Page 4

IMPORTANT NOTE: PLEASE ENSURE THAT ALL RELEVANT PERSONNEL READ THE POINTS LISTED WITHIN THIS LEAFLET AND THAT A COPY

IS GIVEN TO STAFF INVOLVED WITH THE INSTALLATION AND MAINTENANCE OF THIS PRODUCT.

SAFETY NOTE: PLEASE REFER TO ‘THE MANUAL HANDLING OPERATIONS REGULATIONS 1992’ DURING HANDLING.

.

AND GLENWOOD™ ARE TRADEMARKS OR REGISTERED TRADEMARKS OF GLASDON GROUP OR

ITS SUBSIDIARIES IN THE U.K. AND OTHER COUNTRIES

A planned maintenance schedule or regular inspection is

recommended, replacing components as necessary.

Replacement components are available direct from GLASDON.

GLASDON cannot be held responsible for claims arising from incorrect

installation, unauthorised modications or misuse of the product.

© Copyright April 2019

Glasdon UK Ltd reserve the right to alter specications without prior notice.

Stock No. C000/0525 - DWG No. 11B-055-17 Issue 1 - April 2019

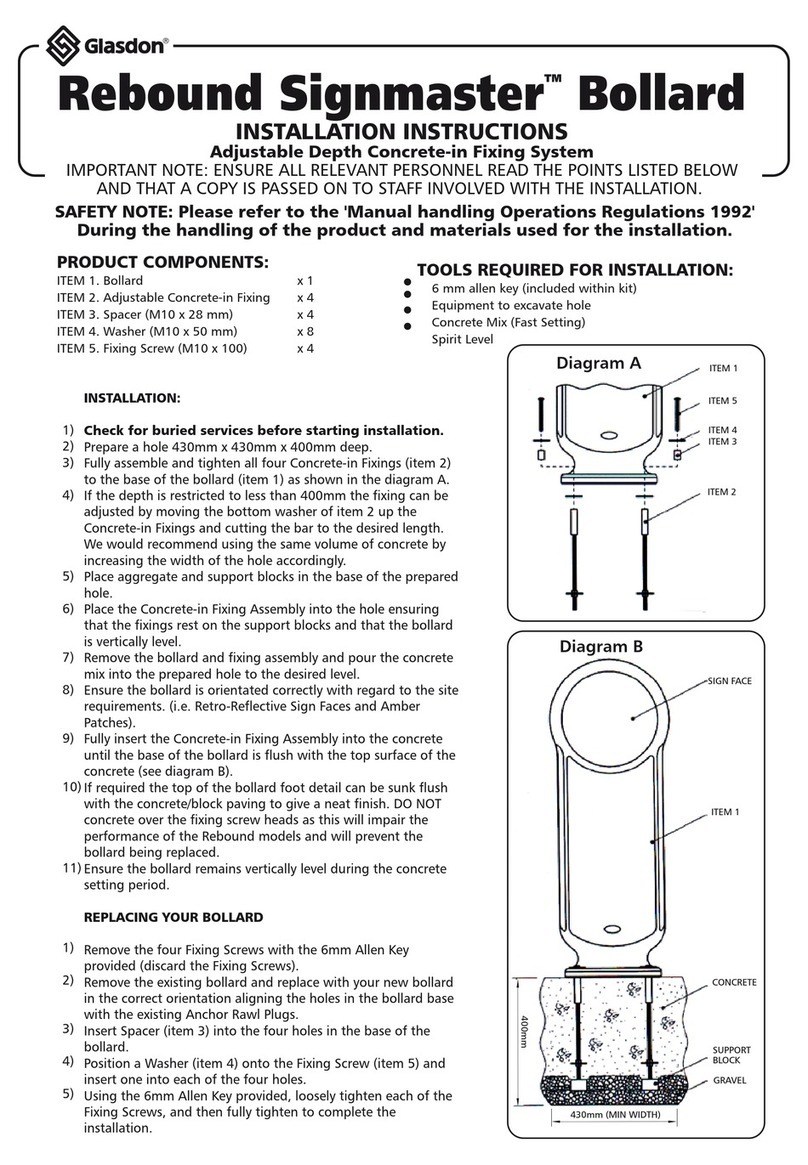

1. Check for buried services before starting

excavations.

2. Mark out and prepare a hole 400mm x

400mm x 315mm deep.

4. Once the post is positioned correctly pour

concrete into the prepared hole to the

ground level.

4. Ensure the post remains vertical during

the concrete setting period. Leave to set.

5. Should block paving be required reduce

the height of the concrete accordingly to

allow the paving to be sited at ground level.

3. Place a small amount of gravel or sand in

the base of the prepared hole and position

post into the hole. Add/remove gravel as

required to help position the post at the

correct height.

-Ensure the top of the post stem is level with

the ground.

