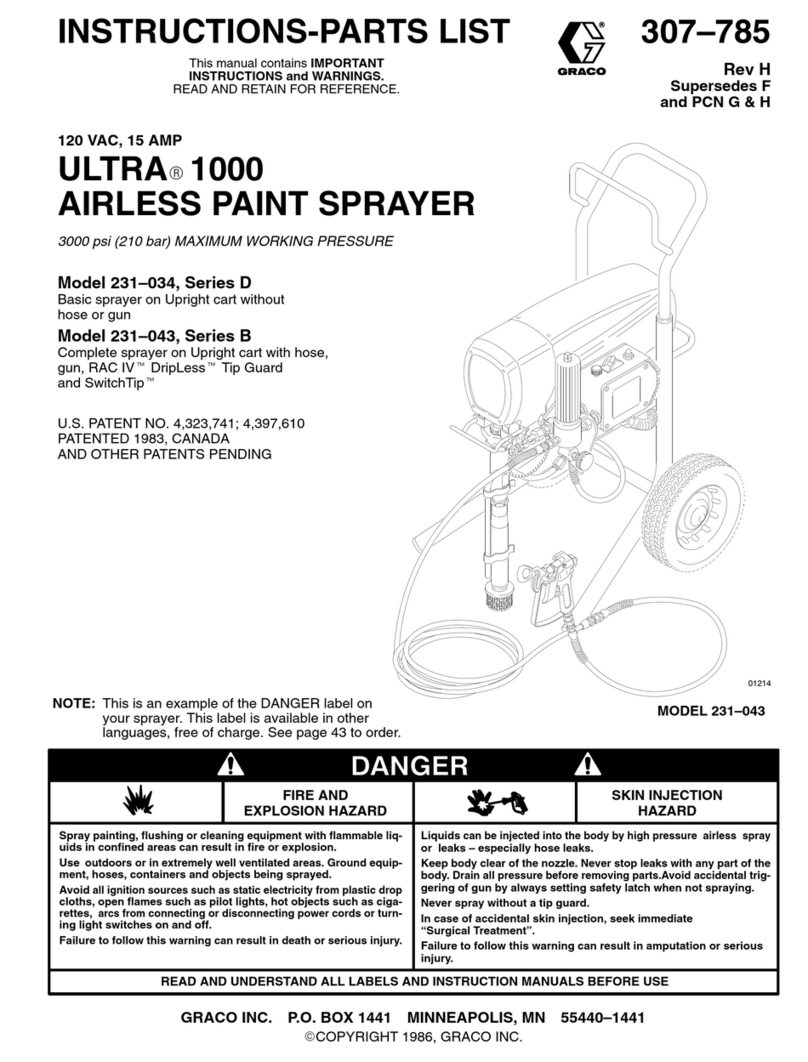

Graco ti13498a Operating instructions

Other Graco Paint Sprayer manuals

Graco

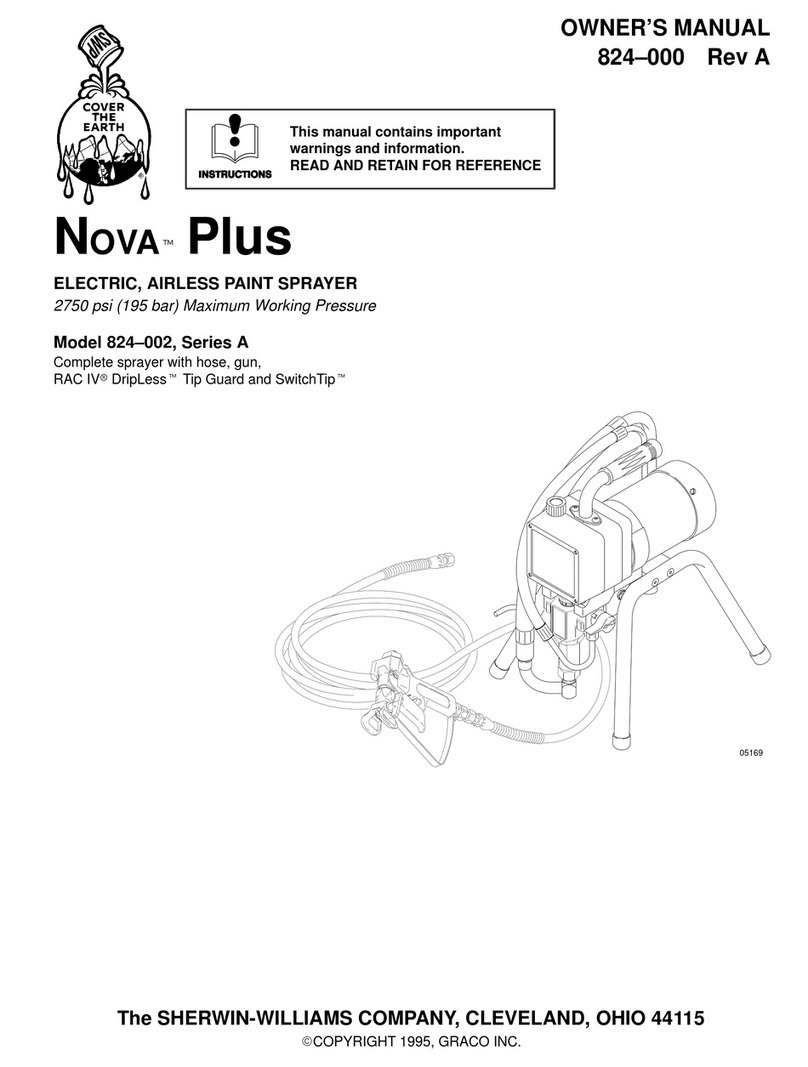

Graco 824-002 User manual

Graco

