2

Contents

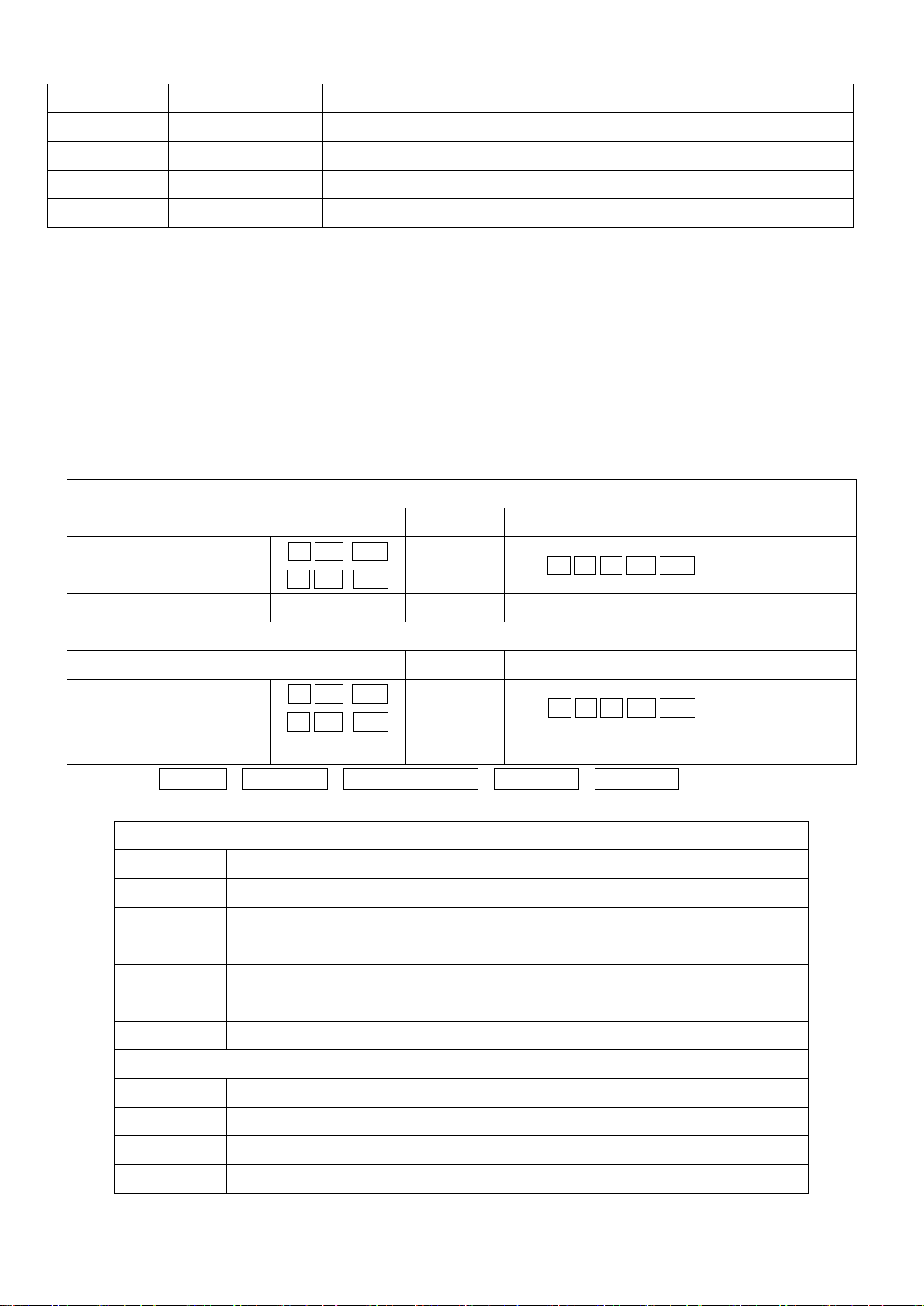

Manual Revision History...................................................................................................................................1

Revision History ................................................................................................................................................1

1. Introduction....................................................................................................................................................4

1.1. About This Manual .............................................................................................................................4

1.2. Glossary..............................................................................................................................................4

1.3. Definitions...........................................................................................................................................5

1.4. Product Application ............................................................................................................................5

