A

B

C-C

A

B

C C

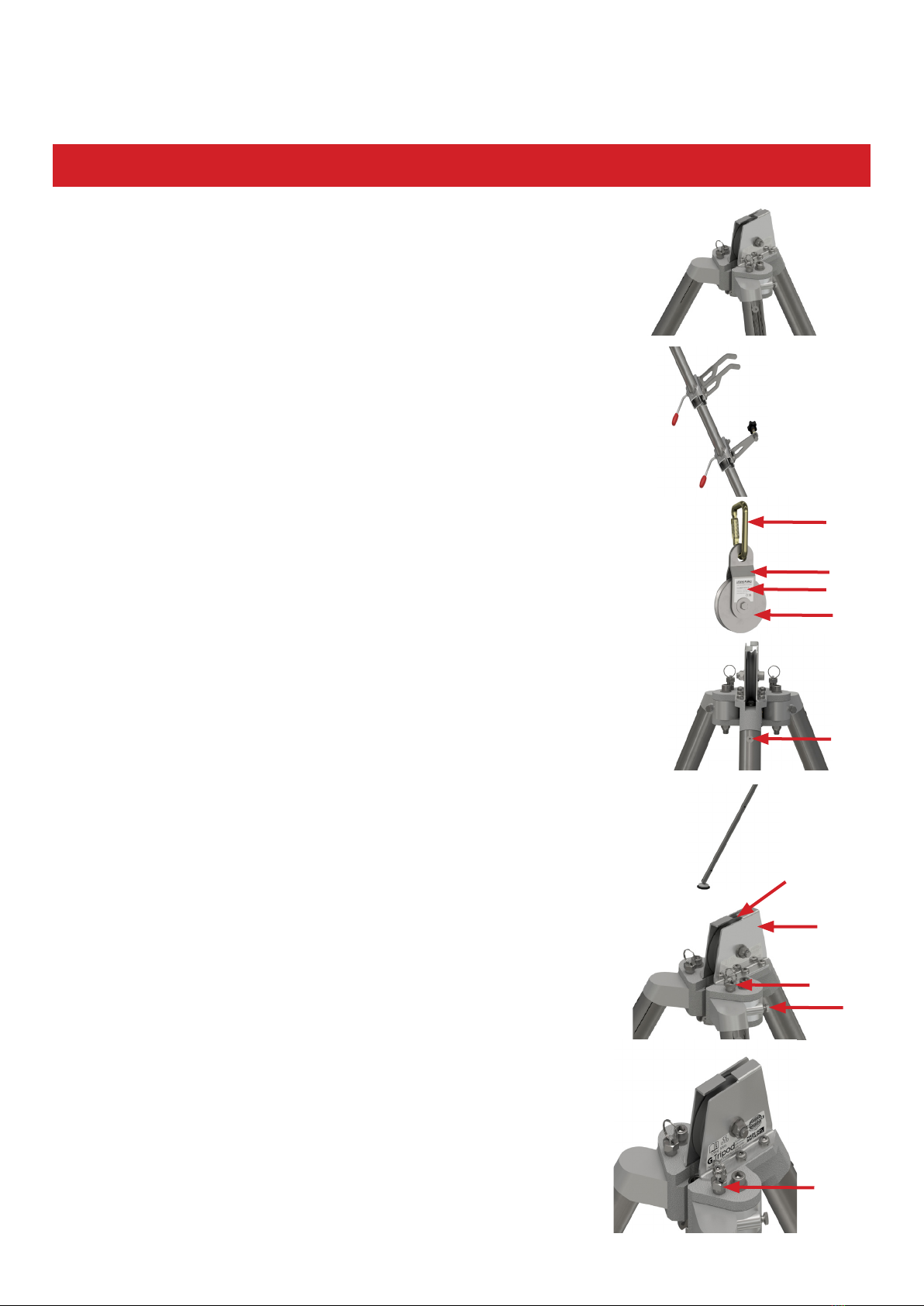

Qty

Part

Number

DescriptionItem

3200-12LOWER LEG

1

3200-18M4 X 8 CSK SCREW, SS5

3200-19M4 FORM A WASHER, SS6

3200-22RUBBER FOOT

7

3200-24M8 x 50 HEX HEAD BOLT, STAINLESS STEEL8

3200-34M8 NYLOC NUT, SS9

1210-03

Middle Head

10

1

210-04

Left Head

11

1

210-05Right Head12

2210-06LOCKING PIN ASSEMBLY13

2210-07M12 x 90 SOCKET HEAD CAP SCREW, BZP14

1

210-09

PULLEY

16

1

210-10Pulley Bush

17

1210-11

Pulley Bolt Sleeve

18

2210-12M12 x 50 SOCKET HEAD CAP SCREW, SS19

2210-15PULLEY BRACKET20

6210-16M8 x 16 BUTTON HEAD SCREW, SS21

1210-19ROPE GUIDE22

1210-20

Locking Ring

23

1

210-21M8 X 10 SET SCREW, STAINLESS STEEL24

1

210-22BALL SPRING PLUNGER25

1210-23

Sealing Cap

26

1210-24BOWNUT27

1

210-253MM x 30 SELLOC PIN, SS28

1

210-26M12 LARGE OD WASHER, SS29

3210-27M8 X 20 CSK SOCKET SCREW, SS30

1210-28

Identity Label

31

2210-29CE LABEL32

3210-32UPPER LEG33

6507-07M8 FORM B WASHER, SS34

2507-09M8 X 25 HEX HEAD SCREW, SS35

3507-40M12 NYLOC NUT, BZP36

2507-85BRASS PLATE HAMMER DRIVE37

6907-31M8 RECTANGLE SPRING WASHER, BZP38

7907-32M12 FORM A WASHER, SS39

3SA200LACLEG ADJUSTMENT CLIP

44

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

DO NOT SCALE

COPYRIGHT NOTE

THIS DRAWING REMAINS

THE PROPERTY OF

GLOBESTOCK LTD AND IS

SUBJECT TO COPYRIGHT.

IT CANNOT BE USED IN

PART OR WHOLE WITHOUT

WRITTEN PERMISSION

FROM GLOBESTOCK LTD.

1.6

ALL DIMENSIONS IN mm

3rd ANGLE PROJECTION

SURFACE FINISH

UNLESS OTHERWISE STATED

BYDATE

LINEAR AND ANGULAR TOLERANCES

NO DECIMAL PLACES `0.5

1 DECIMAL PLACE `0.10

2 DECIMAL PLACES `0.05

GEOMETRIC TOLERANCES

MACHINING `0.10

FABRICATION `0.25

CHANGES TO DRAWINGREV 18/12/2018

DATE

11

GSE 210-00

DRAWN BY

(: +44 1691 654 966

*: info@globestock.co.uk

:: www.globestock.co.uk

Mile Oak Industrial Estate,

Maesbury Road,

Shropshire,

SY10 8GA

of

SHEET 005

Simon Lewis

PART NUMBER

DESCRIPTION

N/A

MATERIAL

G.Tripod General Assembly

SHEET

of

GSE 210-00 1 1 005

001 09-04-01 First issue. DS

1

44

6

7

9

10

11

12

13

14

16

18

19

17

20

21

22

23

24

25

27

29

31

32

33

35

36

37

38

39

002 08-02-06 Bracket screw added, upper leg part number change. DJW

003 24-04-07 Part number change, 507-09 was 707-09. PAS

004 08-05-15 Part number change, 507-09 was 707-09. DJW

005 18-12-18 Assembly updated in line with current build. SPL