6 - INSTRUCTIONS FOR USE

0878_GB_99 - ELECTRIC OVEN

9· 16

01/2012

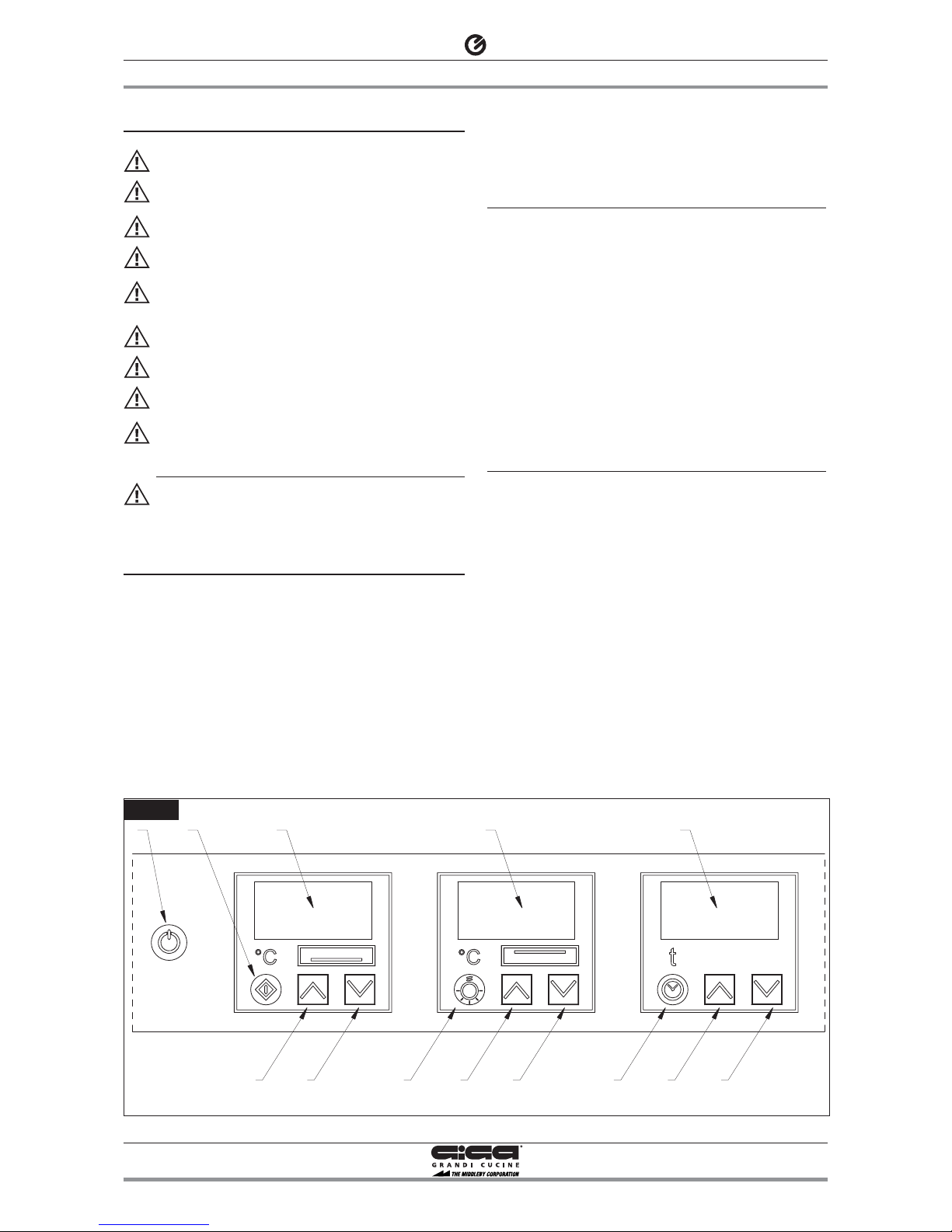

The countdown starts again by pressing button 8.

