Giant BP100 User manual

Other Giant Water Pump manuals

Giant

Giant P470 User manual

Giant

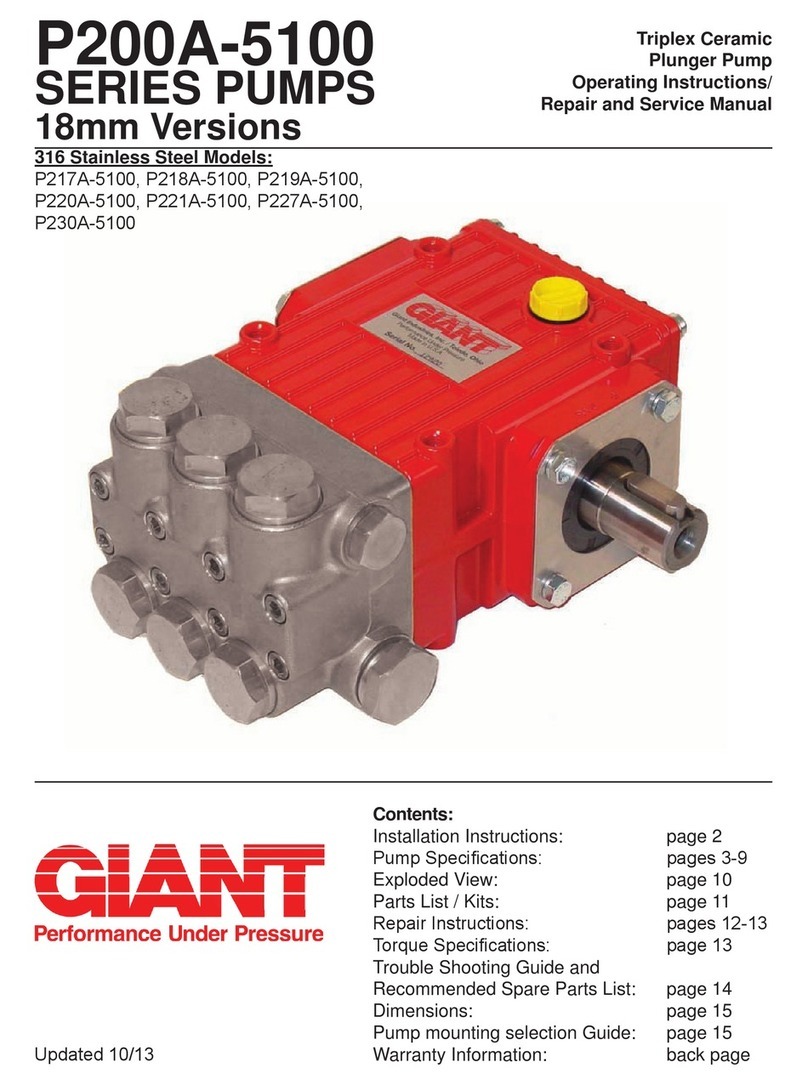

Giant P200A-5100 Series Repair and User manual

Giant

Giant P205 Repair and User manual

Giant

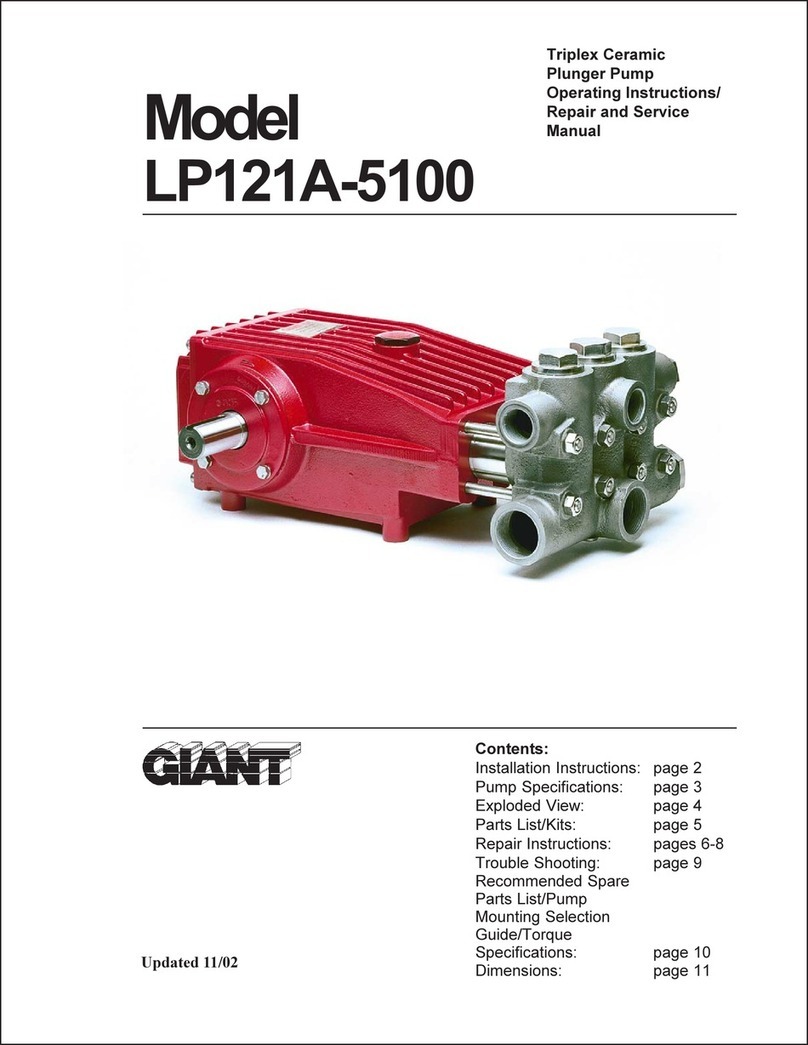

Giant LP121A-5100 User manual

Giant

Giant GP7636GB-2.0 User manual

Giant

Giant GP7150A User manual

Giant

Giant GP7132 User manual

Giant

Giant LP121A-5100 User manual

Giant

Giant MP Series User manual

Giant

Giant HR2527A User manual

Giant

Giant GP5132 Instruction Manual

Giant

Giant P300 Series User manual

Giant

Giant GP7145 User manual

Giant

Giant P200A-3100 Series Repair and User manual

Giant

Giant P435 User manual

Giant

Giant MP Series User manual

Giant

Giant LP301A-0081 User manual

Giant

Giant LP121A User manual

Giant

Giant LP250-5100HK User manual

Giant

Giant P400 Series User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual