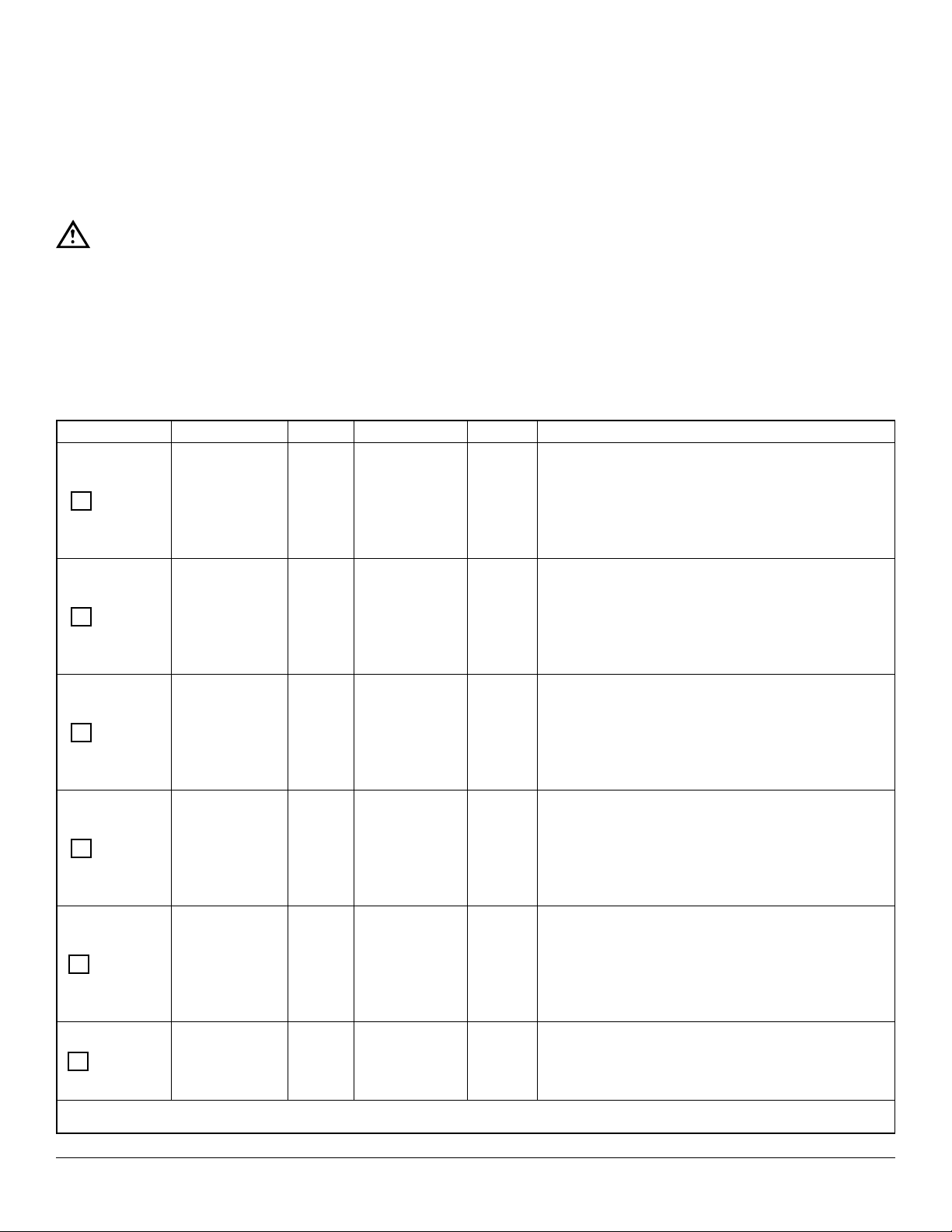

PFC Model Voltage Amps Circuit Amps Watts Power Supply

PFC 570 240 24 25 5700

For Use on an individual branch circuit rated 25A

minimum. For supply connectors, use minimum

no. 10 AWG wire (30A rated). This Fryer must be

properly Connected to a grounded dededicated

240 VAC single phase circuit according to local

installation standards and codes

PFC 570 208 27 30 5700

For Use on an individual branch circuit rated 30A

minimum. For supply connectors, use minimum

no. 8 AWG wire (40A rated). This Fryer must be

properly Connected to a grounded dededicated

208 VAC single phase circuit according to local

installation standards and codes

PFC 375 240 16 20 3750

For Use on an individual branch circuit rated 20A

minimum. For supply connectors, use minimum

no. 12 AWG wire (25A rated). This Fryer must be

properly Connected to a grounded dededicated

240 VAC single phase circuit according to local

installation standards and codes

PFC 300 240 12.5 20 3000

For Use on an individual branch circuit rated 20A

minimum. For supply connectors, use minimum

no. 12 AWG wire (20A rated). This Fryer must be

properly Connected to a grounded dededicated

240 VAC single phase circuit according to local

installation standards and codes

PFC 187 120 16 20 1875

For Use on an individual branch circuit rated 20A

minimum. For supply connectors, use minimum

no. 12 AWG wire (12A rated). This Fryer must be

properly Connected to a grounded dededicated

120 VAC single phase circuit according to local

installation standards and codes

PFC 570* 400/230/3Ø

Wye (4 wire) 9 15 5700

This Fryer must be properly connected to a

grounded dededicated 400 VAC three phase

circuit according to local installation standards and

codes

International only, not available in US or Canada.