INSTALLATION INSTRUCTIONS

NOTE:INSTALLATION OF THESE HEADERS REQUIRES AN ADEQUATE WORK SPACE, GENERAL

MECHANIC'S TOOLS, GENERAL MECHANIC "KNOW-HOW" AND A REASONABLE DEGREE OF

EXPERIENCE.

1. PLACE VEHICLE IN A LOCATION WHERE THE FLOOR IS SOLID AND FLAT, WITH

ADEQUATE LIGHTING. DO NOT ATTEMPT TO WORK ON A HOT ENGINE. HEAT CAUSES

METAL TO EXPAND AND MAKES REMOVAL OF FASTENERS DIFFICULT. DISCONNECT

THE BATTERY CABLES FROM THE BATTERY. RAISE THE FRONT OF THE VEHICLE TO

OBTAIN ADEQUATE ACCESS TO THE BOTTOM EXHAUST MANIFOLD FLANGES.USE

LARGE-BASED JACK STANDS TO SUPPORT THE VEHICLE. DO NOT RELY ON THE

JACK! BLOCK THE TIRES TO PREVENT THE VEHICLE FROM ROLLING OFF THE

JACKSTANDS. THEN UNBOLT AND REMOVE THE FRONT WHEELS.

2. SPRAY WD-40 OR SOME TYPE OF PENETRATING OIL ON ALL ACCESSIBLE

FASTENERS AND FITTINGS BEFORE ATTEMPTING TO REMOVE THEM.

3. FROM UNDERNEATH THE VEHICLE, LOOSEN THE BOLTS CONNECTING THE

EXHAUST SYSTEM TO THE EXHAUST MANIFOLD.SEE PICTURE #1 (ON 4X4 MODELS,

DISCONNECT THE FRONT DRIVESHAFT BY REMOVING THE 4 BOLTS ON THE FLANGE,

AND LET THE DRIVESHAFT HANGOUT OF THE WAY.) PRY THE EXHAUST SYSTEM

BACK ABOUT 1/2" TO GAIN WORK SPACE.FOR AN EASIER REMOVAL OF THE

MANIFOLDS OR INSTALLATION OF THE HEADERS. RECOMMENDED REMOVING

FACTORY Y-PIPE. BE CAREFUL TO NOT DAMAGE THE FACTORY GASKET IN FRONT OF

THE CATALYTIC CONVERTER WHEN REMOVING Y- PIPE. THE GASKET MUST BE RE-

USED. ALSO UNPLUG THE O2 SENSOR ON BOTH SIDES BEFORE REMOVAL OF THE Y-

PIPE. SEE PICTURE’S #1A & 1B

4. IT IS NOT NECESSARY TO REMOVE THE INNER FENDERWELLS, BUT IT MAKES THE

INSTALL EASIER. TO REMOVE THE FENDERWELLS SIMPLY UNSCREW ALL THE SHEET

METAL SCREWS AND FASTENERS ATTACHING IT TO THE FENDER AND FRAME AND THE

FENDERWELL WILL DROP OUT.

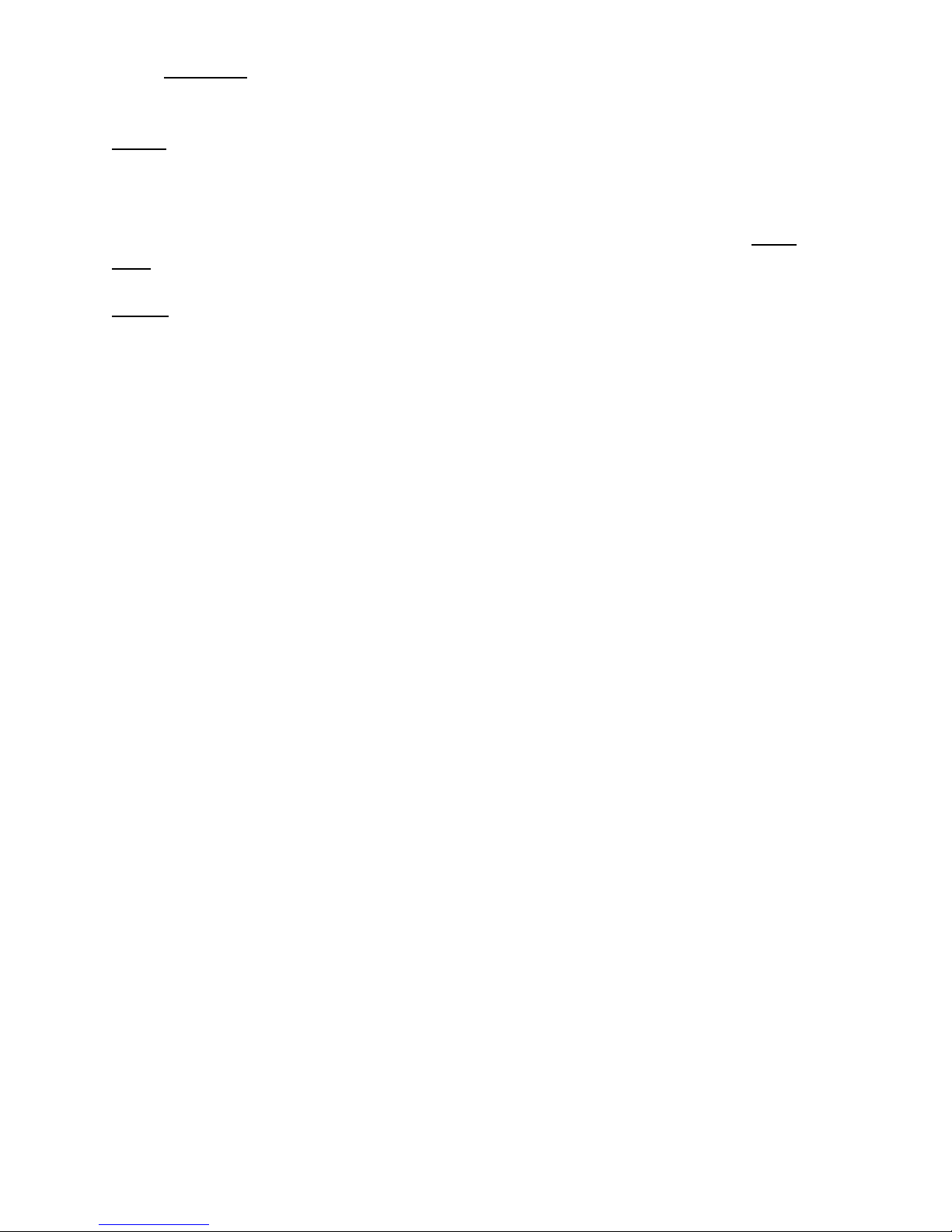

5. WORKING THROUGH THE WHEEL WELL, ON THE DRIVER'S SIDE, LOOSEN THE EGR

TUBE FROM THE MANIFOLD AND DISCONNECT IT FROM THE MANIFOLD. SOME V-10

MODELS DID NOT COME WITH A EGR TUBE. SO USE SUPPLIED EGR PLUG AND PLUG

EGR HOLE IN HEADER.SEE PICTURE #2 THEN LOOSEN THE EGR VALVE ON TOP OF THE

INTAKE MANIFOLD. (DO NOT REMOVE ONLY LOOSEN). THEN REMOVE THE NUTS

DISCONNECT MANIFOLDS

AT THIS POINT.

DISCONNECT Y-PIPE AT THE FLANGE

CONNECTION IN FRONT OF THE

CATALYTIC CONVERTER.