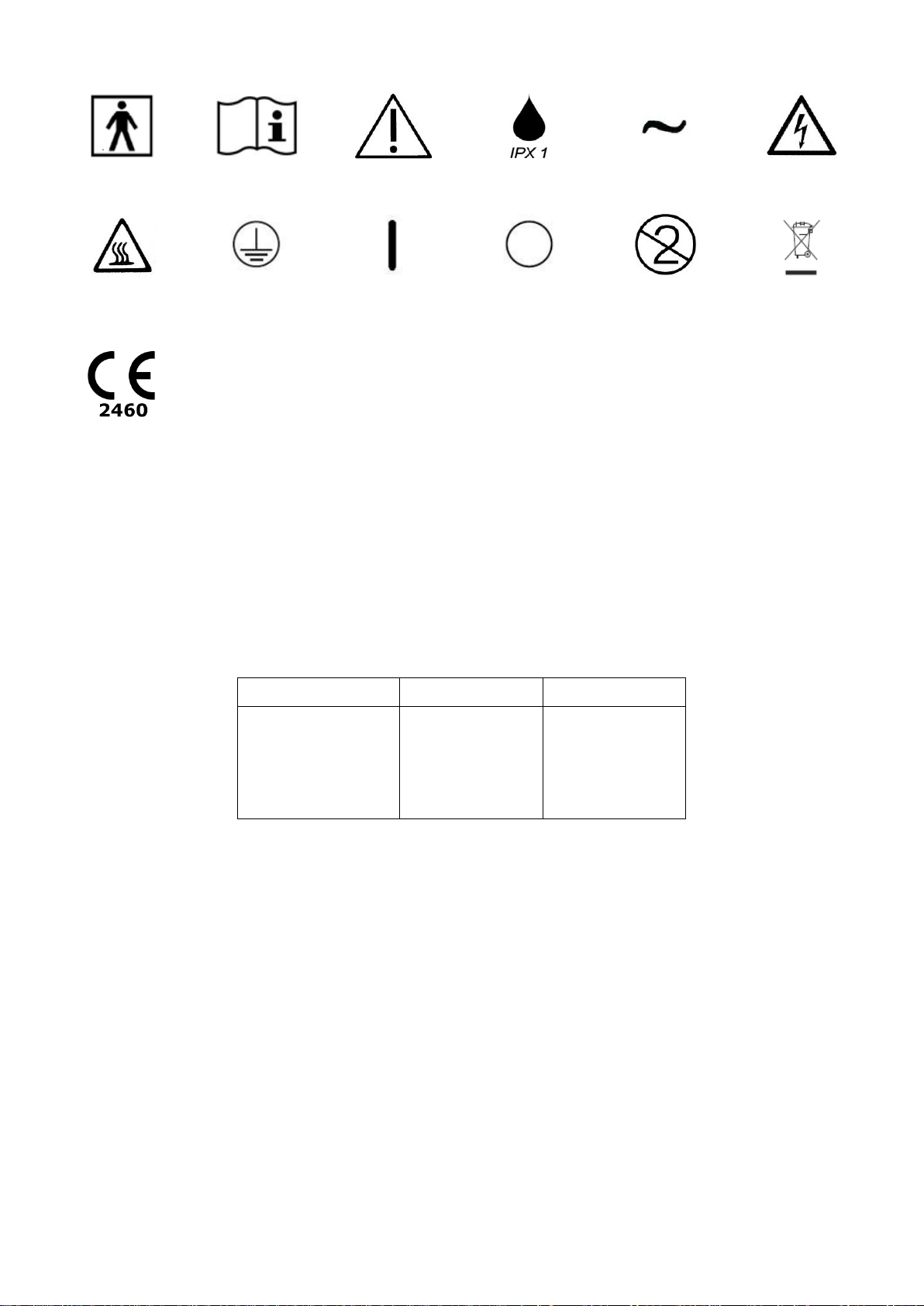

1.5. Humidifier Symbol definition.............................................................................................................6

