5

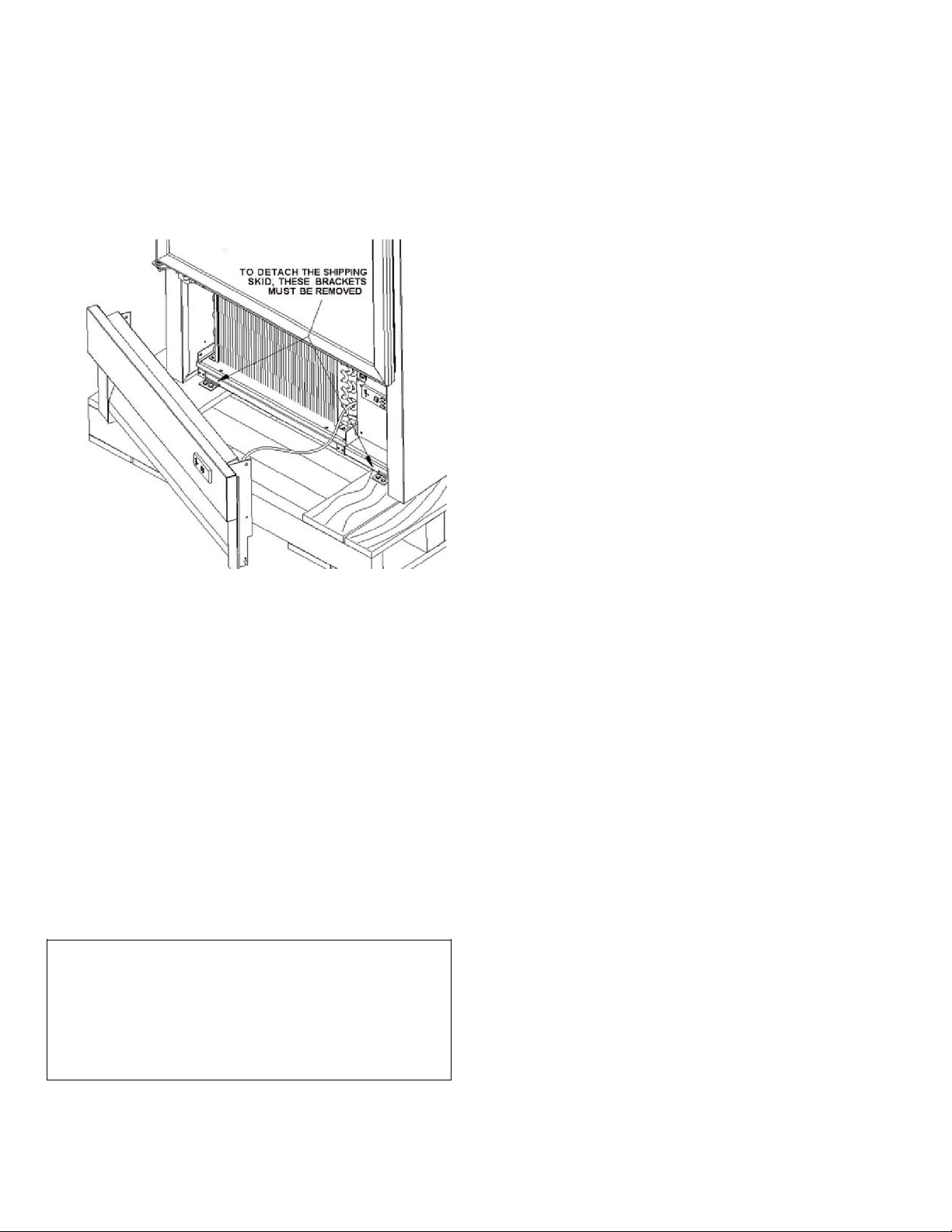

g.) Make sure that the drain line has not been

dislodged or broken during shipping and that the

drain trap terminates properly in the condensate

pan or floor drain. (See Condensate Pan on Top

Mounted Compressor.)

h.) Listen for any unusual noise such as lines vibrating,

fan blades hitting etc. Correct problem by

tightening screws, slightly bending tubing, etc.

i.) Check proper tension on doors. (See Door Closer

Adjustment.)

