Introduction

350W Beam Spot Wash 3 in 1 Moving head light with CMY

Model:GL350BSWT

Moving Head Lighting

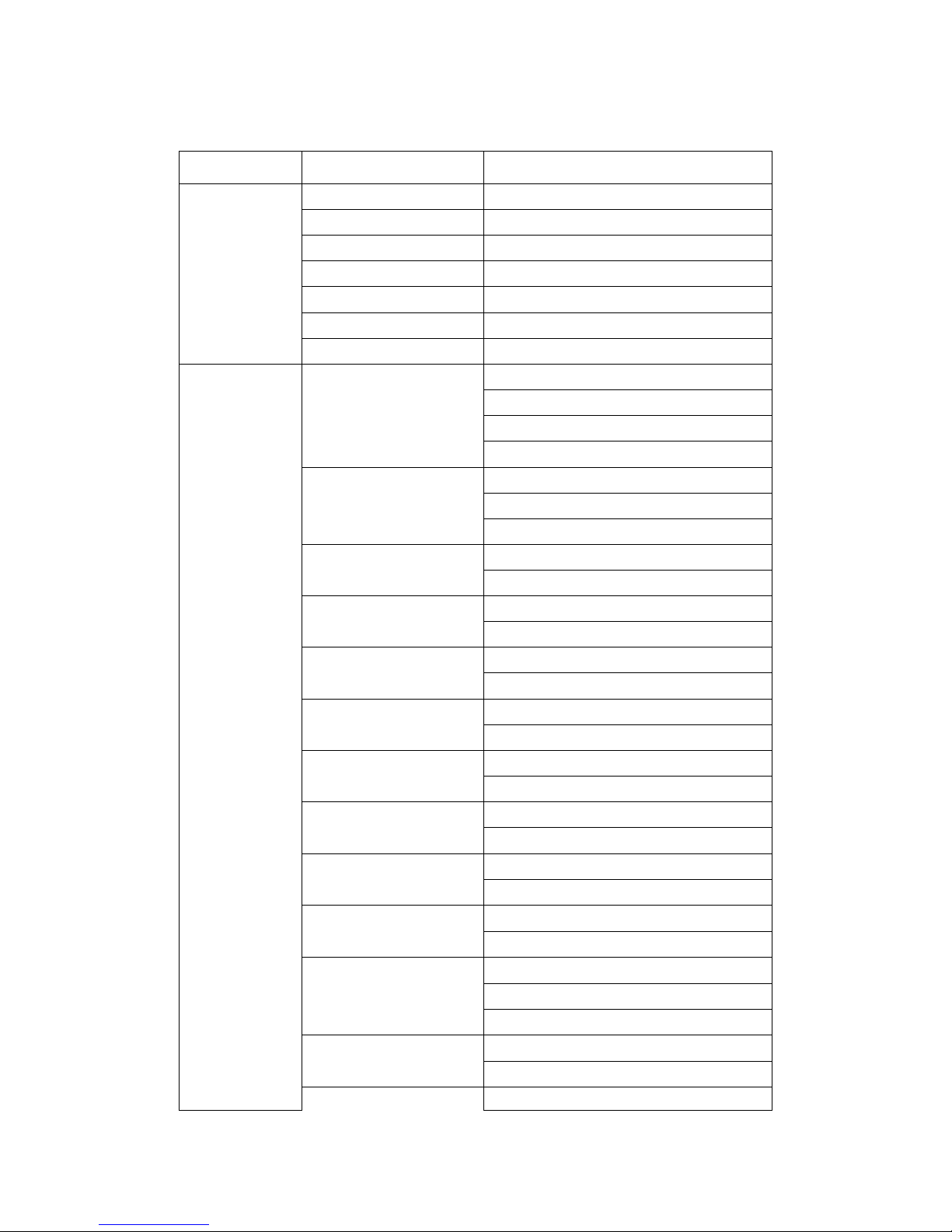

Voltage:AC100V-240V

50/60Hz Power

Consumption:500W Light

source:YODN R17 350W

Color Temperature:8000K

Beam Angle:1.5°- 35° linear fast zooming.

Focus:High precision optical lens,electronic linear control

Linear Dimmer:Mechanical dimmer 0-100%

CMY Color Wheel:Cyan+Magenta+Yellow color wheel with total 15 colors

Rotating Gobo Wheel:12 rotating gobos+White/,bi-directional rotatable and gobo

shaking at variable speeds

Static Gobo Wheel: 13 interchangeable gobos + effect gobo+ white, and

bi-directionally rotatable and gobo shaking at variable speeds

Prism:12+36facet circular prism rotating in both directions at variable speeds

Dimmer:0-100% linear dimmer

Strobe:1-18/second,double lens strobe with adjustable speed

Pan and Tilt: Smoothly,automatic Pan/Tilt position correction,speed adjustable

Range:Pan540°,Tilt 280°

Effect:Color+Gobo+Prism+Strobe automatic operation function

Cooling:Fan Cooling

Control mode:Standard DMX 512, 3 pin,5 pin connector

Channel mode:21/23/28 Channels

Display Interface:LCD screen both in Chinese and English

IP rate:IP20,Built-in overheat protection,triggered high voltage protection.

Net Weight:19KG

Gross Weight:23.5KG(Carton)