-Ensure the post is vertical with the use of a

spirit level.

-Ensure the post is orientated correctly with

regard to the retroreective banding and

the site requirements. (i.e. Red reector faces

oncoming trafc on the near-side and white

reector faces on coming trafc on the off-

side).

Glenwood 170 Extended Base Installation Instructions

315mm

400mm

4

00m

m

Spirit

Level

Layer of

Gravel or

Sand

Ground

Level

C

arriageway (UK)

See our website for a video guide - www.glasdon.com

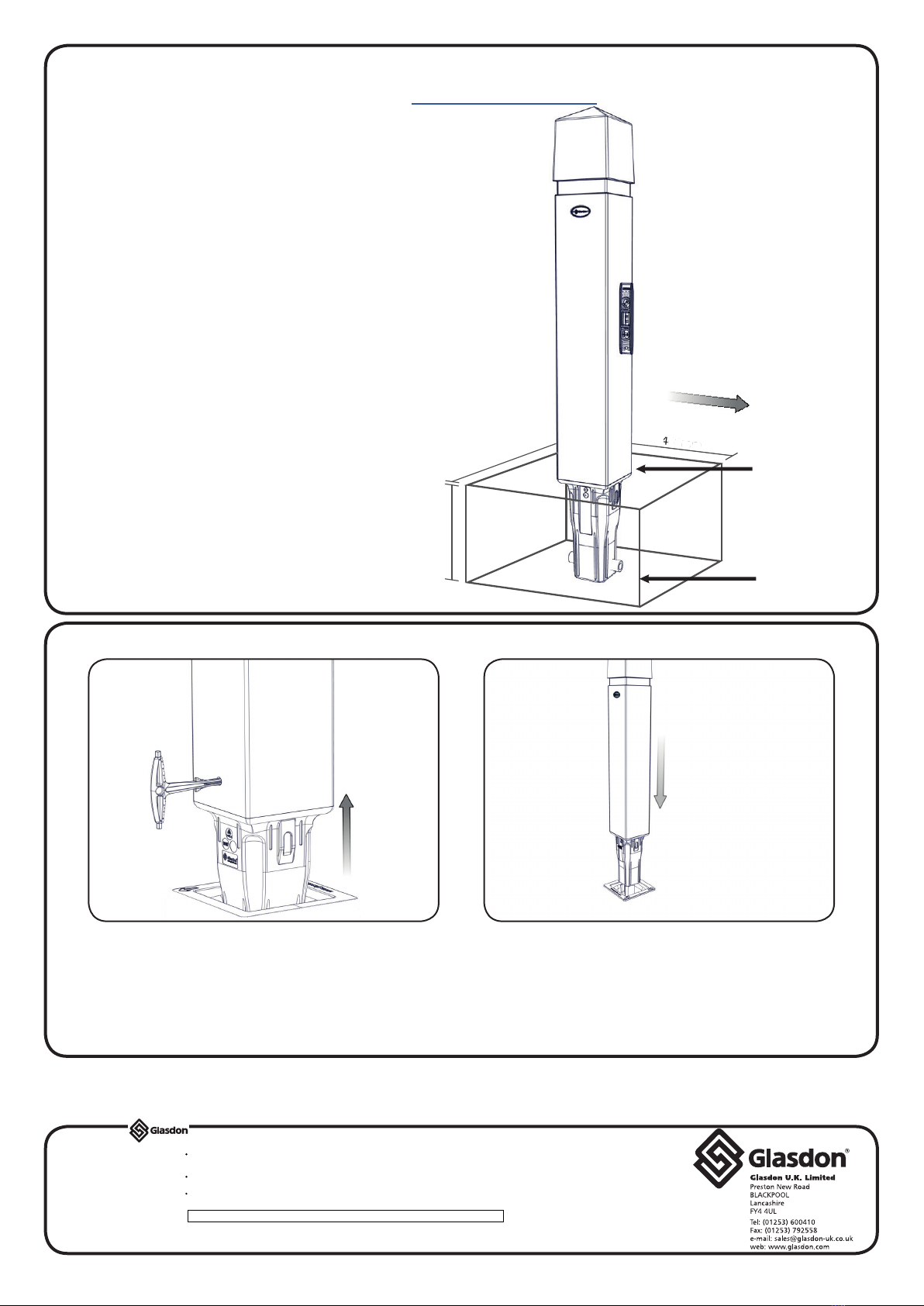

Glenwood 170 Socketed Post Operating Instructions

To remove the post, rmly push the key into

the track and lift to remove the post from the

socket.

To lock the post in place, drop it into the

socket. Ensure the post is orientated correctly

with regard to the retroreective banding

and the site requirements (i.e. red reector

faces oncoming trafc on the near side and

white reector faces oncoming trafc on the

off-side). Test by attempting to pull the post

from the socket.

2.1.