User's Manual

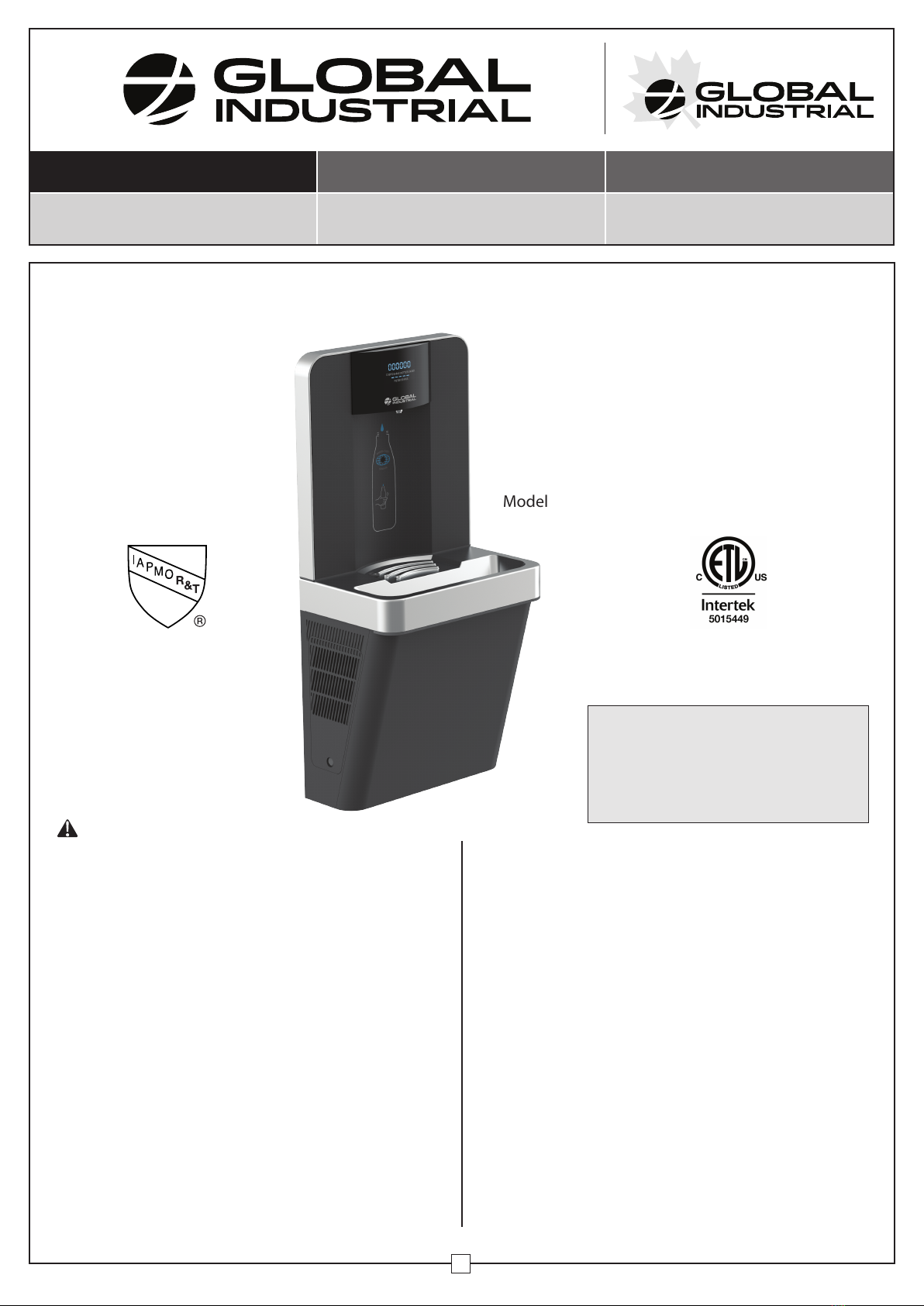

Wall Mounted Water Bottle

Refilling Station

2

Risk of Electrical Shock

• Disconnect power before servicing unit.

• Electric supply must be identical in voltage, cycle and

phase to those specied in the specications below.

Unit must be plugged into a GFCI outlet.

• Always pull the plug – not the cord – when disconnecting

from the outlet.

• DO NOT use if the power cord is worn or damaged.

Power cords should only be replaced by qualied

service technicians using genuine replacement parts.

•Check local codes for electrical requirements.

•DO NOT disassemble or modify unit.

