11 12

3. System operation

4. Maintenance and fault handling

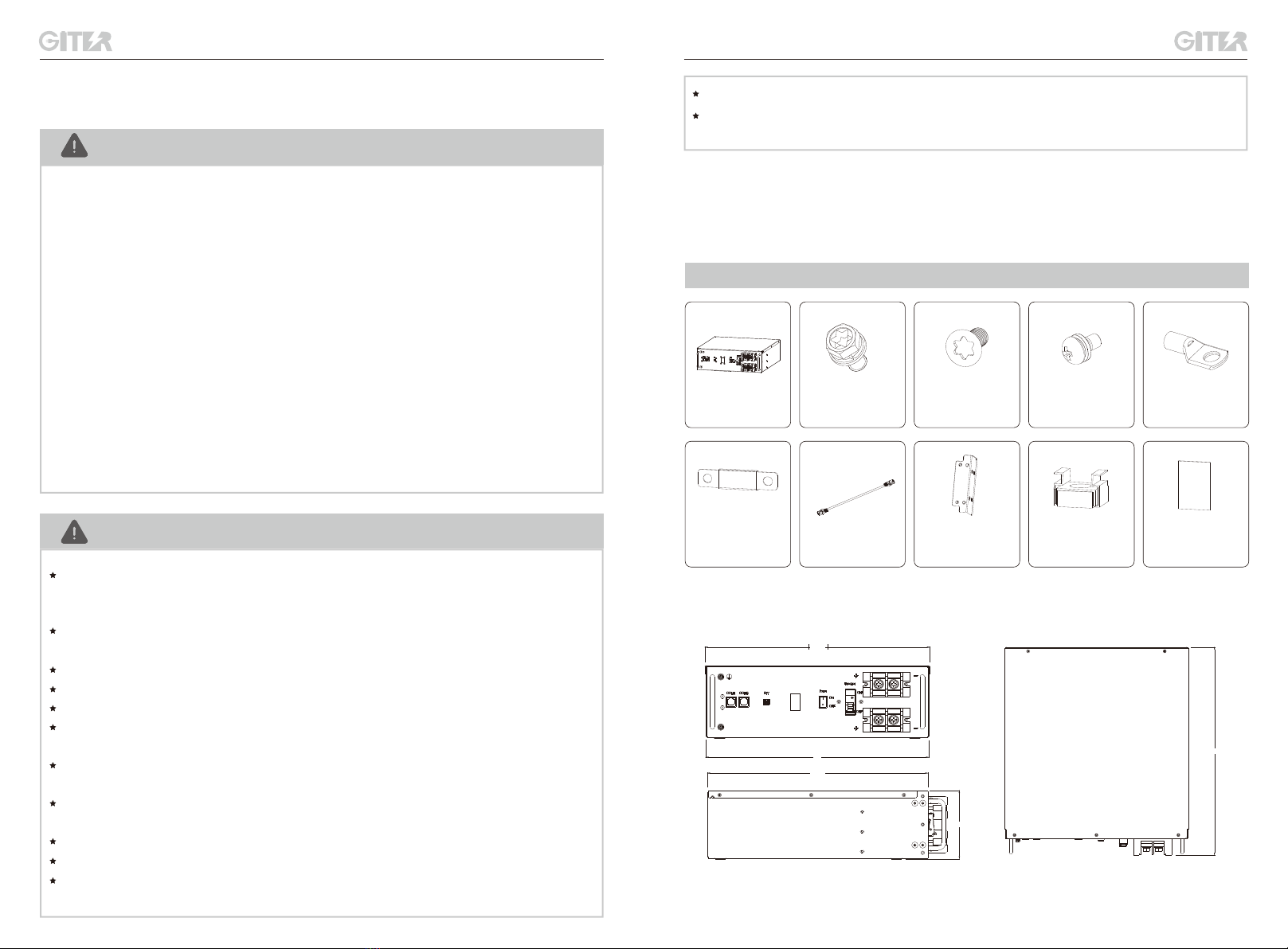

3.1 Power on/off

4.1 Routine maintenance

4.2 Other faults and abnormal phenomena

4.2.1 Unable to turn on

Check all power cables and communication cables carefully.

Common faults and corresponding troubleshooting are listed below.

POWER ON: Switch on the Battery Breaker, turn the Power Switch (Rebound button) "ON" and hold

for 1-2 seconds. Then the battery module will activate and the LED display will light up.

POWER OFF: Turn the Power Switch (Rebound button) "ON" and hold for 5 seconds, and the

battery will be turned off.

Batteries should be turned on in the correct order to avoid damage

• Check if the environment situation meet the requirements of the battery.

• Check whether the charging and discharging function of the battery is normal. When one of the

following situations happen, it is necessary to charge the battery in time: the battery protection code

09 appears, the battery is often under charged, and the battery is stored for more than 3 months.

• Check the battery and its appearance, terminals, cables, LED lights, etc.