When the time counting is on pause the value can be modified by

operating on buttons 9 (increasing) and 10 (decreasing). To restart

the countdown press on button 8.

6.2.3 Interior light

Switch on the oven (see chapter 6.2 “Start-up and shutting down”).

To switch on the interior Light, press button 5.

6.3 Appliance care and frequency of mainte-

nance

6.3.1 Precautions in the event of a malfunction

If any malfunctions occur while the oven is in use, switch off imme-

diately and disconnect all power supplies. Call technical support.

6.3.2 Precautions if not using for long periods

If not using for long periods, clean the appliance thoroughly and

remove any residues, then dry perfectly. We recommend leaving the

door slightly open to allow air to circulate inside the oven and pre-

serve the lining. You can use the protective substances commonly

available on the market to protect the stainless steel parts.

Disconnect the appliance from the power supplies. The room should

be kept dry and well ventilated.

6.4 Cleaning and taking care of the machine

Before beginning any cleaning, make sure the appliance is discon-

nected from the power supply.

We recommend cleaning the oven when it is cold.

Do not use aggressive cleaning agents or abrasive detergents for

cleaning the stainless steel parts of the oven.

Avoid using steel wool on the steel parts, as this could cause rust to

form. For the same reason, protect them from coming into contact

with ferrous materials.

Do not use glass paper or abrasive paper for cleaning; for special

cases, we recommend using abrasive sponges (such as Scotch-Brite).

Caution! Never use water jets to clean the appliance, as compo-

nents may be damaged by water infiltration.

Remove internal accessories from the oven (cylinders, grates, grids

and grid holders). Wash with soap and water and leave to dry.