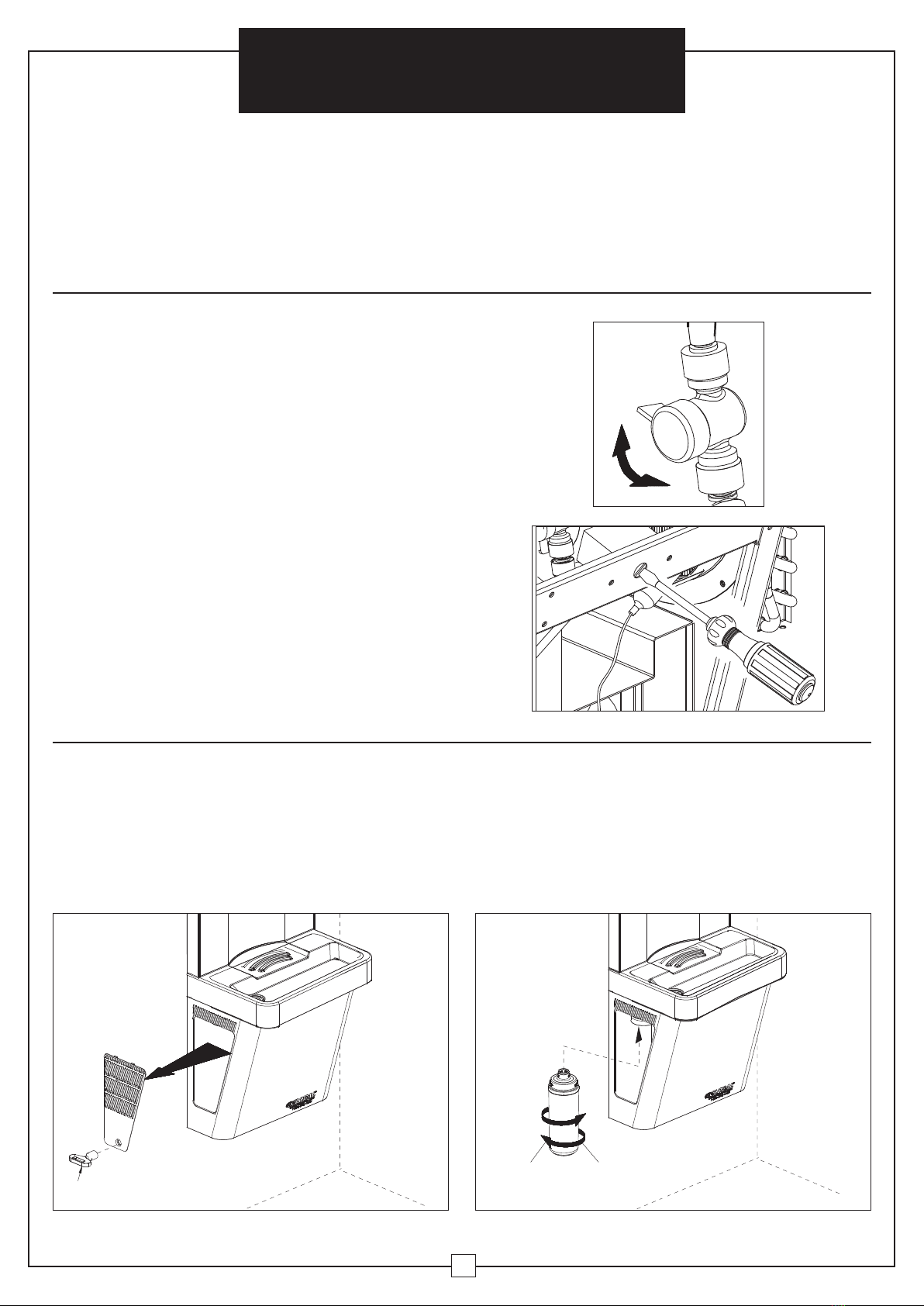

•Use Global Industrial lters only – Model 670336

Note:

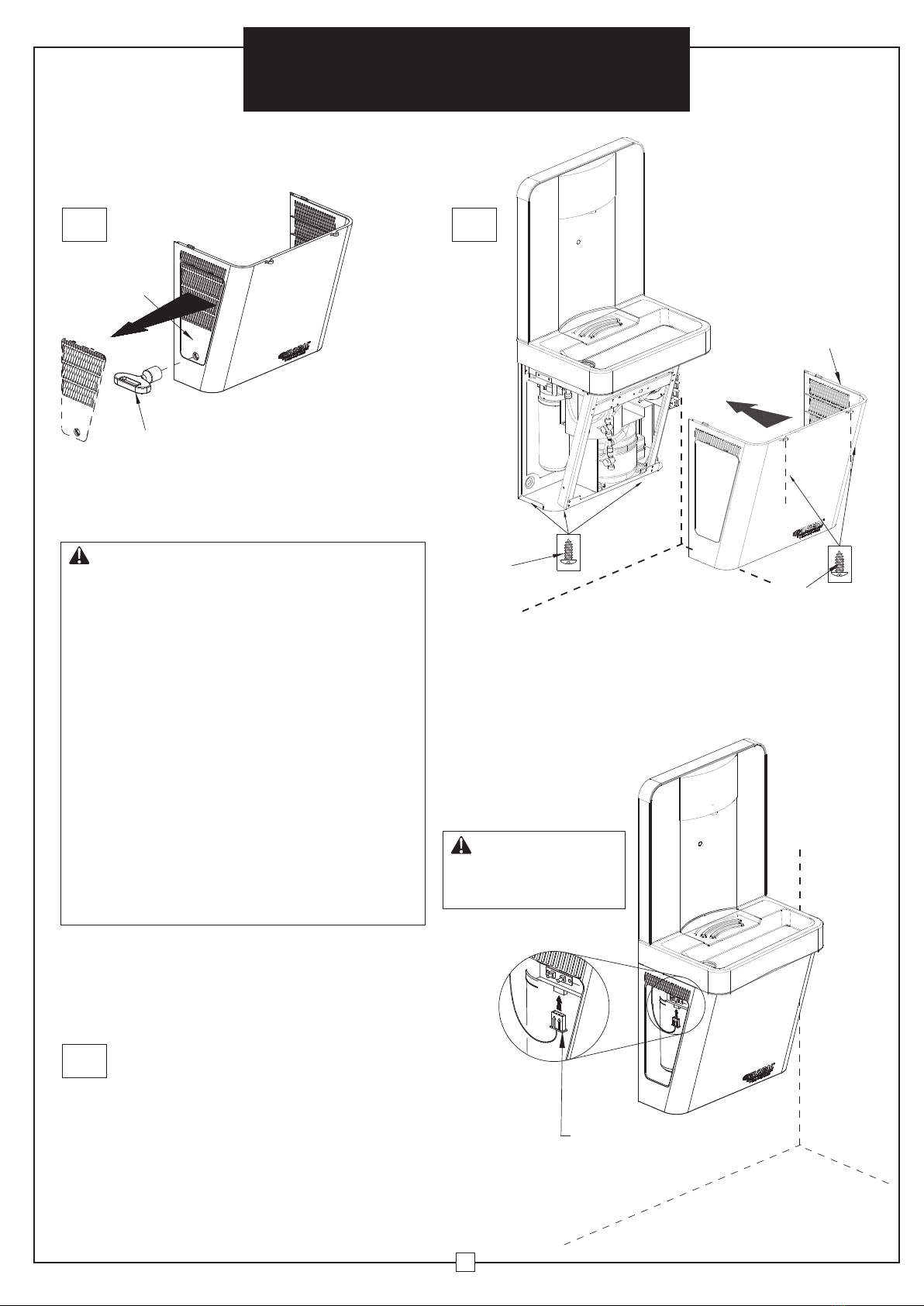

• Prior to installation, consult with local, state, and federal

codes for proper mounting height.

• All installation and service should only be performed by

authorized personnel.

• Dimensions shown below comply with ADA requirements

at time of printing.

• Allow 4" minimum clearance on both sides to allow for

proper ventilation through cabinet louvers.

• Thoroughly ush all water lines and ttings of all foreign

matter before connecting to the Cooling System.

Failure to do so will void warranty.