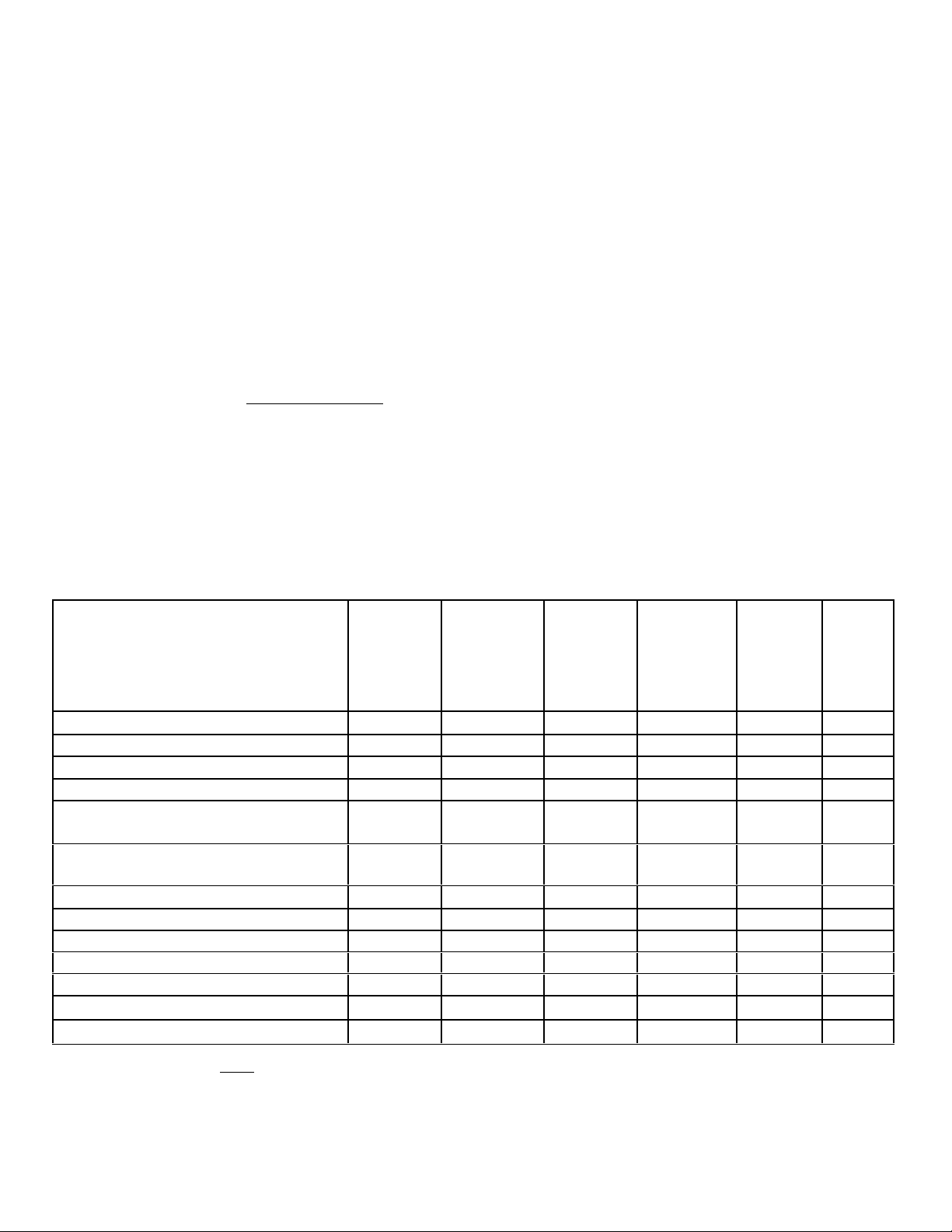

Thermostat Settings

The refrigerator or freezer is shipped from the factory

with a thermostat setting of approximately the mid-point

of the operating range. Final thermostat setting must be

made in the field. Allow the cabinet to operate until the

compressor cycles on the thermostat.

The normal operating temperature ranges are: 42°F to

36°F for Refrigerator models;

20°F to -20°F for Display freezers;

0°F to -20°F for Storage freezers;

0°F to -30°F (or-40°)F for Hardening freezers;

The thermostat is easily adjusted with a standard screw-

driver. In models where the thermostat has control

settings 1 through 7, turn the thermostat to a higher

number to lower the cabinet temperature. See the

section Electronic Control for thermostat adjustment on

units so equipped.