Graco 220-627 B Series Datasheet

Graco

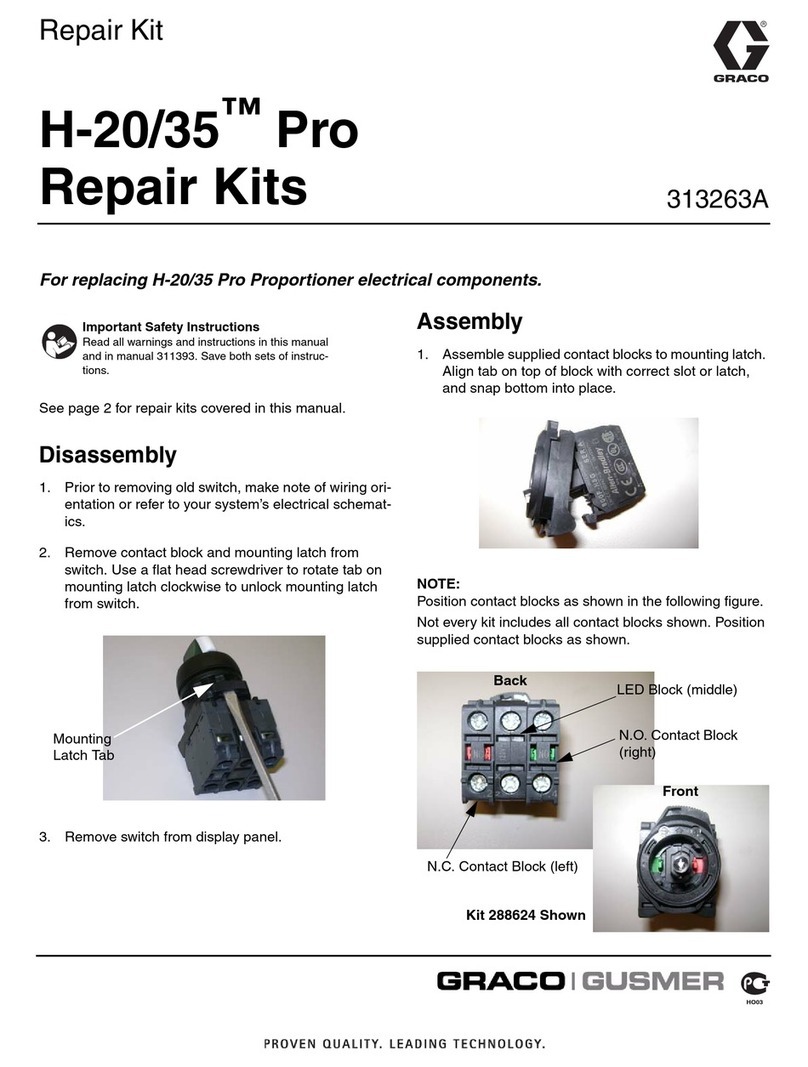

Graco Gusmer H-20/35 Pro User manual

Graco

Graco Series E Instruction Manual

Graco

Graco AIRLESSCO SP400 Hi Boy Operating instructions

Graco

