Notice

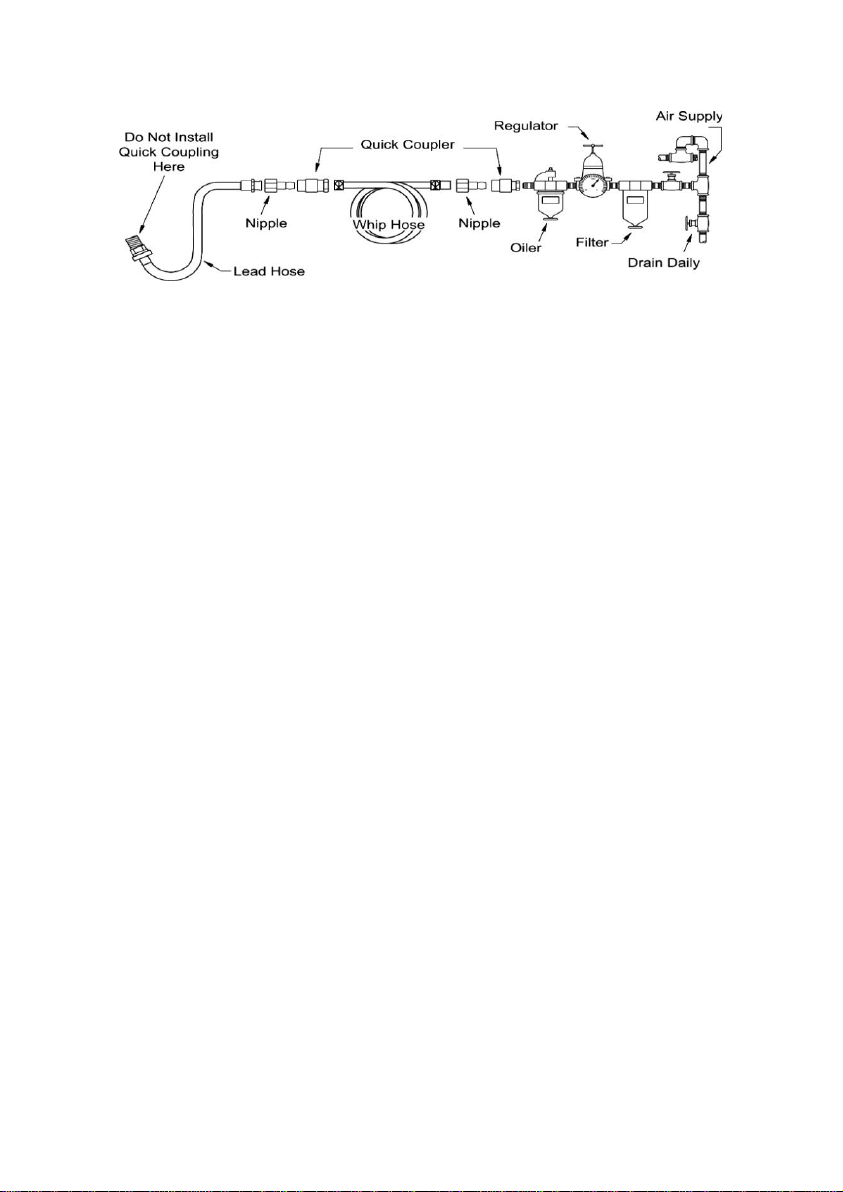

90% of all Air Tool problems are caused by moisture in air lines

This problem can be avoided by using Air Tool Lubricant (See

“Lubrication” & “Air Supply” section of this manual)

FAILURE TO OIL can void your warranty

Warning: Dust created by power sanding, sawing, grinding, drilling, and other activities

contains particles and chemicals known to cause cancer, birth defects or reproductive harm.

Some examples of these chemicals are:

⚫Lead from lead-based paints

⚫Crystalline silica from bricks, cement and other masonry products

⚫Arsenic and chromium from chemically treated lumber

To reduce your exposure to these chemicals, work in well ventilated areas with approved

safety equipment specially designed to filter out microscopic particles.

One Year Limited Warranty

GLOBAL Industrial air tools carry a 1 year warranty to be free from defects in material and

workmanship for one year from date of purchase. We will repair or replace at our discretion

any defective part or unit which proves to be defective in material or workmanship during this

1 year period. The foregoing obligation is GLOBAL sole liability under this or any implied

warranty, and under no circumstances shall it be liable for any incidental or consequential

damages.

Repairs required by abuse, misuse, damage, or repair attempts (other than GLOBAL Industrial)

are not covered by this warranty.

For warranty claims and returns, please contact GLOBAL

Industrial at 1-800-645-2986 or speak to your local sales

representative. Be certain to include your name, address, and

purchase date, and description of the suspected defect.

11 Harbor Park Drive, Port Washington, NY 11050

Phone: 1-800-645-2986