Page 2 Page 3

Section Page

DESIGN

Description 3

Technical Information 4

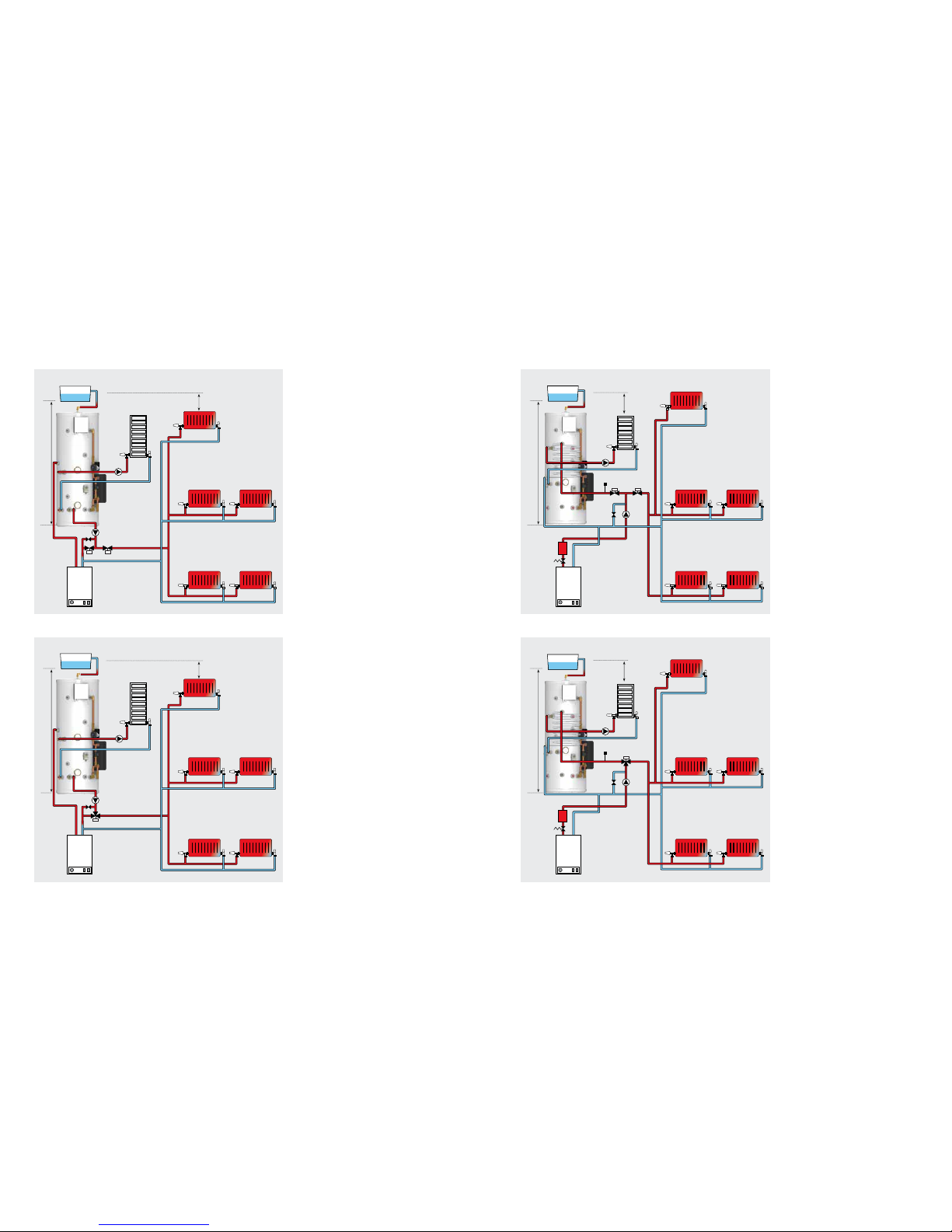

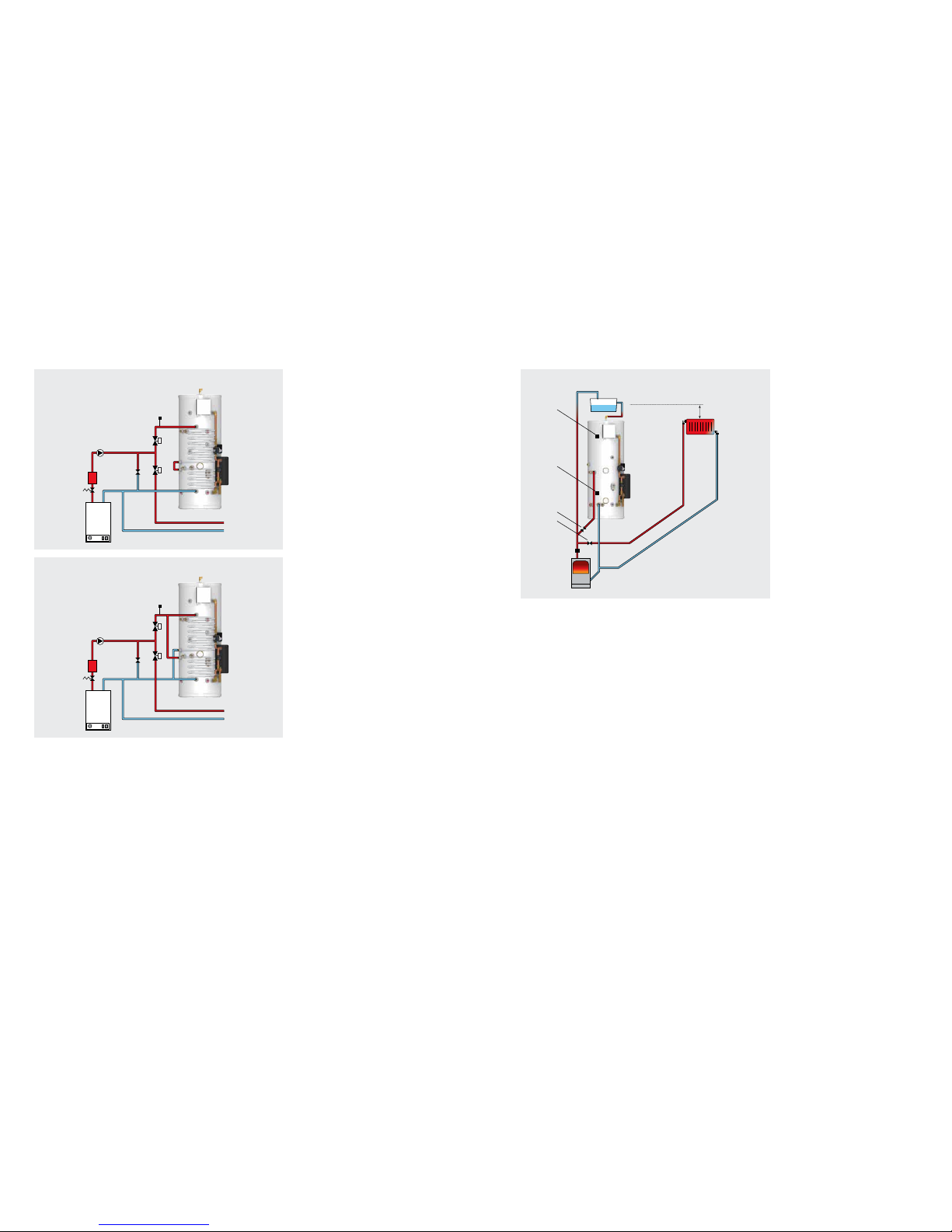

System Design 6

INSTALLATION

Installation 8

Wiring Diagrams 21

Commissioning 28

Installation Review 30

SERVICING AND MAINTENANCE

Servicing and Maintenance 31

Fault Finding 32

Short Parts List 39

APPENDIX

Appendix A 40

Appendix B 41

Notes 42

Terms & Conditions 44

BENCHMARK

Commissioning Check List 46

Service Record 47

ISSUE 4: APRIL 2018

These instructions should be read in conjunction with the installation/servicing

instructions issued by the manufacturer of the heat source being used.

Any installation must be in accordance with the relevant requirements of the Gas

Safety Regulations, Building Regulations, I.E.E. Wiring Regulations and the Water

Fitting Regulations (England and Wales) or Water Byelaws (Scotland). It should be

read in accordance with the relevant recommendations of the following:

BS 6798; BS 5549; BS 5546;

BS 5440:1; BS 5440:2; CP 331:3

BS 6700: BS 5258 and BS 7593: 1993 and BS7671

It must be installed by a competent person as dened by the relevant regulations.

Manufacturers notes must NOT be taken as over-riding statutory obligations.

This product overcomes Part G Building Regulation discharge requirements for

unvented cylinders but the installation is notiable to building control unless it is

carried out under an approved competent person self-certication scheme.

