Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Base Stations Page | 8 Issue 1

Doc. No. 1723-PS-0023 October 2018

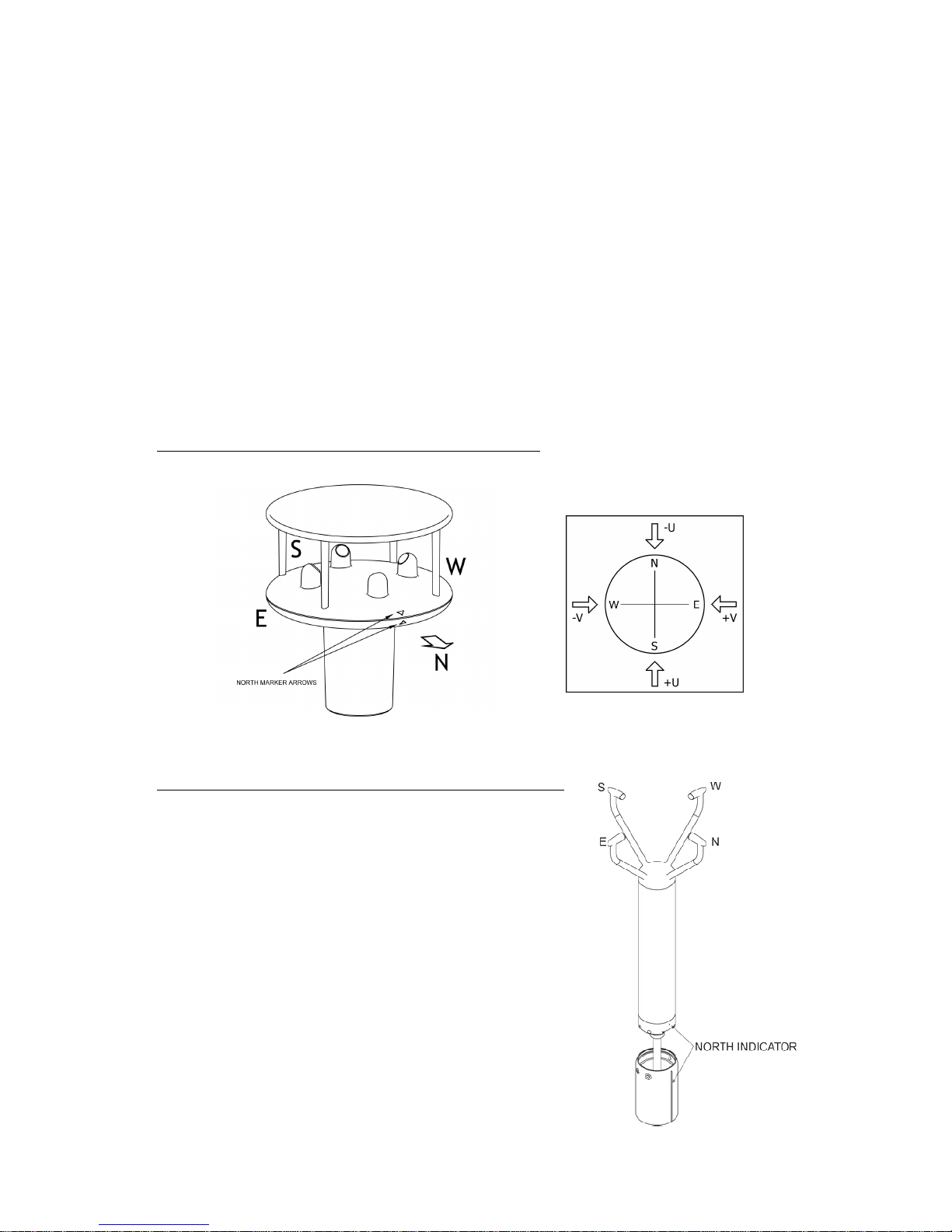

WindMaster Range North Marker and UVW Components

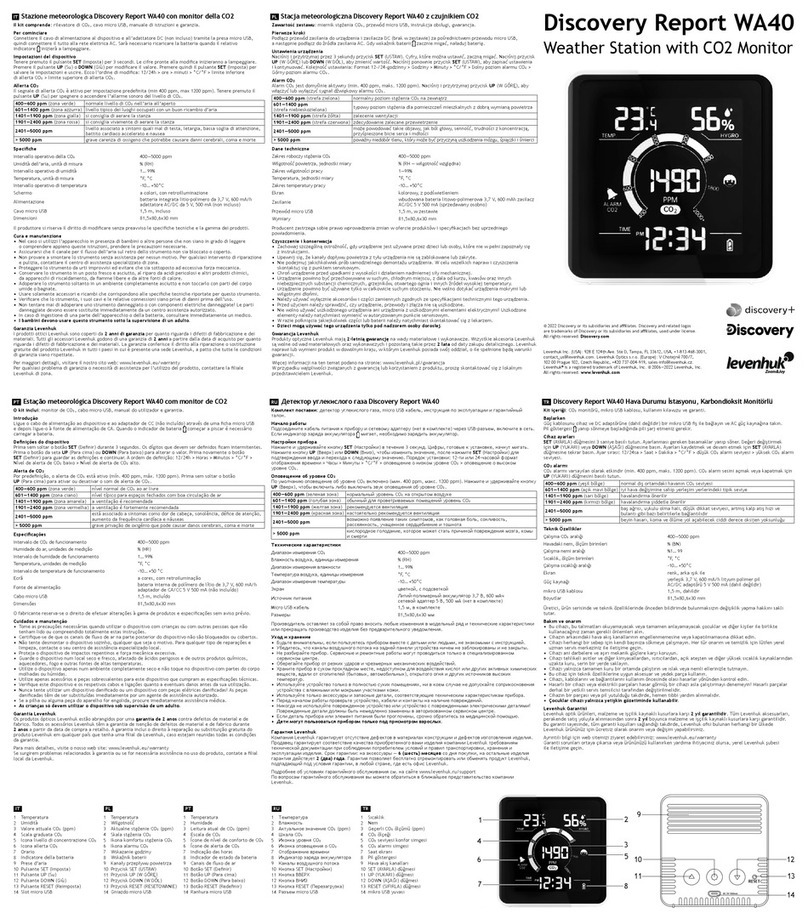

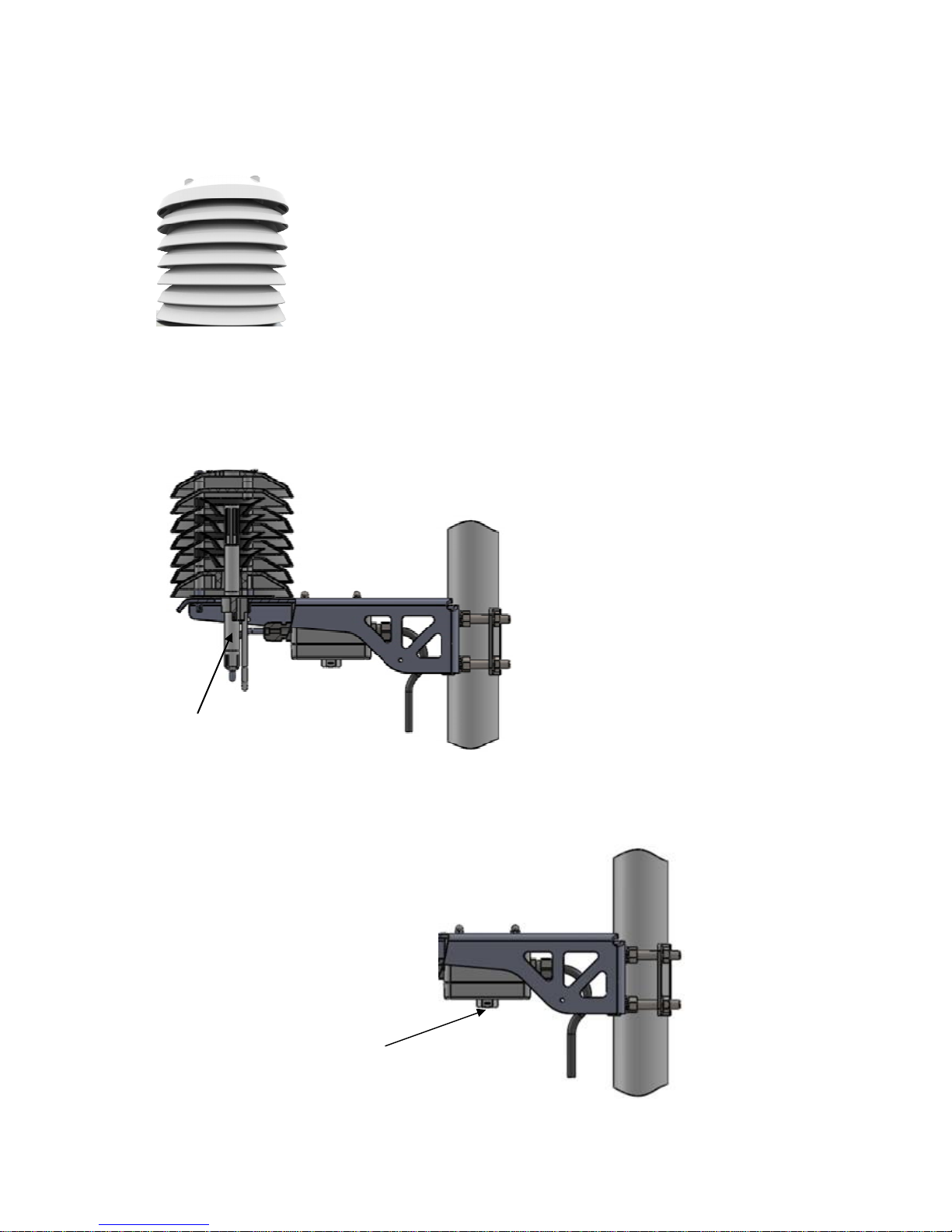

2 Axis Base Station using WindSonics and required Configuration Settings:-

1405-PK-038 WindSonic Option 2 Black

1405-PK-040 WindSonic Option 3 Black

1405-PK-072 WindSonic Option 2 White

1405-PK-073 WindSonic Option 3 White

1405-PK-420 WindSonic 75 Option 2 Black

1405-PK-423 WindSonic 75 Option 3 Black

Configuration Setting M4,U1,O1,L1,P1,B4,H2,NQ,F1,E2,T1,S4,C2,G0,K0,

2 Axis Base Station using WindSonic M and required Configuration Settings:-

1405-PK-200 WindSonic M Heated

1405-PK-201 WindSonic M Heated

1405-PK-300 WindSonic M Unheated

1405-PK-301 WindSonic M Unheated

Configuration Setting M4,U1,O1,L1,P1,B4,H2,NQ,F1,E2,T1,S4,C2,G0,K0,

2 Axis Base Station using WindObservers and required Configuration Settings:-

1390-65-X-XXX WindObserver 65

1390-70-X-XXX WindObserver 70

1390-75-X-XXX WindObserver 75

1390-90-X-XXX WindObserver 90

Configuration for Non-Heated WindObserver is:-

A0,B4,C1,E1,F1,G0000,H1,J1,K1,L1,M4,NQ,O1,P1,T1,U1,V1,X1,Y1,Z1

Configuration for Heated WindObservers is:-

A0,B4,C1,E1,F1,G0000,H2,J1,K1,L1,M4,NQ,O1,P1,T1,U1,V1,X1,Y1,Z1

Note – Applies to Firmware Version 2387 V6.02 onwards.

3 Axis Base Station using WindMasters and required Configuration Settings:-

1590-PK-020 WindMaster

1561-PK-020 WindMaster Pro

1590-PK-050 WindMaster Pipe Mount

1590-PK-130 WindMaster RA

M4,U1,O1,L1,P1,B4,H2,NQ,E1,T1,S1,C2,A4,I1,J1,V1,X1,G0,K0,F1 1,F2 0,F3 1