Graco 244581 Operation manual

Graco

Graco 207947 Operation manual

Graco

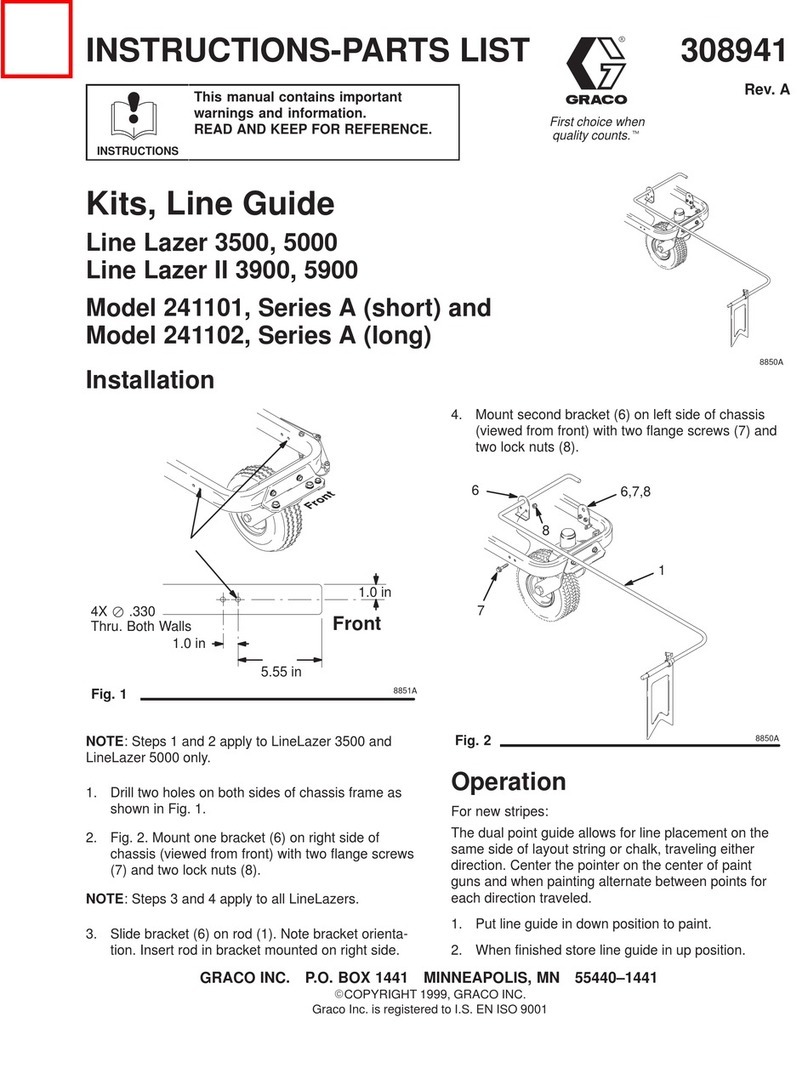

Graco Line Lazer 3500 Operation manual

Graco

Graco GMAX II 5900 Operating instructions