Although the secondary supply (domestic) is at mains pressure, it is not necessary to

t an expansion chamber, pressure or temperature relief valve, the plumbing should

allow any unusual build up of pressure to be relieved at the ball valve.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge unless

they have been given supervision or instruction concerning use of the appliance by

a person responsible for their safety. Children should be supervised at all times to

ensure they do not play with the appliance.

This information is provided to assist generally in the selection of equipment.

Responsibility for selection and specication of our equipment must however remain

that of our customer and any experts or consultants concerned with the installation(s).

PLEASE NOTE: THAT WE DO NOT THEREFORE ACCEPT ANY RESPONSIBILITY FOR

MATTERS OF DESIGN SELECTION OR SPECIFICATION, FOR THE EFFECTIVENESS

OF AN INSTALLATION OR SYSTEM CONTAINING ONE OF OUR PRODUCTS UNLESS

SPECIFICALLY REQUESTED TO DO SO IN WRITING.

All goods are sold subject to our Conditions of Sale which are set out at the rear of this

specication. In the interest of continuously improving the Torrent Stainless range,

Gledhill Building Products Limited reserve the right to modify the product without notice,

and in these circumstances this booklet, which is accurate at the time of printing, should

be disregarded. An updated set of Instructions will be produced and supplied with new

appliances and will be made available for other appliances on request.

