2

TABLE OF CONTENTS

Fuel Tank................................................................16

Stopper Assembly............................................16

Installing the Stopper......................................17

Fuel Tank Installation......................................17

Servo Installation...................................................18

Installing the Fuselage Servos.........................18

Installing the Aileron Servo Tray.....................18

Installing the Aileron Servo.............................19

Throttle Pushrod....................................................20

Installing the Pushrod Wire.............................20

Installing the Servo Connector........................20

Adjusting the Throttle Linkage.......................20

Elevator Pushrod....................................................21

Installing the Control Horn.............................21

Installing the Pushrod......................................21

Adjusting the Elevator Pushrod.......................22

Rudder Pushrod.....................................................22

Installing the Control Horn.............................22

Installing the Pushrod....................................23

Adjusting the Rudder Pushrod........................24

Aileron Linkage....................................................24

Installing the Aileron Linkage.......................24

Adjusting the Aileron Linkage.......................25

Final Assembly......................................................25

Installing the Fuel Lines..................................25

Installing the Switch.......................................26

Installing the Receiver....................................26

Installing the Propeller....................................26

Balancing...............................................................27

Control Throws.......................................................27

Preflight Check.....................................................27

ABC's of Flying....................................................28

Basics of Flight.....................................................28

Glossary of Terms.................................................31

Notes.....................................................................32

Product Evaluation Sheet......................................35

Introduction.............................................................3

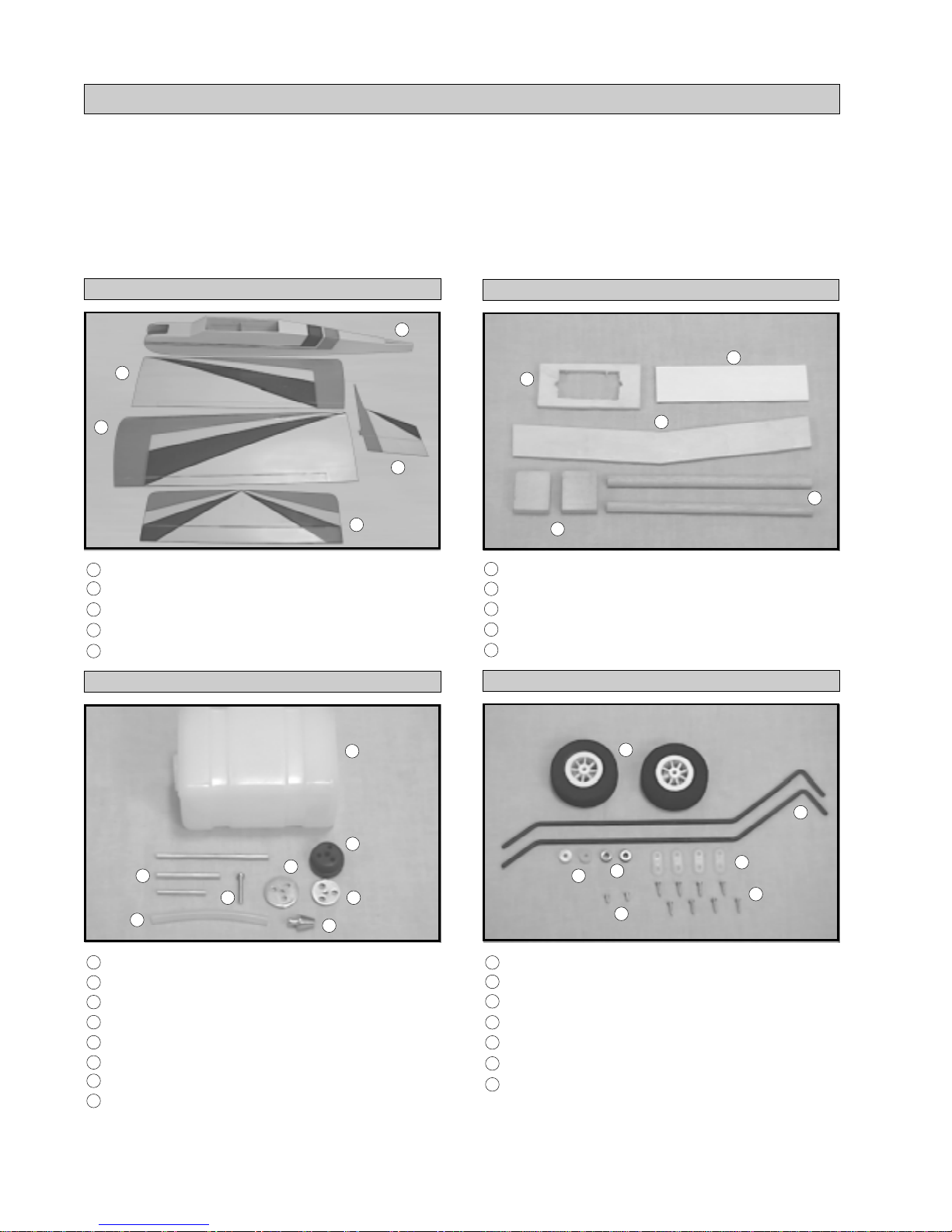

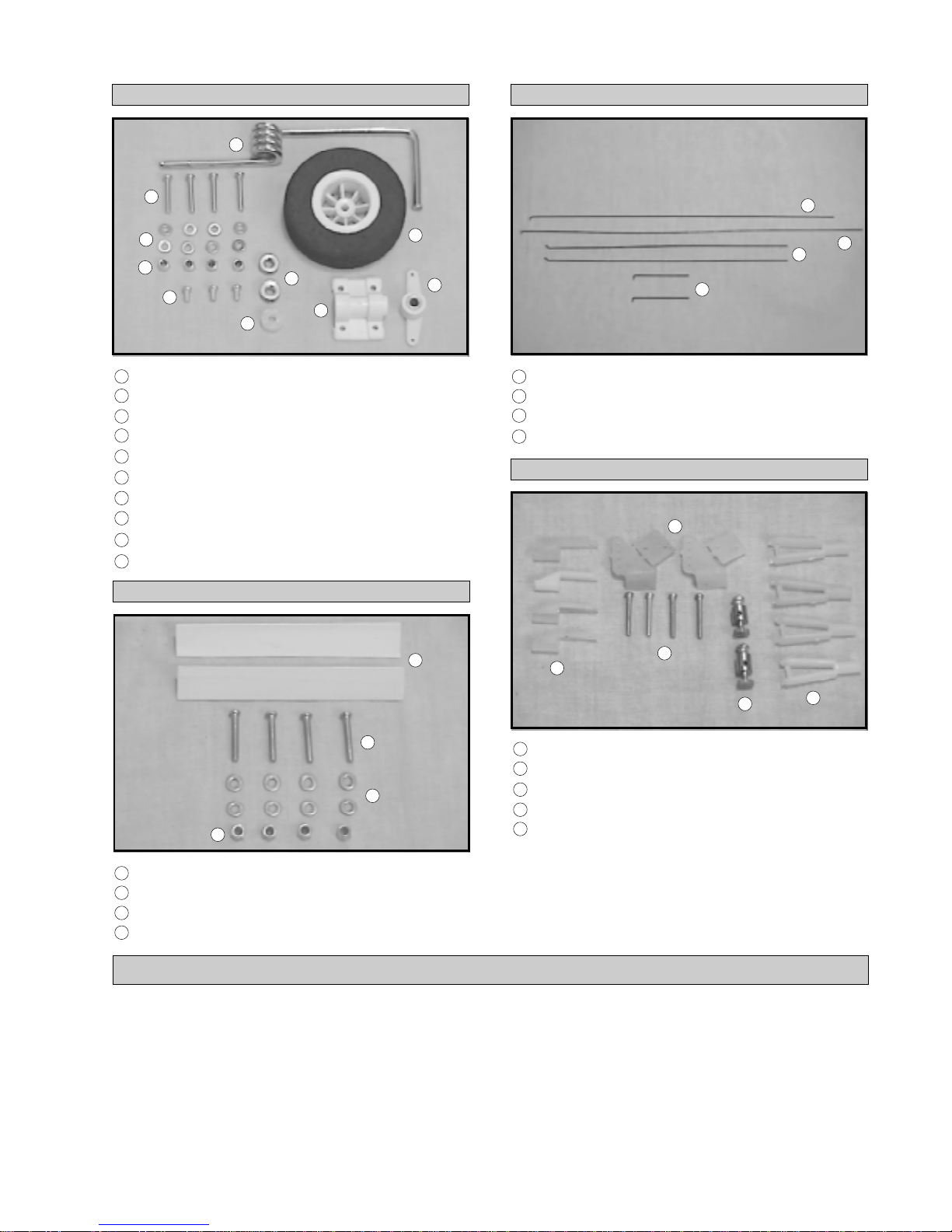

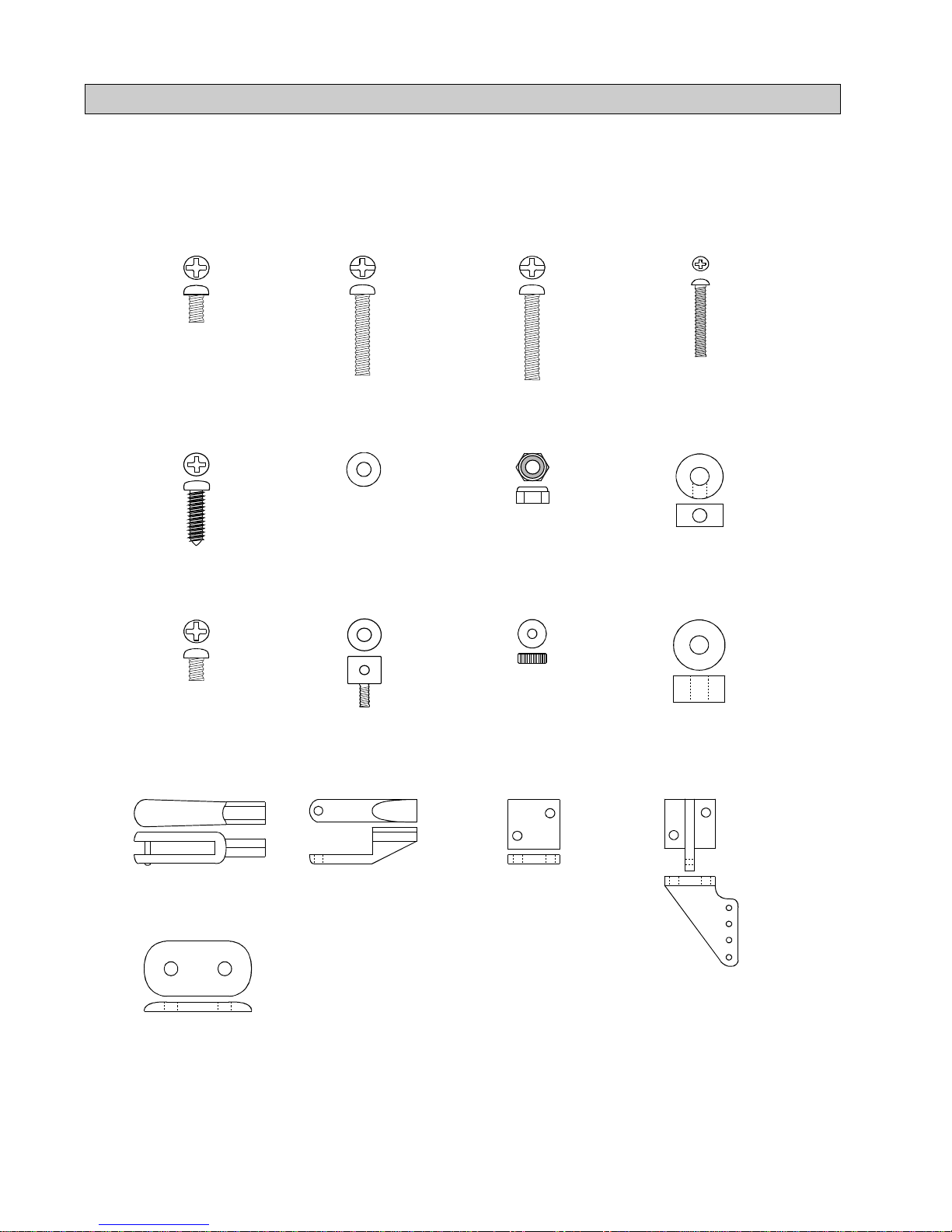

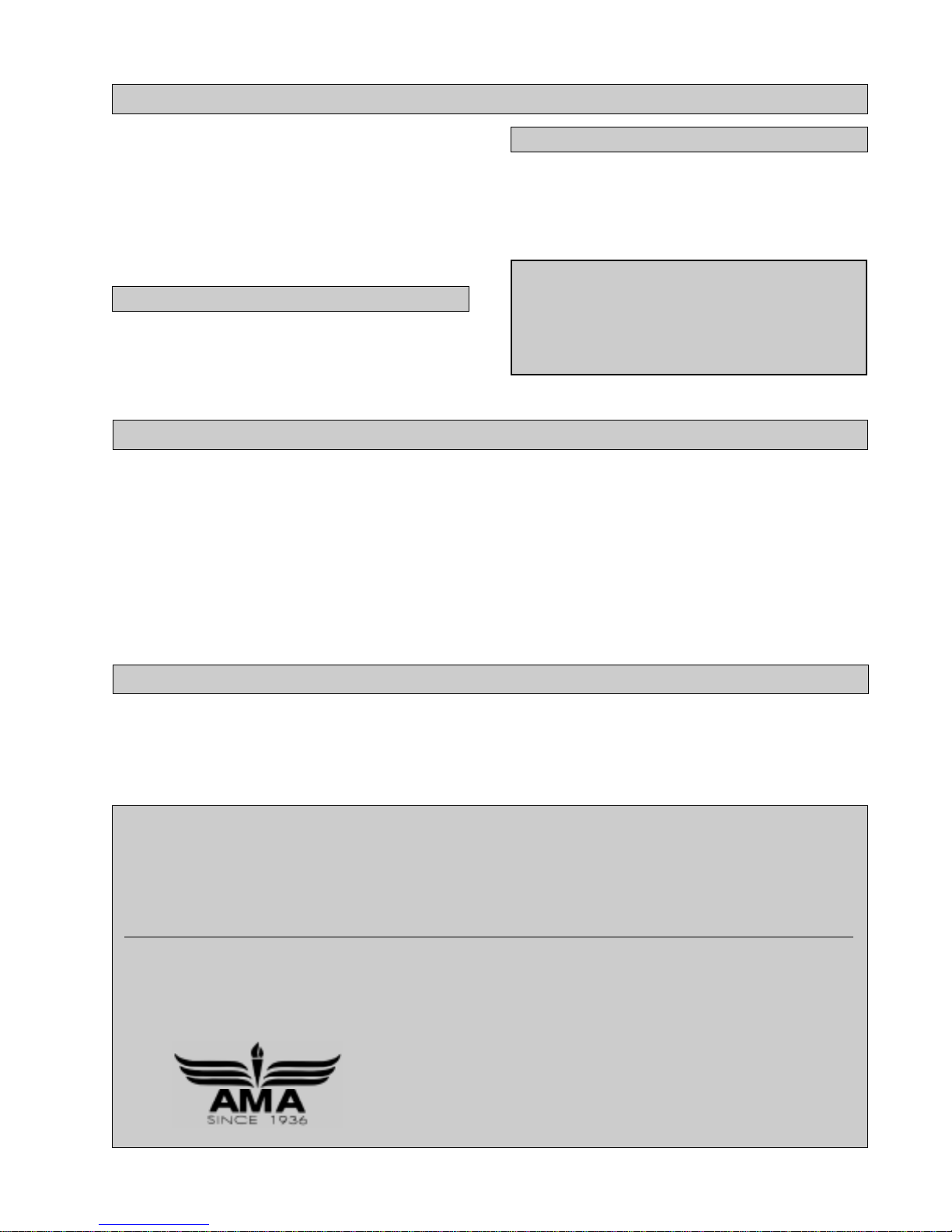

Kit Contents............................................................4

Metric Conversion Chart........................................5

Full Size Hardware Drawings..................................6

Additional Items Required......................................7