Graco

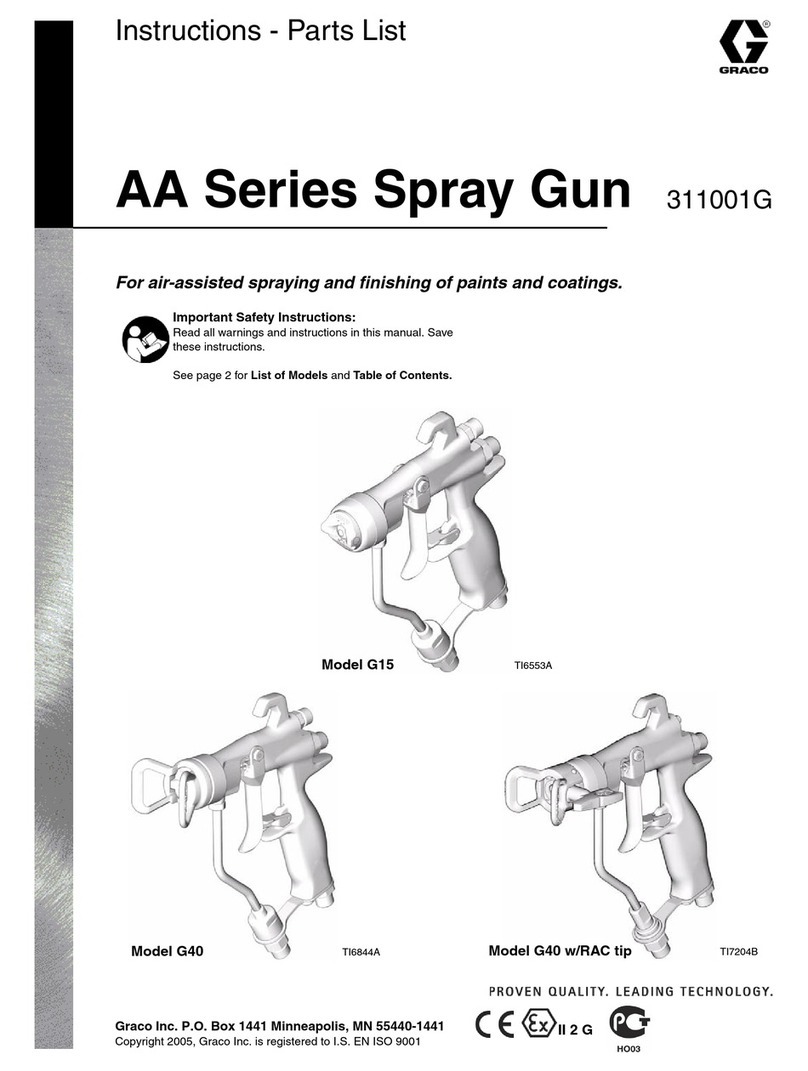

Graco 311001G Datasheet

Graco

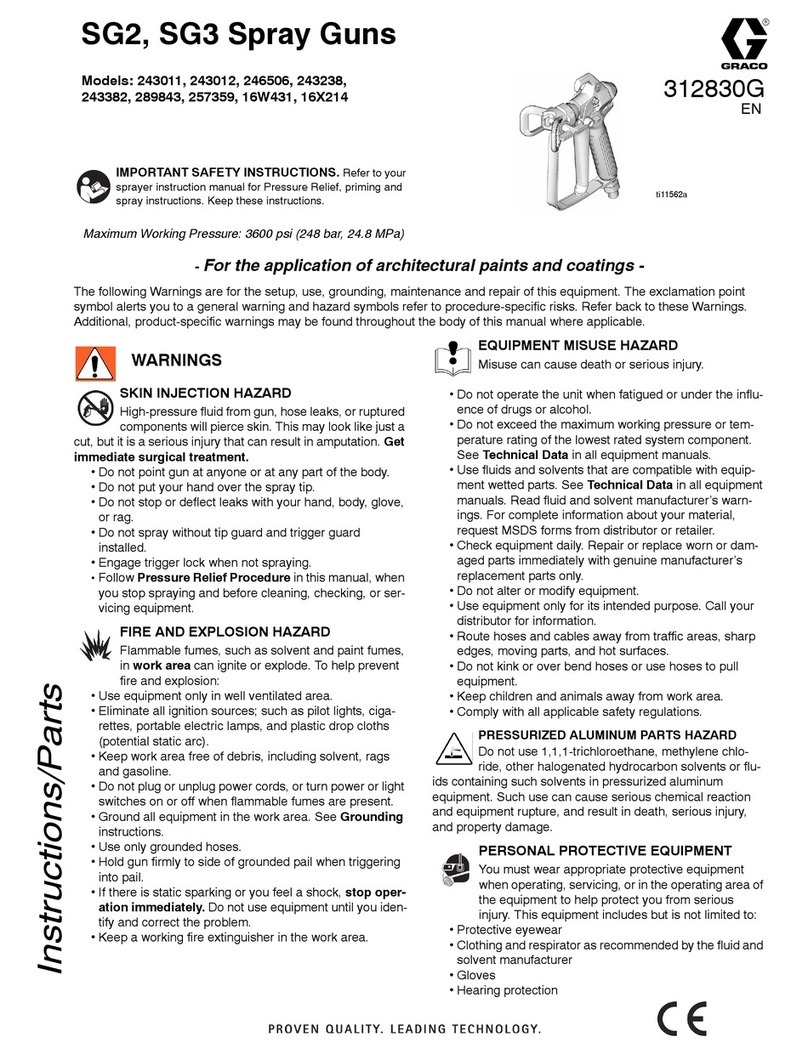

Graco SG2 User manual

Graco

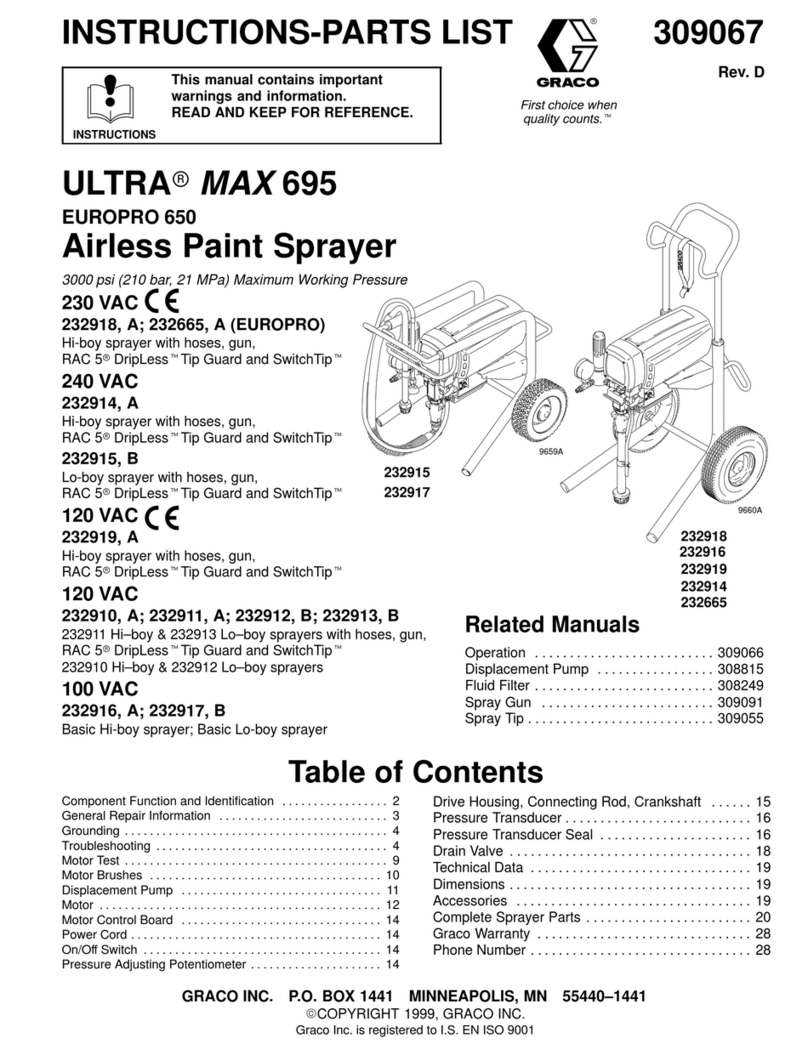