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment for

their needs, that it is installed, commissioned and serviced in accordance with the

manufacturers instructions by competent persons and that it meets the requirements

of the appropriate Building Regulations. The Benchmark Checklist can be used to

demonstrate compliance with Building Regulations and should be provided to the

customer for future reference.

Installers are required to carry out installation, commissioning and servicing work

in accordance with the Benchmark Code of Practice which is available from the

Heating and Hot Water Industry Council who manage and promote the Scheme. Visit

www.centralheating.co.uk for more information.

For information on the HWA Charter Statement, go to the HWA website hotwater.org.uk.

Manufacturer: Gledhill Building Products Ltd

Max. mains inlet water pressure 5.0bar

Max. working pressure - Primary heat exchanger (Indirect models) 3.0bar

Max. working pressure - Solar heat exchanger (Solar models) 6.0bar

Max. working pressure - Open vented thermal store (All models) 10.0m (1.0bar)

Max. working pressure - Open vented central heating system 10.0m (1.0bar)

Max. working pressure - Sealed heating system 3.0bar

Max. ow rate - Measured by ow sensor 32 l/min

Min. ow rate - Measured by ow sensor 1.8 l/min

Immersion heater rating

3kW@230Vac,50Hz

The Torrent Stainless comes complete with plate heat exchanger.This has a very

small volume of water held within it, therefore any minimal expansion will be

accomodated in the supply pipe.

Handling Before Installation

The Torrent Stainless must be handled with care and stored the correct way up in

a dry place. Any manual handling/lifting operations will need to comply with the

requirements of the Manual Handling Operations Regulations issued by the H.S.E.The

appliance can be moved using a sack truck on the rear face although care should be

taken and the route should be even. In apartment buildings containing a number of

storeys we would recommend that the appliances are moved vertically in a mechanical

lift. If it is proposed to use a crane, expert advice should be obtained regarding the

need for slings, lifting beams etc. A specic manual handling assessment is shown in

Appendix B at the rear of this manual.

Maintenance

Modications should not be made to this product. Replacement parts, including

immersion heaters, should be purchased from Gledhill Building Products Limited, or

agents approved by them.The manual must always be left with the Torrent Stainless.

The Environment

This product has been manufactured using many recyclable materials, including the

approved HCFC/CFC free polyurethane foam insulation. At the end of its useful life, it

should be disposed of at a Local Authority Recycling Centre, to maximise the products

full environmental benets.

Note:

The thermal store is supplied with either one or two immersion heaters. These

incorporate a thermostat (XB081) which cuts the electricity supply to the immersion

heater if the control thermostat fails - a thermal cut out. Under no circumstances t

an immersion heater which does not incorporate a thermal cut out.

Why use a thermal store?

a) Alternative energy fuel sources are typically low grade, inherently unpredictable

and are often available in plentiful supply but not when the heat energy is

needed! A thermal store provides the means to harness the energy when it is

available for later conversion into both hot water AND heating.

Being open vented, they provide a simple and inherently safe way to produce

high-performance mains pressure hot water.

Multiple heat sources feed into the thermal store. This means that the energy

available from solar panels or a wood burning stove, for example, can be used

to provide energy into the heating circuit to decrease the use of fossil fuel based

boilers, and hence reduce household running costs.

DESIGN

DESCRIPTION

It is very problematic and inherently unsafe

to connect wood burning stoves or other

uncontrolled heat sources to an unvented

cylinder, and not easily possible to combine

alternative energy heat sources to provide

energy to the heating circuit, hence the

unique advantages of a thermal store.

b) The Torrent Stainless is the ideal product

to use as the heart of an alternative energy

system as it will take energy input not only

from a conventional boiler but also from a

wide variety of alternative energy sources,

including but not limited to:

• solar panels

• wood burning stoves and other

uncontrolled heat sources

• electricity from renewable or low

carbon sources

If the system is congured appropriately

the heat from the alternative energy source

will be available for both hot water AND

heating.

c) The Torrent Stainless becomes the neutral

point in any open vented system because

the open vent and cold feed pipes are

connected to it. The benet of this is that

another device to enable dierent systems

to be joined together at a neutral point is

not required, which would be required in

other systems. In multiple fuel systems, the

Torrent Stainless acts as a low loss header.

d) Alternative energy supplies cannot be relied

upon to raise the temperature of the stored

water above 60 degrees every time they

operate. This is not a problem with a thermal

store because the store water is not the

water that comes out of the tap. The water

that comes out the hot tap is mains cold

water run through a plate heat exchanger

on the outside of the thermal store. This

water heats very quickly and the volume of

stagnent water in the heat exchanger is very

small so there is virtually no legionella risk.

e) The thermal store is open vented and

therefore does not require additional safety

devices such as temperature and pressure

relief valves or an inlet control group and

expansion vessels.

f) The running costs of this cylinder are greatly

reduced by not being required to have

an annual safety inspection where as an

unvented cylinder does.