H69.0.01.6C-02 Operating Manual GMH 285 / GMH 285-BNC page 5 of 8

_____________________________________________________ _____________________________________________________________________________

6 Some Basics Of Pt 1000 Precision Temperature Measurement

Probe Precision/Device Precision

The device is very precise (please refer to technical data). To be able to use this high precision, the

connected temperature probe has to be as precise as possible, too. The following precision classes

are available as a standard at reasonable prices (Platinum resistor thermometers according to

EN60751):

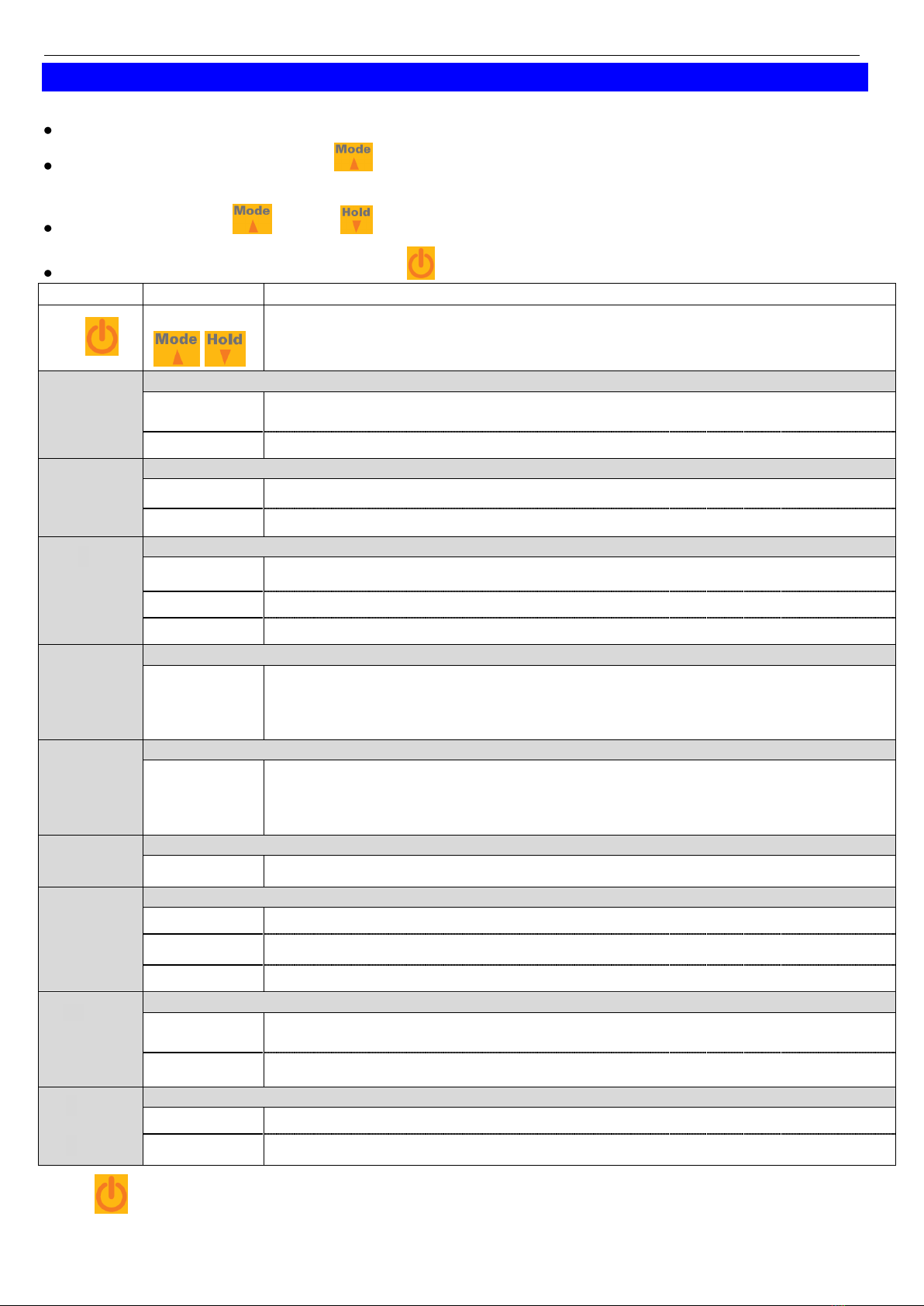

Class Error ranges

B ± (0,3 + 0,005 • | Temperature |)

A ± (0,15 + 0,002 • | Temperature |)

AA (=1/3 DIN B) ± (0,1 + 0,0017 • | Temperature |)

Error over range –50...150°C

For applications demanding higher precision than given by this classes we suggest to adjust the

device to the used probe or to get a calibration certificate for the device combined with the probe.

Attention: if an adjusted or calibrated probe is replaced, also the adjustment or calibration certificate has to

be renewed to maintain the referring overall precision! Be careful when buying third party

temperature probes: Besides the standard EN60751 there are some other obsolete or unusual

standards on the market. If such a probe has to be connected, the user sensor curve (have a

look to the referring chapter) can be used to adjust the instrument!

2-Wire-Measurement

The GMH 285 uses 2 wire measurement, this means, cable and contact resistances may affect measurement precision.

For usual cables up to some meters the cable resistance is negligible. Keep contact clean and free from oxidation to

avoid contact effects.

Allowable temperature Range Of Probes

Pt100 Sensors are defined over a wide temperature range. Depending on probe materials and sort of sensor (e.g.

hybrid sensors, wire wound resistors...) the allowable temperature ranges have to be considered. Exceeding the ranges

at least causes a wrong measurement, it may even damage the probe permanently!

Often it also has to be considered, that the temperature range is just valid for the probe tube, (plastic-) handles can’t

stand the same high temperatures. Therefore the tube length should be selected long enough, that temperature keeps

low at the handle.

Self Heating

The measurement current of the instrument is just 0.3mA. Because of this comparably low current practically now self

heating effect has to be considered, even at air with low movement the self heating is <= 0.01°C.

Cooling by Evaporation

When measuring air temperature the probe has to be dry. Otherwise the cooling due to the evaporation causes too low

measurement.

Heat loss caused by probe construction:

Especially when measuring temperatures which deviate very much from the ambient temperature, measurement errors

often occur if the heat loss caused by the probe is not considered. When measuring fluids therefore the probe should be

emerged sufficiently deep and be stirred continuously. When measuring gases the probe should also emerge as deep

as possible in the gas to be measured (e.g. when measuring in channel/pipes) and the gas should flow around the

probe at sufficient flow.

Measuring Surface Temperature

If temperature of the surface of an object has to be measured, one should pay attention especially when measuring hot

(or very cold) surfaces, that the ambient air cools (or heats) the surface. Additionally the object will be cooled (or

heated) by the probe or the probe can have a better heat flow to the ambient temperature as to the objects surface.

Therefore specially designed surface probes should be used. The measurement precision depends mainly on he

construction of the probe and of the physics of the surface itself. If selecting a probe try to choose one with low mass

and heat flow from sensor to handle. Thermally conductive paste can increase the precision in some cases.

0

0,2

0,4

0,6

0,8

1

1,2

-50 -30 -10 10 30 50 70 90 110 130 150

Fehler Gerät und Temperaturfühler