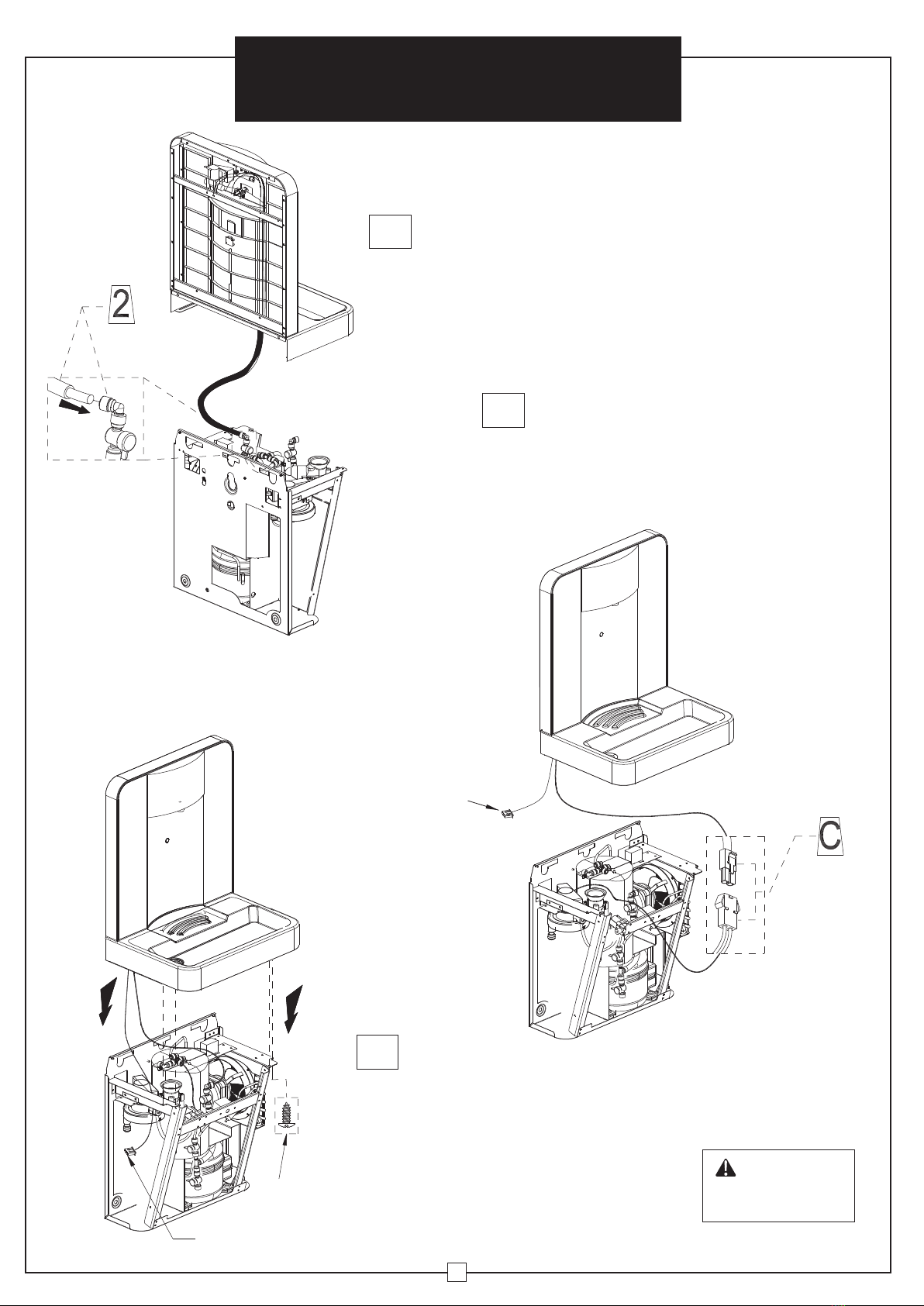

Required Tools:

1. Safety Glasses

2. Safety Gloves

3. Electric Drill

4. Phillips Head Screwdriver

5. Flathead Screwdriver

6. Tape Measure

7. Pencil

8. Level Device

9. (11) 75-lb. Capacity Flat Head Wall Anchors

(appropriate for your wall type)

10. (11) Flat Head Anchor Screws

WARNING

• Review manual thoroughly and verify rough-ins before

installation. Keep these instructions in a safe location

for future reference.

• Keep compressor in upright position for 24 hours

before water connections and initial power-on. Failure

to do so will void warranty.

• It is recommended to assemble this product on a

tabletop or bench.

• Fixture must be mounted to a at nished industry

standard wall surface. The wall surface must have

adequate support to secure the xture, with the

addition of wall anchors (not included) if required.

• All receptacles must be wired to a GFCI protected

circuit. Fixture must be earth grounded per National

Electric Code (NEC).

• Inspect xture and all parts for damage.

Package Contents:

Box 1 - 761319 Top Assembly for Bottle Filler

Box 2 - 761212 Cooling System for Water Fountain

Stainless

Steel Pan

Water

Filter Not Pictured:

Hardware Bag

Mounting Stencil

Mounting Bracket

(attached to rear)

Cooling System

Rubber Gasket

Mounting Bracket

(attached to rear)

Bottle Filler

Top Assembly

Note: This product complies with ADA when installed

according to the requirements outlined in this manual.

Installation may require additional accessories to be fully

compliant. If needed, consult with the local Authority

Having Jurisdiction (AHJ).

Voltage/Hertz 115V/60Hz

*Chilling Capacity 5.3 GPH

Full-Load Amps 1.9 Amps

Rated Watts 185 W

Filter Capacity 4750 or 3600 Gallons

Quick-Fill Rate 1.0 GPM

Water Flow Laminar

Certification

UL399 and CAN/CSA 22.2 No. 120 ADA

Compliant

Overall Dimensions 181/8"W x 16"D x 3713/16"H

System 761219 Certified by IAPMO R&T against

NSF/ANSI/CAN372 for lead free compliance

Filter 670336 certified by NSF to NSF/ANSI 42&53

* At 46° - 54° (F) against ambient air temperature of 77° (F)