NOTE: DO NOT OPERATE MEDUIM TEMPERATURE

CABINETS (REFRIGERATORS) BELOW 32°F

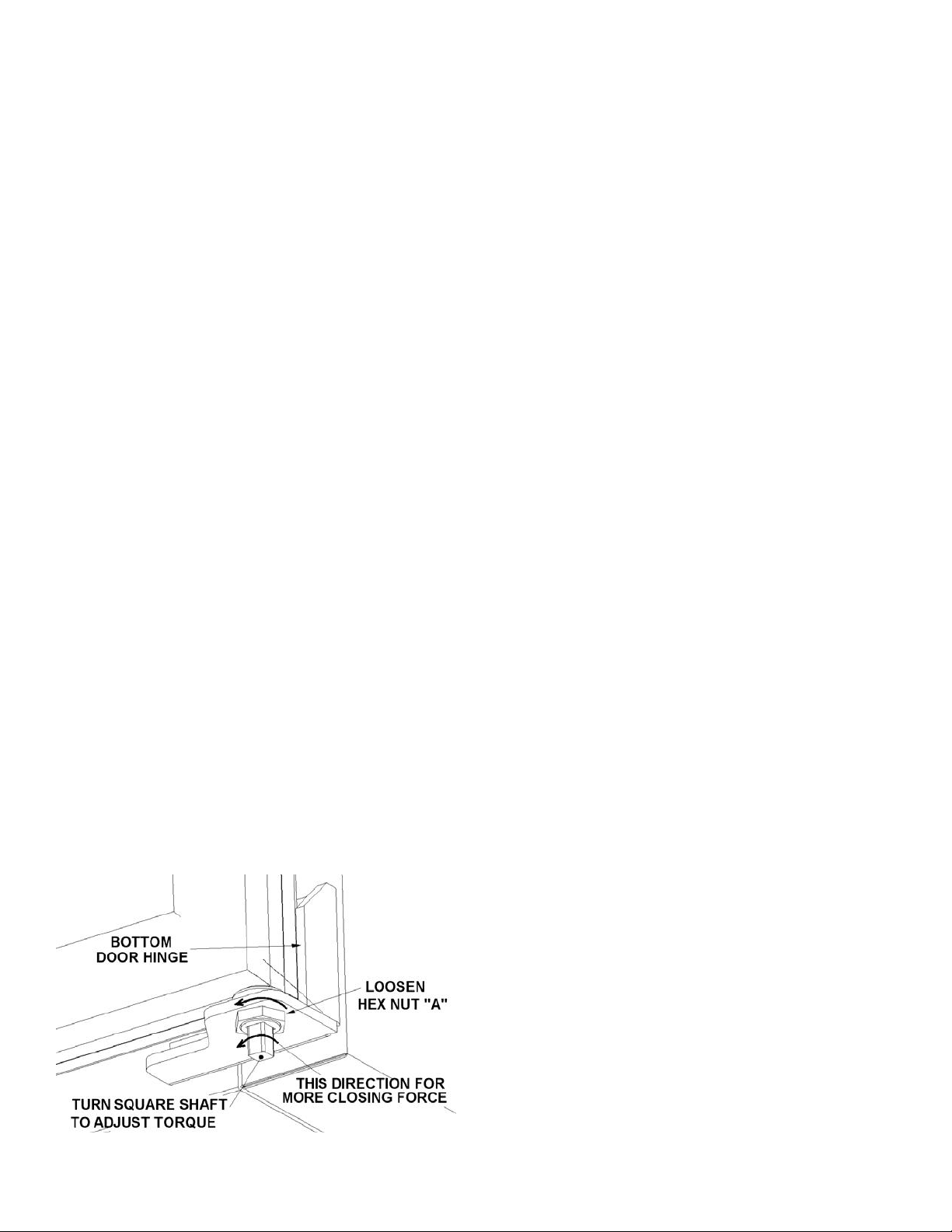

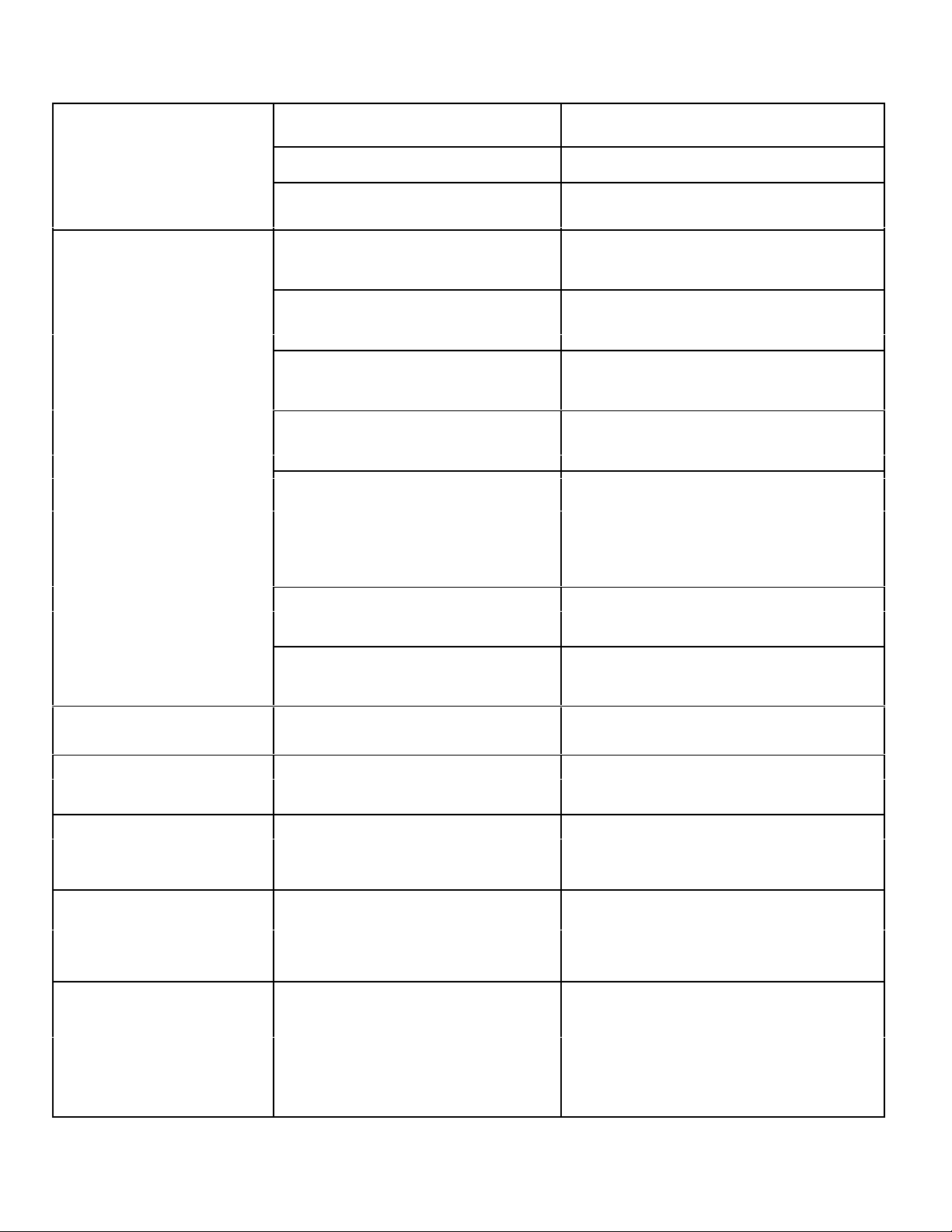

Door Adjustment & Removal

Glass doors use an internal torsion rod to adjust closing

tension; solid doors use a cam in the hinges to control

closing.

Door Closer Adjustment ( Glass Doors)

Loosen Nut "A" and turn the square shaft to increase or

decrease the torsion rod tension to the desired torque.

Turn the square shaft towards door handle to increase

torque; then tighten Nut "A" to lock.

The door should be set to swing smoothly and should

not slam. Also the door should self-close when opened

only a couple. of inches

Removing Outer Doors (Solid Doors)

If the assembled cabinet is too wide to move through narrow

doorways, the cabinet doors can be removed as follows:

1 )Open the door 180°and support the outer edge.

Remove the screws in the upper hinge at the cabinet,

leaving the hinge attached to the door. Lift and

remove from lower hinge pin. CAUTION: The upper

hinge cam is under significant spring tension. Leave

the hinge in the open position (KEEP HANDS

CLEAR)

2) After legs are on and the cabinet is in final position,

set the doors back on the hinge pins.