Tools and Supplies Needed.....................................7

Field Support Equipment Needed...........................7

Wing Assembly.......................................................8

Installing the Dihedral Brace............................8

Joining the Wing Halves...................................8

Installing the Wing Doubler.............................9

Wing Mounting.......................................................9

Installing the Hold Down Dowels.....................9

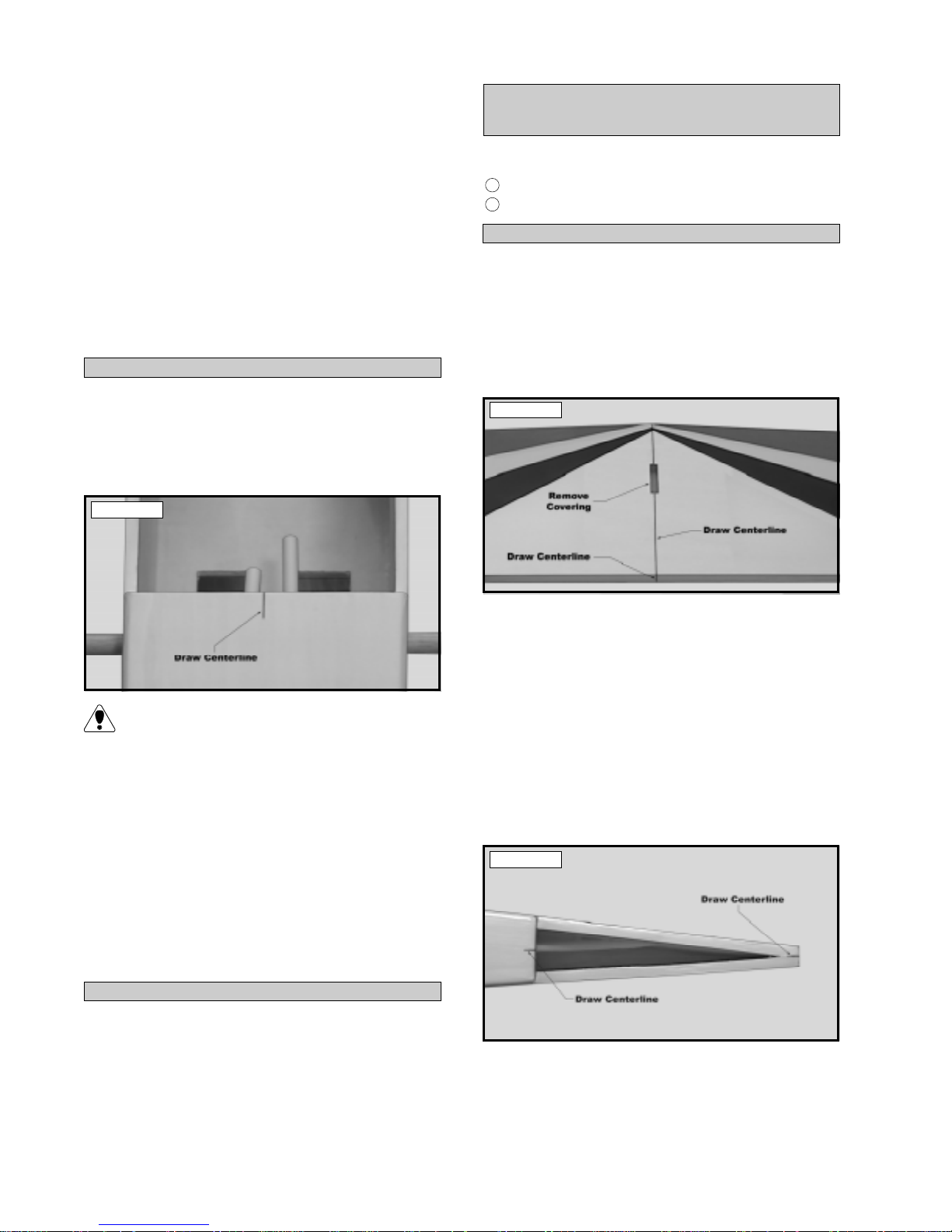

Aligning the Wing............................................10

Mounting the Wing..........................................10

Horizontal Stabilizer Installation............................10

Aligning the Horizontal Stabilizer...................10

Mounting the Horizontal Stabilizer..................11

Installing the Triangle Stock............................11

Vertical Stabilizer Installation................................12

Aligning the Vertical Stabilizer.......................12

Mounting the Vertical Stabilizer.....................12

Control Surface Installation...................................12

Hinging the Ailerons........................................12

Hinging the Elevator.......................................13

Hinging the Rudder.........................................13

Main Gear Installation...........................................13

Installing the Main Gear Wires.......................13

Installing the Main Gear Wheels.....................14

Nose Gear Installation...........................................14

Installing the Nose Gear Bracket.....................14

Installing the Nose Gear Wire.........................15

Installing the Nose Gear Wheel.......................15

Engine Mounting....................................................16

Aligning the Engine.........................................16