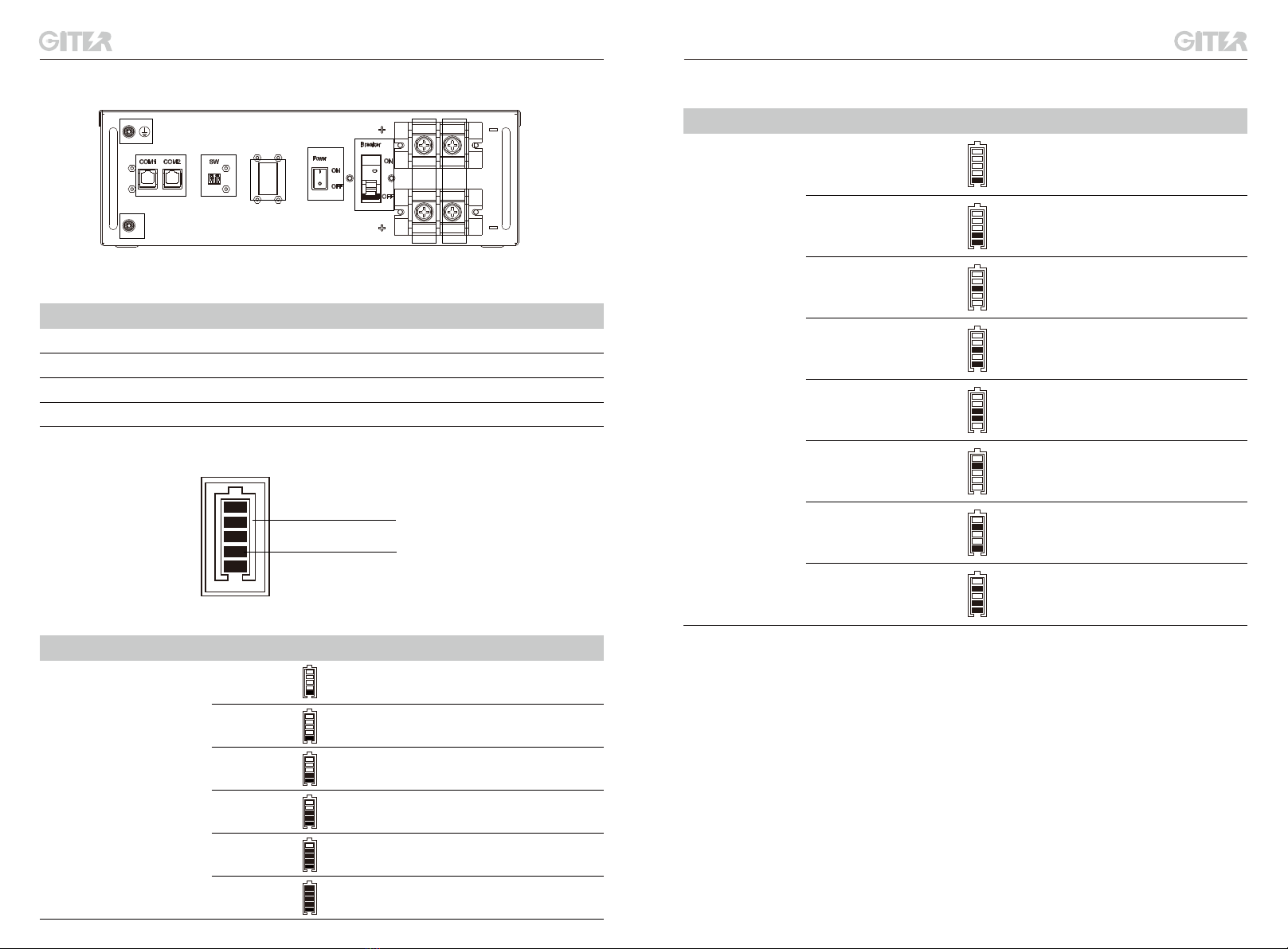

Fault Troubleshooting Description

Turn on the Power

switch and hold for 2

seconds, while the LED

light isn't on in 3

seconds.

Check if there

resistance when you

turn on the switch.

If the switch has no

resistance, please contact

customer service.

4.2.3 Unable to charge

Fault Troubleshooting Description

The battery cannot be

charged normally while it

is not fully charged with

no LED protection code

nor error code.

1.Check if the battery has

been turned on;

2.Check if the power cables

are connected correctly;

3.Check if the battery breaker

is ON;

4.Check if the ambient

temperature is within the

operating range.

If the battery still cannot

be charged normally after

these steps, please

contact customer service.

4.2.4 Unable to discharge

Fault Troubleshooting Description

The battery cannot be

discharged as it should

while it is still alive with no

LED protection code nor

error code.

1. Check if the battery has been

turned on;

2. Check if power cables are

connected correctly;

3. Check if the battery breaker is

on;

4. Check if the ambient

temperature is within the operating

range;

5. Disconnect the power cables

and test the battery output voltage.

If the voltage is too low, please

charge immediately. If there is no

voltage, please contact customer

service. If the voltage is normal,

you can restart the battery.

If the battery still cannot

be discharged normally

after these steps, please

contact customer service.

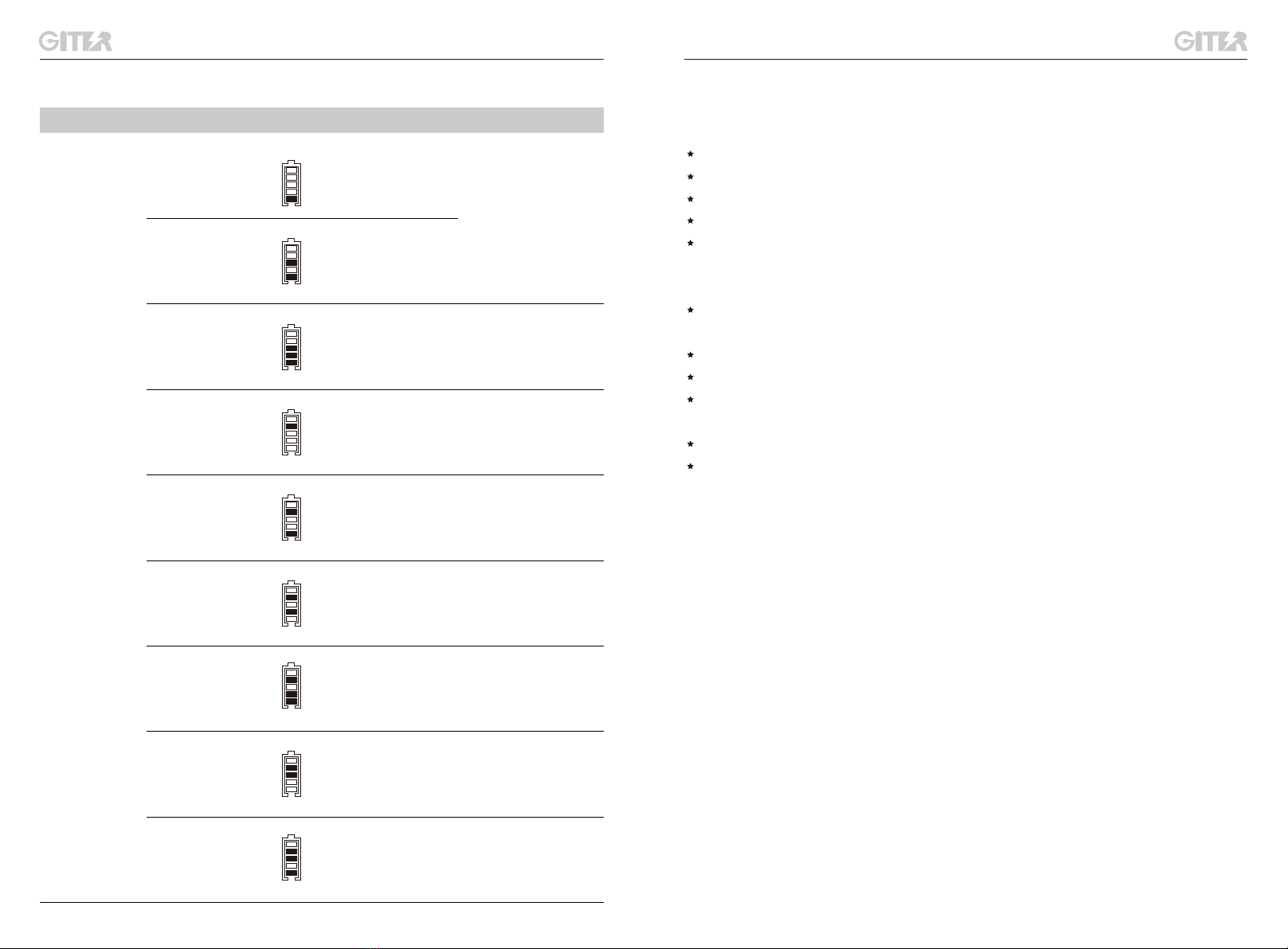

4.2.5 No communication between battery and upper controller (if any)

Fault Troubleshooting Description

The upper controller failed

to detect the batteries

1. Confirm if the battery has been

turned on;

2. Check if the power cables are

connected correctly;

3. Check if the communication

cables are connected correctly

and whether they are damaged;

4. Check if the DIP Switch 2 is

set "ON", which is on the farthest

battery away from the upper

controller;

5. Restart the batteries.

If the battery still cannot

be used normally after

following the steps, please

contact customer service.

4.2.2 Shut down immediately after turning on

Fault Troubleshooting Description

Turn on the Power switch and

hold for 2 seconds, while the

LED light goes off again after 8

seconds.

Check if the switch can

bounce back.

If the switch cannot

bounce back, please

contact customer service.