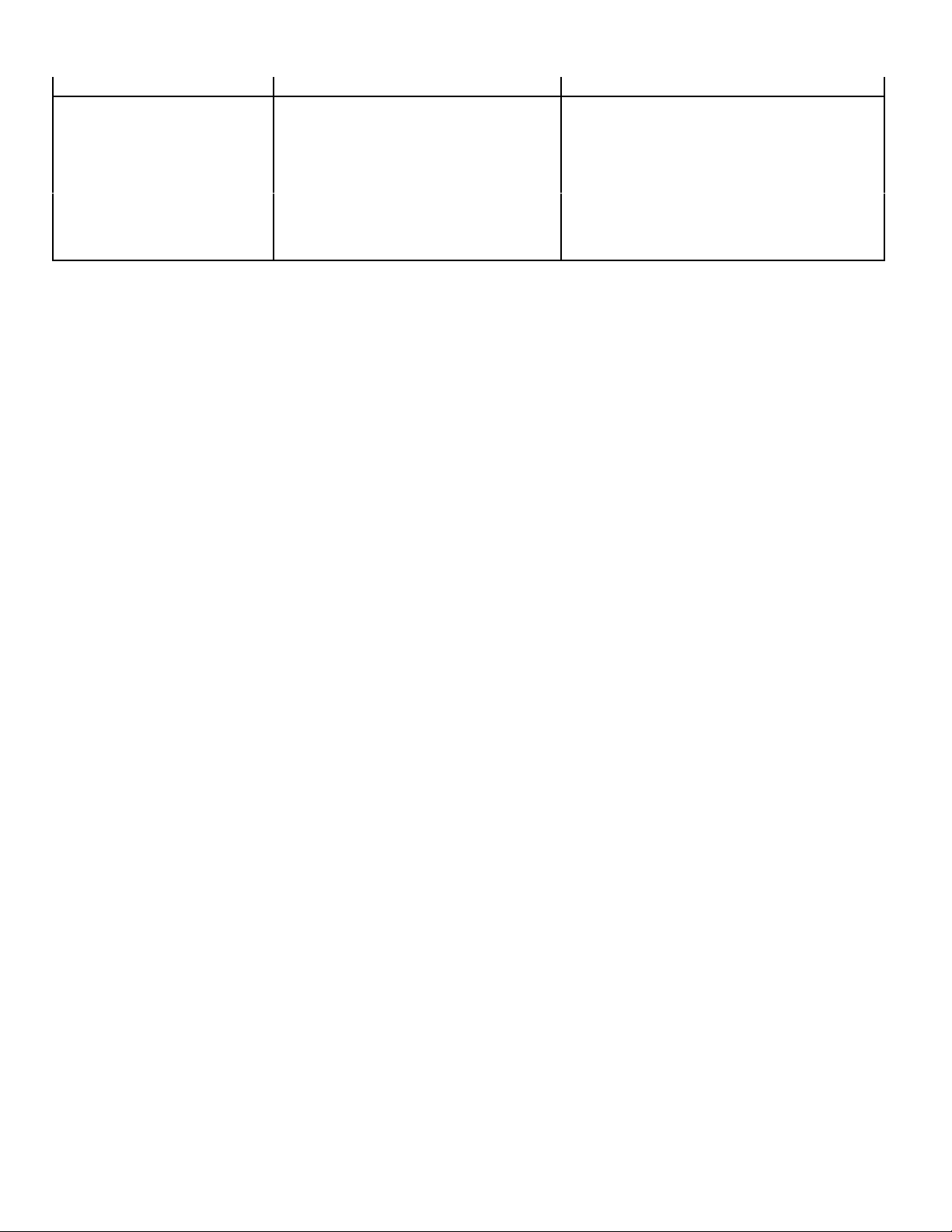

Energy Conservation Measures

These cabinets are designed for efficiency with heavy

foam insulation. However, there are things that the user

can do to maintain the cabinet in operating condition.

1) Do not operate the cabinet any colder than necessary

to maintain safe, product storage temperatures.

2) Make sure the cabinet is located to prevent direct

exposure to sunlight, air ducts, etc.

3) Keep the doors closed except for normal use. Inspect

the doors often to see that they self-close and that the

4) Do not overstock the product in the cabinet which will

block normal air flow.

5)Keep the condenser coil clean. The coils should be

inspected at least twice a year.

6) Have at least annual inspections by a qualified service

company to see that the fan motors are functioning

properly and that the refrigerant charge is correct.

7) These cabinets operate more efficiently in a cooler

ambient than in a "hot ambient. Try to maintain an

ambient below 80°F (27°C) and 65% RI-I. for maxi-

mum efficiency.

ROUTINE MAINTENANCE

Cleaning the Interior

Wash the inside surface of the storage one tablespoon

of baking soda per quart of water.) Rinse thoroughly

with clean, warm water and wipe dry. The procedure

can also be used for cleaning the door gasket. Be sure

the power is turned off before cleaning.

Cleaning the Exterior

Wipe the cabinet exterior occasionally with a cloth

damp-ened in mild detergent water, rinse and wipe dry

with a soft cloth. Do not use abrasive or caustic

cleaners or scouring pads.

Cleaning the Condenser

Clean the condenser periodically by brushing the coil with

a soft brush and/or using a vacuum cleaner with a brush

attachment. Be sure that the power is disconnected