Graco ULTRA R MAX 695 309067 Operation manual

Graco

Graco 17C327 Guide

Graco

Graco PROX17 User manual

Graco

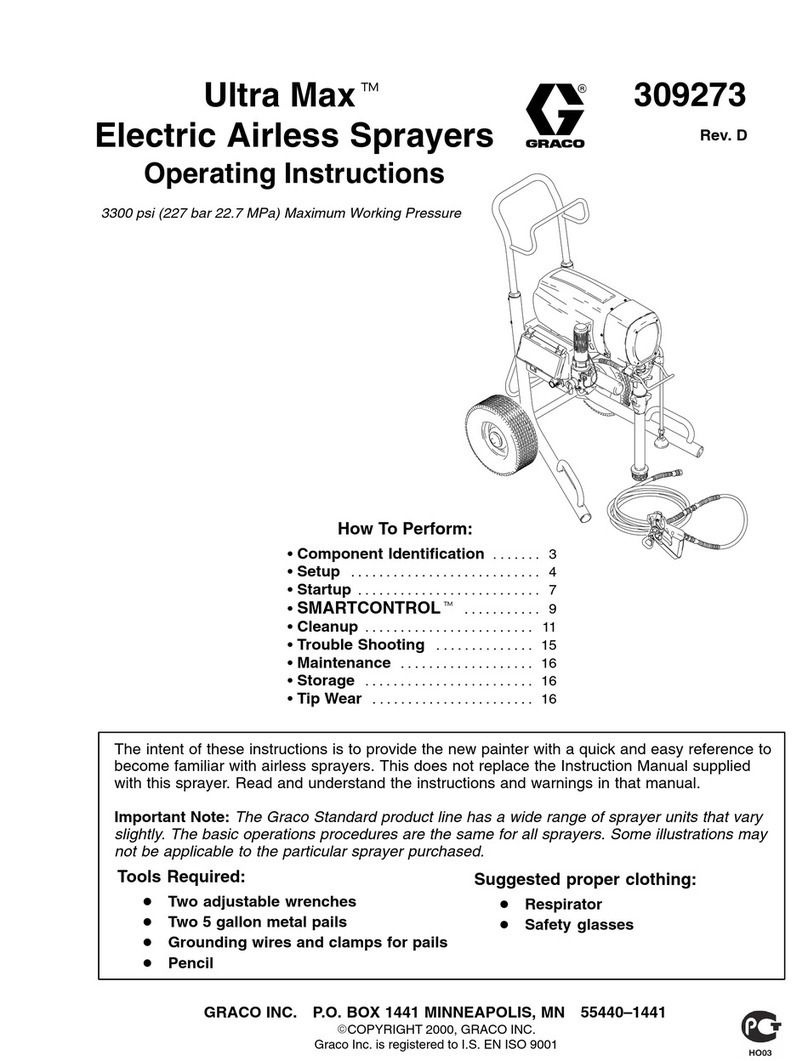

Graco Ultra Max 309273 User manual

Graco

Graco 950 Series Parts list manual

Graco

Graco C Series Operation manual

Graco

Graco GMAX II 3900 Premium Operating instructions

Graco

Graco NOVA 390 PC Guide

Graco

Graco HVLP 2500 Manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual