FRED 8

The programmable spraying system FRED 8 is a tank and pump unit to be carried on one’s

shoulders, in order to leave the operator free to move while spraying preset liquid drug dos-

es.

The structure is divided in two parts. A semi-transparent 8 lt tank at the top, which allows to

check the contents of the tank at a glance while the pump, the battery, the electronic controls,

the main switch and the relevant voltage lamp are located at the bottom.

The device can be carried on one’s shoulders thanks to a pair of adjustable belts. The hose

to feed the spraying nozzle is located on the right hand side and comes complete with oper-

ating control.

The lithium-ion battery is located in a closed compartment with snap-on door. To recharge it

simply plug the battery charger pin into the receptacle next to the switch.

A warning lamp on the charger will be lit red while recharging and turn green once the charge

is complete.

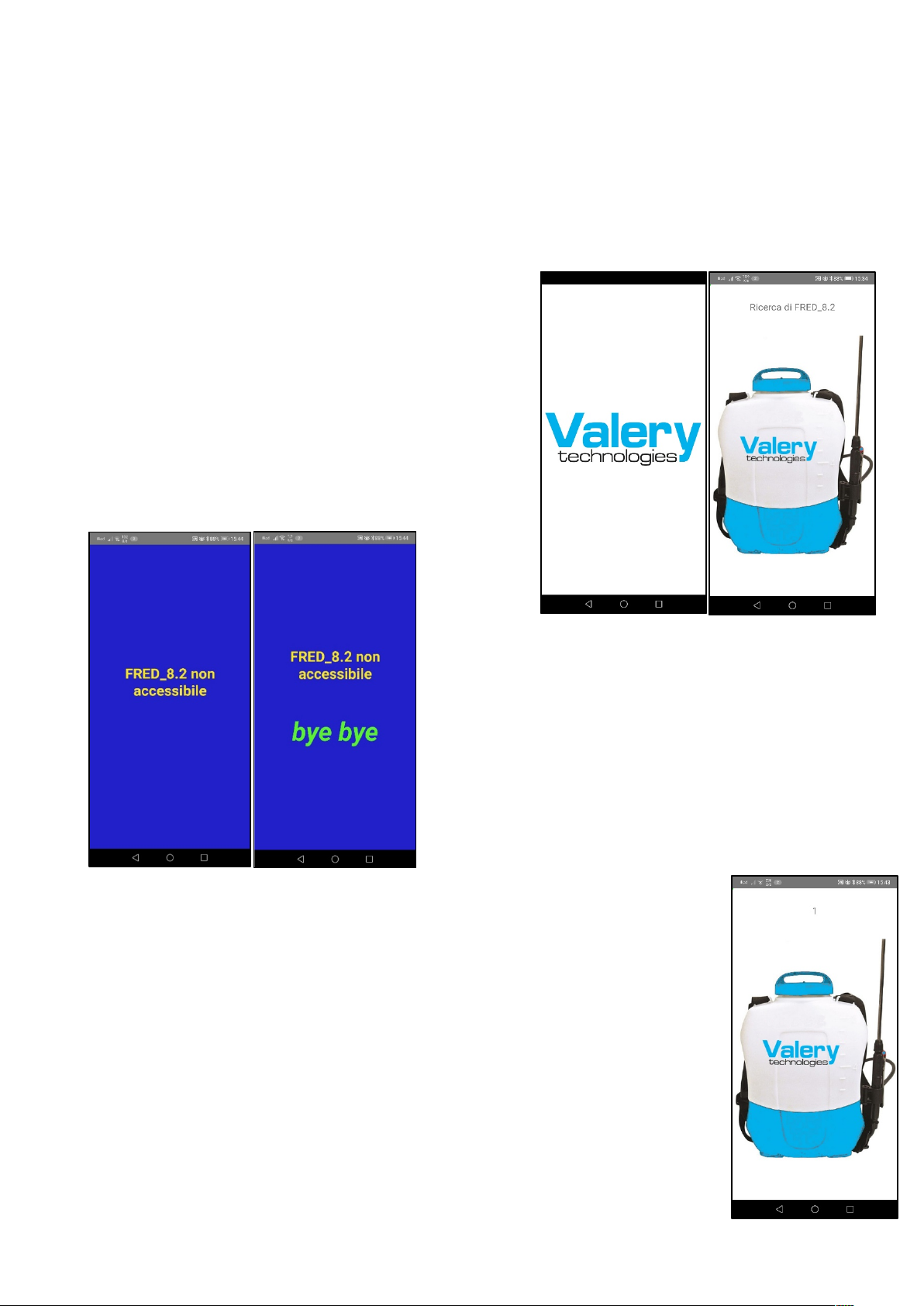

Operation

The operation is easy. After filling the tank with the necessary liquid, the system can be

switched on by acting on the switch on the left hand side. The machine becomes operative

only by using the BLE (BlueTooth Low Energy) connection, used for programming.

Therefore the FRED_8.2 application shall be activated on an Android smartphone near the

sprayer. With no BlueTooth connection the appliance will remain in standby (idle).

Once connection is established, the appliance operates in the manual mode. The pump is

started by pressing the trigger on the spraying nozzle. The pump will be active until the con-

trol is released. This manual condition is useful in the early stages, to fill the product in and at

the end for cleaning and washing the device with detergent or water.

As soon as the appliance is switched to the automatic mode, a preset quantity of product can

be sprayed. By pressing the control without releasing it, the pump will carry out the pro-

grammed number of rotations and supply the exact quantity of liquid to the nozzle. If the con-

trol is revealed before the required number of rotations the spraying operation will stop.

After programming the required quantity and switching the appliance to the automatic mode,

a connection is no longer required. The device can be prepared by a skilled operator and

then delivered to workers who do not have a phone (however a connection is required to take

the appliance back to manual mode).