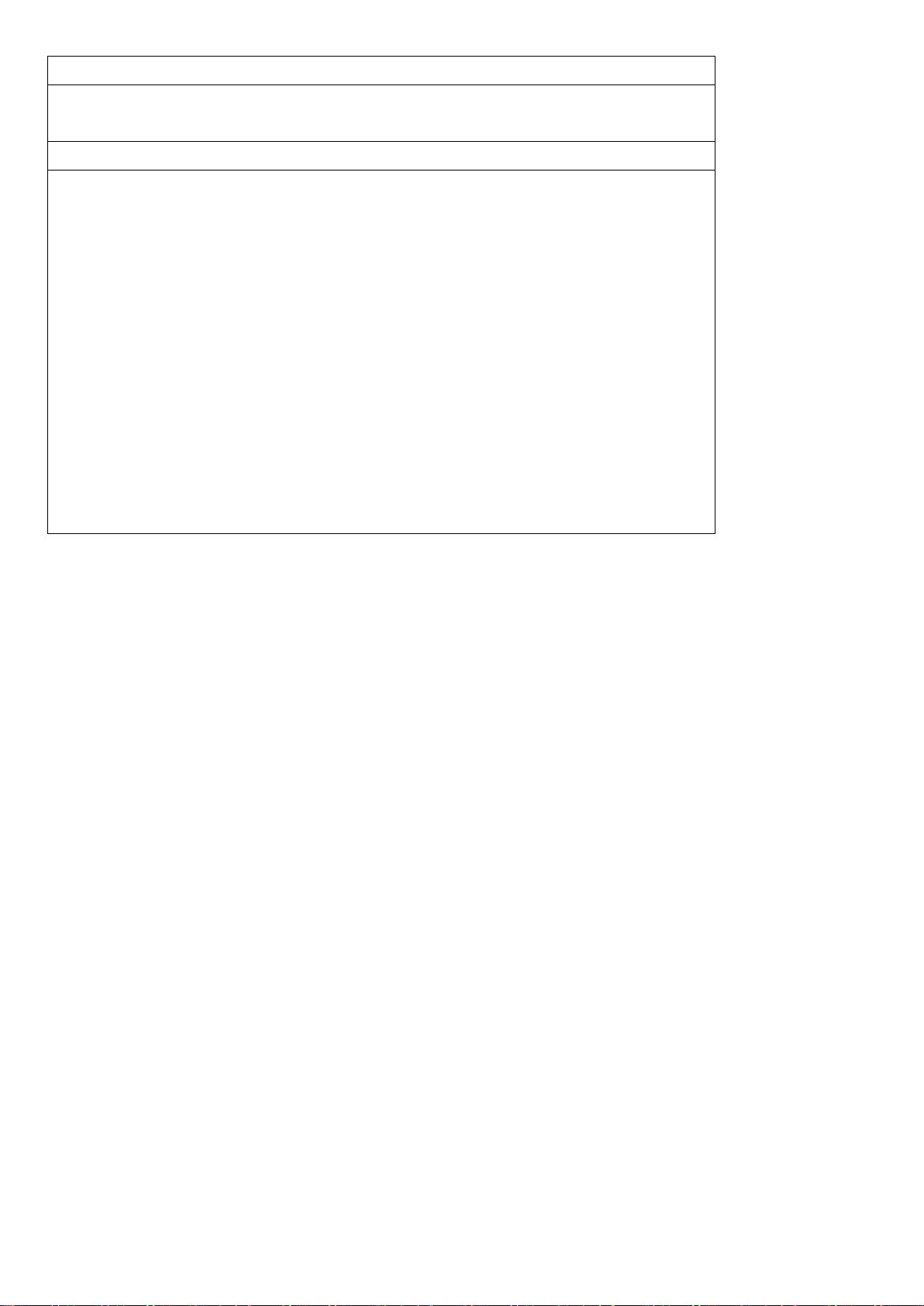

2. Product Specifications ...................................................................................................................................6

2.1. Mechanical..........................................................................................................................................6

2.2. Electrical Rating..................................................................................................................................6

2.3. Temperature Control Range:...............................................................................................................6

2.3.1. Temperature .............................................................................................................................6

2.3.2. Alarm Parameters:....................................................................................................................7

2.4. Performance........................................................................................................................................7

2.5. Operating, Transport and Storage Environment.................................................................................8

2.6. Standards Compliance ........................................................................................................................8

3. Explanation of Controls and Indicators .........................................................................................................8

3.1. Humidifier Operation..........................................................................................................................8

3.2. Power on Self-check...........................................................................................................................8

3.3. Front Panel..........................................................................................................................................9

3.4. Display..............................................................................................................................................11

3.5. Flow Chart ........................................................................................................................................12

3.5.1. Flow Chart for VH-2600........................................................................................................12

3.5.2. Flow Chart for VH-2600A.....................................................................................................13

4. Maintenance Schedule.................................................................................................................................13

4.1. Maintenance Schedule......................................................................................................................13

4.1.1. Humidifier..............................................................................................................................13

4.1.2. Temperature Probe.................................................................................................................14

4.1.3. Heater Wire Adapter ..............................................................................................................14

4.1.4. Mains Plug.............................................................................................................................14

4.1.5. Safety .....................................................................................................................................15

4.1.6. Breathing Circuit....................................................................................................................15

5. Alarm and Troubleshooting..........................................................................................................................15

5.1. Alarm Indicator.................................................................................................................................15

5.2. Troubleshooting ................................................................................................................................17

5.2.1. Low Temperature...................................................................................................................17

5.2.2. High Temperature ..................................................................................................................17

5.2.3. Temperature Fluctuating........................................................................................................17

5.2.4. Excessive Water in Circuit.....................................................................................................18