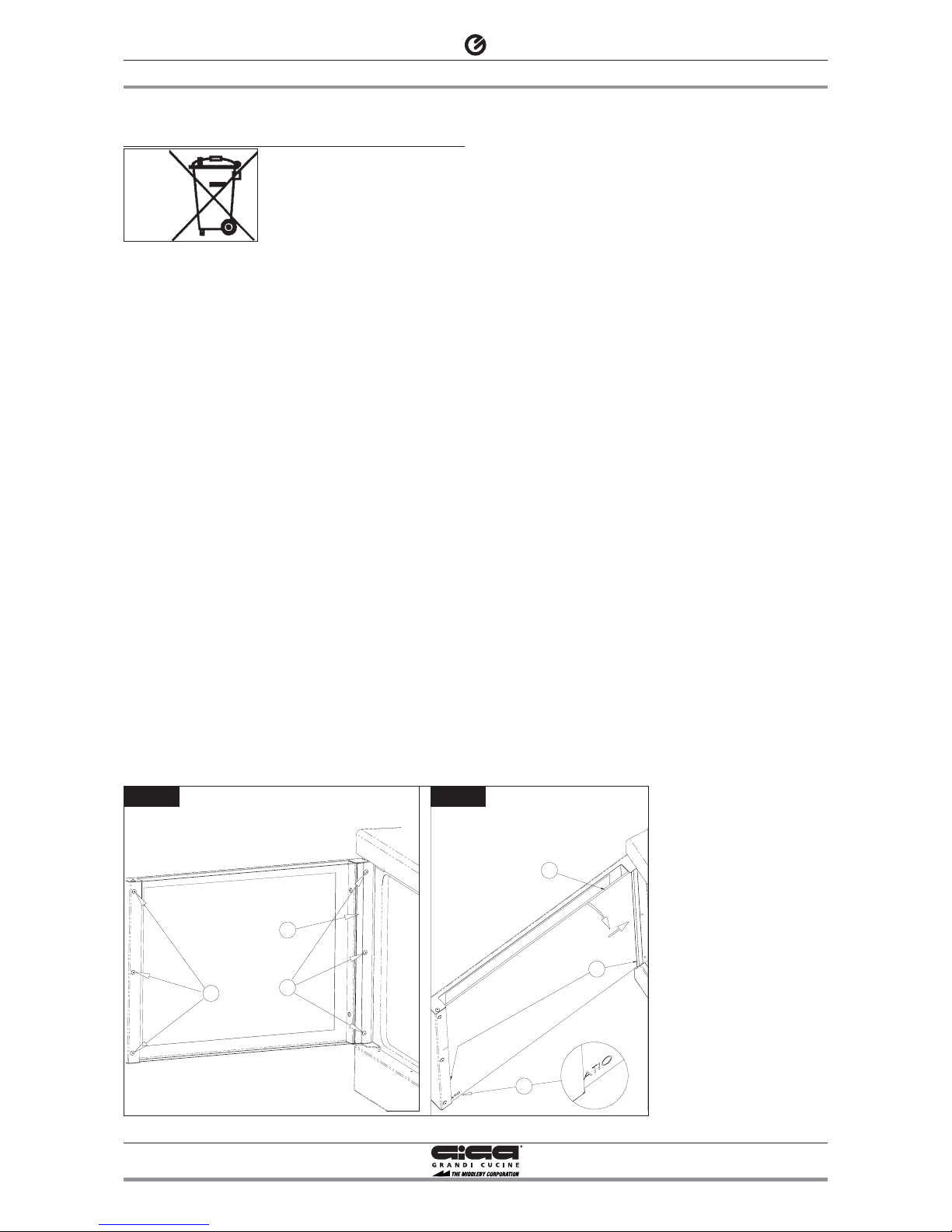

To clean the fan/resistance chamber, remove the relevant guards

(upper and lower) using the supplied key 1 (fig. 3). Disconnect the

appliance from the power supply, loosen without fully

unscrewing the 4 fastening bolts 2 (fig. 3A) inserting the key in the

hole, slide the guard forward (movement A) to release the screw

head, remove the guard by lifting it (movement B). The fan/resistan-

ce chamber can now be accessed for cleaning. For more thorough

cleaning, the fan can be removed by unscrewing the central nut

that secures it to the motor shaft. NB.: the nut is a left nut, the-

refore UNSCREW clockwise and SCREW IN counter-clockwise.

Caution! After cleaning, reassemble the guards following the

instructions in reverse order and making sure they are correctly

positioned. The appliance can now be reconnected to the power

supply.

The internal and external surfaces should be cleaned with a sponge

moistened with hot water and one of the neutral detergent easily

available on the market. Rinse, then dry off carefully using a soft

cloth.

Glass must be cleaned when cool with a cloth dampened with water

and soap, rinsed and thoroughly dried. To facilitate cleaning

between the two sheets of glass, the internal sheet can be removed;

remove the glass fastening plate 1 (fig. 4) by unscrewing the screws

2 (fig. 4) and removing it from its housing, unscrew the screws 3

(fig. 4). Remove the glass 4 with the gaskets 5 (fig. 4A) by rotating it

(movement A) and sliding it from its housing (movement B).

Remove the gaskets from the glass, clean glass and gaskets.

Assemble all parts following these instructions in reverse order.

Caution! One side of the internal sheet of glass has been heat trea-

ted. This side is marked in white (ATIO fig. 4 pos. 4A) at the lower

left corner. The marked side must face the cooking chamber.

The gasket on the oven face can be cleaned with a cloth, water and

neutral soap, rinsed and dried. To facilitate cleaning, it can also be

removed from its housing by simply pulling it and cleaned with soap

and water. When cleaning, avoid bending gaskets with dry curves

which could deform its internal metallic core. Thoroughly dry the

gasket before reassembling it in its housing.

Caution! The manufacturer cannot accept liability or claims

under warranty for any damage to property resulting from

failure to observe the safety regulations, or from incorrect

installation. This also applies where the appliance is used by

the operator for purposes other than those for which it was

designed.